Lockstitch

Encyclopedia

Stitch (textile arts)

In the textile arts, a stitch is a single turn or loop of thread or yarn. Stitches are the fundamental elements of sewing, knitting, embroidery, crochet, and needle lace-making, whether by hand or machine...

made by a sewing machine

Sewing machine

A sewing machine is a textile machine used to stitch fabric, cards and other material together with thread. Sewing machines were invented during the first Industrial Revolution to decrease the amount of manual sewing work performed in clothing companies...

. The term "single needle stitching", often found on dress shirt labels, refers to lockstitch.

Structure

Yarn

Yarn is a long continuous length of interlocked fibres, suitable for use in the production of textiles, sewing, crocheting, knitting, weaving, embroidery and ropemaking. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or...

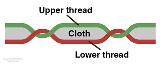

s, an upper and a lower. Lockstitch is so named because the two threads, upper and lower, "lock" (entwine) together in the hole in the fabric which they pass through. The upper thread runs from a spool

Spool

Spool can mean one of the following:*Spool, a usually low-flanged or unflanged cylinder on which thread, wire, cable, paper, film, or tape is wound for distribution or use....

kept on a spindle on top of or next to the machine, through a tension mechanism, through the take-up arm, and finally through the hole in the needle

Sewing needle

A sewing needle is a long slender tool with a pointed tip. The first needles were made of bone or wood; modern ones are manufactured from high carbon steel wire, nickel- or 18K gold plated for corrosion resistance. The highest quality embroidery needles are plated with two-thirds platinum and...

. Meanwhile the lower thread is wound onto a bobbin

Bobbin

A bobbin is a spindle or cylinder, with or without flanges, on which wire, yarn, thread or film is wound. Bobbins are typically found in sewing machines, cameras, and within electronic equipment....

, which is inserted into a case in the lower section of the machine below the material.

To make one stitch, the machine lowers the threaded needle

Sewing machine needle

A sewing machine needle consists of:* shank - clamped by the sewing machine's needle holder* shoulder - where the thick shank tapers down to the shaft...

through the cloth into the bobbin area, where a rotating hook

Rotary hook

The rotary hook is a bobbin driver design used in lockstitch sewing machines of the 19th and 20th century and beyond. It triumphed over competing designs because it can run at higher speeds with less vibration.-Operation:...

(or other hooking mechanism

Bobbin drivers

Throughout history, lockstitch sewing machines have used a variety of methods to drive their bobbins so as to create the lockstitch.-"Rotating shuttle":...

) catches the upper thread at the point just after it goes through the needle. The hook mechanism carries the upper thread entirely around the bobbin case, so that it has made one wrap of the bobbin thread. Then the take-up arm pulls the excess upper thread (from the bobbin area) back to the top, forming the lockstitch. Then the feed dogs

Feed dogs

Feed dogs are the critical component of a "drop feed" sewing machine. A set of feed dogs typically resembles two or three short, thin metal bars, crosscut with diagonal teeth, which move back and forth in slots in a sewing machine's needle plate...

pull the material along one stitch length, and the cycle repeats.

Ideally, the lockstitch is formed in the center of the thickness of the material—that is to say: ideally the upper thread entwines the lower thread in the middle of the material. The thread tension mechanisms, one for the upper thread and one for the lower thread, prevent either thread from pulling the entwine point from out of the middle of the material.

Geometry

The geometry of the lockstitch is controlled by the presence or absence of:- sideways movements of the machine's needle, and

- backwards movements of the machine's feed dogsFeed dogsFeed dogs are the critical component of a "drop feed" sewing machine. A set of feed dogs typically resembles two or three short, thin metal bars, crosscut with diagonal teeth, which move back and forth in slots in a sewing machine's needle plate...

.

In older machines, the needle and feed motion is controlled by mechanical cams. Some modern household machines offer a slot for user-replaceable custom stitch cams. In more recent designs, the needle and feed motion are directly motorized.

Straight

Straight stitch geometry is produced when the needle has no sideways movements and when the feed dogs are following only in the normal forward "four motion" movement.Because its two threads run straight and parallel, a straight stitch is not natively stretchable.

Zigzag

Zigzag stitch geometry is produced when the needle moves rhythmically side to side while sitching, while the feed dogs are following only in the normal forward "four motion" movement. Most lockstitch machines are capable of doing this.Zigzag stitches are used when a stretchable stitch is required, such as when sewing stretchy fabrics.

Blind

Blind stitch geometry is a derivative of the zigzag. It is created in the same manner, except that the needle zigs to the side and then zags back only once every fourth or fifth stitch. It is used to reduce the visibility of hems and other seam edges.Stretch

Stretch stitch geometry is specifically for stretchability. While the needle is moving, as for straight or zigzag stitches, the feed dogs automatically moving the fabric forward and backward. As with zigzag stitches, stretch stitching is controlled by mechanical cams, but because of the dual action, stretch stitch machines have double cams. As the double cam rotates, the first follower rides along one track to move the needle bar from side to side, while the second follower rides along a different track to move the feed dogs forward and reverse.Decorative

By adding controlled motion of the material being sewn through an additional set of motors, arbitrary customized patterns of 100 cm or more in each direction can be sewn, opening the door to the very popular category of programmable household embroidery machines.Home

Most home sewing machines are lockstitch machines, although overlockOverlock

An overlock stitch sews over the edge of one or two pieces of cloth for edging, hemming or seaming. Usually an overlock sewing machine will cut the edges of the cloth as they are fed through , though some are made without cutters...

ers (aka sergers) have entered the home market in the past ten years or so.

Industrial

Of a typical garment factory's sewing machines, half might be lockstitch machines and the other half divided between overlockOverlock

An overlock stitch sews over the edge of one or two pieces of cloth for edging, hemming or seaming. Usually an overlock sewing machine will cut the edges of the cloth as they are fed through , though some are made without cutters...

machines, chain stitch

Chain stitch

Chain stitch is a sewing and embroidery technique in which a series of looped stitches form a chain-like pattern. Chain stitch is an ancient craft - examples of surviving Chinese chain stitch embroidery worked in silk thread have been dated to the Warring States period...

machines, and various other specialized machines.

Industrial lockstitch machines with two needles, each forming an independent lockstitch with their own bobbin, are also very common. There are different types of lockstitch industrial machines. The most commonly used are the drop feed for light and medium duty, and walking foot for medium and heavy duty like the Class 7 with an impressive 3/4" foot lift. This makes the Class 7 able to stitch through heavy materials up to 3/4" with threads as strong as 57 lbs. Originally made by Singer in the US and Europe for supplying the demand of heavy duty clothing for the troops, for many years after the war this class was not available as new because the market was filled. With the outsourcing of many sewing manufacturing jobs, nowadays many Chinese Class 7 machines are available and built by Federal Specifications giving them equal performance as the original ones (FSN:3530-3111-1556, FSN: 3530-3111-3675, FSN: 3530-311-1556, FSN: 3530-3111-3075).either crosses through loops of itself (single thread) or loops of the second thread to prevent it from pulling back to the top of the material.

Most industrial lockstitch machines sew only a straight line of stitches. Industrial zig-zag machines are available, but uncommon, and there are essentially no fancy-pattern stitching industrial machines other than dedicated embroidery and edge decoration machines. Even something as simple as a bar-tack or a buttonhole stitch is usually done by a dedicated machine incapable of doing anything else. When a variety of decorative stitching is required rather than a single stitch, a "commercial" machine (basically a heavy duty household machine) is usually employed.