Letterpress printing

Encyclopedia

Printing press

A printing press is a device for applying pressure to an inked surface resting upon a print medium , thereby transferring the ink...

and movable type

Movable type

Movable type is the system of printing and typography that uses movable components to reproduce the elements of a document ....

, in which a reversed, raised surface is ink

Ink

Ink is a liquid or paste that contains pigments and/or dyes and is used to color a surface to produce an image, text, or design. Ink is used for drawing and/or writing with a pen, brush, or quill...

ed and then pressed into a sheet of paper to obtain a positive right-reading image. It was the normal form of printing text from its invention by Johannes Gutenberg in the mid-15th century until the 19th century and remained in wide use for books and other uses until the second half of the 20th century. In addition to the direct impression of ink

Ink

Ink is a liquid or paste that contains pigments and/or dyes and is used to color a surface to produce an image, text, or design. Ink is used for drawing and/or writing with a pen, brush, or quill...

ed movable type onto paper or another receptive surface, letterpress is also the direct impression of inked printmaking

Printmaking

Printmaking is the process of making artworks by printing, normally on paper. Printmaking normally covers only the process of creating prints with an element of originality, rather than just being a photographic reproduction of a painting. Except in the case of monotyping, the process is capable...

blocks such as photo-etched zinc "cuts" (plates), linoleum blocks, wood engravings, etc., using such a press.

In the 21st century, commercial letterpress has been revived by the use of 'water-wash' photopolymer

Photopolymer

A photopolymer is a polymer that changes its properties when exposed to light, often in the ultraviolet spectrum. These polymers are useful in dentistry for fillings and in rapid prototyping in the stereolithography and 3D printing processes. This material is also used in the creation of ADA...

plates that are adhered to a near-type-high base to produce a relief printing surface typically from digitally-rendered art and typography

Typography

Typography is the art and technique of arranging type in order to make language visible. The arrangement of type involves the selection of typefaces, point size, line length, leading , adjusting the spaces between groups of letters and adjusting the space between pairs of letters...

.

History

In about 1440, Johannes Gutenberg is credited with the invention of modern movable type printing from individually cast, reusable letters set together in a form (frame). He also invented a wooden printing press, based on the extant wine pressWine press

A wine press is a device used to extract juice from crushed grapes during wine making. There are a number of different styles of presses that are used by wine makers but their overall functionality is the same. Each style of press exerts controlled pressure in order to free the juice from the fruit...

, where the type surface was inked with leather covered ink balls and paper laid carefully on top by hand, then slid under a padded surface and pressure applied from above by a large threaded screw. Later metal presses used a knuckle and lever arrangement instead of the screw

Screw

A screw, or bolt, is a type of fastener characterized by a helical ridge, known as an external thread or just thread, wrapped around a cylinder. Some screw threads are designed to mate with a complementary thread, known as an internal thread, often in the form of a nut or an object that has the...

, but the principle was the same. Ink rollers made of composition made inking faster and paved the way for further automation.

With the advent of industrial mechanisation

Industrial Revolution

The Industrial Revolution was a period from the 18th to the 19th century where major changes in agriculture, manufacturing, mining, transportation, and technology had a profound effect on the social, economic and cultural conditions of the times...

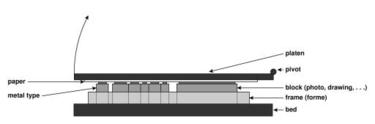

, the inking was carried out by rollers which would pass over the face of the type and move out of the way onto a separate ink plate where they would pick up a fresh film of ink for the following sheet. Meanwhile, a sheet of paper was slid against a hinged platen (see image) which was then rapidly pressed onto the type and swung back again to have the sheet removed and the next sheet inserted (during which operation the now freshly inked rollers would run over the type again). Fully automated, 20th-century presses, such as the Kluge and "Original" Heidelberg Platen (the "Windmill"), incorporated pneumatic feed and delivery of the sheet.

Industrial-scale use in the 20th century

Rotary presses were used for high-speed work. In the oscillating press, the form slid under a drum around which each sheet of paper got wrapped for the impression, sliding back under the inking rollers while the paper was removed and a new sheet inserted. In a newspaperNewspaper

A newspaper is a scheduled publication containing news of current events, informative articles, diverse features and advertising. It usually is printed on relatively inexpensive, low-grade paper such as newsprint. By 2007, there were 6580 daily newspapers in the world selling 395 million copies a...

press, a papier-mâché mixture called a flong

Flong

Flong is a term used in relief printing , which refers to an intermediate step in making of a stereo plate typically used in a rotary press though not exclusively...

was used to make a mould of the entire form of type, then dried and bent, and a curved metal plate cast against it. The plates were clipped to a rotating drum and could print against a continuous reel of paper at the enormously high speeds required for overnight newspaper production.

Rotary letterpress

The invention of ultra-violet curing inks has helped keep the rotary letterpress alive in areas like self-adhesive labels. There is also still a large amount of flexographic printingFlexography

Flexography is a form of printing process which utilizes a flexible relief plate. It is basically an updated version of letterpress that can be used for printing on almost any type of substrate including plastic, metallic films, cellophane, and paper...

, a similar process, which uses rubber plates to print on curved or awkward surfaces, and a lesser amount of relief print

Relief print

A relief print is an image created by a printmaking process where protruding surface faces of the matrix are inked; recessed areas are ink free. Printing the image is therefore a relatively simple matter of inking the face of the matrix and bringing it in firm contact with the paper...

ing from huge wooden letters for lower-quality poster work.

Rotary letterpress machines are still used on a wide scale for printing of self-adhesive and non-self-adhesive labels, tube laminate, cup stock, etc. The printing quality achieved by a modern letterpress machine with UV curing is on par with flexo presses. It is more convenient and user friendly than a flexo press. Water-wash photopolymer plates are used which are as good as any solvent-washed flexo plate. Today even CtP (computer-to-plate

Computer to plate

Computer to plate is an imaging technology used in modern printing processes. In this technology, an image created in a Desktop Publishing application is output directly to a printing plate....

) plates are available making it a full-fledged, modern printing process. Because there is no anilox

Anilox

In printing, anilox is a method used to provide a measured amount of ink to a flexo printing plate.An anilox roll is a hard cylinder, usually constructed of a steel or aluminum core which is coated by an industrial ceramic whose surface contains millions of very fine dimples, known as cells...

roller in the process, the make-ready time also goes down when compared to a flexo press. Inking is controlled by keys very much similar to an offset

Offset printing

Offset printing is a commonly used printing technique in which the inked image is transferred from a plate to a rubber blanket, then to the printing surface...

press. UV inks for Letterpress are in paste form, unlike flexo. There are various manufacturers of UV rotary letterpress machines, viz. Dashen, Nickel, Taiyo Kikai, KoPack, Gallus, etc. which also offer hot/cold foil stamping, rotary die cutting, flatbed die cutting, sheeting, rotary screen printing, adhesive side printing, and inkjet numbering. The central impression presses are more popular than inline presses due to their ease of registration and simple design. Printing of up to nine colours plus varnish is possible with various online converting processes.

Rise of 'craft' letterpress

A small amount of high-quality art and hobby letterpress printing remains—fine Letterpress work is crisper than offset litho because of its impression into the paper, giving greater visual definition to the type and artwork. Today, many of these small Letterpress shops survive by printing fine editions of books or by printing upscale invitations and stationeryStationery

Stationery has historically meant a wide gamut of materials: paper and office supplies, writing implements, greeting cards, glue, pencil case etc.-History of stationery:...

, often using presses that require the press operator to feed paper one sheet at a time by hand. They are just as likely to use new printing methods as old, for instance by printing photopolymer plates (used in modern rotary Letterpress) on restored 19th century presses.

The process requires a high degree of craftsmanship, but in the right hands, Letterpress excels at fine typography. It is used by many small presses that produce fine, handmade, limited-edition books, artists' books

Artists' Books

Artists' books are works of art realized in the form of a book. They are often published in small editions, though sometimes they are produced as one-of-a-kind objects referred to as "uniques"....

, and high-end ephemera

Ephemera

Ephemera are transitory written and printed matter not intended to be retained or preserved. The word derives from the Greek, meaning things lasting no more than a day. Some collectible ephemera are advertising trade cards, airsickness bags, bookmarks, catalogues, greeting cards, letters,...

such as greeting cards and broadsides

Street literature

Street literature or broadsides began in the 16th century and continued until the mid-19th century as a type of printing of large printed sheets of paper, designed to be plastered onto walls...

. Setting type by hand has become less common with the invention of the photopolymer

Photopolymer

A photopolymer is a polymer that changes its properties when exposed to light, often in the ultraviolet spectrum. These polymers are useful in dentistry for fillings and in rapid prototyping in the stereolithography and 3D printing processes. This material is also used in the creation of ADA...

plate.

To bring out the best attributes of Letterpress, printers must understand the capabilities and advantages of what can be a very unforgiving medium. For instance, since most Letterpress equipment prints only one color at a time (unlike presses for offset printing

Offset printing

Offset printing is a commonly used printing technique in which the inked image is transferred from a plate to a rubber blanket, then to the printing surface...

which often use four-color process printing), printing multiple colors can be challenging. The inking system on Letterpress equipment is less precise than on offset presses, which can pose problems with some graphics: detailed, white (or "knocked out") areas, such as small, serif

Serif

In typography, serifs are semi-structural details on the ends of some of the strokes that make up letters and symbols. A typeface with serifs is called a serif typeface . A typeface without serifs is called sans serif or sans-serif, from the French sans, meaning “without”...

type, or very fine halftone

Halftone

Halftone is the reprographic technique that simulates continuous tone imagery through the use of dots, varying either in size, in shape or in spacing...

, surrounded by fields of color, can fill in with ink and lose definition. However, a skilled printer can overcome most of these problems. Working with a Letterpress also gives the printer the option of using a wider range of paper, including handmade, organic, and tree-free. Letterpress printing allows for a large variety of choices. The classic feel and finish of letterpress papers takes printing back to an era of quality and craftsmanship that is not often found in other printing methods today.

While less common in contemporary letterpress printing, it is possible to print halftoned photographs, via photopolymer plates, on letterpress equipment. However, letterpress printing's strengths are crisp lines, patterns, and typography.

Revival since the 1990s

Letterpress publishing has recently undergone a revival in the USA, Canada, and the UK, under the general banner of the 'Small Press Movement'. Renewed interest in letterpress was fueled by Martha Stewart Weddings magazine, which began using pictures of letterpress invitations in the 1990s. The beauty and texture became appealing to brides who began wanting letterpress invitations instead of engraved, thermographed, or offset-printed invitations. At the same time, presses were being discarded by commercial print shops, and became affordable and available to artisans throughout the country. Popular presses are, in particular, VandercookVandercook

Vandercook & Sons was a manufacturer of proof presses, founded in 1909 by Robert Vandercook. They dominated the 20th century proof press industry by developing the first and the most widely used proof presses that did not rely on gravity for the force of their impression...

cylinder proof presses and Chandler & Price

Chandler & Price

Chandler and Price was founded in 1881 in Cleveland, Ohio, by Harrison T. Chandler and William H. Price. They manufactured machinery for printers including a series of hand-fed platen jobbing presses, as well as an automatic feeder for these presses , paper cutters, book presses, and assorted...

platen presses. In the UK there is particular affection for the Arab press, built by Josiah Wade in Halifax.

The movement has been helped by the emergence of a number of organizations that teach Letterpress such as Columbia College Chicago

Columbia College Chicago

Columbia College Chicago is one of the largest art colleges in the United States with nearly 12,000 students pursuing degrees within 120 undergraduate and graduate programs...

's Center for Book and Paper Arts, Art Center College of Design

Art Center College of Design

Art Center College of Design is a private college located in Pasadena, California, and was cited by BusinessWeek as one of the 60 best design schools in the world. The college’s industrial design program is consistently ranked number one by both DesignIntelligence and U.S...

in Pasadena, Calif., New York's Center for Book Arts

Center for Book Arts

The Center for Book Arts in New York City is the first organization of its kind in the United States dedicated to contemporary interpretations of the book as an art object while preserving traditional practices of the art of the book....

, Studio on the Square and The Arm NYC, the Wells College Book Arts Center in Aurora, New York, the San Francisco Center for the Book

San Francisco Center for the Book

The San Francisco Center for the Book is a non-profit organization founded in 1996 by Mary Austin and Kathleen Burch in San Francisco, California in the United States...

, Bookworks, Seattle's School of Visual Concepts

School of Visual Concepts

The School of Visual Concepts in Seattle, Washington, is a vocational school training students and working professionals in the fields of graphic design, advertising art direction, advertising copywriting, web design, and marketing communications....

, Black Rock Press, North Carolina State University

North Carolina State University

North Carolina State University at Raleigh is a public, coeducational, extensive research university located in Raleigh, North Carolina, United States. Commonly known as NC State, the university is part of the University of North Carolina system and is a land, sea, and space grant institution...

, Washington D.C's Corcoran College of Art and Design, Penland School of Crafts

Penland School of Crafts

The Penland School of Crafts is a center for craft education located in the Blue Ridge Mountains in Spruce Pine, North Carolina, about 50 miles from Asheville....

, the Minnesota Center for Book Arts

Minnesota Center for Book Arts

Minnesota Center for Book Arts is the largest and most comprehensive independent non-profit book arts center in the United States. Located in Minneapolis, Minnesota, MCBA is a nationally recognized leader in the celebration and preservation of traditional crafts including hand papermaking,...

, the International Printing Museum

International Printing Museum

The International Printing Museum, in Carson, California, has one of the largest collections of antique printing presses in the United States. It offers educational programs for school groups at the museum, and also has a Ben-Franklin-type printing press on a trailer that travels to schools and...

in Carson, CA and the Bowehouse Press at VCU in Richmond, VA.

Affordable copper, magnesium and photopolymer platemakers and milled aluminum bases have allowed letterpress printers to produce type and images derived from digital artwork, fonts and scans. Economical plates have encouraged the rise of "digital letterpress" in the 21st century, allowing a small number of firms to flourish commercially and enabling a larger number of boutique and hobby printers to avoid the limitations and complications of acquiring and composing metal type. At the same time there has been a renaissance in small-scale type foundries

Type foundry

A type foundry is a company that designs or distributes typefaces. Originally, type foundries manufactured and sold metal and wood typefaces and matrices for line-casting machines like the Linotype and Monotype machines designed to be printed on letterpress printers...

to produce new metal type on Monotype equipment, Thompson casters and the original American Type Founders machines.

The goal before this revival was that you could not tell there was an impression, the type contacted the paper enough to transfer the ink but not leave an impression. However today, when speaking of letterpress, the goal is to have that impression to distinctly note that is letterpress.

Creating artwork

Creating files for Letterpress is similar to conventional printing with these exceptions:- Ink Color: Files are created using spot colorSpot colorIn offset printing, a spot color is any color generated by an ink that is printed using a single run.The widely spread offset-printing process is composed of four spot colors: Cyan, Magenta, Yellow, and Key commonly referred to as CMYK...

s, not CMYK or RGB. A spot colorSpot colorIn offset printing, a spot color is any color generated by an ink that is printed using a single run.The widely spread offset-printing process is composed of four spot colors: Cyan, Magenta, Yellow, and Key commonly referred to as CMYK...

is specified for each color to be used. Typically one or two colors are used. - Paper Color: Dark ink on a light paper gives the best image. Inks are translucent and the paper color will show through. For light colors on dark paper, foil stampingFoil stampingFoil stamping, typically a commercial print process, is the application of pigment or metallic foil, often gold or silver, but can also be various patterns or what is known as pastel foil which is a flat opaque color or white special film-backed material, to paper where a heated die is stamped onto...

or engravingEngravingEngraving is the practice of incising a design on to a hard, usually flat surface, by cutting grooves into it. The result may be a decorated object in itself, as when silver, gold, steel, or glass are engraved, or may provide an intaglio printing plate, of copper or another metal, for printing...

should be used instead of Letterpress. To build up the color density of a specific color, Letterpress pieces can be run through the press two times using the same color. - Screens: GrayscaleGrayscaleIn photography and computing, a grayscale or greyscale digital image is an image in which the value of each pixel is a single sample, that is, it carries only intensity information...

images can be used if made with a coarse screen (85 line or less). A second color should be used instead of screening a color in most cases. - Thickness: Art must be above ¼ point and with no hairlines.

- FontFontIn typography, a font is traditionally defined as a quantity of sorts composing a complete character set of a single size and style of a particular typeface...

s: Type must be five points or larger for best results. For reversed type the point size should be 12 point or larger, smaller type can fill in. An outline strokeComputer fontA computer font is an electronic data file containing a set of glyphs, characters, or symbols such as dingbats. Although the term font first referred to a set of metal type sorts in one style and size, since the 1990s it is generally used to refer to a scalable set of digital shapes that may be...

is often applied to allow for ink gain. - Solids: Letterpress solids will print differently from conventionally printed lithographicLithographyLithography is a method for printing using a stone or a metal plate with a completely smooth surface...

solids. While Letterpress does lay down a thick film of ink, the process tends to show the texture of the sheet. Also, solid areas do not give the appearance of depth that fine type and thin lines do. Solid areas can also cause the paper to ripple, especially on thinner sheets. - RegistrationPrinting registrationIn color printing, registration is the method of correlating overlapping colors on one single image. There are many different styles and types of registration, many of which employ the alignment of specific marks.-Purpose:...

: Letterpress does register well, however, it does not have the capabilities of modern offset printingOffset printingOffset printing is a commonly used printing technique in which the inked image is transferred from a plate to a rubber blanket, then to the printing surface...

. Trapping and key lines do not work well in letterpress printing. A blank area should be incorporated between colors. Black and very dark colors may be overprinted over lighter colors. - Depth: The type depth is dependent on the paper. Typically Letterpress papers are thick and soft to allow the type to create a deep impression. When fold-over items are created, the printer will typically back off on the pressure to avoid embossing the backside of the piece.

- Image and File Prep: Letterpress excels at line copy and type, so vector images work well. Crop marks should be shown as a register color. Images need to bleedBleed (printing)Bleed is a printing term that refers to printing that goes beyond the edge of the sheet after trimming. The bleed is the part on the side of a document that gives the printer a small amount of space to account for movement of the paper, and design inconsistencies...

(extend past the trim line). - Die cut, Emboss and Scores: These effects work well with most Letterpress paper. Images to be embossed or die cut should be called out in a different color layer (typically magenta). Scores should be indicated with a cyan line. Any intricate shapes or patterns should be reviewed with the printer. For thick cover stocks many printers use a kiss cut rather than a score.

- EnvelopeEnvelopeAn envelope is a common packaging item, usually made of thin flat material. It is designed to contain a flat object, such as a letter or card....

s: It is best to print on the flap of a ready-made envelope. Other areas of the ready-made envelopes can be printed but bruising may occur on the other side of the envelope.

Current initiatives

Several dozen colleges and universities around the United States have either begun or re-activated programs teaching letterpress printing in fully equipped facilities. In many cases these letterpress shops are affiliated with the college's library or art department, and in others they are independent, student-run operations or extracurricular activities sponsored by the college. Many are included in degree programs. The College & University Letterpress Printers' Association (CULPA) was founded in 2006 by Abigail Uhteg at the Maryland Institute College of Art in order to help these schools stay connected and share resources.The current renaissance of letterpress printing has created a crop of hobby press shops that are owner-operated and driven by a love of the craft. Several larger printers have added an environmental component to the venerable art by using only wind-generated electricity to drive their presses and plant equipment.

More notable are a few small boutique letterpress shops that are going 100% solar power.

In London, St Bride Library

St Bride Library

St Bride Library is a library in London primarily devoted to printing, book arts, typography and graphic design...

houses a large collection of letterpress information in its collection of 50,000 books: all the classic works on printing technique, visual style, typography, graphic design, calligraphy and more. This is one of the world's foremost collections and is located off Fleet Street in the heart of London's old printing and publishing district. In addition, regular talks, conferences, exhibitions and demonstrations take place.

The St Bride Institute, Edinburgh College of Art

Edinburgh College of Art

Edinburgh College of Art is an art school in Edinburgh, Scotland, providing tertiary education in art and design disciplines for over two thousand students....

, Central Saint Martins College of Art and Design

Central Saint Martins College of Art and Design

Central Saint Martins College of Art and Design is a constituent college of the University of the Arts London. The school has an outstanding international reputation, and is considered one of the world's leading art and design institutions...

, The Arts University College at Bournemouth, University for the Creative Arts Farnham and London College of Communication, run short courses in letterpress as well as offering these facilities as part of their Graphic Design Degree Courses.

The Hamilton Wood Type and Printing Museum

Hamilton Wood Type and Printing Museum

The Hamilton Wood Type and Printing Museum was founded in the year 2000 and is located in Two Rivers, Wisconsin, USA. The museum is run by the Two Rivers Historical Society. It is dedicated to the preservation, study, production and printing of wood type used in letterpress printing...

in Two Rivers, Wisconsin

Two Rivers, Wisconsin

Two Rivers is a city in Manitowoc County, Wisconsin, United States. The population was 11,712 at the 2010 census. It is the birthplace of the ice cream sundae...

houses one of the largest collections of wood type and wood cuts in the world inside one of the Hamilton Manufacturing Company's factory buildings. Also included are presses and vintage prints. The museum hold many workshops and conferences throughout the year and regularly welcomes groups of students from Universities from across the United States.

Manufacturers

- VandercookVandercookVandercook & Sons was a manufacturer of proof presses, founded in 1909 by Robert Vandercook. They dominated the 20th century proof press industry by developing the first and the most widely used proof presses that did not rely on gravity for the force of their impression...

- Chandler & PriceChandler & PriceChandler and Price was founded in 1881 in Cleveland, Ohio, by Harrison T. Chandler and William H. Price. They manufactured machinery for printers including a series of hand-fed platen jobbing presses, as well as an automatic feeder for these presses , paper cutters, book presses, and assorted...

- Kelsey

- HeidelbergHeidelberger DruckmaschinenHeidelberger Druckmaschinen AG is a German precision mechanical engineering company with head offices in Heidelberg . It is a manufacturer of offset printing presses sold globally. The company has a worldwide market share of more than 47% in this area and is the largest global manufacturer of...

- Adana Printing PressesAdana Printing MachinesThe hugely popular Adana Printing presses were manufactured from 1922–1999, in Twickenham, England. Although most of the presses produced by Adana were aimed at hobby printers, they were frequently put to commercial use...

Further reading

- Blumenthal, Joseph. (1973) Art of the printed book, 1455–1955.

- Blumenthal, Joseph. (1977) The Printed Book in America.

- Jury, David (2004). Letterpress: The Allure of the Handmade.

- Lange, Gerald. (1998) Printing digital type on the hand-operated flatbed cylinder press.

- Ryder, John (1977), "Printing for Pleasure, A Practical Guide for Amateurs"

- Stevens, Jen. (2001). Making Books: Design in British Publishing since 1940.

- Ryan, David. (2001). Letter Perfect: The Art of Modernist Typography, 1896–1953.

- Drucker, JohannaJohanna DruckerJohanna Drucker is an author, book artist, visual theorist, and cultural critic. Her scholarly writing documents and critiques visual language: letterforms, typography, visual poetry, art, and lately, digital aesthetics...

. (1997). The Visible Word : Experimental Typography and Modern Art, 1909–1923. - Auchincloss, Kenneth. "The Second Revival: Fine Printing since World War II". In Printing History No. 41: pp. 3–11.

- Cleeton, Glen U. & Pitkin, Charles W. with revisions by Cornwell, Raymond L. . (1963) "General Printing - An illustrated guide to letterpress printing, with hundreds of step-by-step photos".

External links

- Letterpress from LetterArt Printing Studio - examples

- Introduction to Letterpress Printing

- Bibliography of Letterpress Printing

- College & University Letterpress Printers' Association

- The British Printing Society

- British Letterpress: information for hobby printers, and specific UK letterpress machines

- The Fine Press Book Association

- The Letterpress Listserv Archives

- Capitol Press: Preparing files for Letterpress

- Early Rollers and Composition Rollers

- Letterpress in pictures

- Letterpress Studio Directory