Regenerative heat exchanger

Encyclopedia

A regenerative heat exchanger, or more commonly a regenerator, is a type of heat exchanger

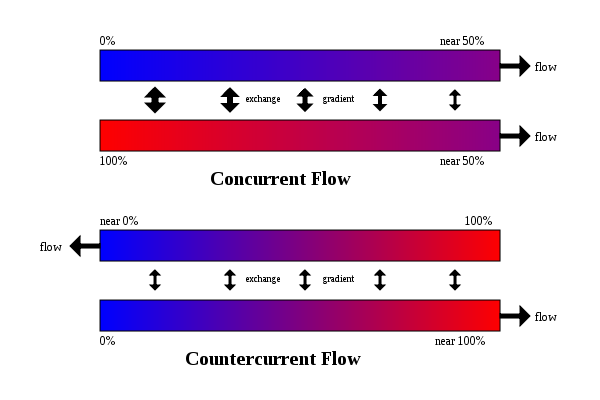

where the flow through the heat exchanger is cyclical and periodically changes direction. It is similar to a countercurrent heat exchanger

. However, a regenerator mixes the two fluid flows while a countercurrent exchanger maintains them separated. The temperature profile remains at a nearly constant temperature, and this includes the fluid entering and exiting each end.

In regenerative heat exchangers, the fluid on either side of the heat exchanger is nearly always the same fluid. The fluid is cycled through the heat exchanger, often reaching high temperatures. The fluid may go through an external processing step, and then it is flowed back through the heat exchanger in the opposite direction for further processing. Usually the application will use this process cyclically or repetitively. Thus, in regenerative heat exchangers, a fluid incoming to a process is heated using the energy contained in the fluid exiting this process.

In regenerative heat exchangers, the fluid on either side of the heat exchanger is nearly always the same fluid. The fluid is cycled through the heat exchanger, often reaching high temperatures. The fluid may go through an external processing step, and then it is flowed back through the heat exchanger in the opposite direction for further processing. Usually the application will use this process cyclically or repetitively. Thus, in regenerative heat exchangers, a fluid incoming to a process is heated using the energy contained in the fluid exiting this process.

The regenerative heat exchanger gives a considerable net savings in energy, since most of the heat energy is reclaimed nearly in a thermodynamically reversible way. This type of heat exchanger can have a thermal efficiency of over 90%, transferring almost all the relative heat energy from one flow direction to the other. Only a small amount of extra heat energy needs to be added at the hot end, and dissipated at the cold end, even to maintain very high or very low temperatures.

in 1816, and is commonly found as a component of his Stirling engine

. The simplest Stirlings, and most models, use a less efficient but simpler to construct, displacer instead.

In a fixed matrix regenerator, a single fluid stream has cyclical, reversible flow; it is said to flow "counter-current". This regenerator may be part of a valve

less system, such as a Stirling engine

. In another configuration, the fluid is ducted through valves to different matrices in alternate operating periods Ph and Pc resulting in outlet temperatures that vary with time.

Another type of regenerator is called a micro scale regenerative heat exchanger. It has a multilayer grating structure in which each layer is offset from the adjacent layer by half a cell which has an opening along both axes perpendicular to the flow axis. Each layer is a composite structure of two sublayers, one of a high thermal conductivity material and another of a low thermal conductivity material. When a hot fluid flows through the cell, heat from the fluid is transferred to the cell wells, and stored there. When the fluid flow reverses direction, heat is transferred from the cell walls back to the fluid.

A third type of regenerator is called a "Rothemuhle" regenerator. This type has a fixed matrix in a disk shape, and streams of fluid are ducted through rotating hoods. The Rothemuhle regenerator is used as an air preheater in some power generating plants. The thermal design of this regenerator is the same as of other types of regenerators.

and low thermal conductivity

in the longitudinal (flow) direction. At cryogenic (very low) temperatures around 20 K

, the specific heat of metals are low, and so a regenerator must be larger for a given heat load.

The design of inlet and outlet headers used to distribute hot and cold fluids in the matrix is much simpler in counter flow regenerators than recuperators. The reason behind this is that both streams flow in different sections for a rotary regenerator and one fluid enters and leaves one matrix at a time in a fixed-matrix regenerator. Furthermore flow sectors for hot and cold fluids in rotary regenerators can be designed to optimize pressure drop in the fluids. The matrix surfaces of regenerators also have self-cleaning characteristics, reducing fluid-side fouling and corrosion. Finally properties such as small surface density and counter-flow arrangement of regenerators make it ideal for gas-gas heat exchange applications requiring effectiveness exceeding 85%. The heat transfer coefficient is much lower for gases than for liquids, thus the enormous surface area in a regenerator greatly increases heat transfer.

Heat exchanger

A heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact...

where the flow through the heat exchanger is cyclical and periodically changes direction. It is similar to a countercurrent heat exchanger

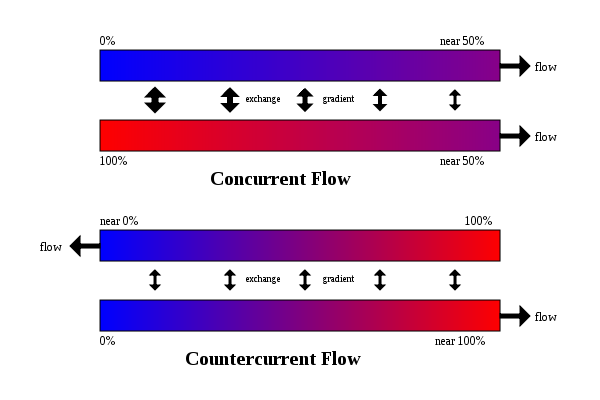

Countercurrent exchange

Countercurrent exchange is a mechanism occurring in nature and mimicked in industry and engineering, in which there is a crossover of some property, usually heat or some component, between two flowing bodies flowing in opposite directions to each other. The flowing bodies can be liquids, gases, or...

. However, a regenerator mixes the two fluid flows while a countercurrent exchanger maintains them separated. The temperature profile remains at a nearly constant temperature, and this includes the fluid entering and exiting each end.

The regenerative heat exchanger gives a considerable net savings in energy, since most of the heat energy is reclaimed nearly in a thermodynamically reversible way. This type of heat exchanger can have a thermal efficiency of over 90%, transferring almost all the relative heat energy from one flow direction to the other. Only a small amount of extra heat energy needs to be added at the hot end, and dissipated at the cold end, even to maintain very high or very low temperatures.

History

The regenerator was invented by Rev. Robert StirlingRobert Stirling

The Reverend Dr Robert Stirling was a Scottish clergyman, and inventor of the stirling engine.- Biography :Stirling was born at Cloag Farm near Methven, Perthshire, the third of eight children...

in 1816, and is commonly found as a component of his Stirling engine

Stirling engine

A Stirling engine is a heat engine operating by cyclic compression and expansion of air or other gas, the working fluid, at different temperature levels such that there is a net conversion of heat energy to mechanical work....

. The simplest Stirlings, and most models, use a less efficient but simpler to construct, displacer instead.

Types of regenerators

In rotary regenerators the matrix rotates continuously through two counter-flowing streams of fluid. In this way, the two streams are mostly separated but the seals are generally not perfect. Only one stream flows through each section of the matrix at a time; however, over the course of a rotation, both streams eventually flow through all sections of the matrix in succession. Each portion of the matrix will be nearly isothermal, since the rotation is perpendicular to both the temperature gradient and flow direction, and not through them. The two fluid streams flow counter-current. The fluid temperatures vary across the flow area; however the local stream temperatures are not a function of time.In a fixed matrix regenerator, a single fluid stream has cyclical, reversible flow; it is said to flow "counter-current". This regenerator may be part of a valve

Valve

A valve is a device that regulates, directs or controls the flow of a fluid by opening, closing, or partially obstructing various passageways. Valves are technically pipe fittings, but are usually discussed as a separate category...

less system, such as a Stirling engine

Stirling engine

A Stirling engine is a heat engine operating by cyclic compression and expansion of air or other gas, the working fluid, at different temperature levels such that there is a net conversion of heat energy to mechanical work....

. In another configuration, the fluid is ducted through valves to different matrices in alternate operating periods Ph and Pc resulting in outlet temperatures that vary with time.

Another type of regenerator is called a micro scale regenerative heat exchanger. It has a multilayer grating structure in which each layer is offset from the adjacent layer by half a cell which has an opening along both axes perpendicular to the flow axis. Each layer is a composite structure of two sublayers, one of a high thermal conductivity material and another of a low thermal conductivity material. When a hot fluid flows through the cell, heat from the fluid is transferred to the cell wells, and stored there. When the fluid flow reverses direction, heat is transferred from the cell walls back to the fluid.

A third type of regenerator is called a "Rothemuhle" regenerator. This type has a fixed matrix in a disk shape, and streams of fluid are ducted through rotating hoods. The Rothemuhle regenerator is used as an air preheater in some power generating plants. The thermal design of this regenerator is the same as of other types of regenerators.

Biology

We use our nose and throat as a regenerative heat exchanger when we breathe. The cooler air coming in is warmed, so that it reaches the lungs as warm air. On the way back out, this warmed air deposits much of its heat back onto the sides of the nasal passages, so that these passages are then ready to warm the next batch of air coming in.Cryogenics

Regenerator heat exchangers are made up of materials with high volumetric heat capacityHeat capacity

Heat capacity , or thermal capacity, is the measurable physical quantity that characterizes the amount of heat required to change a substance's temperature by a given amount...

and low thermal conductivity

Thermal conductivity

In physics, thermal conductivity, k, is the property of a material's ability to conduct heat. It appears primarily in Fourier's Law for heat conduction....

in the longitudinal (flow) direction. At cryogenic (very low) temperatures around 20 K

Kelvin

The kelvin is a unit of measurement for temperature. It is one of the seven base units in the International System of Units and is assigned the unit symbol K. The Kelvin scale is an absolute, thermodynamic temperature scale using as its null point absolute zero, the temperature at which all...

, the specific heat of metals are low, and so a regenerator must be larger for a given heat load.

Advantages of regenerators

The advantages of a regenerator over a recuperating (counter-flowing) heat exchanger is that it has a much higher surface area for a given volume, which provides a reduced exchanger volume for a given energy density, effectiveness and pressure drop. This makes a regenerator more economical in terms of materials and manufacturing, compared to an equivalent recuperator.The design of inlet and outlet headers used to distribute hot and cold fluids in the matrix is much simpler in counter flow regenerators than recuperators. The reason behind this is that both streams flow in different sections for a rotary regenerator and one fluid enters and leaves one matrix at a time in a fixed-matrix regenerator. Furthermore flow sectors for hot and cold fluids in rotary regenerators can be designed to optimize pressure drop in the fluids. The matrix surfaces of regenerators also have self-cleaning characteristics, reducing fluid-side fouling and corrosion. Finally properties such as small surface density and counter-flow arrangement of regenerators make it ideal for gas-gas heat exchange applications requiring effectiveness exceeding 85%. The heat transfer coefficient is much lower for gases than for liquids, thus the enormous surface area in a regenerator greatly increases heat transfer.

Disadvantages of regenerators

The major disadvantage of a regenerator is that there is always some mixing of the fluid streams, and they can not be completely separated. There is an unavoidable carryover of a small fraction of one fluid stream into the other. In the rotary regenerator, the carryover fluid is trapped inside the radial seal and in the matrix, and in a fixed-matrix regenerator, the carryover fluid is the fluid that remains in the void volume of the matrix. This small fraction will mix with the other stream in the following half-cycle. Therefore regenerators are only used when it is acceptable for the two fluid streams to be mixed. Mixed flow is common for gas-to-gas heat and/or energy transfer applications, and less common in liquid or phase-changing fluids since fluid contamination is often prohibited with liquid flows.See also

- Countercurrent exchangeCountercurrent exchangeCountercurrent exchange is a mechanism occurring in nature and mimicked in industry and engineering, in which there is a crossover of some property, usually heat or some component, between two flowing bodies flowing in opposite directions to each other. The flowing bodies can be liquids, gases, or...

- EconomizerEconomizerEconomizers , or economisers , are mechanical devices intended to reduce energy consumption, or to perform another useful function such as preheating a fluid. The term economizer is used for other purposes as well. Boiler, powerplant, and heating, ventilating, and air-conditioning uses are...

- Heat exchangerHeat exchangerA heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact...

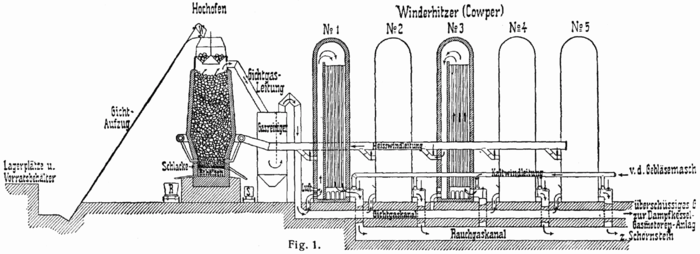

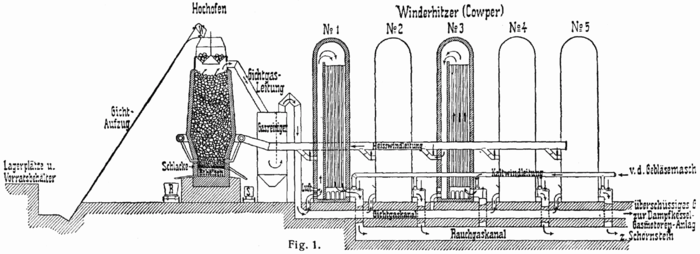

- Hot blastHot blastHot blast refers to the preheating of air blown into a blast furnace or other metallurgical process. This has the result of considerably reducing the fuel consumed in the process...

- RecuperatorRecuperatorA recuperator is a special purpose counter-flow energy recovery heat exchanger positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, in order to recover the waste heat...

- desalinationDesalinationDesalination, desalinization, or desalinisation refers to any of several processes that remove some amount of salt and other minerals from saline water...

- some thermal desalination plants use regenerative heat exchangers