Taprogge

Encyclopedia

Wetter (Ruhr)

Wetter is a town in western Germany and belongs to the area of Ruhr area and the federal state of North Rhine-Westphalia. Wetter belongs to the district of Ennepe-Ruhr-Kreis. The river Ruhr flows through the urban area and separates the district of Altwetter from the districts of Esborn,...

, Germany

Germany

Germany , officially the Federal Republic of Germany , is a federal parliamentary republic in Europe. The country consists of 16 states while the capital and largest city is Berlin. Germany covers an area of 357,021 km2 and has a largely temperate seasonal climate...

. The company is named after founding brothers Ludwig and Josef Taprogge. Founded in 1953, the company is known for its tube cleaning

Tube cleaning

For the article about the tube cleaning of steam locomotive boilers see: Tube cleaning .Tube cleaning describes the activity of, or device for, the cleaning and maintenance of fouled tubes....

systems for steam turbine condensers

Condenser (steam turbine)

A surface condenser is a commonly used term for a water-cooled shell and tube heat exchanger installed on the exhaust steam from a steam turbine in thermal power stations. These condensers are heat exchangers which convert steam from its gaseous to its liquid state at a pressure below atmospheric...

, heat exchanger

Heat exchanger

A heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact...

s and debris

Debris

Debris is rubble, wreckage, ruins, litter and discarded garbage/refuse/trash, scattered remains of something destroyed, or, in geology, large rock fragments left by a melting glacier etc. The singular form of debris is debris...

filters

Filter (water)

A water filter removes impurities from water by means of a fine physical barrier, a chemical process or a biological process. Filters cleanse water to various extents for irrigation, drinking water, aquariums, and swimming pools.-Methods of filtration:...

for water-cooled shell and tube heat exchangers and condensers.

Invention of the tube cleaning system

Josef Taprogge was a turbine engineer in a power plant nearby EssenEssen

- Origin of the name :In German-speaking countries, the name of the city Essen often causes confusion as to its origins, because it is commonly known as the German infinitive of the verb for the act of eating, and/or the German noun for food. Although scholars still dispute the interpretation of...

and was responsible for the cleaning of the turbine

Turbine

A turbine is a rotary engine that extracts energy from a fluid flow and converts it into useful work.The simplest turbines have one moving part, a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades, or the blades react to the flow, so that they move and...

condenser tubes. Cleaning had to be performed while the turbine was out of operation, with the power station

Power station

A power station is an industrial facility for the generation of electric energy....

not being able to supply any electrical energy to the grid during the turbine outage. On the other hand, the careful elimination of fouling

Fouling

Fouling refers to the accumulation of unwanted material on solid surfaces, most often in an aquatic environment. The fouling material can consist of either living organisms or a non-living substance...

from inside of the tubing is important for a high vacuum

Vacuum

In everyday usage, vacuum is a volume of space that is essentially empty of matter, such that its gaseous pressure is much less than atmospheric pressure. The word comes from the Latin term for "empty". A perfect vacuum would be one with no particles in it at all, which is impossible to achieve in...

in the condenser and thereby for the optimal efficiency

Energy conversion efficiency

Energy conversion efficiency is the ratio between the useful output of an energy conversion machine and the input, in energy terms. The useful output may be electric power, mechanical work, or heat.-Overview:...

of the energy

Energy

In physics, energy is an indirectly observed quantity. It is often understood as the ability a physical system has to do work on other physical systems...

generation through water vapour.

To avoid economic losses caused by shutdowns, Josef Taprogge invented a continuously working cleaning system which kept the condenser free from fouling during the operation of the steam turbine. A prototype was installed into the cooling water pipe leading to the condenser. During the time of the German Wirtschaftswunder

Wirtschaftswunder

The term describes the rapid reconstruction and development of the economies of West Germany and Austria after World War II . The expression was used by The Times in 1950...

, the process which was marketed and further developed by Taprogge GmbH was widespread and very well received in the power stations due to its efficiency. The efficiency of the power stations that are equipped with the systems increases by around 2 – 4 %. The cleaning process became well known and the name "Taprogge System" has been used in the technical literature.

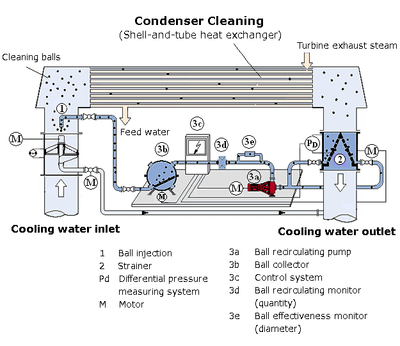

Tube cleaning systems

The patented process uses sponge rubber balls which are injected into the cooling water flow (1) before it enters into the condenser. The diameterDiameter

In geometry, a diameter of a circle is any straight line segment that passes through the center of the circle and whose endpoints are on the circle. The diameters are the longest chords of the circle...

of the cleaning balls is only slightly bigger than the nominal diameter of the condenser tubing. Due to their elasticity

Elasticity (physics)

In physics, elasticity is the physical property of a material that returns to its original shape after the stress that made it deform or distort is removed. The relative amount of deformation is called the strain....

they generate a contact pressure

Pressure

Pressure is the force per unit area applied in a direction perpendicular to the surface of an object. Gauge pressure is the pressure relative to the local atmospheric or ambient pressure.- Definition :...

on their way through the condenser tubes by which fouling is removed from the inner tube walls. At the condenser outlet a strainer (2) is installed in the connecting pipe which separates the balls from the water flow and feeds them into a DN 80 pipe. From there the balls are pumped back to their starting point by a 4 kW impeller pump via a DN 80 pipe. To inject the balls into the cycle, a pressure vessel

Pressure vessel

A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.The pressure differential is dangerous and many fatal accidents have occurred in the history of their development and operation. Consequently, their design,...

with detachable cover is installed downstream of the pump. This so-called collector (3b) is equipped with a screen

Sieve

A sieve, or sifter, separates wanted elements from unwanted material using a woven screen such as a mesh or net. However, in cooking, especially with flour, a sifter is used to aerate the substance, among other things. A strainer is a type of sieve typically used to separate a solid from a liquid...

and a flap

Flap

Flap may refer to:* Flap , a hinged surface on the trailing edge of an airplane wing* Roof flap, an aerodynamic feature of race cars* Flapping, one of the basic mechanics of flight in birds...

. At open flap, the balls can pass and with closed flap they remain in the collector and can be replenished or exchanged. The process works continuously and the tubes remain free of mud

Mud

Mud is a mixture of water and some combination of soil, silt, and clay. Ancient mud deposits harden over geological time to form sedimentary rock such as shale or mudstone . When geological deposits of mud are formed in estuaries the resultant layers are termed bay muds...

, algae

Algae

Algae are a large and diverse group of simple, typically autotrophic organisms, ranging from unicellular to multicellular forms, such as the giant kelps that grow to 65 meters in length. They are photosynthetic like plants, and "simple" because their tissues are not organized into the many...

, bacteria

Bacteria

Bacteria are a large domain of prokaryotic microorganisms. Typically a few micrometres in length, bacteria have a wide range of shapes, ranging from spheres to rods and spirals...

and scaling

Scaling

Scaling may refer to:* Scaling , a linear transformation that enlarges or diminishes objects* Reduced scales of semiconductor device fabrication processes...

. The operation of the system is monitored via sight glasses and electronic

Electronics

Electronics is the branch of science, engineering and technology that deals with electrical circuits involving active electrical components such as vacuum tubes, transistors, diodes and integrated circuits, and associated passive interconnection technologies...

measuring instrument

Measuring instrument

In the physical sciences, quality assurance, and engineering, measurement is the activity of obtaining and comparing physical quantities of real-world objects and events. Established standard objects and events are used as units, and the process of measurement gives a number relating the item...

s. The screen surfaces are arranged on shaft

Axle

An axle is a central shaft for a rotating wheel or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to its surroundings, with the wheels rotating around the axle. In the former case, bearings or bushings are provided at the mounting points where the axle...

s with pivoted bearing

Bearing (mechanical)

A bearing is a device to allow constrained relative motion between two or more parts, typically rotation or linear movement. Bearings may be classified broadly according to the motions they allow and according to their principle of operation as well as by the directions of applied loads they can...

s and can be turned on demand to have fouling removed by the water flow. In this process the balls are caught in the collector. This time-consuming procedure is automatized (3c), gear motors (M) operate the relevant actuators. The minal diameters of the screens have been adjusted to respond to the developments in power station technology and are produced in sizes from nominal diameter 150 mm to 3600 mm. The cleaning ball diameters range from 14 to 30 mm and filling one collector normally requires several hundred of them. However, some cleaning systems can require well over a thousand cleaning balls. The lifetime of the cleaning balls which are produced of biodegradable natural rubber is around 4 weeks.

A specialized technology is the production of tube cleaning systems for seawater

Seawater

Seawater is water from a sea or ocean. On average, seawater in the world's oceans has a salinity of about 3.5% . This means that every kilogram of seawater has approximately of dissolved salts . The average density of seawater at the ocean surface is 1.025 g/ml...

desalination

Desalination

Desalination, desalinization, or desalinisation refers to any of several processes that remove some amount of salt and other minerals from saline water...

plants. As the heated seawater called brine

Brine

Brine is water, saturated or nearly saturated with salt .Brine is used to preserve vegetables, fruit, fish, and meat, in a process known as brining . Brine is also commonly used to age Halloumi and Feta cheeses, or for pickling foodstuffs, as a means of preserving them...

has a particularly corrosive effect, excellent corrosion resistant yet heat conducting materials (like Titanium) have to be used for such systems. Due to the large tube diameters in the evaporators, the cleaning balls have diameters of up to 45 mm.

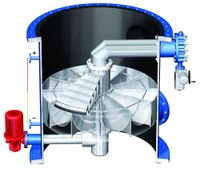

Debris filtration systems

Product (business)

In general, the product is defined as a "thing produced by labor or effort" or the "result of an act or a process", and stems from the verb produce, from the Latin prōdūce ' lead or bring forth'. Since 1575, the word "product" has referred to anything produced...

range was extended by backwash filters to protect the heat exchangers and condensers from macro fouling, like stone

Rock (geology)

In geology, rock or stone is a naturally occurring solid aggregate of minerals and/or mineraloids.The Earth's outer solid layer, the lithosphere, is made of rock. In general rocks are of three types, namely, igneous, sedimentary, and metamorphic...

s, pieces of wood

Wood

Wood is a hard, fibrous tissue found in many trees. It has been used for hundreds of thousands of years for both fuel and as a construction material. It is an organic material, a natural composite of cellulose fibers embedded in a matrix of lignin which resists compression...

, fibres, plastic

Plastic

A plastic material is any of a wide range of synthetic or semi-synthetic organic solids used in the manufacture of industrial products. Plastics are typically polymers of high molecular mass, and may contain other substances to improve performance and/or reduce production costs...

sheeting, and mussel

Mussel

The common name mussel is used for members of several families of clams or bivalvia mollusca, from saltwater and freshwater habitats. These groups have in common a shell whose outline is elongated and asymmetrical compared with other edible clams, which are often more or less rounded or oval.The...

s. Foreign matter will first settle on the filter surface. As fouling builds up, differential pressure between filter inlet and outlet increases and the filter has to be cleaned by backwashing. For this purpose an electrically driven rotor covers the filter surface which is connected with a pipe leading outside. Installed in this pipe is a valve

Valve

A valve is a device that regulates, directs or controls the flow of a fluid by opening, closing, or partially obstructing various passageways. Valves are technically pipe fittings, but are usually discussed as a separate category...

that is opened during the backwash process. The accumulated fouling is drawn off and discharged via the pipe which, downstream of the condenser, leads to the main cooling water pipe or a debris container. This technology was spread in power stations and industrial plants the world over. Depending on the flow rates to be filtered, the filters are produced in nominal diameters from 150 mm to DN 3200 mm. The filter surface consists of stainless steel

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

with punched

Punching

Punching is a metal forming process that uses a punch press to force a tool, called a punch, through the workpiece to create a hole via shearing. The punch often passes through the work into a die. A scrap slug from the hole is deposited into the die in the process. Depending on the material being...

holes. For difficult types of debris, filter surfaces of plastic

Plastic

A plastic material is any of a wide range of synthetic or semi-synthetic organic solids used in the manufacture of industrial products. Plastics are typically polymers of high molecular mass, and may contain other substances to improve performance and/or reduce production costs...

or grids can be used. A further type produced by the company are fine filters with filtration degrees from 50 to 1000 µm.

Water intake systems

Polyhedron

In elementary geometry a polyhedron is a geometric solid in three dimensions with flat faces and straight edges...

housing with plain filter surfaces. It is cleaned by pressurized air blast. In contrast to submarine rakes for seaborne matter, the stainless steel filter has no moving parts and masters biggest water flows. The filter surfaces are made of coated

Coating

Coating is a covering that is applied to the surface of an object, usually referred to as the substrate. In many cases coatings are applied to improve surface properties of the substrate, such as appearance, adhesion, wetability, corrosion resistance, wear resistance, and scratch resistance...

plastic provided with drilled

Drilling

Drilling is a cutting process that uses a drill bit to cut or enlarge a hole in solid materials. The drill bit is a multipoint, end cutting tool...

holes.

Literature

- Heat Exchanger Fouling, Fundamental Approaches and Technical Solutions; Editor: Prof.Dr.-Ing. Hans Mueller-Steinhagen ISBN 3-934736-00-9.

External links

- Taprogge GmbH (German and English)