Landslide mitigation

Encyclopedia

Landslide mitigation refers to lessen the effect of landslides by constructing various man made projects at the slopes which are vulnerable to landslides planning for landslides hazard mitigation as its phenomenon is instant. Landslides can be triggered by many often concomitant causes. In addition to shallow erosion or reduction of sheer strength caused by seasonal rainfall, causes triggered by anthropic activities such as adding excessive weight above the slope, digging at mid-slope or at the foot of the slope, can also be included. However, often individual phenomena join together to generate instability, also after some time has elapsed, which, other than in well-instrumented limited areas, do not allow a reconstruction of the evolution of the occurred landslide.

It is therefore pointless, for the purpose of planning landslide hazard mitigation measures, to classify the work as a function of the phenomenon or of more important phenomena, renouncing any attempt to precisely describe all the causes or the conditions which, at different times, contribute to the occurrence of the landslide.

Therefore, slope stabilisation methods in rock or in earth, can be collocated into three types of measure:

• Geometric methods, in which the geometry of the hillside is changed (in general the slope);

• Hydrogeological methods, in which an attempt is made to lower the groundwater level or to reduce the water content of the material;

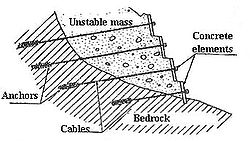

• Chemical and mechanical methods, in which attempts are made to increase the shear strength of the unstable mass or to introduce active external forces (e.g. anchors, rock or ground nailing) or passive (e.g. structural wells, piles or reinforced ground) to contrast the destabilising forces.

The different type of material conditions the engineering solution adopted, although It always comes back, in principle, to the previously introduced classification.

Reinforcement measures generally consist of the introduction of metal elements whose purpose is to increase the shear strength of the rock and to reduce the stress release created, for example, following cutting.

Reinforcement measures generally consist of the introduction of metal elements whose purpose is to increase the shear strength of the rock and to reduce the stress release created, for example, following cutting.

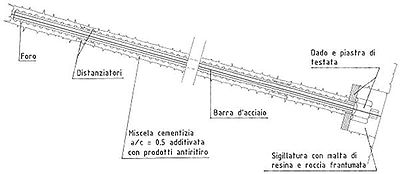

Reinforcement measures are made up of metal rock nails or anchors. Anchorage can be classified as active anchorage, in the case in which they are subjected to pretensioning, and passive anchorage.

Passive anchorage can be used both to nail single unstable blocks and to reinforce large portions of rock. They can also be used as the pre-reinforcement elements of a scarp to be re-profiled in order to limit hillside decompression associated with cutting.

In an anchorage are defined:

When the anchorage acts over a short length it is defined as a bolt. It is therefore a specific type of anchorage, not structurally connected to the free length, made up of an element resistant to traction, normally a steel bar of less than 12 m, protected against corrosion by a concrete sheath.

As far as the anchorage device to the ground is concerned, it can be chemical, or use mechanical expansion or concreting.

In the first case, some polyester resin cartridges are placed in the perforation to fill the ring space around the end part of the bolt. The main advantage of this type of anchorage lies in its simplicity and in the speed of installation. The main disadvantage is in its limited strength.

In the second case, the anchorage is composed of steel wedges driven into the sides of the hole. The advantage of this type of anchorage lies in the speed of installation and in the fact that the tensioning can be achieved in the instant the anchorage is put to work.

the main disadvantage with this type of anchorage is that it can only be used with hard rock. Moreover, the maximum traction force is limited.

In the third case, the anchorage is obtained by concreting the whole metal bar. This is the most-used method since the materials are cheap and installation is simple. Injected concrete mixes can be used in many different rocks and grounds; moreover, the concrete sheath protects the bar from corrosion. The concrete mixture is generally made up of water and cement in the ratio W/C = 0.40-0.45, since in this way a sufficiently fluid mixture is obtained to allow pumping into the hole, while at the same time, when set, providing high mechanical strength.

As far as the working mechanism of a rock nail is concerned, the strains of the rock induce a stress state in the nail composed of shear and traction stress, due to the roughness of the joints, to their opening and to the direction of the nail, generally non-orthogonal to the joint itself. The execution phases of setting up the nail provides for:

• formation of any header niche and perforation;

• setting up of a reinforcement bar (e.g. a 4–6 m long FeB44k bar);

• concrete injection of the bar;

• sealing of the header or of the top part of the hole.

It is anyway opportune to close up and cement any cracks in the rock to prevent pressure caused by water during the freeze-thaw cycles from producing progressive breaking in the reinforcement system set up. To this purpose a procedure is provided for of:

1. cleaning out and washing of the cracks;

2. plastering of the crack;

3. predisposition of the injection tubes at suitable inter-axes, parallel to the crack, through which the concrete mix is injected;

4. sequential injection of the mixture from bottom to top and at low pressure (1-3 atm.) until refusal or until no flow back of the mixture is noted from the tubes placed higher up.

The injection mixtures will have approximately the following composition:

Spriz-Beton (shotcrete

)

As defined by the American Concrete Institute "Shotcrete is mortar or concrete conveyed through a hose and pneumatically projected at high velocity onto a surface.

Drainage

The presence of water within a rocky hillside is one of the major factors leading to instability. Knowledge of the water pressure and of the runoff mode is the basis for being able both to carry out credible stability analyses, and to plan measures aimed at improving hillside stability.

Hoek and Bray (1981) provide a scheme of possible measures that can be actuated on a hillside to reduce not only the amount of water, which they believe in itself to be negligible as an instability factor, but above all the pressure brought to bear by the water.

The proposed scheme was elaborated taking three principles into account:

• Preventing water entering the hillside through open or discontinuity traction cracks

• Reducing water pressure in the vicinity of potential breakage surfaces through selective shallow and sub-shallow drainage.

• Placing drainage in order to reduce water pressure in the immediate vicinity of the hillside.

The measures that can be achieved to reduce the effects of water can be shallow or in depth.

Shallow drainage work has the main function of intercepting surface runoff

water and keeping it away from potentially unstable areas. In reality, on rocky hillsides this type of measure although contributing to reducing the amount of infiltration, alone is insufficient to stabilise a hillside.

Deep drainage is the most effective with this type of slope.

Sub horizontal drainage is very effective in reducing pore-pressure along crack surfaces or potential breakage surfaces. In rocks the choice of drain spacing, slope, and length is subordinated to, apart from the hillside geometry, above all the structural formation of the mass. Features such as position, spacing and discontinuity opening persistence condition, apart from the mechanical characteristics of the rock, the water runoff mode inside the mass. Therefore, only by intercepting the mostly drained discontinuities can there be an efficient result. The sub horizontal drains are accompanied by surficial collectors which gather the water and take it away through networks of small surface channels.

Vertical drainage is generally associated with sunken pumps which have the task of draining the water and lowering the groundwater level. The use of continuous cycle pumps implies very high running costs conditioning the use of this technique for only limited periods.

Drainage galleries are rather different in terms of efficiency. They are considered to be the most efficient drainage system for rocks even if they have the drawback of requiring very high technological and financial investment.

In particular, used in rocks this technique can be highly efficient in lowering water pressure. Drainage galleries can be associated with a series of radial drains which augment their efficiency. The positioning of this type of work is certainly connected to the local morphological, geological and structural conditions.

Detachment measures are carried out where there are risk conditions due to infrastructures or the passage of people at the foot of the hillside. Generally this type of measure can solve the problem by eliminating the hazard. However, it should be ensured that once the measure is carried out, the problem does not re-emerge in the short term. In fact, where there are very cracked rocks, the shallower rock portions can undergo mechanical incoherence, sometimes encouraged by extremes of climate, causing the isolation of unstable blocks.

The measure can be effected in various ways, which range from demolition with pick axes to the use of explosives. In the case of high and/or not easily accessible faces it is necessary to turn to specialists who work acrobatically.

When explosives are used, sometimes controlled demolition is needed, with the aim of minimising or nullifying the undesired effects resulting from the explosion of the charges, safeguarding the integrity of the surrounding rock.

Controlled demolition is based on the drilling of holes placed at a short distance from each other and parallel to the scarp to be demolished. The diameter of the holes generally varies from 40 to 80 mm; the spacing of the holes is generally about 10 to 12 times the diameter. The charge fuse times are established so that those at the outer edges explode first and the more internal ones successively, so that the area of the operation is delimited.

The protection of natural and quarry faces can have two different aims:

The protection of natural and quarry faces can have two different aims:

1. Protecting the rock from alterations,

2. Protecting the infrastructure and towns from rockfalls.

It is therefore necessary to identify above all the cause of the alteration or the possibility of rockfall. Successively the area of operations needs to be delimited, the most suitable procedure to solve the problem and, finally, to control the effectiveness of the measure itself over a period of time.

The most-used passive protection measures are:

1. boulder-gathering trenches at the foot of the hillside,

2. metal containment nets,

3. boulder barriers.

As far as the boulder barriers are concerned, they are generally composed of suitably rigid metal nets. Moreover, lately, various structural types have been put on the market, for which the manufactures specify the kinetic energy of absorption.

One of the structural control methods for boulder containment nets starts from the concept of projectile collision, on the basis of which the maximum applied force and the corresponding resultant buckling are expressed, by means of a static analysis, leading to the quantification of the forces divided up among the various structural elements.

Another type of boulder containment barrier is the earth embankment, possibly reinforced with geo-synthetics (reinforced ground).The advantage of this type of work, compared to nets, is easier maintenance and lower environmental impact minor.The absorption of kinetic energy is generally greater than that of metal nets.

• Lowering the slope

• Positioning infill at the foot of the slope

Slope re-profiling work

Slopes can be reduced by digging out the brow of the slope. This is effective for correcting shallow forms of instability, where movement is limited to layers of ground near to the surface and when the slopes are higher than 5m. Moreover, the steps created in this way and suitably achieved also reduce surface erosion.

However, caution should be exercised to avoid the onset of local breakage following the cuts made.

Infill at the foot of the slope, instead, has a stabilising effect in the case of translational or deep rotational landslide, in which the landslide surface at the top submerges and describes a sub-vertical surface that re-emerges in the area at the foot of the slope. The choice of reducing the slope and infilling at the foot is rarely a problem since there are generally specific constraints to be respected at the top or at the foot of the slope.

Generally in slope stabilisation where there are no constraints (often this occurs for natural slopes) a combination of slope reduction and infilling at the foot of the slope is adopted to avoid heavy work of just one type. Included among work at the foot of the slope are the berm and some gravitational structures like gabions or reinforced ground, that is, concrete blocks.

In the case of natural slopes the choice of re-profiling scheme is not so clear as in the case of artificial slopes. Often the profile is highly irregular with large areas of not recent natural creep, so that its shallow development can make some areas unserviceable as a cutting or infill point.

Where the buried shape of the old landslide is complicated, depositing of infill material in one area can lead to destabilising another.

When planning this type of work the stepping effect of the cuts and infill should be taken into account: their beneficial influence on the increase in Safety Factor will be reduced in relationship to the size of the landslide under examination. Moreover, it is very important to ensure that neither the cuts nor the infill mobilise the existing or potential creep plane of the landslide.

Generally, infilling at the foot of the landslide should be preferred to cutting at the top (to reduce weight at the top of the slope), since the latter solution proves to be often more expensive than the former. Moreover, in complex and compound landslides, infill at the foot of the slope, at the tip of the foot itself, has a lesser probability of interfering with the interaction of the individual landslide elements.

An important aspect of stabilisation work that changes the morphology of the slope is that, in more precisely mechanical terms, effecting cuts and infill generates non-drained charge and discharge stresses.

In fact, in the case of positioning infill, the safety factor SF, will be less in the short term than in the long term. In the case of effecting a cut in the slope, SF will be less in the long term rather than in the short term. therefore in both cases it is opportune to calculate the SF both in the short and the long term.

Finally, it should be remembered that the effectiveness of infill increases with time on condition that it is associated with an appropriate infill drainage system, obtained through an underlying drainage cover or appropriate shallow drainage.

More generally therefore re-profiling systems are associated with and integrated by surficial protection of the slope against erosion and by regulation of meteoric waters through drainage systems made up of ditches and small channels (clad or unclad and prefabricated) to run off the water collected.

These surficial water regulation systems are obtained by modelling the land itself around the body of the landslide large ground ditches in the case of incoherent material landslides) or by means of flexible suitably placed drainage pipes able to collect the water.

These surficial water regulation systems are obtained by modelling the land itself around the body of the landslide large ground ditches in the case of incoherent material landslides) or by means of flexible suitably placed drainage pipes able to collect the water.

These provisions will serve the purpose of avoiding penetration of the landslide body by circulating water or into any cracks or fissures, further decreasing ground shear strength.

These provisions will serve the purpose of avoiding penetration of the landslide body by circulating water or into any cracks or fissures, further decreasing ground shear strength.

A problem that could be caused by water near the surface of the hillside is the erosion of surface material due to water runoff. This proves hazardous in terms of stability since it tends to weaken the slope by removing material as well as triggering excess pressure due to the water flow.

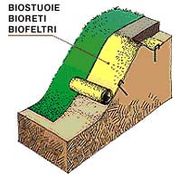

For defence against erosion, a series of solutions can be used, such as:

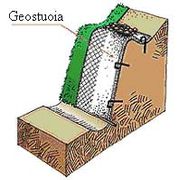

• Geomats

• Geogrids

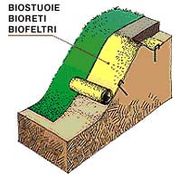

• Brushwood mats

These measures share the superficial character of their installation given their low environmental impact.

Geomats or rather anti-eroding biomats or bionets are purpose-made synthetic products for the protection and grassing of slopes subject to surface wash through two main erosion control mechanisms: the containment and reinforcement of the surficial ground; the protection from the impact of the raindrops.

Geogrids

Geogrids

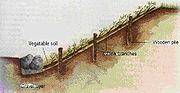

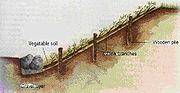

- Wicker or brushwood mats are made of vegetal material. Very long and flexible willow branches can be used, which are then covered with infill soil. Alternating stakes of different woody species are used and they are woven to form a barrier against the downward drag of the material eroded by the free water on the surface

In relation to hillside morphology, the kinematism of movement predicted and to the depth of the creep surfaces, the reduction in pore-pressure by drainage can be obtained using shallow and deep drains.

Usually, shallow drainage is adopted when the potential hillside movement is foreseen as shallow landslide affecting the ground to a depth of about 5-6m. When there is deeper surface slipping, deep drainage has to be introduced, but shallow drainage systems can be provided anyway with the aim of running off that aliquot of surficial water directly connected to seasonal rainfall.

There are two types of shallow drainage solution:

There are two types of shallow drainage solution:

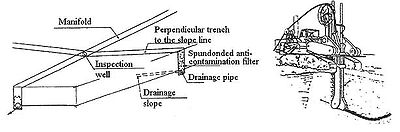

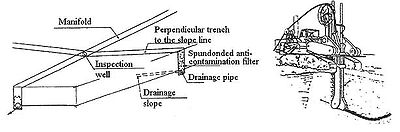

Traditional drainage trenches are cut in an unbroken length and filled with highly permeable granular draining material;

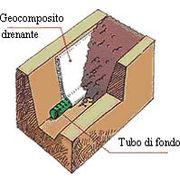

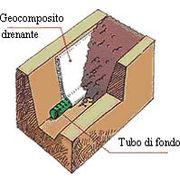

These systems consist of unbroken trenches with scarped sides covered with geocomposites, generally with 25m. Long panels, having draining characteristics. The bottom of the trench houses a drainage tube with the task of bottom discharge placed in continuity the geocomposite canvas.

Deep drainage in earth slopes can be obtained by means of the following works:

large diameter drainage wells equipped with sub-horizontal drains.

These systems can have just a structural function, just a draining function or both. The draining elements are the microdrains, perforated and positioned sub-horizontally and fanned out, oriented uphill to favour water discharge by gravity.

The size of the wells is chosen with the aim of allowing the insertion and functioning of the perforation equipment for the microdrains. Generally, the minimum internal diameter to be adopted must be greater than 3.5 m, for drains with a length of 20 to 30 m.

Longer drains require wells with a diameter of up to 8–10 m. To determine the network of microdrains planners have to take into consideration the makeup of the subsoil and the hydraulic regime of the slope, to provide for the correct number and distribution of the microdrains.

The drainage in these wells is passive, realised by linking the bottom of adjacent wells by sub-horizontal perforations (provided with temporary sheathing pipes) in which the microdrains are placed at a gradient of about 15-20° and are equipped with microperforated PVC pipes, protected by non-filtering fabric along the draining length.

Once all the drain is inserted in the hole and having embedded the latter in the ground, the temporary sheathing is completely removed and the head of the drain is cemented to the well.

In this way a discharge line is created linking all the wells emerging to the surface downhill, where the water is discharged naturally without the help of raising pumps.

The wells are placed at such a distance apart that the individual collecting areas of the microdrains, appertaining to each well, are overlaid. In this way all the volume of the slope involved with the water table is drained.

Medium-diameter drainage wells linked at the bottom. The technique involves the dry cutting with temporary sheathing pipes, of aligned drainage wells, with a diameter of 1200–1500 mm., positioned at an interaxis of 6–8 m., their bottoms linked together to a bottom tube for the discharge of drained water. In this way the water discharge takes place passively, due to gravity by perforated pipes with mini-tubes, positioned at the bottom of the wells themselves.

The linking pipes, generally made of steel, are blind in the linking length and perforated or windowed in the length corresponding to the well. The wells have a concrete bung at the bottom and are filled, after withdrawal of the temporary sheathing pipe, with dry draining material and are closed with an impermeable clay bung.

In normal conditions, these wells reach a depth of 20–30 m, but, in especially favourable cases, a depth of even 50 m can be reached.

Some of these wells have drainage functions across their whole section and others can be inspected. The latter serve for maintenance of the whole drainage screen. Such wells that can be inspected are also a support point for the creation of new drainage wells and access for the installation, also on a later occasion, for a range of sub-horizontal drains at the bottom or along the walls of the wells themselves, with the purpose of increasing the drainage capacity of the well.

• Isolated wells fitted with drainage pumps

This system provides for the installation of a drainage pump for each well.

The distribution of the wells is established according to the permeability of the land to be drained, the lowering of the water pressure to be achieved and the area that has to be involved in this work, so that the water pressure area deriving from the depression fans generated by the single drainage points, responds to the needs of the plan.

The use of isolated wells with a drainage pumps leads to high running costs and imposes a very time-consuming level of control and maintenance.

• Deep drainage trenches

Deep drainage trenches consist of unbroken cuts with a small cross-section that can be covered at the bottom with geofabric canvas

having a primary filter function.

They are filled with draining material that has a filtering function and exploits the passive drainage to carry away the drained water downhill. The effectiveness of these systems is connected to the geometry of the trench and the continuity of the draining material along the whole trench. As far as the geometry of the cut is concerned attention should be paid to the slope given to the bottom of the cut. In fact, deep drainage trenches do not have bottom piping that is inserted in the end part of the trench, downhill, where the depth of the cut is reduced until the campaign level is reached.

• Drainage galleries fitted with microdrains

Drainage galleries constitute a rather expensive stabilisation provision for large, deep landslide movements, to be carried out where the ground is unsuitable for cutting trenches or drainage wells and when it is impossible to work on the surface owing to a lack of space for the work machinery.

Their effectiveness is due to the extensiveness of the area to be drained. Moreover, these drainage systems have to be realised on the stable part of the slope.

The drainage systems are placed inside the galleries and are made up of microdrains, with lengths that can reach 50–60 m and are spatially oriented in a suitable directions.

The sizes of the galleries are conditioned by the need to insert the drain perforation equipment. For this reason the minimum transversal internal size of the galleries vary from a minimum of 2 m, when using special reduced size equipment, and to at least 3.5 m, when using traditional equipment.

• Siphon drain

This is a technique conceived and developed in France, which works like the system of isolated drainage wells but overcoming the inconvenience of installing a pump for each well. In fact, the system on the principle that once motion is triggered in the siphon tube, avoiding the entry of air into the loop, the motion is uninterrupted. For this reason, in this system, the condition that the two ends of the siphon tube are submerged in the water of the two permanent storage tanks, must always be checked.

This drain is created vertically starting from the campaign level but can also be sub-vertical or inclined. The diameter of the well can vary from 100 to 300 mm; inside a PVC pipe is placed or a perforated or microperforated steel pipe, filled with draining material.

The siphon drain in this way carries off of drainage water by gravity without the need for drainage pumps or pipes linking the bottom of each well. This system proves to be economically advantageous and relatively simple to set up even if it necessitates a programme of controls and maintenance.

• Microdrains

Microdrains is a simple to create drainage system with contained costs. They consist of small diameter perforations, made from surface locations, in trenches, in wells or in galleries. The microdrains are set to work in a sub-horizontal or sub-vertical position, according to the type of application.

• Insertion of reinforcement elements in the ground;

• The improvement of the mechanical characteristics of the ground volume affected by landslide through chemical, thermal or mechanical treatment.

• Large diameter wells supported by one or more crowns of consolidated and possibly reinforced earth columns;

• Anchors

• Networks of micropiles

• Nailing

• Geogrids for reinforced ground

• Cellular faces

Large diameter wells supported by one or more crowns of consolidated and possibly reinforced earth columns

To guarantee slope stability it may be necessary to insert very rigid, strong element. These elements are large diameter full section or ring section reinforced concrete wells.

The wells can have a circular or elliptical section. The depth of the static wells can reach 30-40m. Often the static stabilising action of the wells is integrated with a series of microdrains laid out radially on several levels, also to reduce pore-pressure, if it is hazardous.

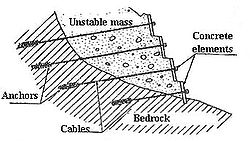

The equilibrium of an unstable slope also can be achieved by increasing resistance to landsliding by means of the application of active forces to the unstable ground. These forces increase the normal stress and therefore resistance to friction along the creeping surface. Anchors can be applied for this purpose, linked at the surface to each other by a beam frame, which is generally made of reinforced concrete. Here, the anchors are installed at node points.

The equilibrium of an unstable slope also can be achieved by increasing resistance to landsliding by means of the application of active forces to the unstable ground. These forces increase the normal stress and therefore resistance to friction along the creeping surface. Anchors can be applied for this purpose, linked at the surface to each other by a beam frame, which is generally made of reinforced concrete. Here, the anchors are installed at node points.

The anchors are then fixed in a certainly stable place. They are usually realised with orthogonal axes to the slope surface and therefore, at first approximately orthogonal to the surface of the creep.

The adoption of this system sometimes gives anchorage problems, as in the case of silt-clayey ground. In fact, where there is water or the anchors are embedded in a clayey sub-layer, the adherence of the anchor to the ground has to be assured.

Moreover, it is opportune that the surface contained within the grid of the beam frame is protected, using geofabrics, in order to avoid erosion removing the ground underlying the beam frame.

This solution provides for a plant of a series of micropiles that make up a three-dimensional grid, variably tilted and linked at the head by a rigid reinforced concrete mortise.

This structure constitutes a reinforcement for the ground, inducing an intrinsic improvement of the ground characteristics incorporated in the micropiles. A measure of this type proves effective in cases of not very extensive landslide.

The effectiveness of solutions with micropiles is linked to the possibility of inserting micropiles over the whole width of the landslide area. In the case of rotational landslides in soft clay, the piles contribute to increasing the resisting moment by friction on the upper part of the pile shaft found in the landslide.

This functionality is usually valid for micropiles working using the point. In the case of suspended piles, strength is governed by the part of the pile offering the least resistance. As an operational method, those piles that destined to the most unstable area of the slope should be positioned first, subsequently those around the unstable area, in order to reduce any possible lateral ground displacements.

Preliminary design methods for the micropiles, nowadays are entrusted to the use of codes that carry out numerical simulations, but which are subject to simplifications in the models that necessitate characterisations of rather precise potential landslide material.

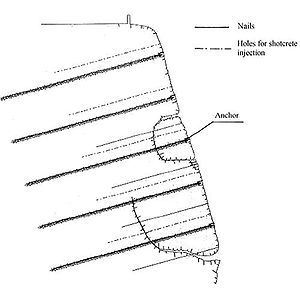

The soil nailing technique applied to temporarily and/or permanently stabilise natural slopes and artificial scarps, fall back on a fundamental principle in the field of construction technique: mobilising the intrinsic mechanical characteristics of the ground, such as cohesion and the angle of internal friction, so that the ground actively collaborates with the stabilisation work.

Nailing, on a par with anchors, induce normal stress to the advantage of stability. One nailing solution is that of rapid response diffuse nailing: CLOUJET, where the nails are embedded in the ground by means of an expanded bulb obtained by means of injecting mortar at high pressure into the anchorage area.

Drainage is an integral part of the CLOUJET project since the hydraulic regime, considered in the form of pore-pressure applied normally to the fractured surfaces, directly influences the characteristics of the system.

The drained water, both through fabric and by means of pipes embedded in the ground with a pre-determined gradient, flows together at the foot of the slope where it is collected in a suitable collector parallel to the direction of the face.

Another system suitable for stabilizing slopes and landslides is a soil nail and root technology (SNART). Here steel nails are inserted very rapidly into a slope by percussion, vibration or screw methods. Grid spacing is typically 0.8 to 1.5 m, nails are 25 to 50 mm in diameter and may be as long as 20 m. Nails are installed perpendicular to and through the failure plane (or potential failure plane), and as such are designed in bending and shear (rather than tension) using geotechnical engineering principles. Potential failure surfaces less than 2 m deep normally require the nails to be wider near the top, and is typically achieved with steel plates fastened at the nail heads. An effective and aesthetic facing to prevent soil loss between the nails can be designed using plant roots.

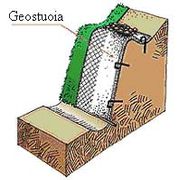

The geogrids are synthetic materials used to reinforce the ground.

The geogrids are synthetic materials used to reinforce the ground.

The insertion of geosynthetic reinforcements (generally in the direction in which the deformation has developed) therefore has the function of reinforcing the ground conferring greater stiffness and stability upon it and the capacity to be subjected to greater deformations without reaching fracture point.

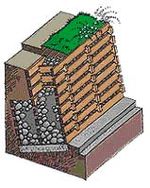

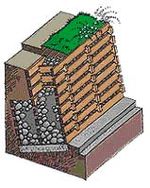

Cellular faces, also known by the name of "crib faces" are special supporting walls realised by means of head grids prefabricated in reinforced concrete or in wood (treated externally with preservatives).The heads have a length of about 1-2m and the work can also reach 5m in height.

Cellular faces, also known by the name of "crib faces" are special supporting walls realised by means of head grids prefabricated in reinforced concrete or in wood (treated externally with preservatives).The heads have a length of about 1-2m and the work can also reach 5m in height.

Compacted granular material is inserted in the spaces of the grid. The characteristic modularity of the system confers notable flexibility of use on its use both in terms of adaptability to the morphology of the ground and because the structure does not require any deep foundation other than a laying plane of lean concrete useful to make the support plane of the whole structure regular.

This solution can also take vegetal ground into the grid spaces, to favour the camouflaging of the work into the surroundings by means of the vegetation rooting on the exposed face.

The phases of this work are:

PHASE I

Perforation phase: insertion, with perforation destroying the nucleus, of a set of poles into the ground up to the depth of treatment required by the project.

PHASE II

Extraction and programmed injection phase: injection of the mixture at very high pressure is done during the extraction phase of the set of poles.

It is in this phase that through the insistence of the jet in a certain direction for a certain interval of time, the effect is obtained by the speed of extraction and rotation of the set of poles, so that volumes of ground can be treated in the shape and size desired.

(see http://www.pacchiosi.com/tecnologie/pages/PS1_ita.html)

(see http://www.pacchiosi.com/tecnologie/pages/PS1_ita.html)

The high energy jet produces a mixture of the ground and a continuous and systematic "claquage" with only a local effect within the radius of action without provoking deformations at the surface that could induce negative consequences on the stability of adjacent constructions.

The projection of the mixture at high speed through the nozzles, using the effect of the elevated energy in play, allows the modification of the natural disposition and mechanical characteristics of the ground in the desired direction and in accordance with the mixture used (cement, bentonite, water, chemical, mixtures etc.). Depending on the characteristics of the natural ground, the type of mixture used, and work parameters, compression strength from 1 to 500 kgf/cm² (100 kPa to 50 MPa) can be obtained in the treated area.

The realisation of massive consolidated ground elements of various shapes and sizes (buttresses and spurs) within the mass to be stabilised, is achieved by acting opportunely on the injection parameters. In this way the following can be obtained: thin diaphragms, horizontal and vertical cylinders of various diameter and generally any geometrical shapes.

Another improvement system of the mechanical characteristics of the ground is that of thermal treatment of potentially unstable hillsides made up of clayey materials.

Once on the railways, for the treatment of unstable slopes in clayey grounds, the lighting of wood or coal fires was used in holes dug into the slope, to harden the surrounding ground.

In large diameter holes (from 200 to 400 mm.), about 0.8-1.2m. apart and horizontally interconnected, burners were introduced to form cylinders of hardened clay. The temperatures reached were around 800°C. These clay cylinders worked like piles giving greater shear strength to the creep surface.

This system was useful for surface creep, as in the case of an embankment. In other cases the depth of the holes or the amount of fuel necessary led to either the exclusion of this technique or made the effort ineffective.

Other stabilisation attempts were made by using electro-osmotic treatment of the ground. This type of treatment is applicable only in clayey grounds.

It consists of subjecting the material to the action of a continuous electrical field, introducing pairs of electrodes embedded in the ground. These electrodes, when current is introduced cause the migration of the ion charges in the clay.

Therefore the inter-pore waters are collected in the cathode areas and they are dragged by the ion charges. In this way a reduction in water content is achieved.

Moreover, by suitable choice of anodic electrode a structural transformation of the clay can be induced due to the ions freed by the anode triggering a series of chemo-physical reactions improving the mechanical characteristics of the unstable ground.

This stabilisation method, however, is effective only in homogeneous clayey grounds. This condition is hard to find in unstable slopes, therefore electro-osmotic treatment, after some applications, has been abandoned.

It is therefore pointless, for the purpose of planning landslide hazard mitigation measures, to classify the work as a function of the phenomenon or of more important phenomena, renouncing any attempt to precisely describe all the causes or the conditions which, at different times, contribute to the occurrence of the landslide.

Therefore, slope stabilisation methods in rock or in earth, can be collocated into three types of measure:

• Geometric methods, in which the geometry of the hillside is changed (in general the slope);

• Hydrogeological methods, in which an attempt is made to lower the groundwater level or to reduce the water content of the material;

• Chemical and mechanical methods, in which attempts are made to increase the shear strength of the unstable mass or to introduce active external forces (e.g. anchors, rock or ground nailing) or passive (e.g. structural wells, piles or reinforced ground) to contrast the destabilising forces.

The different type of material conditions the engineering solution adopted, although It always comes back, in principle, to the previously introduced classification.

Reinforcement measures

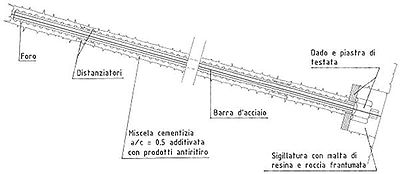

Reinforcement measures are made up of metal rock nails or anchors. Anchorage can be classified as active anchorage, in the case in which they are subjected to pretensioning, and passive anchorage.

Passive anchorage can be used both to nail single unstable blocks and to reinforce large portions of rock. They can also be used as the pre-reinforcement elements of a scarp to be re-profiled in order to limit hillside decompression associated with cutting.

In an anchorage are defined:

- the header: the set of elements (anchorage plate, blocking device, etc.) with the purpose of transmitting the traction strength of the anchor to the anchored structure or to the rock,

- the reinforcement: part of the anchor, concreted and otherwise, placed under traction; can be constituted by a metal rod, a metal cable, a strand, etc.;

- the length of the foundation: the deepest portion of the anchor, fixed to the rock with chemical bonds or mechanical devices, which transfer the load to the rock itself,

- the free length: the non-concreted length.

When the anchorage acts over a short length it is defined as a bolt. It is therefore a specific type of anchorage, not structurally connected to the free length, made up of an element resistant to traction, normally a steel bar of less than 12 m, protected against corrosion by a concrete sheath.

As far as the anchorage device to the ground is concerned, it can be chemical, or use mechanical expansion or concreting.

In the first case, some polyester resin cartridges are placed in the perforation to fill the ring space around the end part of the bolt. The main advantage of this type of anchorage lies in its simplicity and in the speed of installation. The main disadvantage is in its limited strength.

In the second case, the anchorage is composed of steel wedges driven into the sides of the hole. The advantage of this type of anchorage lies in the speed of installation and in the fact that the tensioning can be achieved in the instant the anchorage is put to work.

the main disadvantage with this type of anchorage is that it can only be used with hard rock. Moreover, the maximum traction force is limited.

In the third case, the anchorage is obtained by concreting the whole metal bar. This is the most-used method since the materials are cheap and installation is simple. Injected concrete mixes can be used in many different rocks and grounds; moreover, the concrete sheath protects the bar from corrosion. The concrete mixture is generally made up of water and cement in the ratio W/C = 0.40-0.45, since in this way a sufficiently fluid mixture is obtained to allow pumping into the hole, while at the same time, when set, providing high mechanical strength.

As far as the working mechanism of a rock nail is concerned, the strains of the rock induce a stress state in the nail composed of shear and traction stress, due to the roughness of the joints, to their opening and to the direction of the nail, generally non-orthogonal to the joint itself. The execution phases of setting up the nail provides for:

• formation of any header niche and perforation;

• setting up of a reinforcement bar (e.g. a 4–6 m long FeB44k bar);

• concrete injection of the bar;

• sealing of the header or of the top part of the hole.

It is anyway opportune to close up and cement any cracks in the rock to prevent pressure caused by water during the freeze-thaw cycles from producing progressive breaking in the reinforcement system set up. To this purpose a procedure is provided for of:

1. cleaning out and washing of the cracks;

2. plastering of the crack;

3. predisposition of the injection tubes at suitable inter-axes, parallel to the crack, through which the concrete mix is injected;

4. sequential injection of the mixture from bottom to top and at low pressure (1-3 atm.) until refusal or until no flow back of the mixture is noted from the tubes placed higher up.

The injection mixtures will have approximately the following composition:

- cement 10 kg;

- water 65 l

- fluidity and anti-shrinkage additive or bentonite 1-5 kg.

Spriz-Beton (shotcrete

Shotcrete

Shotcrete is concrete conveyed through a hose and pneumatically projected at high velocity onto a surface, as a construction technique....

)

As defined by the American Concrete Institute "Shotcrete is mortar or concrete conveyed through a hose and pneumatically projected at high velocity onto a surface.

Drainage

The presence of water within a rocky hillside is one of the major factors leading to instability. Knowledge of the water pressure and of the runoff mode is the basis for being able both to carry out credible stability analyses, and to plan measures aimed at improving hillside stability.

Hoek and Bray (1981) provide a scheme of possible measures that can be actuated on a hillside to reduce not only the amount of water, which they believe in itself to be negligible as an instability factor, but above all the pressure brought to bear by the water.

The proposed scheme was elaborated taking three principles into account:

• Preventing water entering the hillside through open or discontinuity traction cracks

• Reducing water pressure in the vicinity of potential breakage surfaces through selective shallow and sub-shallow drainage.

• Placing drainage in order to reduce water pressure in the immediate vicinity of the hillside.

The measures that can be achieved to reduce the effects of water can be shallow or in depth.

Shallow drainage work has the main function of intercepting surface runoff

Surface runoff

Surface runoff is the water flow that occurs when soil is infiltrated to full capacity and excess water from rain, meltwater, or other sources flows over the land. This is a major component of the water cycle. Runoff that occurs on surfaces before reaching a channel is also called a nonpoint source...

water and keeping it away from potentially unstable areas. In reality, on rocky hillsides this type of measure although contributing to reducing the amount of infiltration, alone is insufficient to stabilise a hillside.

Deep drainage is the most effective with this type of slope.

Sub horizontal drainage is very effective in reducing pore-pressure along crack surfaces or potential breakage surfaces. In rocks the choice of drain spacing, slope, and length is subordinated to, apart from the hillside geometry, above all the structural formation of the mass. Features such as position, spacing and discontinuity opening persistence condition, apart from the mechanical characteristics of the rock, the water runoff mode inside the mass. Therefore, only by intercepting the mostly drained discontinuities can there be an efficient result. The sub horizontal drains are accompanied by surficial collectors which gather the water and take it away through networks of small surface channels.

Vertical drainage is generally associated with sunken pumps which have the task of draining the water and lowering the groundwater level. The use of continuous cycle pumps implies very high running costs conditioning the use of this technique for only limited periods.

Drainage galleries are rather different in terms of efficiency. They are considered to be the most efficient drainage system for rocks even if they have the drawback of requiring very high technological and financial investment.

In particular, used in rocks this technique can be highly efficient in lowering water pressure. Drainage galleries can be associated with a series of radial drains which augment their efficiency. The positioning of this type of work is certainly connected to the local morphological, geological and structural conditions.

Geometry modification

This type of measure is used in those cases in which, below the material to be removed, the rock face is sound and stable (for example unstable material at the top of the hillside, rock blocks thrusting out from the hillside profile, vegetation that can widen the rock joints, rock blocks isolated from the joints).Detachment measures are carried out where there are risk conditions due to infrastructures or the passage of people at the foot of the hillside. Generally this type of measure can solve the problem by eliminating the hazard. However, it should be ensured that once the measure is carried out, the problem does not re-emerge in the short term. In fact, where there are very cracked rocks, the shallower rock portions can undergo mechanical incoherence, sometimes encouraged by extremes of climate, causing the isolation of unstable blocks.

The measure can be effected in various ways, which range from demolition with pick axes to the use of explosives. In the case of high and/or not easily accessible faces it is necessary to turn to specialists who work acrobatically.

When explosives are used, sometimes controlled demolition is needed, with the aim of minimising or nullifying the undesired effects resulting from the explosion of the charges, safeguarding the integrity of the surrounding rock.

Controlled demolition is based on the drilling of holes placed at a short distance from each other and parallel to the scarp to be demolished. The diameter of the holes generally varies from 40 to 80 mm; the spacing of the holes is generally about 10 to 12 times the diameter. The charge fuse times are established so that those at the outer edges explode first and the more internal ones successively, so that the area of the operation is delimited.

Protection measures

1. Protecting the rock from alterations,

2. Protecting the infrastructure and towns from rockfalls.

It is therefore necessary to identify above all the cause of the alteration or the possibility of rockfall. Successively the area of operations needs to be delimited, the most suitable procedure to solve the problem and, finally, to control the effectiveness of the measure itself over a period of time.

The most-used passive protection measures are:

1. boulder-gathering trenches at the foot of the hillside,

2. metal containment nets,

3. boulder barriers.

As far as the boulder barriers are concerned, they are generally composed of suitably rigid metal nets. Moreover, lately, various structural types have been put on the market, for which the manufactures specify the kinetic energy of absorption.

One of the structural control methods for boulder containment nets starts from the concept of projectile collision, on the basis of which the maximum applied force and the corresponding resultant buckling are expressed, by means of a static analysis, leading to the quantification of the forces divided up among the various structural elements.

Another type of boulder containment barrier is the earth embankment, possibly reinforced with geo-synthetics (reinforced ground).The advantage of this type of work, compared to nets, is easier maintenance and lower environmental impact minor.The absorption of kinetic energy is generally greater than that of metal nets.

Geometry modification

The operation of re-profiling a slope with the aim of improving its stability, can be achieved through various procedures:• Lowering the slope

• Positioning infill at the foot of the slope

Slope re-profiling work

Slopes can be reduced by digging out the brow of the slope. This is effective for correcting shallow forms of instability, where movement is limited to layers of ground near to the surface and when the slopes are higher than 5m. Moreover, the steps created in this way and suitably achieved also reduce surface erosion.

However, caution should be exercised to avoid the onset of local breakage following the cuts made.

Infill at the foot of the slope, instead, has a stabilising effect in the case of translational or deep rotational landslide, in which the landslide surface at the top submerges and describes a sub-vertical surface that re-emerges in the area at the foot of the slope. The choice of reducing the slope and infilling at the foot is rarely a problem since there are generally specific constraints to be respected at the top or at the foot of the slope.

Generally in slope stabilisation where there are no constraints (often this occurs for natural slopes) a combination of slope reduction and infilling at the foot of the slope is adopted to avoid heavy work of just one type. Included among work at the foot of the slope are the berm and some gravitational structures like gabions or reinforced ground, that is, concrete blocks.

In the case of natural slopes the choice of re-profiling scheme is not so clear as in the case of artificial slopes. Often the profile is highly irregular with large areas of not recent natural creep, so that its shallow development can make some areas unserviceable as a cutting or infill point.

Where the buried shape of the old landslide is complicated, depositing of infill material in one area can lead to destabilising another.

When planning this type of work the stepping effect of the cuts and infill should be taken into account: their beneficial influence on the increase in Safety Factor will be reduced in relationship to the size of the landslide under examination. Moreover, it is very important to ensure that neither the cuts nor the infill mobilise the existing or potential creep plane of the landslide.

Generally, infilling at the foot of the landslide should be preferred to cutting at the top (to reduce weight at the top of the slope), since the latter solution proves to be often more expensive than the former. Moreover, in complex and compound landslides, infill at the foot of the slope, at the tip of the foot itself, has a lesser probability of interfering with the interaction of the individual landslide elements.

An important aspect of stabilisation work that changes the morphology of the slope is that, in more precisely mechanical terms, effecting cuts and infill generates non-drained charge and discharge stresses.

In fact, in the case of positioning infill, the safety factor SF, will be less in the short term than in the long term. In the case of effecting a cut in the slope, SF will be less in the long term rather than in the short term. therefore in both cases it is opportune to calculate the SF both in the short and the long term.

Finally, it should be remembered that the effectiveness of infill increases with time on condition that it is associated with an appropriate infill drainage system, obtained through an underlying drainage cover or appropriate shallow drainage.

More generally therefore re-profiling systems are associated with and integrated by surficial protection of the slope against erosion and by regulation of meteoric waters through drainage systems made up of ditches and small channels (clad or unclad and prefabricated) to run off the water collected.

A problem that could be caused by water near the surface of the hillside is the erosion of surface material due to water runoff. This proves hazardous in terms of stability since it tends to weaken the slope by removing material as well as triggering excess pressure due to the water flow.

For defence against erosion, a series of solutions can be used, such as:

• Geomats

• Geogrids

Geogrids

A geogrid is geosynthetic material used to reinforce soils and similar materials. Geogrids are commonly used to reinforce retaining walls, as well as subbases or subsoils below roads or structures. Soils pull apart under tension. Compared to soil, geogrids are strong in tension...

• Brushwood mats

These measures share the superficial character of their installation given their low environmental impact.

Geomats or rather anti-eroding biomats or bionets are purpose-made synthetic products for the protection and grassing of slopes subject to surface wash through two main erosion control mechanisms: the containment and reinforcement of the surficial ground; the protection from the impact of the raindrops.

Geogrids

A geogrid is geosynthetic material used to reinforce soils and similar materials. Geogrids are commonly used to reinforce retaining walls, as well as subbases or subsoils below roads or structures. Soils pull apart under tension. Compared to soil, geogrids are strong in tension...

- Wicker or brushwood mats are made of vegetal material. Very long and flexible willow branches can be used, which are then covered with infill soil. Alternating stakes of different woody species are used and they are woven to form a barrier against the downward drag of the material eroded by the free water on the surface

Draining techniques

Drainage systems are adopted to reduce the neutral stresses in a potentially unstable hillside. In terms of safety for global stability, these measures translate into the lowering of the water level inside the mass, which consequently leads to reduction in pore-pressure in the ground and an increase in the shear strength available in particular along the potential creep surface.In relation to hillside morphology, the kinematism of movement predicted and to the depth of the creep surfaces, the reduction in pore-pressure by drainage can be obtained using shallow and deep drains.

Usually, shallow drainage is adopted when the potential hillside movement is foreseen as shallow landslide affecting the ground to a depth of about 5-6m. When there is deeper surface slipping, deep drainage has to be introduced, but shallow drainage systems can be provided anyway with the aim of running off that aliquot of surficial water directly connected to seasonal rainfall.

Shallow drainage

- Shallow drainage trenches

Traditional drainage trenches are cut in an unbroken length and filled with highly permeable granular draining material;

- Shallow drainage trenches equipped with geocomposites

These systems consist of unbroken trenches with scarped sides covered with geocomposites, generally with 25m. Long panels, having draining characteristics. The bottom of the trench houses a drainage tube with the task of bottom discharge placed in continuity the geocomposite canvas.

Deep drainage

Deep drainage acts by modifying the filtration routes in the ground. Often they are more expensive than shallow drains, but they are usually more effective because they remove the quantity of water that induces instability in the hillside, from within the ground and diminish the neutral stresses directly where necessary.Deep drainage in earth slopes can be obtained by means of the following works:

large diameter drainage wells equipped with sub-horizontal drains.

These systems can have just a structural function, just a draining function or both. The draining elements are the microdrains, perforated and positioned sub-horizontally and fanned out, oriented uphill to favour water discharge by gravity.

The size of the wells is chosen with the aim of allowing the insertion and functioning of the perforation equipment for the microdrains. Generally, the minimum internal diameter to be adopted must be greater than 3.5 m, for drains with a length of 20 to 30 m.

Longer drains require wells with a diameter of up to 8–10 m. To determine the network of microdrains planners have to take into consideration the makeup of the subsoil and the hydraulic regime of the slope, to provide for the correct number and distribution of the microdrains.

The drainage in these wells is passive, realised by linking the bottom of adjacent wells by sub-horizontal perforations (provided with temporary sheathing pipes) in which the microdrains are placed at a gradient of about 15-20° and are equipped with microperforated PVC pipes, protected by non-filtering fabric along the draining length.

Once all the drain is inserted in the hole and having embedded the latter in the ground, the temporary sheathing is completely removed and the head of the drain is cemented to the well.

In this way a discharge line is created linking all the wells emerging to the surface downhill, where the water is discharged naturally without the help of raising pumps.

The wells are placed at such a distance apart that the individual collecting areas of the microdrains, appertaining to each well, are overlaid. In this way all the volume of the slope involved with the water table is drained.

Medium-diameter drainage wells linked at the bottom. The technique involves the dry cutting with temporary sheathing pipes, of aligned drainage wells, with a diameter of 1200–1500 mm., positioned at an interaxis of 6–8 m., their bottoms linked together to a bottom tube for the discharge of drained water. In this way the water discharge takes place passively, due to gravity by perforated pipes with mini-tubes, positioned at the bottom of the wells themselves.

The linking pipes, generally made of steel, are blind in the linking length and perforated or windowed in the length corresponding to the well. The wells have a concrete bung at the bottom and are filled, after withdrawal of the temporary sheathing pipe, with dry draining material and are closed with an impermeable clay bung.

In normal conditions, these wells reach a depth of 20–30 m, but, in especially favourable cases, a depth of even 50 m can be reached.

Some of these wells have drainage functions across their whole section and others can be inspected. The latter serve for maintenance of the whole drainage screen. Such wells that can be inspected are also a support point for the creation of new drainage wells and access for the installation, also on a later occasion, for a range of sub-horizontal drains at the bottom or along the walls of the wells themselves, with the purpose of increasing the drainage capacity of the well.

• Isolated wells fitted with drainage pumps

This system provides for the installation of a drainage pump for each well.

The distribution of the wells is established according to the permeability of the land to be drained, the lowering of the water pressure to be achieved and the area that has to be involved in this work, so that the water pressure area deriving from the depression fans generated by the single drainage points, responds to the needs of the plan.

The use of isolated wells with a drainage pumps leads to high running costs and imposes a very time-consuming level of control and maintenance.

• Deep drainage trenches

Deep drainage trenches consist of unbroken cuts with a small cross-section that can be covered at the bottom with geofabric canvas

Geotextile

Geotextiles are permeable fabrics which, when used in association with soil, have the ability to separate, filter, reinforce, protect, or drain...

having a primary filter function.

They are filled with draining material that has a filtering function and exploits the passive drainage to carry away the drained water downhill. The effectiveness of these systems is connected to the geometry of the trench and the continuity of the draining material along the whole trench. As far as the geometry of the cut is concerned attention should be paid to the slope given to the bottom of the cut. In fact, deep drainage trenches do not have bottom piping that is inserted in the end part of the trench, downhill, where the depth of the cut is reduced until the campaign level is reached.

• Drainage galleries fitted with microdrains

Drainage galleries constitute a rather expensive stabilisation provision for large, deep landslide movements, to be carried out where the ground is unsuitable for cutting trenches or drainage wells and when it is impossible to work on the surface owing to a lack of space for the work machinery.

Their effectiveness is due to the extensiveness of the area to be drained. Moreover, these drainage systems have to be realised on the stable part of the slope.

The drainage systems are placed inside the galleries and are made up of microdrains, with lengths that can reach 50–60 m and are spatially oriented in a suitable directions.

The sizes of the galleries are conditioned by the need to insert the drain perforation equipment. For this reason the minimum transversal internal size of the galleries vary from a minimum of 2 m, when using special reduced size equipment, and to at least 3.5 m, when using traditional equipment.

• Siphon drain

This is a technique conceived and developed in France, which works like the system of isolated drainage wells but overcoming the inconvenience of installing a pump for each well. In fact, the system on the principle that once motion is triggered in the siphon tube, avoiding the entry of air into the loop, the motion is uninterrupted. For this reason, in this system, the condition that the two ends of the siphon tube are submerged in the water of the two permanent storage tanks, must always be checked.

This drain is created vertically starting from the campaign level but can also be sub-vertical or inclined. The diameter of the well can vary from 100 to 300 mm; inside a PVC pipe is placed or a perforated or microperforated steel pipe, filled with draining material.

The siphon drain in this way carries off of drainage water by gravity without the need for drainage pumps or pipes linking the bottom of each well. This system proves to be economically advantageous and relatively simple to set up even if it necessitates a programme of controls and maintenance.

• Microdrains

Microdrains is a simple to create drainage system with contained costs. They consist of small diameter perforations, made from surface locations, in trenches, in wells or in galleries. The microdrains are set to work in a sub-horizontal or sub-vertical position, according to the type of application.

Reinforcement measure

The stabilisation of the hillside in terms of an increase in the mechanical characteristics of the potentially unstable ground, can be effected by means of two different approaches:• Insertion of reinforcement elements in the ground;

• The improvement of the mechanical characteristics of the ground volume affected by landslide through chemical, thermal or mechanical treatment.

Insertion of reinforcement elements in the ground

This category of work uses:• Large diameter wells supported by one or more crowns of consolidated and possibly reinforced earth columns;

• Anchors

• Networks of micropiles

• Nailing

• Geogrids for reinforced ground

• Cellular faces

Large diameter wells supported by one or more crowns of consolidated and possibly reinforced earth columns

To guarantee slope stability it may be necessary to insert very rigid, strong element. These elements are large diameter full section or ring section reinforced concrete wells.

The wells can have a circular or elliptical section. The depth of the static wells can reach 30-40m. Often the static stabilising action of the wells is integrated with a series of microdrains laid out radially on several levels, also to reduce pore-pressure, if it is hazardous.

Anchors

The anchors are then fixed in a certainly stable place. They are usually realised with orthogonal axes to the slope surface and therefore, at first approximately orthogonal to the surface of the creep.

The adoption of this system sometimes gives anchorage problems, as in the case of silt-clayey ground. In fact, where there is water or the anchors are embedded in a clayey sub-layer, the adherence of the anchor to the ground has to be assured.

Moreover, it is opportune that the surface contained within the grid of the beam frame is protected, using geofabrics, in order to avoid erosion removing the ground underlying the beam frame.

Networks of micropiles

This solution provides for a plant of a series of micropiles that make up a three-dimensional grid, variably tilted and linked at the head by a rigid reinforced concrete mortise.

This structure constitutes a reinforcement for the ground, inducing an intrinsic improvement of the ground characteristics incorporated in the micropiles. A measure of this type proves effective in cases of not very extensive landslide.

The effectiveness of solutions with micropiles is linked to the possibility of inserting micropiles over the whole width of the landslide area. In the case of rotational landslides in soft clay, the piles contribute to increasing the resisting moment by friction on the upper part of the pile shaft found in the landslide.

This functionality is usually valid for micropiles working using the point. In the case of suspended piles, strength is governed by the part of the pile offering the least resistance. As an operational method, those piles that destined to the most unstable area of the slope should be positioned first, subsequently those around the unstable area, in order to reduce any possible lateral ground displacements.

Preliminary design methods for the micropiles, nowadays are entrusted to the use of codes that carry out numerical simulations, but which are subject to simplifications in the models that necessitate characterisations of rather precise potential landslide material.

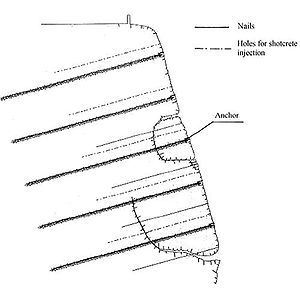

Nailing

The soil nailing technique applied to temporarily and/or permanently stabilise natural slopes and artificial scarps, fall back on a fundamental principle in the field of construction technique: mobilising the intrinsic mechanical characteristics of the ground, such as cohesion and the angle of internal friction, so that the ground actively collaborates with the stabilisation work.

Nailing, on a par with anchors, induce normal stress to the advantage of stability. One nailing solution is that of rapid response diffuse nailing: CLOUJET, where the nails are embedded in the ground by means of an expanded bulb obtained by means of injecting mortar at high pressure into the anchorage area.

Drainage is an integral part of the CLOUJET project since the hydraulic regime, considered in the form of pore-pressure applied normally to the fractured surfaces, directly influences the characteristics of the system.

The drained water, both through fabric and by means of pipes embedded in the ground with a pre-determined gradient, flows together at the foot of the slope where it is collected in a suitable collector parallel to the direction of the face.

Another system suitable for stabilizing slopes and landslides is a soil nail and root technology (SNART). Here steel nails are inserted very rapidly into a slope by percussion, vibration or screw methods. Grid spacing is typically 0.8 to 1.5 m, nails are 25 to 50 mm in diameter and may be as long as 20 m. Nails are installed perpendicular to and through the failure plane (or potential failure plane), and as such are designed in bending and shear (rather than tension) using geotechnical engineering principles. Potential failure surfaces less than 2 m deep normally require the nails to be wider near the top, and is typically achieved with steel plates fastened at the nail heads. An effective and aesthetic facing to prevent soil loss between the nails can be designed using plant roots.

Geogrids

The insertion of geosynthetic reinforcements (generally in the direction in which the deformation has developed) therefore has the function of reinforcing the ground conferring greater stiffness and stability upon it and the capacity to be subjected to greater deformations without reaching fracture point.

Cellular faces

Compacted granular material is inserted in the spaces of the grid. The characteristic modularity of the system confers notable flexibility of use on its use both in terms of adaptability to the morphology of the ground and because the structure does not require any deep foundation other than a laying plane of lean concrete useful to make the support plane of the whole structure regular.

This solution can also take vegetal ground into the grid spaces, to favour the camouflaging of the work into the surroundings by means of the vegetation rooting on the exposed face.

Improvement in the mechanical characteristics of the soil volume affected by landslide by means of chemical, thermal or mechanical treatment

Among the treatments belonging to the group of intrinsic improvements of a mechanical character in the ground, the technique of jet-grouting is often used, in particular as a substituting and/or integrating element for technologies used for the previously described structural measures.The phases of this work are:

PHASE I

Perforation phase: insertion, with perforation destroying the nucleus, of a set of poles into the ground up to the depth of treatment required by the project.

PHASE II

Extraction and programmed injection phase: injection of the mixture at very high pressure is done during the extraction phase of the set of poles.

It is in this phase that through the insistence of the jet in a certain direction for a certain interval of time, the effect is obtained by the speed of extraction and rotation of the set of poles, so that volumes of ground can be treated in the shape and size desired.

The high energy jet produces a mixture of the ground and a continuous and systematic "claquage" with only a local effect within the radius of action without provoking deformations at the surface that could induce negative consequences on the stability of adjacent constructions.

The projection of the mixture at high speed through the nozzles, using the effect of the elevated energy in play, allows the modification of the natural disposition and mechanical characteristics of the ground in the desired direction and in accordance with the mixture used (cement, bentonite, water, chemical, mixtures etc.). Depending on the characteristics of the natural ground, the type of mixture used, and work parameters, compression strength from 1 to 500 kgf/cm² (100 kPa to 50 MPa) can be obtained in the treated area.

The realisation of massive consolidated ground elements of various shapes and sizes (buttresses and spurs) within the mass to be stabilised, is achieved by acting opportunely on the injection parameters. In this way the following can be obtained: thin diaphragms, horizontal and vertical cylinders of various diameter and generally any geometrical shapes.

Another improvement system of the mechanical characteristics of the ground is that of thermal treatment of potentially unstable hillsides made up of clayey materials.

Once on the railways, for the treatment of unstable slopes in clayey grounds, the lighting of wood or coal fires was used in holes dug into the slope, to harden the surrounding ground.

In large diameter holes (from 200 to 400 mm.), about 0.8-1.2m. apart and horizontally interconnected, burners were introduced to form cylinders of hardened clay. The temperatures reached were around 800°C. These clay cylinders worked like piles giving greater shear strength to the creep surface.

This system was useful for surface creep, as in the case of an embankment. In other cases the depth of the holes or the amount of fuel necessary led to either the exclusion of this technique or made the effort ineffective.

Other stabilisation attempts were made by using electro-osmotic treatment of the ground. This type of treatment is applicable only in clayey grounds.

It consists of subjecting the material to the action of a continuous electrical field, introducing pairs of electrodes embedded in the ground. These electrodes, when current is introduced cause the migration of the ion charges in the clay.

Therefore the inter-pore waters are collected in the cathode areas and they are dragged by the ion charges. In this way a reduction in water content is achieved.

Moreover, by suitable choice of anodic electrode a structural transformation of the clay can be induced due to the ions freed by the anode triggering a series of chemo-physical reactions improving the mechanical characteristics of the unstable ground.

This stabilisation method, however, is effective only in homogeneous clayey grounds. This condition is hard to find in unstable slopes, therefore electro-osmotic treatment, after some applications, has been abandoned.

Soil slope stabilization

Coir Geotextiles are another product which is used for erosion control globally and is used for bioengineering and slope stabilization applications due to the mechanical strength necessary to hold soil together. It is been proven that coir geotextiles last for approximately 3 – 5 years depending on the weight, and by the time the product degrades, it converts itself it to humus, which enriches the soil.With steel wire mesh

Steel wire mesh may be used for soil and rock slope stabilization. After leveling, the surface is covered by a steel-wire mesh, which is fastened to the slope and tensioned. It is a cost-effective approach.See also

- Landslide classificationLandslide classificationThere have been known various classifications of landslides and other types of mass wasting.For example, the McGraw-Hill Encyclopedia of Science and Technology distinguishes the following types of landslides:*fall *fall...

- GeotechnicsGeotechnicsGeotechnics is the application of scientific methods and engineering principles to the acquisition, interpretation, and use of knowledge of materials of the Earth's crust and earth materials for the solution of engineering problems...

- Avalanche controlAvalanche controlAvalanche control or avalanche defense activities reduce the hazard avalanches pose to human life, activity, and property. Avalanche control begins with a risk assessment conducted by surveying for potential avalanche terrain by identifying geographic features such as vegetation patterns,...

, mitigation of a similar disaster type