Angle grinder

Encyclopedia

Power tool

A power tool is a tool that is actuated by an additional power source and mechanism other than the solely manual labour used with hand tools. The most common types of power tools use electric motors. Internal combustion engines and compressed air are also commonly used...

used for cutting, grinding and polishing

Polishing

Polishing is the process of creating a smooth and shiny surface by rubbing it or using a chemical action, leaving a surface with a significant specular reflection In some materials polishing is also able to reduce diffuse reflection to...

.

Angle grinders can be powered by an electric motor

Electric motor

An electric motor converts electrical energy into mechanical energy.Most electric motors operate through the interaction of magnetic fields and current-carrying conductors to generate force...

, petrol engine

Petrol engine

A petrol engine is an internal combustion engine with spark-ignition, designed to run on petrol and similar volatile fuels....

or compressed air

Compressed air

Compressed air is air which is kept under a certain pressure, usually greater than that of the atmosphere. In Europe, 10 percent of all electricity used by industry is used to produce compressed air, amounting to 80 terawatt hours consumption per year....

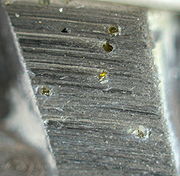

. The motor drives a geared head at a right-angle on which is mounted an abrasive

Abrasive

An abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away...

disc

Grinding wheel

A grinding wheel is an expendable wheel that is composed of an abrasive compound used for various grinding and abrasive machining operations...

or a thinner cut-off disc, either of which can be replaced when worn. Angle grinders typically have an adjustable guard and a side-handle for two-handed operation. Certain angle grinders, depending on their speed range, can be used as a sander, employing a sanding disc with a backing pad or disc. The backing system is typically made of hard plastic, phenolic resin, or medium-hard rubber depending on the amount of flexibility desired.

Uses

Diamond Blade

A diamond blade is a saw blade which has diamonds fixed on the blade's base to use the diamonds to cut hard or abrasive materials. There are many types of diamond blades, and they have been applied in many industries, for example, construction industry to cut stone, concrete, asphalt, bricks, coal...

), abrasive grinding discs, grinding stones, sanding discs, wire brush

Wire brush

A wire brush is a tool, consisting of a handle, usually wood or plastic, occasionally bone, and a brush. The brush is usually made from a large number of steel wire bristles. The steel used is generally a high carbon variety and very hard. Other wire brushes feature bristles made from brass or...

wheels and polishing pads. The angle grinder has large bearing

Bearing (mechanical)

A bearing is a device to allow constrained relative motion between two or more parts, typically rotation or linear movement. Bearings may be classified broadly according to the motions they allow and according to their principle of operation as well as by the directions of applied loads they can...

s to counter side forces generated during cutting

Cutting

Cutting is the separation of a physical object, or a portion of a physical object, into two portions, through the application of an acutely directed force. An implement commonly used for cutting is the knife or in medical cases the scalpel...

, unlike a power drill

Drill

A drill or drill motor is a tool fitted with a cutting tool attachment or driving tool attachment, usually a drill bit or driver bit, used for drilling holes in various materials or fastening various materials together with the use of fasteners. The attachment is gripped by a chuck at one end of...

, where the force is axial.

Angle grinders are widely used in metalworking

Metalworking

Metalworking is the process of working with metals to create individual parts, assemblies, or large scale structures. The term covers a wide range of work from large ships and bridges to precise engine parts and delicate jewelry. It therefore includes a correspondingly wide range of skills,...

and construction

Construction

In the fields of architecture and civil engineering, construction is a process that consists of the building or assembling of infrastructure. Far from being a single activity, large scale construction is a feat of human multitasking...

, as well as in emergency rescues. They are commonly found in workshops, service garages and auto body repair shops. There is a large variety of angle grinders to choose from when trying to find the right one for the job. The most important factors in choosing the right grinder are the disc size and how powerful the motor is. Other factors include power source (pneumatic

Pneumatics

Pneumatics is a branch of technology, which deals with the study and application of use of pressurized gas to effect mechanical motion.Pneumatic systems are extensively used in industry, where factories are commonly plumbed with compressed air or compressed inert gases...

or electric

Electricity

Electricity is a general term encompassing a variety of phenomena resulting from the presence and flow of electric charge. These include many easily recognizable phenomena, such as lightning, static electricity, and the flow of electrical current in an electrical wire...

), rpm

Revolutions per minute

Revolutions per minute is a measure of the frequency of a rotation. It annotates the number of full rotations completed in one minute around a fixed axis...

, and arbor

Mandrel

A mandrel is one of the following:* an object used to shape machined work.* a tool component that grips or clamps materials to be machined.* a tool component that can be used to grip other moving tool components.- Variants :...

size. Generally disc size and power increase together. Disc size is usually measured in inches or millimetres. Common disc sizes for angle grinders in the U.S.A. include 4, 4.5, 5, 6, 7, 9 and 12 inches. Discs for pneumatic grinders also come much smaller. Pneumatic grinders are generally used for lighter duty jobs where more precision

Accuracy and precision

In the fields of science, engineering, industry and statistics, the accuracy of a measurement system is the degree of closeness of measurements of a quantity to that quantity's actual value. The precision of a measurement system, also called reproducibility or repeatability, is the degree to which...

is required. This is likely because pneumatic grinders can be small and light yet remain powerful, because they do not contain heavy copper motor windings, while it is harder for an electric grinder to maintain adequate power with smaller size. Electric grinders are more commonly used for larger, heavy duty jobs. However, there are also small electric grinders and large pneumatic grinders.

Safety

Through a sound power level and vibrations study conducted by the National Institute for Occupational Safety and HealthNational Institute for Occupational Safety and Health

The National Institute for Occupational Safety and Health is the United States’ federal agency responsible for conducting research and making recommendations for the prevention of work-related injury and illness. NIOSH is part of the Centers for Disease Control and Prevention within the U.S...

, grinders under an unloaded condition ranged from 91 to 103 dBA

A-weighting

A Weighting curve is a graph of a set of factors, that are used to 'weight' measured values of a variable according to their importance in relation to some outcome. The most commonly known example is frequency weighting in sound level measurement where a specific set of weighting curves known as A,...

.