100-pounder breech-loader

Encyclopedia

The Armstrong RBL 7 inch gun, also known as the 110-pounder, was an early attempt to use William Armstrong

's new and innovative breechloading mechanism for heavy rifled guns.

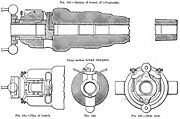

The Armstrong "screw" breech mechanism used involved a heavy block inserted in a vertical slot in the barrel behind the chamber, with a large hollow screw behind it which was manually screwed tight against the block after loading. A metal cup on the front of the block, together with the pressure of the screw behind it, provided "obturation" and sealed the breech to prevent escape of gasses rearward on firing. The sliding block was known as the "vent-piece", as the vent tube was inserted through it to fire the gun. In modern terms it was a vertical sliding block.

The Armstrong "screw" breech mechanism used involved a heavy block inserted in a vertical slot in the barrel behind the chamber, with a large hollow screw behind it which was manually screwed tight against the block after loading. A metal cup on the front of the block, together with the pressure of the screw behind it, provided "obturation" and sealed the breech to prevent escape of gasses rearward on firing. The sliding block was known as the "vent-piece", as the vent tube was inserted through it to fire the gun. In modern terms it was a vertical sliding block.

To load the gun, the vent-piece was raised, the shell was inserted through the hollow screw and rammed home into the bore, and the powder cartridge was likewise inserted through the screw into the chamber. The vent-piece was lowered, the screw was tightened, a tube was inserted in the top of the vent-piece, and the gun was fired.

Shells had a thin lead coating which made them fractionally larger than the gun's bore, and which engaged with the gun's rifling grooves to impart spin to the shell. This spin, together with the elimination of windage as a result of the tight fit, enabled the gun to achieve greater range and accuracy than existing smoothbore muzzle-loaders with a smaller powder charge.

On top of each powder cartridge was a "lubricator" consisting of tallow and linseed oil between two tin plates, backed by a felt wad coated with beeswax and finally by millboard. The lubricator followed the shell down the bore, the lubricant was squeezed out between the tin plates and the wad behind it cleaned out any lead deposits left from the shell coating leaving the bore clean for the next round.

, and the British Government requested it be implemented for heavy guns despite Armstrong's protests that the mechanism was unsuited to heavy guns :

The gun as first made weighed 72 cwt (8,064 lb) but the heavier 82 cwt (9,184 lb) version, incorporating a strengthening coil over the powder chamber, was the first to enter service in 1861. It was intended to replace the smoothbore muzzle-loading 68-pounder gun

, and was intended to be Britain's first modern rifled breech-loading naval gun. The lighter 72 cwt version eventually entered service in 1863 for land use only.

The British government's Select Committee on Ordnance held lengthy hearings in 1862 and 1863 on the relative merits of the Armstrong breechloaders compared to other breechloaders and muzzle-loaders. It finally announced :

The British government's Select Committee on Ordnance held lengthy hearings in 1862 and 1863 on the relative merits of the Armstrong breechloaders compared to other breechloaders and muzzle-loaders. It finally announced :

It was considered that with a maximum gunpowder propellant charge of only 12 pounds (soon reduced to 11 lb for the 82 cwt gun and 10 lb for the 72 cwt gun) the gun was incapable of a high enough muzzle velocity to penetrate the armour of enemy ships :

Critics also considered that the manual labour needed to raise the heavy (136 lb) vent piece out of the breech before reloading was an unnecessary combat impediment. Another objection raised was that obturation (i.e. sealing of the breech on firing) depended on how tightly the gunners turned the breech screw after loading :

As these limitations were imposed by the current Armstrong breechloading design, and as no other suitable breechloading mechanism was available, production of the 110-pounder was discontinued in 1864 and Britain reverted to muzzle-loading heavy guns.

The abandonment of the Armstrong breech-loading design led Britain to begin a major program of building rifled muzzle-loaders to equip its fleet. The Armstrong 110-pound gun was succeeded by various RML 7 and 8-inch guns. 7-inch Armstrong breech-loaders under construction at the time of cancellation were completed as RML 64-pounder muzzle-loaders. However, the gun construction method developed by Armstrong for breech-loaders, of a wrought-iron "A" tube surrounded by wrought-iron coils, was considered sound and was retained for the first generation of new rifled muzzle-loaders in the mid-1860s.

When Britain returned to breech-loaders in 1880 it used the Elswick cup and De Bange obturation systems, both of which used the power of the gun's firing to achieve obturation rather than manual labour.

and Bombardment of Shimonoseki

in 1863 and 1864. We have two descriptions of the same incident aboard HMS Euryalus

at the Bombardment of Kagoshima in August 1863:

The guns while functioning well when correctly handled were hence seen to be difficult and potentially dangerous to use under the stress of combat.

William George Armstrong, 1st Baron Armstrong

William George Armstrong, 1st Baron Armstrong CB, FRS was an effective Tyneside industrialist who founded the Armstrong Whitworth manufacturing empire.-Early life:...

's new and innovative breechloading mechanism for heavy rifled guns.

Description

To load the gun, the vent-piece was raised, the shell was inserted through the hollow screw and rammed home into the bore, and the powder cartridge was likewise inserted through the screw into the chamber. The vent-piece was lowered, the screw was tightened, a tube was inserted in the top of the vent-piece, and the gun was fired.

Shells had a thin lead coating which made them fractionally larger than the gun's bore, and which engaged with the gun's rifling grooves to impart spin to the shell. This spin, together with the elimination of windage as a result of the tight fit, enabled the gun to achieve greater range and accuracy than existing smoothbore muzzle-loaders with a smaller powder charge.

On top of each powder cartridge was a "lubricator" consisting of tallow and linseed oil between two tin plates, backed by a felt wad coated with beeswax and finally by millboard. The lubricator followed the shell down the bore, the lubricant was squeezed out between the tin plates and the wad behind it cleaned out any lead deposits left from the shell coating leaving the bore clean for the next round.

History

This method had already proved successful in the RBL 12 pounder 8 cwt field gunRBL 12 pounder 8 cwt Armstrong gun

The Armstrong Breech Loading 12 pounder 8 cwt, later known as RBL 12 pounder 8 cwt, was an early modern 3-inch rifled breech-loading field gun of 1859.-Design:The gun incorporated some advanced features for its day...

, and the British Government requested it be implemented for heavy guns despite Armstrong's protests that the mechanism was unsuited to heavy guns :

"The threatening aspects of the continent required that large rifled guns should be procured for naval and siege purposes. I was therefore called upon to produce 40-pounders and 100-pounders without having had an opportunity of testing the patterns by previous trials, though I had stated in my original report that I apprehended that the application of breech-loading to large guns would involve an application of parts which would be inconveniently heavy to handle... I was at first in hopes that the same material which had been used and found to be sufficient for the 40-pounder, would be found equally suitable for the 100-pounder; but that turns out not to be the case. The vent-piece for the 100-pounder continues still to be a difficulty". Sir W Armstrong to the Select Committee on Ordnance in 1863.

The gun as first made weighed 72 cwt (8,064 lb) but the heavier 82 cwt (9,184 lb) version, incorporating a strengthening coil over the powder chamber, was the first to enter service in 1861. It was intended to replace the smoothbore muzzle-loading 68-pounder gun

68-pounder gun

The 68-pounder cannon was an artillery piece designed and used by the British Armed Forces in the mid-19th century. The cannon was a smoothbore muzzle-loading gun manufactured in several weights, the most common being , and fired projectiles of . Colonel William Dundas designed the 112 cwt version...

, and was intended to be Britain's first modern rifled breech-loading naval gun. The lighter 72 cwt version eventually entered service in 1863 for land use only.

"... the preponderance of opinion seems to be against any breech-loading systems for the larger guns"

It was considered that with a maximum gunpowder propellant charge of only 12 pounds (soon reduced to 11 lb for the 82 cwt gun and 10 lb for the 72 cwt gun) the gun was incapable of a high enough muzzle velocity to penetrate the armour of enemy ships :

"These guns can only be fired with comparatively small charges, and therefore their projectiles would do no injury to ironclad vessels, but their shells would no doubt be most destructive to wooden ships." : the sarcastic comment of Lieutenant-Colonel C H Owen, Royal Artillery, reflecting the establishment opinion in 1873.

Critics also considered that the manual labour needed to raise the heavy (136 lb) vent piece out of the breech before reloading was an unnecessary combat impediment. Another objection raised was that obturation (i.e. sealing of the breech on firing) depended on how tightly the gunners turned the breech screw after loading :

"My objection has been to the Armstrong breech-loader. My objection to that is, that the breech-plug is only a valve; and the first principle of every valve, whether the vessel contain water or oil, or gas, is that the pressure of that fluid should press the valve tighter. Now Sir William Armstrong's breech-loader is on a diametrically opposite system; nothing there confines the gas but the actual amount of labour expended in the screwing up of the breech. If the gas is stronger than the man, aided by the screw, the gas will escape"... Captain Blakely to the Select Committee on Ordnance.

As these limitations were imposed by the current Armstrong breechloading design, and as no other suitable breechloading mechanism was available, production of the 110-pounder was discontinued in 1864 and Britain reverted to muzzle-loading heavy guns.

The abandonment of the Armstrong breech-loading design led Britain to begin a major program of building rifled muzzle-loaders to equip its fleet. The Armstrong 110-pound gun was succeeded by various RML 7 and 8-inch guns. 7-inch Armstrong breech-loaders under construction at the time of cancellation were completed as RML 64-pounder muzzle-loaders. However, the gun construction method developed by Armstrong for breech-loaders, of a wrought-iron "A" tube surrounded by wrought-iron coils, was considered sound and was retained for the first generation of new rifled muzzle-loaders in the mid-1860s.

When Britain returned to breech-loaders in 1880 it used the Elswick cup and De Bange obturation systems, both of which used the power of the gun's firing to achieve obturation rather than manual labour.

Use in action

The gun was not employed in a major war, but was used extensively by Royal Navy ships against land fortifications in the Bombardment of KagoshimaBombardment of Kagoshima

The Bombardment of Kagoshima, also known as the , took place on 15–17 August 1863 during the Late Tokugawa shogunate. The British Royal Navy was fired on from the coastal batteries near town of Kagoshima and in retaliation bombarded the town...

and Bombardment of Shimonoseki

Bombardment of Shimonoseki

The Battles for Shimonoseki refers to a series of military engagements in 1863 and 1864, fought to control Shimonoseki Straits by joint naval forces from the Great Britain, France, the Netherlands and the United States, against the Japanese feudal domain of Chōshū, which took place off and on the...

in 1863 and 1864. We have two descriptions of the same incident aboard HMS Euryalus

HMS Euryalus (1853)

HMS Euryalus was a fourth-rate wooden-hulled screw frigate of the Royal Navy, with a 400HP steam engine that could make over 12 knots. She was launched at Chatham in 1853, was 212 feet long, displaced 3125 tons and had a complement of 515...

at the Bombardment of Kagoshima in August 1863:

"We had on our main-deck 32-pr. 56 cwt. muzzle-loaders; and they, of course, gave no trouble... in the forecastle we had a 7-in. B.L. 110-pr. Armstrong. Whether the men in the heat of the action became hurried I cannot say; but certain it is that the breech piece of this gun blew out with tremendous effect, the concussion knocking down the whole gun's crew, and apparently paralysing the men, until Webster, captain of the forecastle and of the gun, roused them by shouting: 'Well; is there ere a b----- of you will go and get the spare vent piece?'" -- Letter from an officer of HMS Euryalus to historian William Laird ClowesWilliam Laird ClowesSir William Laird Clowes was a British journalist and historian whose principal work was The Royal Navy, A History from the Earliest Times to 1900, a text that is still in print. He also wrote numerous technical pieces on naval technology and strategy and was also noted for his articles concerning...

many years after the event.

"My opinion, and also that of the gunnery lieutenant, is that for long range they [Armstrong guns], are most successful. The 100-pounder (sic) as a pivot gunPivot gunA pivot gun was a type of cannon mounted on a fixed central emplacement which permitted it to be moved through a wide horizontal arc. They were a common weapon aboard ships and in land fortifications for several centuries but became obsolete after the invention of gun turrets...

is superior to the 95 cwt. solid 8-inch gun ; but as broadside guns between decks we do not like them; the smoke is too great. Rear choke carriages with such heavy guns are very slow in working and the decks dreadfully cut up. The common shell is one of its great efficiencies, the bursting charge is so great. At Kagosima one vent-piece of the pivot-gun broke and a piece went up to foreyard, but no one was hurt, and it was the fault of the captain of the gun not putting the tin cap in. If the gun is understood and worked properly, it is very successful". -- An officer from HMS Euryalus, published in The TimesThe TimesThe Times is a British daily national newspaper, first published in London in 1785 under the title The Daily Universal Register . The Times and its sister paper The Sunday Times are published by Times Newspapers Limited, a subsidiary since 1981 of News International...

on 25 April 1864.

The guns while functioning well when correctly handled were hence seen to be difficult and potentially dangerous to use under the stress of combat.

Surviving examples

- An 82cwt gun at Victoria Barracks, SydneyVictoria Barracks, SydneyVictoria Barracks is an Australian Army base in Sydney, New South Wales, Australia. Victoria Barracks is located in the suburb of Paddington, between Oxford Street and Moore Park Road...

- An 82cwt gun at Saint HelierSaint HelierSaint Helier is one of the twelve parishes of Jersey, the largest of the Channel Islands in the English Channel. St. Helier has a population of about 28,000, roughly 31.2% of the total population of Jersey, and is the capital of the Island . The urban area of the parish of St...

, JerseyJerseyJersey, officially the Bailiwick of Jersey is a British Crown Dependency off the coast of Normandy, France. As well as the island of Jersey itself, the bailiwick includes two groups of small islands that are no longer permanently inhabited, the Minquiers and Écréhous, and the Pierres de Lecq and... - A 72cwt gun at Fort Nelson, Portsmouth, UKFort Nelson, PortsmouthFort Nelson, in the civil parish of Boarhunt in the English county of Hampshire, is one of five defensive forts built on the summit of Portsdown Hill in the 1860s, overlooking the important naval base of Portsmouth. It is now part of the Royal Armouries, housing their collection of...

- At Fort Henry, OntarioFort Henry, OntarioFort Henry is located in Kingston, Ontario, Canada on Point Henry, a strategic point located near the mouth of the Cataraqui River where it flows into the St. Lawrence River, at the upper end of the Thousand Islands...

, Canada - A 72 cwt gun at Quebec Citadel, Canada

- A 72 cwt gun at Fort Levi, Quebec