Particle counter

Encyclopedia

Applications of particle counters are separated into three primary categories:

- Aerosol particle counters

- Liquid particle counters

Aerosol particle counters

Aerosol Particle Counters are used to determine the air quality by counting and sizing the number of particles in the air. This information is useful in determining the amount of particles inside a building or in the ambient air. It also is useful in understanding the cleanliness level in a controlled environment. A common controlled environment aerosol particle counters are used is a cleanroomCleanroom

A cleanroom is an environment, typically used in manufacturing or scientific research, that has a low level of environmental pollutants such as dust, airborne microbes, aerosol particles and chemical vapors. More accurately, a cleanroom has a controlled level of contamination that is specified by...

. Cleanrooms are used extensively in semiconductor manufacturing, biotechnology

Biotechnology

Biotechnology is a field of applied biology that involves the use of living organisms and bioprocesses in engineering, technology, medicine and other fields requiring bioproducts. Biotechnology also utilizes these products for manufacturing purpose...

, pharmaceutical, disk drive, aerospace

Aerospace

Aerospace comprises the atmosphere of Earth and surrounding space. Typically the term is used to refer to the industry that researches, designs, manufactures, operates, and maintains vehicles moving through air and space...

and other fields that are very sensitive to environmental contamination. Cleanrooms have defined particle count limits. Aerosol particle counters are used to test and classify a cleanroom to ensure its performance is up to a specific cleanroom classification standard. Several standards exist for cleanroom classification. The most frequently referred to classification is from the United States. Though originating in the United States, the standard Federal Standard 209E

FED-STD-209E

FED-STD-209 E Airborne Particulate Cleanliness Classes in Cleanrooms and Cleanzones was canceled on November 29, 2001 by the U.S. General Services Administration...

was the first and most commonly referred to. This standard was replaced in 1999 by an international standard, however Federal Standard 209E

FED-STD-209E

FED-STD-209 E Airborne Particulate Cleanliness Classes in Cleanrooms and Cleanzones was canceled on November 29, 2001 by the U.S. General Services Administration...

remains today the most widely referenced standard in the world.

US FED STD 209EFED-STD-209EFED-STD-209 E Airborne Particulate Cleanliness Classes in Cleanrooms and Cleanzones was canceled on November 29, 2001 by the U.S. General Services Administration...

cleanroom standards

| Particles/ft³ | ||||||

| Class | 0.1 µm | 0.2 µm | 0.3 µm | 0.5 µm | 1 µm | 5 µm |

| 1 | 35 | 7 | 3 | 1 | ||

| 10 | 350 | 75 | 30 | 10 | 1 | |

| 100 | 3500 | 750 | 300 | 100 | 10 | 1 |

| 1,000 | 1,000 | 100 | 10 | |||

| 10,000 | 10,000 | 1,000 | 100 | |||

| 100,000 | 100,000 | 10,000 | 1,000 |

The Replacement standard is ISO 14644-1 and is meant to completely replace Federal Standard 209E

FED-STD-209E

FED-STD-209 E Airborne Particulate Cleanliness Classes in Cleanrooms and Cleanzones was canceled on November 29, 2001 by the U.S. General Services Administration...

. This ISO Standard can be found through the non-profit organization, IEST. Each of these standards represents the maximum allowable number of particles in a unit of air. The typical unit is either cubic feet or cubic meters. The particle counts are always listed as cumulative.

ISO 14644-1 cleanroom standards

| particle/m³ | ||||||

| Class | 0.1 µm | 0.2 µm | 0.3 µm | 0.5 µm | 1.0 µm | 5.0 µm |

| ISO 1 | 10 | 2 | ||||

| ISO 2 | 100 | 24 | 10 | 4 | ||

| ISO 3 | 1,000 | 237 | 102 | 35 | 8 | |

| ISO 4 | 10,000 | 2,370 | 1,020 | 352 | 83 | |

| ISO 5 | 100,000 | 23,700 | 10,200 | 3,520 | 832 | 29 |

| ISO 6 | 1,000,000 | 237,000 | 102,000 | 35,200 | 8,320 | 293 |

| ISO 7 | 352,000 | 83,200 | 2,930 | |||

| ISO 8 | 3,520,000 | 832,000 | 29,300 | |||

| ISO 9 | 35,200,000 | 8,320,000 | 293,000 |

Cleanroom class comparison

| ISO 14644-1 | FED STD 209E |

| ISO 3 | 1 |

| ISO 4 | 10 |

| ISO 5 | 100 |

| ISO 6 | 1,000 |

| ISO 7 | 10,000 |

| ISO 8 | 100,000 |

Liquid particle counters

Liquid Particle Counters are used to determine the quality of the liquid passing through them. The size and number of particles can determine if the liquid is clean enough to be used for the designed application. Liquid particle counters can be used to test the quality of drinking waterDrinking water

Drinking water or potable water is water pure enough to be consumed or used with low risk of immediate or long term harm. In most developed countries, the water supplied to households, commerce and industry is all of drinking water standard, even though only a very small proportion is actually...

or cleaning solutions, or the cleanliness of power generation equipment, manufacturing parts, or injectable drugs

Injection (medicine)

An injection is an infusion method of putting fluid into the body, usually with a hollow needle and a syringe which is pierced through the skin to a sufficient depth for the material to be forced into the body...

.

Liquid particle counters are also used to determine the cleanliness level of hydraulic fluids, the reason being that 75-80% of hydraulic breakdowns can be attributed to contamination. There are various types, installed on the equipment, or portable units that can be transported to site ( e.g. a construction site) and then used on the machine ( e.g. a bulldozer) to determine fluid cleanliness. By determining and monitoring these levels, and following a pro-active or predictive maintenance program, the user can reduce hydraulic failures, increase uptime and machine availability, and to reduce oil consumption. They can also be used to assure that hydraulic fluids have been cleaned using filtration, to acceptable or target cleanliness levels. There are various standards in use in the hydraulic industry, of which ISO 4406:1999, NAS1638 and SAE AS 4059 are probably the most common.

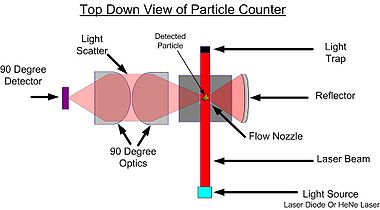

Detection methods

There are several methods used for detecting and measuring particle size or size distribution (though many exist); Light Blocking (obscuration), Light Scattering, coulter principle and direct imaging.The Light Blocking optical particle counter method is typical useful for detecting and sizing particles greater than 1 micrometer

Micrometer

A micrometer , sometimes known as a micrometer screw gauge, is a device incorporating a calibrated screw used widely for precise measurement of small distances in mechanical engineering and machining as well as most mechanical trades, along with other metrological instruments such as dial, vernier,...

in size and is based upon the amount of light a particle blocks when passing through the detection area of the particle counter. This type of technique allows high resolution and reliable measurement.

The Light Scattering

Scattering

Scattering is a general physical process where some forms of radiation, such as light, sound, or moving particles, are forced to deviate from a straight trajectory by one or more localized non-uniformities in the medium through which they pass. In conventional use, this also includes deviation of...

Method is capable of detecting smaller sizing particles. This technique is based upon the amount of light that is redirected by a particle passing through the detection area of the particle counter. This redirection is referred to as light scattering

Scattering

Scattering is a general physical process where some forms of radiation, such as light, sound, or moving particles, are forced to deviate from a straight trajectory by one or more localized non-uniformities in the medium through which they pass. In conventional use, this also includes deviation of...

. Typical detection sensitivity of the Light Scattering method is 0.05 micrometre or larger. However, employment of the condensation nuclei counter (CNC) technique would allow a higher detection sensitivity in particle sizes down to nanometer range. A typical application is monitoring of ultrapure water in semiconductor fabs.

The light blocking method is specified for particle counters that are used for counting in hydraulic and lubricating fluids. Particle counters are used here to measure contamination of hydraulic oil, and therefore allow the user to maintain their hydraulic system, reduce breakdowns, schedule maintenance during no or slow work periods, monitor filter performance etc. Particle counters used for this purpose typically use ISO Standard 4406:1999 as their reporting standard, and ISO Standard 11171 as the calibration standard. Others also in use are NAS 1638 and its successor SAE AS4059D.

Direct imaging is a technique that uses the light emitted by a laser as a source to illuminate a cell where particle are passing through. The technique does not measures the light blocked by the particles but rather measures the area of the particles functioning like an automated microscope. A pulsed laser diode freezes the particle motion. The light transmitted through the fluid is imaged onto an electronic camera with macro focusing optics. The particles in the sample will block the light and the resulting silhouettes will be imaged

onto the digital camera chip.

Remote Particle Counters

Small particle counters that are used to monitor a fixed location typically inside a cleanroom or Minienvironment to continuously monitor particle levels 24 hours / day seven days a week. These smaller counters typically do not have a local display and are connected to a network of other particle counters and other types of sensors to monitoring the overall cleanroom performance. This network of sensors is typically connected to a facility monitoring system (FMS), data acquisitionData acquisition

Data acquisition is the process of sampling signals that measure real world physical conditions and converting the resulting samples into digital numeric values that can be manipulated by a computer. Data acquisition systems typically convert analog waveforms into digital values for processing...

system or programmable logic controller

Programmable logic controller

A programmable logic controller or programmable controller is a digital computer used for automation of electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or light fixtures. PLCs are used in many industries and machines...

.

This computer based system can integrate into a database, alarming and may have e-mail capability to notify facility or process personnel when conditions inside the cleanroom have exceeded predetermined environmental limits. Remote particle counters are available in several different configurations, from single channel to models that detect up to 8 channels simultaneously. Remote particle counters can have a particle size detection range from 0.1 to 100 micrometres and may feature one of a variety of output options including 4-20 mA, RS-485 Modbus

Modbus

Modbus is a serial communications protocol published by Modicon in 1979 for use with its programmable logic controllers . Simple and robust, it has since become one of the de facto standard communications protocols in the industry, and it is now amongst the most commonly available means of...

, ethernet and pulse output.

Manifold particle counters

Modified aerosol portable particle counter that has been attached to a sequencing sampling system. The sequencing sampling system allows for one particle counter to sample multiple locations, via a series of tubes drawing air from up to 32 locations inside a cleanroom. Typically less expensive then utilizing remote particle counters, however each tube is monitored in sequence.Handheld particle counters

Small self contained particle counter that is easily transported and used. Though lower flow rates of 0.1 ft³/min (CFM) (0.2 m³/h) than larger portables with 1 ft³/m (2 m³/h), handhelds are useful for most of the same applications. However longer sample times may be required when doing cleanroomCleanroom

A cleanroom is an environment, typically used in manufacturing or scientific research, that has a low level of environmental pollutants such as dust, airborne microbes, aerosol particles and chemical vapors. More accurately, a cleanroom has a controlled level of contamination that is specified by...

certification and testing. Most handheld particle counters have direct mount isokinetic sampling probes. You may use a barbed probe on a short piece of sample tubing, but it is recommended that the length of the tubing not exceed 6 ft (1.8 m), due to loss of larger particles in the sample tubing.