Duplex worm

Encyclopedia

As a result of this, different lead angles on both tooth profiles are obtained. With this the tooth thickness is continuously increasing all over the worm length, while the gap between two threads is decreasing.

At the worm wheel, the different modules result in different addendum modification coefficients and rolling circle diameters at both flanks. Because of this the profiles are different at the front and at the rear flank. The thickness of each tooth and the tooth gaps remain constant at the circumference of the wheel.

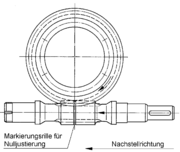

Backlash adjustment is done by shifting the worm axially, so that the section of the worm with the needed tooth thickness will be in contact with the wheel, giving the desired backlash (fig. 1).

This way, backlash can be easily adjusted to any desired value when mounting the gear, and even worn gears can be readjusted at any time delicately and continuously, without modifying the tooth contact or creating meshing interference.

Other Possibilities of Backlash Adjustment

- variation of center distance, by rotating an eccentricEccentric (mechanism)In mechanical engineering, an eccentric is a circular disk solidly fixed to a rotating axle with its centre offset from that of the axle ....

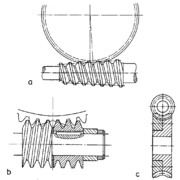

hub, in which the worm shaft and/or the worm gear wheel are cradled - axial shifting of a conical worm (fig. 2a)

- division of the worm in two halves (fig. 2b), to be rotated or shifted relatively to each other. (system Ott)

- division of the wheel in two disks (fig. 2c), to be rotated relatively to each other.

However all these methods demonstrate substantial disadvantages:

- adjustments and/or readjustments are interfering with the geometrically accurate meshing.

- they shift the contact profile zone and change its form and size.

- with this they decrease the load-carrying capacity and deteriorate the efficiency.

- each adjustment causes a tremendous amount of start-up wear.

- the dangers of wrong assembly and destruction of the worm gear set are tremendous.

They permit an always geometrically accurate teeth contact and beyond that, very delicate backlash adjustment. Neither the evolved contact area, the load-carrying capacity nor the actual efficiency are affected. In addition as duplex teeth are executed as involute gear

Involute gear

The involute gear profile is the most commonly used system for gearing today. In an involute gear, the profiles of the teeth are involutes of a circle. In involute gear design contact between a pair of gear teeth occurs...

they are insensitive in regards to modifications of the center distance, e.g. caused by worm shaft deflections.

Applications

Duplex gears are mainly utilized where any backlash is unwanted or can be harmful, to maintain repeated high precision positioning in both directions, to prevent impulse loaded damage, and when the contact flanks are alternating. Common applications include: rotaryRotary table

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed axis...

and tilting tables, milling machine

Milling machine

A milling machine is a machine tool used to machine solid materials. Milling machines are often classed in two basic forms, horizontal and vertical, which refers to the orientation of the main spindle. Both types range in size from small, bench-mounted devices to room-sized machines...

s, and presses

Machine press

A machine press, commonly shortened to press, is a machine tool that changes the shape of a workpiece.-Servomechanism:A servomechanism press, also known as a servo press or a electro press, is a press driven by an AC servo motor. The torque produced is converted to a linear force via a ball screw....

.

External links

- HENSCHEL MUTAX - DUPLEX (dual lead) worm gear with backlash-adjustable teeth specification