Gardon gauge

Encyclopedia

A Gardon gauge or Circular-foil gauge is a heat flux sensor

primarily intended for the measurement of high intensity radiation. It is a sensor that is designed to measure the radiation flux density (in watts per metre squared) from a field of view of 180 degrees.

The most common application of Gardon gauges is in exposure testing of sample materials for their resistance to fire and flames.

A so-called Schmidt-Boelter Gauge has the same outward appearance as a Gardon Gauge, but employs different sensor technology. The Schmidt-Boelter has a plated constantan wire wrapped around a insulating chip. Both are heat flux sensors. The only difference is practical; Gardon gauges can be manufactured in such a way that they withstand extremely high flux levels. The range for Schmidt-Boelter technology is more limited. On the other hand the Schmidt-Boelter technology can reach higher sensitivities at a lower response time.

A typical Gardon gauge is water cooled and does not require any power to operate.

A typical Gardon gauge is water cooled and does not require any power to operate.

A high intensity radiation spectrum

extends approximately from 300 to 2,800 nm. Gardon gauges usually cover that spectrum with a spectral sensitivity that is as “flat” as possible.

For a flux density

or irradiance

measurement it is required by definition that the response to “beam” radiation varies with the cosine of the angle of incidence; i.e. full response at when the radiation hits the sensor perpendicularly (normal to the surface, 0 degrees angle of incidence), zero response when the radiation is at the horizon (90 degrees angle of incidence, 90 degrees zenith angle), and 0.5 at 60 degrees angle of incidence. It follows from the definition that a Gardon gauge should have a so-called “directional response” or “cosine response” that is close to the ideal cosine characteristic.

The black coating on the thermopile sensor absorbs the radiation. This radiation is converted to heat. The heat flows through the sensor to the sensor housing and from the housing to the cooling water. The thermopile sensor generates a voltage output signal that is proportional to the heat flux.

Gardon- or Schmidt Boelter gauges are unprotected heat flux sensors, and that they are highly sensitive to local convection. In general users should make sure that:

Calibration is typically done relative to NIST .

Heat flux sensor

A heat flux sensor is a transducer that generates an electrical signal proportional to the total heat rate applied to the surface of the sensor. The measured heat rate is divided by the surface area of the sensor to determine the heat flux....

primarily intended for the measurement of high intensity radiation. It is a sensor that is designed to measure the radiation flux density (in watts per metre squared) from a field of view of 180 degrees.

The most common application of Gardon gauges is in exposure testing of sample materials for their resistance to fire and flames.

Explanation

Heat flux sensors can be made according to various designs. The sensor of a Gardon gauge consists of a foil connected to the sensor body at its external radius, and connected to a thin wire at the center, named after its originator Robert Gardon. The foil center and side are the hot- and cold joint of a thermocouple respectively. When radiation hits the sensor this generates a signal.A so-called Schmidt-Boelter Gauge has the same outward appearance as a Gardon Gauge, but employs different sensor technology. The Schmidt-Boelter has a plated constantan wire wrapped around a insulating chip. Both are heat flux sensors. The only difference is practical; Gardon gauges can be manufactured in such a way that they withstand extremely high flux levels. The range for Schmidt-Boelter technology is more limited. On the other hand the Schmidt-Boelter technology can reach higher sensitivities at a lower response time.

A high intensity radiation spectrum

Spectrum

A spectrum is a condition that is not limited to a specific set of values but can vary infinitely within a continuum. The word saw its first scientific use within the field of optics to describe the rainbow of colors in visible light when separated using a prism; it has since been applied by...

extends approximately from 300 to 2,800 nm. Gardon gauges usually cover that spectrum with a spectral sensitivity that is as “flat” as possible.

For a flux density

Flux density

-Formal Statement:The flux density is simply defined as the amount of flux passing through a unit-area. -Mathematical Statement:The flux density would essentially be the number of field lines passing through a defined unit-area...

or irradiance

Irradiance

Irradiance is the power of electromagnetic radiation per unit area incident on a surface. Radiant emittance or radiant exitance is the power per unit area radiated by a surface. The SI units for all of these quantities are watts per square meter , while the cgs units are ergs per square centimeter...

measurement it is required by definition that the response to “beam” radiation varies with the cosine of the angle of incidence; i.e. full response at when the radiation hits the sensor perpendicularly (normal to the surface, 0 degrees angle of incidence), zero response when the radiation is at the horizon (90 degrees angle of incidence, 90 degrees zenith angle), and 0.5 at 60 degrees angle of incidence. It follows from the definition that a Gardon gauge should have a so-called “directional response” or “cosine response” that is close to the ideal cosine characteristic.

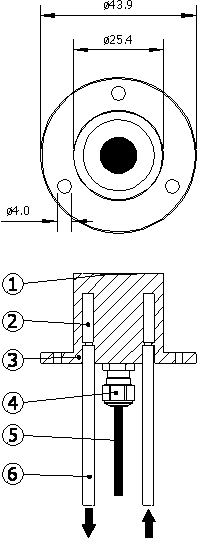

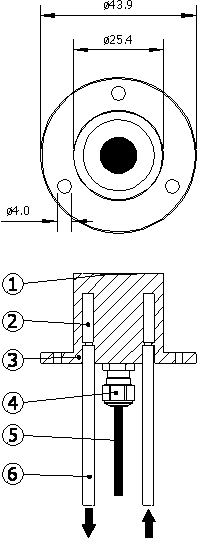

Design of gardon gauges

In order to attain the proper directional and spectral characteristics, a Gardon gauge’s main components are:- A thermopileThermopileA thermopile is an electronic device that converts thermal energy into electrical energy. It is composed of several thermocouples connected usually in series or, less commonly, in parallel....

sensor with a black coating. This sensor absorbs all radiation, has a flat spectrum covering the 300 to 50,000 nanometer range, and has a near-perfect cosine response.

The black coating on the thermopile sensor absorbs the radiation. This radiation is converted to heat. The heat flows through the sensor to the sensor housing and from the housing to the cooling water. The thermopile sensor generates a voltage output signal that is proportional to the heat flux.

Usage

Gardon Gauges are frequently used in fire testing. Typically installed vertically and next to the sample under testing.Gardon- or Schmidt Boelter gauges are unprotected heat flux sensors, and that they are highly sensitive to local convection. In general users should make sure that:

- Radiation is dominant, which is generally the case above 50 kW per square meter

- Convection is not carrying away too much of the flux; this may happen at high air speeds or in case the sensor temperature and air temperature are very different (so air temperatures above 500°C

Standardisation

Gardon Gauges are standardised according to the ASTM standard.Calibration is typically done relative to NIST .