Frit compression

Encyclopedia

Frit compression is the technique used to fabricate buckypaper

and buckydiscs from a suspension of carbon nanotubes in a solvent. This is a quick, efficient method over surfactant-casting or acid oxidation filtration of carbon nanotubes.

molecule). The problem was the difficulty in removing the surfactant afterwards, where the surfactant has been linked with cell lysis and tissue inflammation.

Acid oxidation of carbon nanotubes can also be used in filtration to form buckypaper, but requires a high degree of surface acidic groups in order to obtain efficient dispersal in aqueous solution.

An alternative casting method was developed in 2008 to produce buckypaper that did not require the use of surfactants or the acid oxidation of carbon nanotubes in order to obtain high-purity buckypaper for biomedical applications.

An alternative casting method was developed in 2008 to produce buckypaper that did not require the use of surfactants or the acid oxidation of carbon nanotubes in order to obtain high-purity buckypaper for biomedical applications.

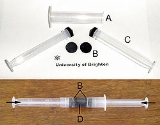

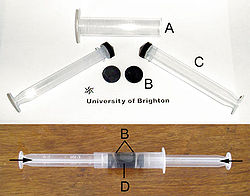

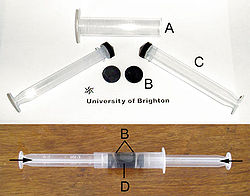

The frit-compression system was adapted from a Solid phase extraction

(SPE) column, where a suspension of carbon nanotubes is squeezed between two polypropylene frits (70 micrometre pore diameter) inside a syringe column. The pore structure of the frit allows a rapid exit of the solvent leaving the carbon nanotubes to be pressed together. The presence of the solvent controls the interaction between the tubes allowing the formation of tube-tube junctions; its surface tension directly affects the overlap of adjoining nanotubes thus gaining control over the porosity and pore diameter distribution of buckypaper. The distribution of carbon nanotubes in solvent does not have to be a stable suspension, rather a general dispersion serves much easier to keep the nanotubes between the frits rather than pass through them.

Once the system is compressed, the frit-carbon nanotube sandwich is removed from the syringe housing and allowed to dry. The frits can then be removed to leave intact buckypaper. This methodology rapidly speeds up the casting process, avoids use of surfactants and acid oxidation, and the solvent can be fully recovered.

Buckypaper

Buckypaper is a thin sheet made from an aggregate of carbon nanotubes. The nanotubes are approximately 50,000 times thinner than a human hair. Originally, it was fabricated as a way to handle carbon nanotubes, but it is also being studied and developed into applications by several research groups,...

and buckydiscs from a suspension of carbon nanotubes in a solvent. This is a quick, efficient method over surfactant-casting or acid oxidation filtration of carbon nanotubes.

Background

Traditional methods of buckypaper production involves the use of surfactants to disperse carbon nanotubes into aqueous solutions. It was found that filtering this suspension allowed the nanotubes to pack together in a paper-like mat, thus coining the term “buckypaper” (bucky being the reference to the buckminsterfullereneBuckminsterfullerene

Buckminsterfullerene is a spherical fullerene molecule with the formula . It was first intentionally prepared in 1985 by Harold Kroto, James Heath, Sean O'Brien, Robert Curl and Richard Smalley at Rice University...

molecule). The problem was the difficulty in removing the surfactant afterwards, where the surfactant has been linked with cell lysis and tissue inflammation.

Acid oxidation of carbon nanotubes can also be used in filtration to form buckypaper, but requires a high degree of surface acidic groups in order to obtain efficient dispersal in aqueous solution.

Synthesis

The frit-compression system was adapted from a Solid phase extraction

Solid phase extraction

Solid-phase extraction is a separation process by which compounds that are dissolved or suspended in a liquid mixture are separated from other compounds in the mixture according to their physical and chemical properties. Analytical laboratories use solid phase extraction to concentrate and purify...

(SPE) column, where a suspension of carbon nanotubes is squeezed between two polypropylene frits (70 micrometre pore diameter) inside a syringe column. The pore structure of the frit allows a rapid exit of the solvent leaving the carbon nanotubes to be pressed together. The presence of the solvent controls the interaction between the tubes allowing the formation of tube-tube junctions; its surface tension directly affects the overlap of adjoining nanotubes thus gaining control over the porosity and pore diameter distribution of buckypaper. The distribution of carbon nanotubes in solvent does not have to be a stable suspension, rather a general dispersion serves much easier to keep the nanotubes between the frits rather than pass through them.

Once the system is compressed, the frit-carbon nanotube sandwich is removed from the syringe housing and allowed to dry. The frits can then be removed to leave intact buckypaper. This methodology rapidly speeds up the casting process, avoids use of surfactants and acid oxidation, and the solvent can be fully recovered.