Architectural glass

Encyclopedia

Architectural glass is glass that is used as a building material

. It is most typically used as transparent glazing material in the building envelope, including windows in the external walls. Glass

is also used for internal partitions and as an architectural feature. When used in buildings, glass is often of a safety type

, which include reinforced, toughened and laminated glasses.

windows, albeit with poor optical qualities, began to appear in the most important buildings in Rome and the most luxurious villas of Herculaneum and Pompeii.

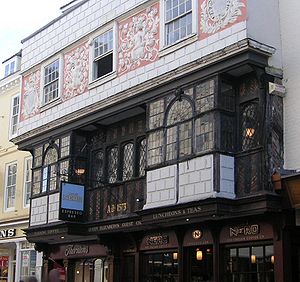

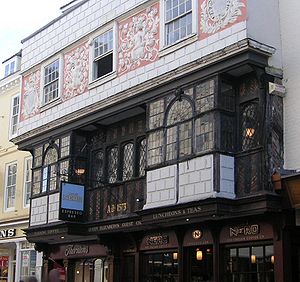

One of the earliest methods of glass window manufacture was the crown glass method. Hot blown glass was cut open opposite the pipe, then rapidly spun on a table before it could cool. Centrifugal force shaped the hot globe of glass into a round, flat sheet. The sheet would then be broken off the pipe and trimmed to form a rectangular window to fit into a frame.

One of the earliest methods of glass window manufacture was the crown glass method. Hot blown glass was cut open opposite the pipe, then rapidly spun on a table before it could cool. Centrifugal force shaped the hot globe of glass into a round, flat sheet. The sheet would then be broken off the pipe and trimmed to form a rectangular window to fit into a frame.

At the center of a piece of crown glass, a thick remnant of the original blown bottle neck would remain, hence the name "bullseye." Optical distortions produced by the bullseye could be reduced by grinding the glass. The development of diaper

latticed windows was in part because three regular diamond-shaped panes could be conveniently cut from a piece of Crown glass, with minimum waste and with minimum distortion.

This method for manufacturing flat glass

panels was very expensive and could not be used to make large panes. It was replaced in the 19th century by the cylinder, sheet, and rolled plate processes, but it is still used in traditional construction and restoration.

Drawn Sheet glass was made by dipping a leader into a vat of molten glass then pulling that leader straight up while a film of glass hardened just out of the vat - this is known as the Fourcault process

Drawn Sheet glass was made by dipping a leader into a vat of molten glass then pulling that leader straight up while a film of glass hardened just out of the vat - this is known as the Fourcault process

. This film or ribbon was pulled up continuously held by tractors on both edges while it cooled. After 12 meters or so it was cut off the vertical ribbon and tipped down to be further cut. This glass is clear but has thickness variations due to small temperature changes just out of the vat as it was hardening. These variations cause lines of slight distortions. This glass may still be seen in older houses. Float glass replaced this process.

, down which it is carried by a system of rollers.

Before the float process, mirrors were plate glass as sheet glass had visual distortions that were akin to those seen in amusement park or fun-fair mirrors.

The elaborate patterns found on figured (or 'Cathedral') rolled-plate glass are produced in a similar fashion to the rolled plate glass process except that the plate is cast between two rollers, one of which carries a pattern. On occasions both rollers can carry a pattern. The pattern is impressed upon the sheet by a printing roller which is brought down upon the glass as it leaves the main rolls while still soft. This glass shows a pattern in high relief. The glass is then annealed in a lehr

The elaborate patterns found on figured (or 'Cathedral') rolled-plate glass are produced in a similar fashion to the rolled plate glass process except that the plate is cast between two rollers, one of which carries a pattern. On occasions both rollers can carry a pattern. The pattern is impressed upon the sheet by a printing roller which is brought down upon the glass as it leaves the main rolls while still soft. This glass shows a pattern in high relief. The glass is then annealed in a lehr

.

The glass used for this purpose is typically whiter in colour than the clear glasses used for other applications.

This glass can be laminated or toughened depending on the depth of the pattern to produce a safety glass.

process invented in the 1950s by Sir Alastair Pilkington

of Pilkington Glass, in which molten glass is poured onto one end of a molten tin

bath. The glass floats on the tin, and levels out as it spreads along the bath, giving a smooth face to both sides. The glass cools and slowly solidifies as it travels over the molten tin and leaves the tin bath in a continuous ribbon. The glass is then annealed by cooling in an oven called a lehr

. The finished product has near-perfect parallel surfaces.

The side of the glass that has been in contact with the tin has a very small amount of the tin is embedded in its surface. This quality makes that side of the glass easier to be coated in order to turn it into a mirror, however that side is also softer and easier to scratch.

Glass is produced in standard metric thicknesses of 2, 3, 4, 5, 6, 8, 10, 12, 15, 19 and 22 mm. Molten glass floating on tin in a nitrogen/hydrogen atmosphere will spread out to a thickness of about 6 mm and stop due to surface tension

. Thinner glass is made by stretching the glass while it floats on the tin and cools. Similarly, thicker glass is pushed back and not permitted to expand as it cools on the tin.

glass is architectural glass used around the turn of the century to provide lighting to underground spaces and areas that would otherwise be too difficult to light. Prism glass uses a unique convex lens design to help illuminate more than ordinary glass. Prism glass can sometimes be found on sidewalks and in this form is known as vault lighting. It is similar to deck prism

s that were used to light spaces below deck on sailing ships.

used in areas where privacy or visual obscuration is desired while admitting light, such as underground parking garages, washrooms, and municipal swimming baths. Glass block was originally developed in the early 1900s to provide natural light in industrial factories

.

is glass without internal stresses caused by heat treatment, i.e., rapid cooling, or by toughening or heat strengthening. Glass becomes annealed if it is heated above a transition point then allowed to cool slowly, without being quenched. Float glass is annealed during the process of manufacture. However, most toughened glass is made from float glass that has been specially heat-treated.

Annealed glass breaks into large, jagged shards that can cause serious injury, and thus, the reason it is considered a hazard in architectural

applications. Building code

s in many parts of the world restrict the use of annealed glass in areas where there is a high risk

of breakage and injury

, for example in bathroom

s, in door

panels, fire exits and at low heights in school

s or domestic houses.

Laminated glass is manufactured by bonding two or more layers of glass together with layers of PVB

Laminated glass is manufactured by bonding two or more layers of glass together with layers of PVB

, under heat and pressure, to create a single sheet of glass. When broken, the PVB interlayer keeps the layers of glass bonded and prevents it from breaking apart. The interlayer can also give the glass a higher sound insulation rating.

There are several types of laminated glasses manufactured using different types of glass and interlayers which produce different results when broken.

Laminated glass that is made up of annealed glass is normally used when safety is a concern, but tempering is not an option. Windshield

s are typically laminated glasses. When broken, the PVB layer prevents the glass from breaking apart creating a "spider web" cracking pattern.

Tempered laminated glass is designed to shatter into small pieces, preventing possible injury. When both pieces of glass are broken it produces a "wet blanket" effect and it will fall out of its opening.

Heat strengthened laminated glass is stronger than annealed, but not as strong as tempered. It is often used where security is a concern. It has a larger break pattern than tempered, but because it holds its shape (unlike the "wet blanket" effect of tempered laminated glass) it remains in the opening and can withstand more force for a longer period of time, making it much more difficult to get through.

Toughened (or tempered) glass is a type of safety glass that has increased strength and will usually shatter in small, square pieces when broken. It is used when strength, thermal resistance and safety are important considerations. Using toughened glass on automobile windshields would be a problem when a small stone hits the windshield at speed, as it would shatter into small squares endangering the driver and passengers. In commercial structures it is used in unframed assemblies such as frameless doors, structurally loaded applications and door lites and vision lites adjacent to doors. Toughened glass is typically four to six times the strength of annealed

Toughened (or tempered) glass is a type of safety glass that has increased strength and will usually shatter in small, square pieces when broken. It is used when strength, thermal resistance and safety are important considerations. Using toughened glass on automobile windshields would be a problem when a small stone hits the windshield at speed, as it would shatter into small squares endangering the driver and passengers. In commercial structures it is used in unframed assemblies such as frameless doors, structurally loaded applications and door lites and vision lites adjacent to doors. Toughened glass is typically four to six times the strength of annealed

glass.

The glass is chemically strengthened by submerging the glass in a bath containing a potassium salt (typically potassium nitrate) at 450 °C (842 °F). This causes sodium ions in the glass surface to be replaced by potassium ions from the bath solution.

Unlike toughened glass, chemically strengthened glass may be cut after strengthening, but loses its added strength within the region of approximately 20 mm of the cut. Similarly, when the surface of chemically strengthened glass is deeply scratched, this area loses its additional strength.

Chemically strengthened glass was used on some fighter aircraft

canopies.

is a relatively new product, which help to find solutions while designing buildings and vehicles.

The idea of heating glass is based on usage of energy-efficient

low-emissive glass which is generally simple silicate glass with special metallic oxides covering. Low-emissive covering decreases the loss of heat approximately by 30 %. Heatable glass can be used in all kinds of standard glazing

systems, made of wood, plastic, aluminum or steel.

, aimed at building, automotive and other technical applications. A nanometre-scale coating of titanium dioxide

on the outer surface of glass introduces two mechanisms which lead to the self-cleaning property. The first is a photo-catalytic effect, in which ultra-violet rays catalyse the breakdown of organic compounds on the window surface; the second is a hydrophilic effect in which water is attracted to the surface of the glass, forming a thin sheet which washes away the broken-down organic compounds.

or glazing element of two or more layers of glazing separated by a spacer along the edge and sealed to create a dead air space between the layers. This type of glazing has functions of thermal insulation and noise reduction

. When the space is filled with an inert gas it is part of energy conservation

sustainable architecture

design for low energy buildings.

An evacuated glazing unit is made by sealing the edges of two glass sheets, typically by using a solder glass, and evacuating the space inside with a vacuum pump. The evacuated space between the two sheets can be very shallow and yet be a good insulator, yielding insulative window glass with nominal thicknesses as low as 6 mm overall. The reasons for this low thickness are deceptively complex, but the potential insulation is good essentially because there can be no convection or gaseous conduction in a vacuum.

Unfortunately, evacuated glazing does have some disadvantages; its manufacture is complicated and difficult. For example, a necessary stage in the manufacture of evacuated glazing is outgassing

; that is, heating it to liberate any gases adsorbed on the inner surfaces, which could otherwise later escape and destroy the vacuum. This heating process currently means that evacuated glazing cannot be toughened or heat-strengthened. If an evacuated safety glass is required, the glass must be laminated. The high temperatures necessary for outgassing also tend to destroy the highly effective "soft" low-emissivity

coatings that are often applied to one or both of the internal surfaces (i.e. the ones facing the air gap) of other forms of modern insulative glazing, in order to prevent loss of heat through infrared

radiation. Slightly less effective "hard" coatings are still suitable for evacuated glazing, however.

Furthermore, because of the atmospheric pressure present on the outside of an evacuated glazing unit, its two glass sheets must somehow be held apart in order to prevent them flexing together and touching each other, which would defeat the object of evacuating the unit. The task of holding the panes apart is performed by a grid of spacers, which typically consist of small stainless steel discs that are placed around 20 mm apart. The spacers are small enough that they are visible only at very close distances, typically up to 1 m. However, the fact that the spacers will conduct some heat often leads in cold weather to the formation of temporary, grid-shaped patterns on the surface of an evacuated window, consisting either of small circles of interior condensation centred around the spacers, where the glass is slightly colder than average, or, when there is dew outside, small circles on the exterior face of the glass, in which the dew is absent because the spacers make the glass near them slightly warmer.

The conduction of heat between the panes, caused by the spacers, tends to limit evacuated glazing’s overall insulative effectiveness. Nevertheless, evacuated glazing is still as insulative as much thicker conventional double glazing and tends to be stronger, since the two constituent glass sheets are pressed together by the atmosphere, and hence react practically as one thick sheet to bending forces. Evacuated glazing also offers very good sound insulation in comparison with other popular types of window glazing.

Building material

Building material is any material which is used for a construction purpose. Many naturally occurring substances, such as clay, sand, wood and rocks, even twigs and leaves have been used to construct buildings. Apart from naturally occurring materials, many man-made products are in use, some more...

. It is most typically used as transparent glazing material in the building envelope, including windows in the external walls. Glass

Glass

Glass is an amorphous solid material. Glasses are typically brittle and optically transparent.The most familiar type of glass, used for centuries in windows and drinking vessels, is soda-lime glass, composed of about 75% silica plus Na2O, CaO, and several minor additives...

is also used for internal partitions and as an architectural feature. When used in buildings, glass is often of a safety type

Safety glass

Safety glass is glass with additional safety features. Designs include:* Toughened glass * Laminated glass* Wire mesh glass...

, which include reinforced, toughened and laminated glasses.

Cast glass

Cast glassGlass

Glass is an amorphous solid material. Glasses are typically brittle and optically transparent.The most familiar type of glass, used for centuries in windows and drinking vessels, is soda-lime glass, composed of about 75% silica plus Na2O, CaO, and several minor additives...

windows, albeit with poor optical qualities, began to appear in the most important buildings in Rome and the most luxurious villas of Herculaneum and Pompeii.

Crown glass

At the center of a piece of crown glass, a thick remnant of the original blown bottle neck would remain, hence the name "bullseye." Optical distortions produced by the bullseye could be reduced by grinding the glass. The development of diaper

Diapering

Diaper is any of a wide range of decorative patterns used in a variety of works of art, such as stained glass, heraldic shields, architecture, silverwork etc. Its chief use is in the enlivening of plain surfaces.-Etymology:...

latticed windows was in part because three regular diamond-shaped panes could be conveniently cut from a piece of Crown glass, with minimum waste and with minimum distortion.

This method for manufacturing flat glass

Flat glass

Flat glass, sheet glass, or plate glass is a type of glass, initially produced in plane form, commonly used for windows, glass doors, transparent walls, and windshields. For modern architectural and automotive applications, the flat glass is sometimes bent after production of the plane sheet...

panels was very expensive and could not be used to make large panes. It was replaced in the 19th century by the cylinder, sheet, and rolled plate processes, but it is still used in traditional construction and restoration.

Cylinder glass

In this manufacturing process glass is blown into a cylindrical iron mould. The ends are cut off and a cut is made down the side of the cylinder. The cut cylinder is then placed in an oven where the cylinder unrolls into a flat glass sheet.Drawn Sheet glass (Fourcault process)

Fourcault process

The Fourcault Process is a method of manufacturing flat glass. First developed in Belgium by Émile Fourcault during the early 1900s, the process was used globally. Fourcault is an example of a "vertical draw" process, in that the glass is drawn against gravity in an upward direction...

. This film or ribbon was pulled up continuously held by tractors on both edges while it cooled. After 12 meters or so it was cut off the vertical ribbon and tipped down to be further cut. This glass is clear but has thickness variations due to small temperature changes just out of the vat as it was hardening. These variations cause lines of slight distortions. This glass may still be seen in older houses. Float glass replaced this process.

Cast plate glass

Developed by James Hartley, 1848. The glass is taken from the furnace in large iron ladles, which are carried upon slings running on overhead rails; from the ladle the glass is thrown upon the cast-iron bed of a rolling-table; and is rolled into sheet by an iron roller, the process being similar to that employed in making plate-glass, but on a smaller scale. The sheet thus rolled is roughly trimmed while hot and soft, so as to remove those portions of glass which have been spoiled by immediate contact with the ladle, and the sheet, still soft, is pushed into the open mouth of an annealing tunnel or temperature-controlled oven called a lehrLehr (glassmaking)

A lehr is a temperature-controlled kiln for annealing objects made of glass. The name derives from the German verb lehren meaning to teach and is cognate with the English lere also meaning to learn or acquire knowledge of ....

, down which it is carried by a system of rollers.

Polished plate glass

The polished plate glass process starts with sheet or rolled plate glass. This glass is dimensionally inaccurate and often created visual distortions. These rough panes were ground flat and then polished clear. This was a fairly expensive process.Before the float process, mirrors were plate glass as sheet glass had visual distortions that were akin to those seen in amusement park or fun-fair mirrors.

Rolled plate (figured) glass

Lehr (glassmaking)

A lehr is a temperature-controlled kiln for annealing objects made of glass. The name derives from the German verb lehren meaning to teach and is cognate with the English lere also meaning to learn or acquire knowledge of ....

.

The glass used for this purpose is typically whiter in colour than the clear glasses used for other applications.

This glass can be laminated or toughened depending on the depth of the pattern to produce a safety glass.

Float glass

90% of the world's flat glass is produced by the float glassFloat glass

Float glass is a sheet of glass made by floating molten glass on a bed of molten metal, typically tin, although lead and various low melting point alloys were used in the past. This method gives the sheet uniform thickness and very flat surfaces. Modern windows are made from float glass...

process invented in the 1950s by Sir Alastair Pilkington

Alastair Pilkington

Lionel Alexander Bethune Pilkington, and his associate Kenneth Bickerstaff, both of Great Britain, developed the world's first commercially successful manufacture of high quality flat glass using their float glass process...

of Pilkington Glass, in which molten glass is poured onto one end of a molten tin

Tin

Tin is a chemical element with the symbol Sn and atomic number 50. It is a main group metal in group 14 of the periodic table. Tin shows chemical similarity to both neighboring group 14 elements, germanium and lead and has two possible oxidation states, +2 and the slightly more stable +4...

bath. The glass floats on the tin, and levels out as it spreads along the bath, giving a smooth face to both sides. The glass cools and slowly solidifies as it travels over the molten tin and leaves the tin bath in a continuous ribbon. The glass is then annealed by cooling in an oven called a lehr

Lehr (glassmaking)

A lehr is a temperature-controlled kiln for annealing objects made of glass. The name derives from the German verb lehren meaning to teach and is cognate with the English lere also meaning to learn or acquire knowledge of ....

. The finished product has near-perfect parallel surfaces.

The side of the glass that has been in contact with the tin has a very small amount of the tin is embedded in its surface. This quality makes that side of the glass easier to be coated in order to turn it into a mirror, however that side is also softer and easier to scratch.

Glass is produced in standard metric thicknesses of 2, 3, 4, 5, 6, 8, 10, 12, 15, 19 and 22 mm. Molten glass floating on tin in a nitrogen/hydrogen atmosphere will spread out to a thickness of about 6 mm and stop due to surface tension

Surface tension

Surface tension is a property of the surface of a liquid that allows it to resist an external force. It is revealed, for example, in floating of some objects on the surface of water, even though they are denser than water, and in the ability of some insects to run on the water surface...

. Thinner glass is made by stretching the glass while it floats on the tin and cools. Similarly, thicker glass is pushed back and not permitted to expand as it cools on the tin.

Prism glass

PrismPrism (optics)

In optics, a prism is a transparent optical element with flat, polished surfaces that refract light. The exact angles between the surfaces depend on the application. The traditional geometrical shape is that of a triangular prism with a triangular base and rectangular sides, and in colloquial use...

glass is architectural glass used around the turn of the century to provide lighting to underground spaces and areas that would otherwise be too difficult to light. Prism glass uses a unique convex lens design to help illuminate more than ordinary glass. Prism glass can sometimes be found on sidewalks and in this form is known as vault lighting. It is similar to deck prism

Deck prism

A deck prism is a prism inserted into the deck of a ship to provide light down below.For centuries, sailing ships used deck prisms to provide a safe source of natural sunlight to illuminate areas below decks. Before electricity, light below a vessel's deck was provided by candles, oil and kerosene...

s that were used to light spaces below deck on sailing ships.

Glass block

Glass block, also known as glass brick, is an architectural element made from glassGlass

Glass is an amorphous solid material. Glasses are typically brittle and optically transparent.The most familiar type of glass, used for centuries in windows and drinking vessels, is soda-lime glass, composed of about 75% silica plus Na2O, CaO, and several minor additives...

used in areas where privacy or visual obscuration is desired while admitting light, such as underground parking garages, washrooms, and municipal swimming baths. Glass block was originally developed in the early 1900s to provide natural light in industrial factories

Factory

A factory or manufacturing plant is an industrial building where laborers manufacture goods or supervise machines processing one product into another. Most modern factories have large warehouses or warehouse-like facilities that contain heavy equipment used for assembly line production...

.

Annealed glass

Annealed glassAnnealing (glass)

Annealing is a process of slowly cooling glass to relieve internal stresses after it was formed. The process may be carried out in a temperature-controlled kiln known as a Lehr. Glass which has not been annealed is liable to crack or shatter when subjected to a relatively small temperature change...

is glass without internal stresses caused by heat treatment, i.e., rapid cooling, or by toughening or heat strengthening. Glass becomes annealed if it is heated above a transition point then allowed to cool slowly, without being quenched. Float glass is annealed during the process of manufacture. However, most toughened glass is made from float glass that has been specially heat-treated.

Annealed glass breaks into large, jagged shards that can cause serious injury, and thus, the reason it is considered a hazard in architectural

Architecture

Architecture is both the process and product of planning, designing and construction. Architectural works, in the material form of buildings, are often perceived as cultural and political symbols and as works of art...

applications. Building code

Building code

A building code, or building control, is a set of rules that specify the minimum acceptable level of safety for constructed objects such as buildings and nonbuilding structures. The main purpose of building codes are to protect public health, safety and general welfare as they relate to the...

s in many parts of the world restrict the use of annealed glass in areas where there is a high risk

Risk

Risk is the potential that a chosen action or activity will lead to a loss . The notion implies that a choice having an influence on the outcome exists . Potential losses themselves may also be called "risks"...

of breakage and injury

Injury

-By cause:*Traumatic injury, a body wound or shock produced by sudden physical injury, as from violence or accident*Other injuries from external physical causes, such as radiation injury, burn injury or frostbite*Injury from infection...

, for example in bathroom

Bathroom

A bathroom is a room for bathing in containing a bathtub and/or a shower and optionally a toilet, a sink/hand basin/wash basin and possibly also a bidet....

s, in door

Door

A door is a movable structure used to open and close off an entrance, typically consisting of a panel that swings on hinges or that slides or rotates inside of a space....

panels, fire exits and at low heights in school

School

A school is an institution designed for the teaching of students under the direction of teachers. Most countries have systems of formal education, which is commonly compulsory. In these systems, students progress through a series of schools...

s or domestic houses.

Laminated glass

Polyvinyl butyral

Polyvinyl butyral is a resin usually used for applications that require strong binding, optical clarity, adhesion to many surfaces, toughness and flexibility. It is prepared from polyvinyl alcohol by reaction with butyraldehyde. The major application is laminated safety glass for automobile...

, under heat and pressure, to create a single sheet of glass. When broken, the PVB interlayer keeps the layers of glass bonded and prevents it from breaking apart. The interlayer can also give the glass a higher sound insulation rating.

There are several types of laminated glasses manufactured using different types of glass and interlayers which produce different results when broken.

Laminated glass that is made up of annealed glass is normally used when safety is a concern, but tempering is not an option. Windshield

Windshield

The windshield or windscreen of an aircraft, car, bus, motorbike or tram is the front window. Modern windshields are generally made of laminated safety glass, a type of treated glass, which consists of two curved sheets of glass with a plastic layer laminated between them for safety, and are glued...

s are typically laminated glasses. When broken, the PVB layer prevents the glass from breaking apart creating a "spider web" cracking pattern.

Tempered laminated glass is designed to shatter into small pieces, preventing possible injury. When both pieces of glass are broken it produces a "wet blanket" effect and it will fall out of its opening.

Heat strengthened laminated glass is stronger than annealed, but not as strong as tempered. It is often used where security is a concern. It has a larger break pattern than tempered, but because it holds its shape (unlike the "wet blanket" effect of tempered laminated glass) it remains in the opening and can withstand more force for a longer period of time, making it much more difficult to get through.

Toughened glass (tempered glass)

Annealing (glass)

Annealing is a process of slowly cooling glass to relieve internal stresses after it was formed. The process may be carried out in a temperature-controlled kiln known as a Lehr. Glass which has not been annealed is liable to crack or shatter when subjected to a relatively small temperature change...

glass.

Heat-strengthened glass

Heat-strengthened glass is glass that has been heat treated to induce surface compression, but not to the extent of causing it to "dice" on breaking in the manner of tempered glass. On breaking, heat-strengthened glass breaks into sharp pieces that are typically somewhat smaller than those found on breaking annealed glass, and is intermediate in strength between annealed and toughened glasses.Chemically strengthened glass

Chemically strengthened glass is a type of glass that has increased strength. When broken it still shatters in long pointed splinters similar to float (annealed) glass. For this reason, it is not considered a safety glass and must be laminated if a safety glass is required. Chemically strengthened glass is typically six to eight times the strength of annealed glass.The glass is chemically strengthened by submerging the glass in a bath containing a potassium salt (typically potassium nitrate) at 450 °C (842 °F). This causes sodium ions in the glass surface to be replaced by potassium ions from the bath solution.

Unlike toughened glass, chemically strengthened glass may be cut after strengthening, but loses its added strength within the region of approximately 20 mm of the cut. Similarly, when the surface of chemically strengthened glass is deeply scratched, this area loses its additional strength.

Chemically strengthened glass was used on some fighter aircraft

Fighter aircraft

A fighter aircraft is a military aircraft designed primarily for air-to-air combat with other aircraft, as opposed to a bomber, which is designed primarily to attack ground targets...

canopies.

Low-emissivity glass

Glass coated with a low-emissivity substance can reflect radiant infrared energy, encouraging radiant heat to remain on the same side of the glass from which it originated, while letting visible light pass. This often results in more efficient windows because radiant heat originating from indoors in winter is reflected back inside, while infrared heat radiation from the sun during summer is reflected away, keeping it cooler inside.Heatable glass

Electrically heatable glassGlass

Glass is an amorphous solid material. Glasses are typically brittle and optically transparent.The most familiar type of glass, used for centuries in windows and drinking vessels, is soda-lime glass, composed of about 75% silica plus Na2O, CaO, and several minor additives...

is a relatively new product, which help to find solutions while designing buildings and vehicles.

The idea of heating glass is based on usage of energy-efficient

Efficient energy use

Efficient energy use, sometimes simply called energy efficiency, is the goal of efforts to reduce the amount of energy required to provide products and services. For example, insulating a home allows a building to use less heating and cooling energy to achieve and maintain a comfortable temperature...

low-emissive glass which is generally simple silicate glass with special metallic oxides covering. Low-emissive covering decreases the loss of heat approximately by 30 %. Heatable glass can be used in all kinds of standard glazing

Glazing

Glazing, which derives from the Middle English for 'glass', is a part of a wall or window, made of glass. Glazing also describes the work done by a professional "glazier"...

systems, made of wood, plastic, aluminum or steel.

Self-cleaning glass

A recent innovation is so-called self-cleaning glassSelf-cleaning glass

Self-cleaning glass is a specific type of glass with a surface which keeps itself free of dirt and grime.-Introduction:The field of self-cleaning coatings on glass is divided into two categories: hydrophobic and hydrophilic....

, aimed at building, automotive and other technical applications. A nanometre-scale coating of titanium dioxide

Titanium dioxide

Titanium dioxide, also known as titanium oxide or titania, is the naturally occurring oxide of titanium, chemical formula . When used as a pigment, it is called titanium white, Pigment White 6, or CI 77891. Generally it comes in two different forms, rutile and anatase. It has a wide range of...

on the outer surface of glass introduces two mechanisms which lead to the self-cleaning property. The first is a photo-catalytic effect, in which ultra-violet rays catalyse the breakdown of organic compounds on the window surface; the second is a hydrophilic effect in which water is attracted to the surface of the glass, forming a thin sheet which washes away the broken-down organic compounds.

Insulated glazing

Insulated glazing, or double glazing, consists of a windowWindow

A window is a transparent or translucent opening in a wall or door that allows the passage of light and, if not closed or sealed, air and sound. Windows are usually glazed or covered in some other transparent or translucent material like float glass. Windows are held in place by frames, which...

or glazing element of two or more layers of glazing separated by a spacer along the edge and sealed to create a dead air space between the layers. This type of glazing has functions of thermal insulation and noise reduction

Noise reduction

Noise reduction is the process of removing noise from a signal.All recording devices, both analogue or digital, have traits which make them susceptible to noise...

. When the space is filled with an inert gas it is part of energy conservation

Energy conservation

Energy conservation refers to efforts made to reduce energy consumption. Energy conservation can be achieved through increased efficient energy use, in conjunction with decreased energy consumption and/or reduced consumption from conventional energy sources...

sustainable architecture

Sustainable architecture

Sustainable architecture is a general term that describes environmentally conscious design techniques in the field of architecture. Sustainable architecture is framed by the larger discussion of sustainability and the pressing economic and political issues of our world...

design for low energy buildings.

Evacuated glazing

Another recent innovation for insulated glazing is evacuated glass, which as yet is produced commercially only in Japan and China. The extreme thinness of evacuated glazing offers many new architectural possibilities, particularly in building conservation and historicist architecture, where evacuated glazing can replace traditional single glazing, which is much less energy-efficient.An evacuated glazing unit is made by sealing the edges of two glass sheets, typically by using a solder glass, and evacuating the space inside with a vacuum pump. The evacuated space between the two sheets can be very shallow and yet be a good insulator, yielding insulative window glass with nominal thicknesses as low as 6 mm overall. The reasons for this low thickness are deceptively complex, but the potential insulation is good essentially because there can be no convection or gaseous conduction in a vacuum.

Unfortunately, evacuated glazing does have some disadvantages; its manufacture is complicated and difficult. For example, a necessary stage in the manufacture of evacuated glazing is outgassing

Outgassing

Outgassing is the release of a gas that was dissolved, trapped, frozen or absorbed in some material. As an example, research has shown how the concentration of carbon dioxide in the Earth's atmosphere has sometimes been linked to ocean outgassing...

; that is, heating it to liberate any gases adsorbed on the inner surfaces, which could otherwise later escape and destroy the vacuum. This heating process currently means that evacuated glazing cannot be toughened or heat-strengthened. If an evacuated safety glass is required, the glass must be laminated. The high temperatures necessary for outgassing also tend to destroy the highly effective "soft" low-emissivity

Low-emissivity

Low emissivity - actually low thermal emissivity - is a quality of a surface that radiates, or emits, low levels of radiant thermal energy. All materials absorb, reflect and emit radiant energy...

coatings that are often applied to one or both of the internal surfaces (i.e. the ones facing the air gap) of other forms of modern insulative glazing, in order to prevent loss of heat through infrared

Infrared

Infrared light is electromagnetic radiation with a wavelength longer than that of visible light, measured from the nominal edge of visible red light at 0.74 micrometres , and extending conventionally to 300 µm...

radiation. Slightly less effective "hard" coatings are still suitable for evacuated glazing, however.

Furthermore, because of the atmospheric pressure present on the outside of an evacuated glazing unit, its two glass sheets must somehow be held apart in order to prevent them flexing together and touching each other, which would defeat the object of evacuating the unit. The task of holding the panes apart is performed by a grid of spacers, which typically consist of small stainless steel discs that are placed around 20 mm apart. The spacers are small enough that they are visible only at very close distances, typically up to 1 m. However, the fact that the spacers will conduct some heat often leads in cold weather to the formation of temporary, grid-shaped patterns on the surface of an evacuated window, consisting either of small circles of interior condensation centred around the spacers, where the glass is slightly colder than average, or, when there is dew outside, small circles on the exterior face of the glass, in which the dew is absent because the spacers make the glass near them slightly warmer.

The conduction of heat between the panes, caused by the spacers, tends to limit evacuated glazing’s overall insulative effectiveness. Nevertheless, evacuated glazing is still as insulative as much thicker conventional double glazing and tends to be stronger, since the two constituent glass sheets are pressed together by the atmosphere, and hence react practically as one thick sheet to bending forces. Evacuated glazing also offers very good sound insulation in comparison with other popular types of window glazing.

Building code seismic requirements

The most current building code enforced in most jurisdictions in the United States is the 2006 International Building Code (IBC, 2006). The 2006 IBC references for the 2005 edition of the standard Minimum Design Loads for buildings and other Structures prepared by the American Society of Civil Engineers (ASCE, 2005) for its seismic provisions. ASCE 7-05 contains specific requirements for nonstructural components including requirements for architectural glass.See also

- Insulated glazingInsulated glazingInsulated glazing also known as double glazing are double or triple glass window panes separated by an air or other gas filled space to reduce heat transfer across a part of the building envelope....

- Solar thermal collectorSolar thermal collectorA solar thermal collector is a solar collector designed to collect heat by absorbing sunlight. The term is applied to solar hot water panels, but may also be used to denote more complex installations such as solar parabolic, solar trough and solar towers or simpler installations such as solar air...

- Building construction

- GlazingGlazingGlazing, which derives from the Middle English for 'glass', is a part of a wall or window, made of glass. Glazing also describes the work done by a professional "glazier"...

- LeadlightLeadlightLeadlights or leaded lights are decorative windows made of small sections of glass supported in lead cames. The technique of creating windows using glass and lead came is discussed at lead came and copper foil glasswork...

- Stained glassStained glassThe term stained glass can refer to coloured glass as a material or to works produced from it. Throughout its thousand-year history, the term has been applied almost exclusively to the windows of churches and other significant buildings...

- Stained glass - British glass, 1811-1918

- Glass museums and galleries

- Heatable glassHeatable GlassElectrically heatable glass and windows are relatively new products, which help solve problems in the design of buildings and vehicles.The idea of heating glass is based on the use of energy-efficient low-emissive glass, which is generally simple silicate glass with a special metallic oxides...

External links

- Glass Association of North America (GANA) – Architectural Glass educational documents and videos

- National Glass Association (NGA) – History and Types of Glass

- Welsh School of Architectural Glass, Swansea UK's leading centre for teaching and research in architectural glass founded in 1935