Cardboard

Encyclopedia

Shipping container

A shipping container is a container with strength suitable to withstand shipment, storage, and handling. Shipping containers range from large reusable steel boxes used for intermodal shipments to the ubiquitous corrugated boxes...

s.

The corrugated medium and linerboard are made of containerboard

Containerboard

Containerboard, also referred to as CCM , is a type of paperboard specially manufactured for the production of corrugated board. The term encompasses both linerboard and corrugating medium , the two types of paper that make up corrugated board...

, a paper-like material usually over 0.01 inch (0.254 mm) thick. Paperboard

Paperboard

Paperboard is a thick paper based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker than paper. According to ISO standards, paperboard is a paper with a basis weight above 224 g/m2, but there are exceptions. Paperboard can be single...

and corrugated fiberboard are sometimes called cardboard, although cardboard might be any heavy paper-pulp based board.

History

In the mid-19th century, an ingenious concept enabled flimsy sheets of paper to be transformed into a rigid, stackable and cushioning form of packaging for delicate goods in transitCorrugated (also called pleated) paper was patent

Patent

A patent is a form of intellectual property. It consists of a set of exclusive rights granted by a sovereign state to an inventor or their assignee for a limited period of time in exchange for the public disclosure of an invention....

ed in England in 1856, and used as a liner for tall hat

Hat

A hat is a head covering. It can be worn for protection against the elements, for ceremonial or religious reasons, for safety, or as a fashion accessory. In the past, hats were an indicator of social status...

s, but corrugated boxboard was not patented and used as a shipping material until December 20, 1871. The patent was issued to Albert Jones of New York City

New York City

New York is the most populous city in the United States and the center of the New York Metropolitan Area, one of the most populous metropolitan areas in the world. New York exerts a significant impact upon global commerce, finance, media, art, fashion, research, technology, education, and...

for single-sided (single-face) corrugated board. Jones used the corrugated board for wrapping bottles and glass lantern chimneys. The first machine for producing large quantities of corrugated board was built in 1874 by G. Smyth, and in the same year Oliver Long improved upon Jones' design by inventing corrugated board with liner sheets on both sides. This was corrugated board as we know it today.

The Scottish-born Robert Gair

Robert Gair

Robert Gair invented the folding carton in 1890 .Brooklynite Robert Gair was a printer and paper bag maker in the 1870s. He invented the paperboard folding carton by accident: a metal ruler normally used to crease bags shifted in position and cut the bag. Gair found that by cutting and creasing...

invented the pre-cut paperboard

Paperboard

Paperboard is a thick paper based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker than paper. According to ISO standards, paperboard is a paper with a basis weight above 224 g/m2, but there are exceptions. Paperboard can be single...

box in 1890 – flat pieces manufactured in bulk that folded into boxes. Gair's invention came about as a result of an accident: he was a Brooklyn printer and paper-bag maker during the 1870s, and one day, while he was printing an order of seed bags, a metal ruler normally used to crease bags shifted in position and cut them. Gair discovered that by cutting and creasing in one operation he could make prefabricated paperboard boxes. Applying this idea to corrugated boxboard was a straightforward development when the material became available in the early twentieth century.

The corrugated box was initially used for packaging glass and pottery containers. Later, the case enabled fruit and produce to be brought from the farm to the retailer without bruising, improving the return to the producers and opening up export markets.

Manufacture of corrugated board

The key raw material in corrugating is paper, different grades for each layer making up the corrugated box. Due to supply chain and scale considerations, paper is produced in separate plants called paper mills. Most corrugating plants keep an inventory of paper reels.

In the classical corrugator, the paper is softened with high-pressure steam. After the board is formed it is dried in the so-called dry-end. Here the newly formed corrugated board is heated from the bottom by hot plates. On the top, various pressures are applied by a load system on the belt.

The corrugated medium is often 0.026 lb/sqft basis weight in the U.S.; in the UK, a 90 g/m2 fluting paper is common. At the single-facer, it is heated, moistened, and formed into a fluted pattern on geared wheels. This is joined to a flat linerboard with a starch

Starch

Starch or amylum is a carbohydrate consisting of a large number of glucose units joined together by glycosidic bonds. This polysaccharide is produced by all green plants as an energy store...

based adhesive to form single face board. At the double-backer, a second flat linerboard is adhered to the other side of the fluted medium to form single wall corrugated board. Linerboards are test liners (recycled paper) or kraft paper

Kraft paper

Kraft paper or kraft is paper or paperboard produced from chemical pulp produced in the kraft process.Pulp produced by the kraft process is stronger than that made by other pulping processes; acidic sulfite processes degrade cellulose more, leading to weaker fibers, and mechanical pulping...

board (of various grades). The liner may be bleached white, mottled white, colored, or preprinted.

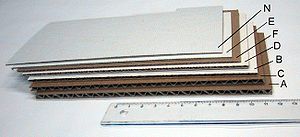

Common flute sizes are "A", "B", "C", "E" and "F" or microflute. The letter designation relates to the order that the flutes were invented, not the relative sizes. Flute size refers to the number of flutes per lineal foot, although the actual flute dimensions for different corrugator manufacuturers may vary slightly. Measuring the number of flutes per lineal foot is a more reliable method of identifying flute size than measuring board thickness, which can vary due to manufacturing conditions. The most common flute size in corrugated boxes is "C" flute.

Standard US Corrugated Flutes

| Flute Designation | Flutes per linear foot | Flute thickness (in) | Flutes per linear meter | Flute thickness (mm) |

|---|---|---|---|---|

| A flute | 33 +/− 3 | 3/16 | 108 +/− 10 | 4.8 |

| B flute | 47 +/− 3 | 1/8 | 154 +/− 10 | 3.2 |

| C flute | 39 +/− 3 | 5/32 | 128 +/− 10 | 4.0 |

| E flute | 90 +/− 4 | 1/16 | 295 +/− 13 | 1.6 |

| F flute | 128 +/− 4 | 1/32 | 420 +/− 13 | 0.8 |

Corrugated fiberboard can be specified by the construction (single face, singlewall, doublewall, etc.), flute size, burst strength, edge crush strength, flat crush, basis weights of components (pounds per thousand square feet, grams per square meter, etc.), surface treatments and coatings, etc. TAPPI

TAPPI

TAPPI is a registered not-for-profit, international Non-Governmental Organization of about 14,000 member engineers, scientists, managers, academics and others involved in the areas of pulp, and paper...

and ASTM test methods for these are standardized.

The choice of corrugated medium, flute size, combining adhesive, and linerboards can be varied to engineer a corrugated board with specific properties to match a wide variety of potential uses. Double and triple-wall corrugated board is also produced for high stacking strength and puncture resistance

Puncture resistance

Puncture resistance denotes the relative ability of a material to inhibit the progression of a tear once it has been pierced by a cut or a nick. Tests devised to measure puncture resistance are generally application-specific, covering items such as roofing and packaging materials, protective...

.

Most corrugators are two knife corrugators, which means that they can produce two different sheet lengths side-by-side. This leads to an optimisation problem, known as the cutting stock problem

Cutting stock problem

The cutting-stock problem is an optimization problem, or more specifically, an integer linear programming problem. It arises from many applications in industry. Imagine that you work in a paper mill and you have a number of rolls of paper of fixed width waiting to be cut, yet different customers...

.

Box design

Corrugated box design

Corrugated box design is the process of matching design factors for corrugated fiberboard boxes with the functional physical, processing and end-use requirements...

to meet the particular needs of the product being shipped, the hazards of the shipping environment, (shock, vibration, compression, moisture, etc.), and the needs of retailers and consumers.

The most common box style is the Regular Slotted Container (RSC). All flaps are the same length from the score to the edge. Typically, the major flaps meet in the middle and the minor flaps do not.

The manufacturer's joint is most often joined with adhesive but may also be taped or stitched. The box is shipped flat (knocked down) to the packager who sets up the box, fills it, and closes it for shipment. Box closure may be by tape, adhesive, staples, strapping, etc.

The size of a box can be measured for either internal (for product fit) or external (for handling machinery or palletizng) dimensions. Boxes are usually specified and ordered by the internal dimensions.

Box styles in Europe are typically defined by a 4-digit code specified by FEFCO: for example, a regular slotted container (RSC) is coded 0201. FEFCO styles are normally the basis for more complicated special designs that incorporate, for instance, locking tabs or internal fittings.

Manufacturing

Boxes can be formed in the same plant as the corrugator. Part of the scoring and cutting takes place in-line on the corrugator. Alternatively, sheets of corrugated board may be sent to a different manufacturing facility for box fabrication; these are sometimes called "sheet plants".The corrugated board is creased or scored to provide controlled bending of the board. Most often, slots are cut to provide flaps on the box. Scoring and slotting can also be accomplished by die-cutting.

Single-face laminate

A limitation of common corrugated material has been the difficulty in applying fine graphic print for informative and marketing purposes. The reasons for this stem from the fact that prefabricated corrugated sheets are relatively thick and spongy, compared to the thin and incompressible nature of solid fibre paper such as paperboardPaperboard

Paperboard is a thick paper based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker than paper. According to ISO standards, paperboard is a paper with a basis weight above 224 g/m2, but there are exceptions. Paperboard can be single...

. Due to these characteristics of corrugated, it has been mainly printed using a flexographic

Flexography

Flexography is a form of printing process which utilizes a flexible relief plate. It is basically an updated version of letterpress that can be used for printing on almost any type of substrate including plastic, metallic films, cellophane, and paper...

process, which is by nature a coarse application with loose registration properties.

A more recent development popular in usage is a hybrid product featuring the structural benefits of corrugated combined with the high-graphics print of lithography

Lithography

Lithography is a method for printing using a stone or a metal plate with a completely smooth surface...

previously restricted to paperboard folding cartons. This application, generally referred to as 'Single-Face Laminate', begins its process as a traditional fluted medium adhered to a single linerboard (single-face), but in place of a second long-fibered liner, a pre-printed sheet of paperboard such as SBS (solid bleached sulfate

Solid bleached board

Solid Bleached Board or Solid bleached sulphate is a virgin fibre grade of paperboard.This grade is made purely from bleached chemical pulp and usually has a mineral or synthetic pigment coated top surface in one or more layers as well as a coated reverse side...

) is laminated to the outer facing. The sheet can then be converted with the same processes used for other corrugated manufacturing into any desired form.

Specialized equipment is necessary for the material construction of SFL, so users may expect to pay a premium for these products. However, this cost is often offset by the savings over a separate paperboard sleeve and the labor necessary to assemble the completed package.

Recycling

Old corrugated containers are an excellent source of fibre for recycling. They can be compressed and baled for cost effective transport. The baled boxes are put in a hydropulper, which is a large vat of warm water for cleaning and processing. The pulp slurry is then used to make new paper and fiber products.Mill and corrugator scrap, or broke, is the cleanest source for recycling. The high rates of post-consumer recycling reflect the efficiency of recycling mills to clean and process the incoming materials. Several technologies are available to sort, screen, filter, and chemically treat the recycled paper.

Many extraneous materials are readily removed. Twine, strapping, etc. are removed from the hydropulper by a "ragger". Metal straps and staples can be screened out or removed by a magnet. Film-backed pressure sensitive tape

Pressure sensitive tape

Pressure-sensitive tape, known also in various countries as PSA tape, adhesive tape, self-stick tape, sticky tape, or just tape, is an adhesive tape that will stick with application pressure, without the need for solvent, heat, or water for activation...

stays intact: the PSA adhesive and the backing are both removed together.

Materials which are more difficult to remove include wax coatings on corrugated boxes and "stickies", soft rubbery particles which can clog the paper maker and contaminate the recycled paper. Stickies can originate from book bindings, hot melt adhesives, pressure-sensitive adhesives from paper label

Label

A label is a piece of paper, polymer, cloth, metal, or other material affixed to a container or article, on which is printed a legend, information concerning the product, addresses, etc. A label may also be printed directly on the container or article....

s, laminating adhesives of reinforced gummed tapes, etc.

Corrugated fiberboard shredders are now available which convert post-consumer corrugated board into packing/cushioning materials by means of a specialized shredding process.

Recycling corrugated fiberboard helps countries without sustainable wood resources build a paper and packaging industry locally.

See also

- BoxBoxBox describes a variety of containers and receptacles for permanent use as storage, or for temporary use often for transporting contents. The word derives from the Greek πύξος , "box, boxwood"....

- Box compression testBox compression testThe container compression test measures the compressive strength of packages such as boxes, drums, and cans. It usually provides a plot of deformation vs compressive force....

- composition board

- Corrugated plasticCorrugated plasticCorrugated plastic or corriboard - also known under the tradenames of Coroplast, IntePro, Correx, Twinplast, Corriflute or Corflute - refers to a wide range of extruded twinwall plastic-sheet products produced from high-impact polypropylene resin with a similar make-up to corrugated fiberboard. It...

- FoamcoreFoamcoreFoam core or Foam board is a very strong, lightweight and easily cut material used for the mounting of photographic prints, as backing in picture framing, in 3D design, and in painting. It is also in a material category referred to as "Paper-faced Foam Board"...

(foam board) - Bulk box

- paperboardPaperboardPaperboard is a thick paper based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker than paper. According to ISO standards, paperboard is a paper with a basis weight above 224 g/m2, but there are exceptions. Paperboard can be single...

- Paper recyclingPaper recyclingPaper recycling is the process of recovering waste paper and remaking it into new paper products. There are three categories of paper that can be used as feedstocks for making recycled paper: mill broke, pre-consumer waste, and post-consumer waste. Mill broke is paper trimmings and other paper...

- Packaging and labellingPackaging and labellingPackaging is the science, art, and technology of enclosing or protecting products for distribution, storage, sale, and use. Packaging also refers to the process of design, evaluation, and production of packages. Packaging can be described as a coordinated system of preparing goods for transport,...

- Paste boardCard stockCard stock, also called cover stock or pasteboard, is a paper stock that is thicker and more durable than normal writing or printing paper, but thinner and more flexible than other forms of paperboard. Card stock is often used for business cards, postcards, playing cards, catalog covers,...

- Posterboard

ASTM Standards

- D1974 Standard Practice for Methods of Closing, Sealing, sucking, blowing and Reinforcing Fiberboard Boxes

- D4727 Standard Specification for Corrugated and Solid Fiberboard Sheet Stock (Container Grade) and Cut Shapes

- D5118 Standard Practice for Fabrication of Fiberboard Shipping Boxes

- D5168 Standard Practice for Fabrication and Closure of Triple-Wall Corrugated Fiberboard Containers

- D5639 Standard Practice for Selection of Corrugated Fiberboard Materials and Box Construction Based on Performance Requirements

- D6804 Standard Guide for Hand Hole Design in Corrugated Boxes

- and others

Further reading

- "Fibre Box Handbook", Fibre Box Association

- Koning, J., "Corrugated Crossroads, A Reference Guide for the Corrugated Industry", TAPPI Press, 1995, ISBN 0-89852-299-4

- European Corrugated Board Industry

- Good Manufacturing Practices for Corrugated and Solid Board Packaging This GMP-standard allows packaging for the food industry to be made to the highest standards of consumer safety. All details at the website of the European Federation of Corrugated Board Manufacturers (FEFCO)

- Brody, A. L., and Marsh, K, S., "Encyclopedia of Packaging Technology", John Wiley & Sons, 1997, ISBN 0-471-06397-5

- Soroka, W, "Fundamentals of Packaging Technology", IoPP, 2002, ISBN 1-930268-25-4

- "Guide for Packaging for Small Parcel Shipments", 2005, IoPP

- Asian Corrugated Carton Association