Gnome Monosoupape

Encyclopedia

The Monosoupape (French

for single-valve), was a rotary engine

design first introduced in 1913 by Gnome Engine Company (since 1915 called Gnome et Rhône

). It used a clever arrangement of internal transfer ports and a single valve to replace a large number of moving parts found on more conventional rotary engines, and made the Monosoupape engines some of the most reliable of the era. British aircraft designer Thomas Sopwith

described the Monosoupape as "one of the greatest single advances in aviation".

Produced under license in Britain the engine was built in large numbers in both seven and nine-cylinder versions, the latter being produced with two different displacements

.

s and other complex devices that operated during the inlet phase of the combustion cycle on more conventional engines. Instead, a single exhaust valve on the cylinder

head was operated by a pushrod that opened the valve when the pressure dropped at the end of the power stroke. The inlet valve, which was operated by a counterweight, was placed in the centre of the piston crown, where it opened to allow the fuel–air charge to enter from the engine's central crankcase.

Although ingenious, the system had several drawbacks: the cylinder heads had to be removed both in order to perform maintenance of the intake valve, which could easily become jammed, and in order to adjust the timing and pressures correctly for the rod-less operation; and the Gnomes exhibited even poorer fuel economy than other rotaries because the inlet valves opened at times that were not efficient.

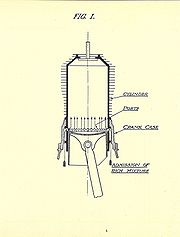

In 1913, Louis Seguin and his brother Laurent (engineers who founded the Société Des Moteurs Gnome [the Gnome motor company] in 1905) introduced the new Monosoupape series, which eliminated the inlet valve, replacing it with piston-controlled transfer ports similar to those found in a two-stroke engine. Beginning with the power stroke, the four-stroke

In 1913, Louis Seguin and his brother Laurent (engineers who founded the Société Des Moteurs Gnome [the Gnome motor company] in 1905) introduced the new Monosoupape series, which eliminated the inlet valve, replacing it with piston-controlled transfer ports similar to those found in a two-stroke engine. Beginning with the power stroke, the four-stroke

engine operated normally until the piston was just about to reach the bottom of its stroke (bottom dead center, or BDC), when the exhaust valve was opened "early". This let the still-hot burnt combustion gases "pop" out of the engine while the piston was still moving down, relieving exhaust pressure and preventing exhaust gases from entering the crankcase. After a small additional amount of travel, the piston uncovered 36 small ports around the base of the cylinder, leading to the crankcase

which held additional fuel–air mixture (the charge). No transfer took place at this point since there was no pressure differential; the cylinder was still open to the air and thus at ambient pressure. The overhead valve exhausted directly into the slipstream

since there was no exhaust manifold

in order to save weight.

During the exhaust stroke, total scavenging occurred as the air moving past the cylinder exterior lowered the pressure inside due to the direct exposure of the exhaust port to the slipstream. The piston continued its exhaust stroke until top dead center (TDC) was reached, but the valve did not close. The piston began to move down on its intake stroke with the valve still open, pulling fresh (presumably un-filtered) air into the cylinder. It remained open until it was two-thirds of the way down, at which point the valve closed and the remainder of the intake stroke greatly reduced the air pressure. When the piston uncovered the transfer ports again, the cylinder sucked in the balance of the charge.

The charge was an overly rich mixture of air, which was acquired through the hollow crankshaft

, and fuel that was continuously injected by a fuel nozzle on the end of a fuel line, entering the crankcase through the hollow crankshaft. The nozzle was in the proximity of, and aimed at, the inside base of the cylinder where the transfer ports were located. The fuel nozzle was stationary with the crankshaft, and the cylinders rotated into position in turn. The compression stroke was conventional.

The spark plug

was installed horizontally into the rear of the cylinder at the top but had no connecting high-voltage wire. An internal-tooth ring gear mounted on the engine drove a stationary magneto

mounted on the firewall, whose high-voltage output terminal was in close proximity to the spark plug terminals as they passed by. This arrangement eliminated the need for points

, distributor

, high-voltage wiring and capacitor

s found in conventional mechanically timed ignition systems. This ring gear also drove the oil pump, which supplied oil to all bearing

s, and through hollow pushrods to the rockers and valves and also drove an air pump which pressurized the fuel tank.

or throttle, and since most of its air supply was taken in through the exhaust valve, it could not be controlled by adjusting the air supply to the crankcase like other rotaries. Monosoupapes therefore had a single petrol regulating control used for a limited degree of speed regulation. In early examples, engine speed could be controlled by varying the opening time and extent of the exhaust valves using levers acting on the valve tappet rollers, but this was later abandoned due to causing burning of the valves. Instead, a blip switch was used, which cut out the ignition when pressed. This was used sparingly to avoid damaging the engine, since it was only safe to be used when the fuel supply was also cut. Some later Monosoupapes were fitted with a selector switch which allowed the pilot to cut out six cylinders so that each cylinder fired only once per three engine revolutions but the engine remained in perfect balance.

was injected into the fuel–air mix with a small pump. Castor oil was used because it could not be easily dissolved into the fuel, and because it possessed lubrication qualities superior to mineral oils of the day. Over two gallons of castor oil were sprayed into the air during each hour of engine operation. This explains why most rotaries were fitted with a three-quarters cowl ring, open at the bottom. The cowl directed the spray of castor oil, along with sparks from the exhaust, away from the flammable aircraft structure. Unburnt castor oil from the engine tended to be hurled into the pilot's face, often having a laxative effect on the pilot if ingested.

Because the entire engine rotated, it had to be precisely balanced, requiring precision machining of all parts. As a result, Monosoupapes were extremely expensive to build, the 100 hp models costing $4,000 in 1916 (approx. $65,000 in 2000 dollars). However, they weighed slightly less than the earlier two-valve engines and also used less lubricating oil.

Gnome Monosoupape 9 Type B-2 Nine-cylinder rotary engine, 100 hp (75 kW). Bore and stroke: 110 x 150 mm (4.3 x 5.9 in). 2,188 units produced under license in Britain.

Gnome Monosoupape 9 Type N Nine-cylinder rotary engine, 150 hp (112 kW). Bore and stroke: 115 x 170 mm (4.5 x 6.7 in).

French language

French is a Romance language spoken as a first language in France, the Romandy region in Switzerland, Wallonia and Brussels in Belgium, Monaco, the regions of Quebec and Acadia in Canada, and by various communities elsewhere. Second-language speakers of French are distributed throughout many parts...

for single-valve), was a rotary engine

Rotary engine

The rotary engine was an early type of internal-combustion engine, usually designed with an odd number of cylinders per row in a radial configuration, in which the crankshaft remained stationary and the entire cylinder block rotated around it...

design first introduced in 1913 by Gnome Engine Company (since 1915 called Gnome et Rhône

Gnome et Rhône

Gnome et Rhône was a major French aircraft engine manufacturer. Between 1914 and 1918 they produced 25,000 of their 9-cylinder Delta and Le Rhône 110 hp rotary designs, while another 75,000 were produced by various licensees, powering the majority of aircraft in the first half of the war on...

). It used a clever arrangement of internal transfer ports and a single valve to replace a large number of moving parts found on more conventional rotary engines, and made the Monosoupape engines some of the most reliable of the era. British aircraft designer Thomas Sopwith

Thomas Sopwith

Sir Thomas Octave Murdoch Sopwith, CBE, Hon FRAeS was an English aviation pioneer and yachtsman.-Early life:...

described the Monosoupape as "one of the greatest single advances in aviation".

Produced under license in Britain the engine was built in large numbers in both seven and nine-cylinder versions, the latter being produced with two different displacements

Engine displacement

Engine displacement is the volume swept by all the pistons inside the cylinders of an internal combustion engine in a single movement from top dead centre to bottom dead centre . It is commonly specified in cubic centimeters , litres , or cubic inches...

.

Background

Earlier Gnome (as opposed to Le Rhône) designs used a unique arrangement of valves in order to avoid needing pushrodOverhead valve

An overhead valve engine, also informally called pushrod engine or I-head engine, is a type of piston engine that places the camshaft within the cylinder block , and uses pushrods or rods to actuate rocker arms above the cylinder...

s and other complex devices that operated during the inlet phase of the combustion cycle on more conventional engines. Instead, a single exhaust valve on the cylinder

Cylinder (engine)

A cylinder is the central working part of a reciprocating engine or pump, the space in which a piston travels. Multiple cylinders are commonly arranged side by side in a bank, or engine block, which is typically cast from aluminum or cast iron before receiving precision machine work...

head was operated by a pushrod that opened the valve when the pressure dropped at the end of the power stroke. The inlet valve, which was operated by a counterweight, was placed in the centre of the piston crown, where it opened to allow the fuel–air charge to enter from the engine's central crankcase.

Although ingenious, the system had several drawbacks: the cylinder heads had to be removed both in order to perform maintenance of the intake valve, which could easily become jammed, and in order to adjust the timing and pressures correctly for the rod-less operation; and the Gnomes exhibited even poorer fuel economy than other rotaries because the inlet valves opened at times that were not efficient.

Description

Four-stroke cycle

A four-stroke engine, also known as four-cycle, is an internal combustion engine in which the piston completes four separate strokes—intake, compression, power, and exhaust—during two separate revolutions of the engine's crankshaft, and one single thermodynamic cycle.There are two...

engine operated normally until the piston was just about to reach the bottom of its stroke (bottom dead center, or BDC), when the exhaust valve was opened "early". This let the still-hot burnt combustion gases "pop" out of the engine while the piston was still moving down, relieving exhaust pressure and preventing exhaust gases from entering the crankcase. After a small additional amount of travel, the piston uncovered 36 small ports around the base of the cylinder, leading to the crankcase

Crankcase

In an internal combustion engine of the reciprocating type, the crankcase is the housing for the crankshaft. The enclosure forms the largest cavity in the engine and is located below the cylinder, which in a multicylinder engine are usually integrated into one or several cylinder blocks...

which held additional fuel–air mixture (the charge). No transfer took place at this point since there was no pressure differential; the cylinder was still open to the air and thus at ambient pressure. The overhead valve exhausted directly into the slipstream

Slipstream

A slipstream is a region behind a moving object in which a wake of fluid is moving at velocities comparable to the moving object . The term slipstream also applies to the similar region adjacent to an object with a fluid moving around it...

since there was no exhaust manifold

Exhaust manifold

In automotive engineering, an exhaust manifold collects the exhaust gases from multiple cylinders into one pipe. The word manifold comes from the Old English word manigfeald and refers to the folding together of multiple inputs and outputs.In contrast, an inlet manifold is the part of an engine...

in order to save weight.

During the exhaust stroke, total scavenging occurred as the air moving past the cylinder exterior lowered the pressure inside due to the direct exposure of the exhaust port to the slipstream. The piston continued its exhaust stroke until top dead center (TDC) was reached, but the valve did not close. The piston began to move down on its intake stroke with the valve still open, pulling fresh (presumably un-filtered) air into the cylinder. It remained open until it was two-thirds of the way down, at which point the valve closed and the remainder of the intake stroke greatly reduced the air pressure. When the piston uncovered the transfer ports again, the cylinder sucked in the balance of the charge.

The charge was an overly rich mixture of air, which was acquired through the hollow crankshaft

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

, and fuel that was continuously injected by a fuel nozzle on the end of a fuel line, entering the crankcase through the hollow crankshaft. The nozzle was in the proximity of, and aimed at, the inside base of the cylinder where the transfer ports were located. The fuel nozzle was stationary with the crankshaft, and the cylinders rotated into position in turn. The compression stroke was conventional.

The spark plug

Spark plug

A spark plug is an electrical device that fits into the cylinder head of some internal combustion engines and ignites compressed fuels such as aerosol, gasoline, ethanol, and liquefied petroleum gas by means of an electric spark.Spark plugs have an insulated central electrode which is connected by...

was installed horizontally into the rear of the cylinder at the top but had no connecting high-voltage wire. An internal-tooth ring gear mounted on the engine drove a stationary magneto

Magneto (electrical)

A magneto is an electrical generator that uses permanent magnets to produce alternating current.Magnetos adapted to produce pulses of high voltage are used in the ignition systems of some gasoline-powered internal combustion engines to provide power to the spark plugs...

mounted on the firewall, whose high-voltage output terminal was in close proximity to the spark plug terminals as they passed by. This arrangement eliminated the need for points

Contact breaker

A contact breaker is a type of electrical switch, and the term typically refers to the switching device found in the distributor of the ignition systems of spark-ignition internal combustion engines.-Purpose:...

, distributor

Distributor

A distributor is a device in the ignition system of an internal combustion engine that routes high voltage from the ignition coil to the spark plugs in the correct firing order. The first reliable battery operated ignition was developed by Dayton Engineering Laboratories Co. and introduced in the...

, high-voltage wiring and capacitor

Capacitor

A capacitor is a passive two-terminal electrical component used to store energy in an electric field. The forms of practical capacitors vary widely, but all contain at least two electrical conductors separated by a dielectric ; for example, one common construction consists of metal foils separated...

s found in conventional mechanically timed ignition systems. This ring gear also drove the oil pump, which supplied oil to all bearing

Bearing (mechanical)

A bearing is a device to allow constrained relative motion between two or more parts, typically rotation or linear movement. Bearings may be classified broadly according to the motions they allow and according to their principle of operation as well as by the directions of applied loads they can...

s, and through hollow pushrods to the rockers and valves and also drove an air pump which pressurized the fuel tank.

Control

The Monosoupape had no carburetorCarburetor

A carburetor , carburettor, or carburetter is a device that blends air and fuel for an internal combustion engine. It is sometimes shortened to carb in North America and the United Kingdom....

or throttle, and since most of its air supply was taken in through the exhaust valve, it could not be controlled by adjusting the air supply to the crankcase like other rotaries. Monosoupapes therefore had a single petrol regulating control used for a limited degree of speed regulation. In early examples, engine speed could be controlled by varying the opening time and extent of the exhaust valves using levers acting on the valve tappet rollers, but this was later abandoned due to causing burning of the valves. Instead, a blip switch was used, which cut out the ignition when pressed. This was used sparingly to avoid damaging the engine, since it was only safe to be used when the fuel supply was also cut. Some later Monosoupapes were fitted with a selector switch which allowed the pilot to cut out six cylinders so that each cylinder fired only once per three engine revolutions but the engine remained in perfect balance.

Lubrication

The lubrication system, as with all rotary engines, was a total-loss type in which castor oilCastor oil

Castor oil is a vegetable oil obtained from the castor bean . Castor oil is a colorless to very pale yellow liquid with mild or no odor or taste. Its boiling point is and its density is 961 kg/m3...

was injected into the fuel–air mix with a small pump. Castor oil was used because it could not be easily dissolved into the fuel, and because it possessed lubrication qualities superior to mineral oils of the day. Over two gallons of castor oil were sprayed into the air during each hour of engine operation. This explains why most rotaries were fitted with a three-quarters cowl ring, open at the bottom. The cowl directed the spray of castor oil, along with sparks from the exhaust, away from the flammable aircraft structure. Unburnt castor oil from the engine tended to be hurled into the pilot's face, often having a laxative effect on the pilot if ingested.

Because the entire engine rotated, it had to be precisely balanced, requiring precision machining of all parts. As a result, Monosoupapes were extremely expensive to build, the 100 hp models costing $4,000 in 1916 (approx. $65,000 in 2000 dollars). However, they weighed slightly less than the earlier two-valve engines and also used less lubricating oil.

Variants

Gnome Monosoupape 7 Type A Seven-cylinder rotary engine, 80 hp (60 kW). Bore and stroke: 110 x 150 mm (4.3 x 5.9 in).Gnome Monosoupape 9 Type B-2 Nine-cylinder rotary engine, 100 hp (75 kW). Bore and stroke: 110 x 150 mm (4.3 x 5.9 in). 2,188 units produced under license in Britain.

Gnome Monosoupape 9 Type N Nine-cylinder rotary engine, 150 hp (112 kW). Bore and stroke: 115 x 170 mm (4.5 x 6.7 in).

Monosoupape 7

- Avro 504Avro 504The Avro 504 was a World War I biplane aircraft made by the Avro aircraft company and under licence by others. Production during the War totalled 8,970 and continued for almost 20 years, making it the most-produced aircraft of any kind that served in World War I, in any military capacity, during...

- Avro 511

- Bristol-Coanda G.B.75

- Sopwith PupSopwith PupThe Sopwith Pup was a British single seater biplane fighter aircraft built by the Sopwith Aviation Company. It entered service with the Royal Flying Corps and the Royal Naval Air Service in the autumn of 1916. With pleasant flying characteristics and good maneuverability, the aircraft proved very...

Monosoupape 9 Type B-2

- Avro 504Avro 504The Avro 504 was a World War I biplane aircraft made by the Avro aircraft company and under licence by others. Production during the War totalled 8,970 and continued for almost 20 years, making it the most-produced aircraft of any kind that served in World War I, in any military capacity, during...

- Airco DH.2Airco DH.2|-DH.2 aces:Distinguished pilots of the DH.2 included Victoria Cross winner Lanoe Hawker , who was the first commander of No 24 Squadron and ace Alan Wilkinson. The commander of No. 32 Squadron, Lionel Rees won the Victoria Cross flying the D.H.2 for single handedly attacking a formation of 10...

- Airco DH.5Airco DH.5-Bibliography:* Bruce, J.M. Warplanes of the First World War, Vol. 1. London: MacDonald, 1965, pp. 128–132.* Jackson, A.J. De Havilland Aircraft since 1915. London: Putnam, 1962....

- Alcock Scout

- BAT BantamBAT Bantam-External links:** Contemporary technical description of F.K.23 Bantam with photographs and drawings.-See also:...

- Blackburn Scout

- Blackburn T.BBlackburn Twin Blackburn-External links:* at the British Aircraft Directory...

- Blackburn TriplaneBlackburn Triplane-External links:*http://www.flightglobal.com/pdfarchive/view/1919/1919%20-%201580.html*http://www.flightglobal.com/pdfarchive/view/1939/1939%20-%201632.html*http://www.flightglobal.com/pdfarchive/view/1959/1959%20-%201251.html...

- Bristol-Coanda T.B.8Bristol TB.8-External links:...

- Bristol ScoutBristol ScoutThe Bristol Scout was a simple, single seat, rotary-engined biplane originally intended as a civilian racing aircraft. Like other similar fast, light aircraft of the period - it was acquired by the RNAS and the RFC as a "scout", or fast reconnaissance type...

- Coventry Ordnance Works Biplane No 2

- F.B.A. C Flying boat

- Nieuport 12Nieuport 12|-See also:...

- Nieuport 28Nieuport 28|-See also:-Bibliography:* Cheesman E.F. Fighter Aircraft of the 1914-1918 War. Letchworth, UK: Harleyford Publications, 1960, pp. 98–99....

- Royal Aircraft Factory B.E.8Royal Aircraft Factory B.E.8|-See also:-References:*Bruce, J.M. British Aeroplanes 1914-18. London:Putnam, 1957.*Bruce, J.M. The Aircraft of the Royal Flying Corps . London:Putnam, 1982. ISBN 0 370 30084 x....

- Royal Aircraft Factory F.E.8Royal Aircraft Factory F.E.8|-See also:-References:NotesBibliography* Bruce, J.M. The Aeroplanes of the Royal Flying Corps . London: Putnam, 1982. ISBN 0-370-30084-X.* Bruce, J.M. British Aeroplanes 1914–18. London: Putnam, 1957....

- Short S.70

- Short S.80

- Short Type C

- Sopwith Circuit Seaplane

- Sopwith GunbusSopwith Gunbus|-See also:-References:*Bruce, J.M. British Aeroplanes 1914-18. London:Putnam, 1957.*Bruce, J.M. War Planes of the First World War: Volume Two Fighters. London:Macdonald, 1968. ISBN 0 356 01473 8....

- Sopwith TabloidSopwith Tabloid|-See also:-References:* Bruce, J.M. "". Flight. 8 November 1957. pp. 733–736.* Bruce, J.M. "". Flight. 15 November 1957. pp. 765–766.* Bruce, J.M. "". Flight. 29 November 1957. pp. 845–848....

- Sopwith Sociable

- Sopwith (Admiralty Type ) 807 Folder Seaplane

- Sopwith Two-Seat ScoutSopwith Two-Seat Scout|-See also:...

- Sopwith SchneiderSopwith Tabloid|-See also:-References:* Bruce, J.M. "". Flight. 8 November 1957. pp. 733–736.* Bruce, J.M. "". Flight. 15 November 1957. pp. 765–766.* Bruce, J.M. "". Flight. 29 November 1957. pp. 845–848....

- Sopwith PupSopwith PupThe Sopwith Pup was a British single seater biplane fighter aircraft built by the Sopwith Aviation Company. It entered service with the Royal Flying Corps and the Royal Naval Air Service in the autumn of 1916. With pleasant flying characteristics and good maneuverability, the aircraft proved very...

- Sopwith F.1 CamelSopwith CamelThe Sopwith Camel was a British First World War single-seat biplane fighter introduced on the Western Front in 1917. Manufactured by Sopwith Aviation Company, it had a short-coupled fuselage, heavy, powerful rotary engine, and concentrated fire from twin synchronized machine guns. Though difficult...

- Vickers Gunbus (FB.2, 3, 5, 6 and 7)

- Vickers E.S.1 BulletVickers E.S.1|-See also:-Notes: Also sometimes called Vickers E.S.2, although contemporary reports all refer to these aircraft as E.S.1s.-References:* Andrews, C.F. and Morgan, E.B. Vickers Aircraft since 1908. London:Putnam, Second edition, 1988. ISBN 0 85177 815 1....

- Vickers F.B.12Vickers F.B.12|-See also:...

- Vickers F.B 19 Bullet