SR Leader Class

Encyclopedia

The Leader was a class of experimental 0-6-6-0

T articulated steam locomotive

, produced in the United Kingdom to the design of the innovative engineer Oliver Bulleid

. The Leader was an attempt to extend the life of steam traction by eliminating many of the operational drawbacks associated with existing steam locomotives. It was intended as a replacement for the ageing fleet of M7 class

tank engines still in operation on the Southern Railway (SR). Design work began in 1946 and development continued after the nationalisation of the railways in 1948, under the auspices of British Railways (BR).

The Leader project was part of Bulleid's desire to modernise the steam locomotive based on experience gained with the Southern Railway's fleet of electric stock. Bulleid considered that attitudes towards the labour-intensity of steam operation had changed during the post-war period, favouring dieselisation

and electrification

. In an effort to demonstrate the continued potential of steam, Bulleid pushed forward the boundaries of steam-power, allowing it to compete with diesel and electric locomotives in terms of labour-saving and ease of operation.

The design incorporated many novel features, such as the use of thermic siphons, bogies and cabs at either end of the locomotive, resulting in its unique—for a steam locomotive—modern diesel-like appearance. Several of its innovations proved to be unsuccessful however, partly accounting for the project's cancellation in the early 1950s. Five Leader locomotives were begun, although only one was completed. The operational locomotive was trialled on the former Southern Railway network around Brighton

. Problems with the design, indifferent reports on performance and political pressure surrounding spiralling development costs, led to all locomotives of the class being scrapped by 1951.

wheel arrangement had an unacceptably high axle-loading of 20 tons (20.4 tonnes), which increased the risk of damaging the Southern Railway's track. By developing the proposal further, Bulleid settled for a 0-6-6-0T design of bogied locomotive, which spread the weight more evenly over the rails and reduced the axle-loading.

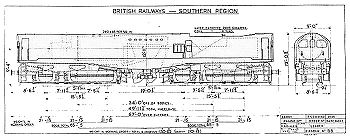

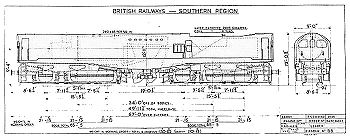

A series of initial ideas were presented to the Southern Railway management by Bulleid that incorporated double-ended running, giving the locomotive driver maximum visibility in either direction without a boiler

A series of initial ideas were presented to the Southern Railway management by Bulleid that incorporated double-ended running, giving the locomotive driver maximum visibility in either direction without a boiler

or tender

obscuring his view. The need for a turntable

to turn the locomotive around was therefore eliminated, although the initial designs were rejected by the operating department because of problems with welding technique. The accepted design included two 0-6-0

steam bogies with weight-saving sleeve valve

s and chains to couple the driving axles. The boiler was offset to provide space for a communication corridor, allowing the driver to access both cabs without leaving the locomotive, an arrangement which led to later problems. The firebox, near the centre of the locomotive, was fed by the fireman from a third cab, linked to both driving cabs by the communication corridor. The entire ensemble was placed on a common frame and thus often referred to as an 0-6-6-0T.

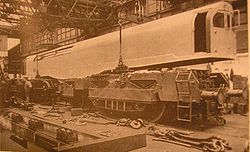

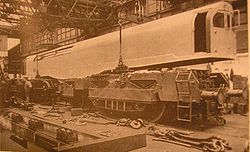

The Leader prototype was constructed at Brighton railway works

, work beginning in 1946. An initial order for five locomotives was placed straight from the drawing board in 1946 and a further 31 were ordered in 1947, although, with nationalisation looming, this was merely a gesture. The latter order was cancelled after the Southern Railway was taken into public ownership, to allow trials to be carried out on the prototype.

on his Pacific locomotives. The valve gear

used the unusual sleeve valve

arrangement that was also tested on the ex-LB&SCR H1 class

Hartland Point in parallel with the construction of the first Leader locomotive. The Leader was the first steam locomotive to use a form of sleeve valve since Cecil Paget

's locomotive of 1908

and the concurrent testing of the principle on Hartland Point hints at the rushed nature of the locomotive's conception. The locomotive sat on the unusual Bulleid-Firth-Brown

wheels, which were lighter, yet stronger, than the spoked equivalent.

The use of sleeve valves and oil baths to lubricate the moving parts of the engine units was inspired by contemporary internal combustion engine

practice. This included oscillating gear that gave a 25-degree axial movement to the sleeves, allowing even lubrication of the moving parts. However, this resulted in an over-complicated mechanism that was difficult to maintain, perpetuating the seizures it was meant to eradicate. This feature was removed from both bogies of the prototype as the trials progressed. Another innovative feature of the steam bogie assembly was the ability to interchange them when faults occurred, an easy operation for maintenance staff when compared to the complexities of overhauling a regular steam locomotive's motion.

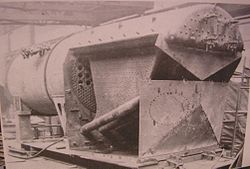

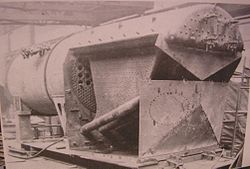

The three cylinders of each bogie were cast in mono-block format, each surrounded by two annular inlet steam chests and a single large outlet steam chest. These had the added function of keeping the cylinder heated by hot steam to maintain the temperature and pressure of steam entering the cylinders. However, these castings were difficult to machine accurately. The steam-sealing arrangements needed for this system were also complex, with each of the six cylinders and valve sleeves requiring 24 sealing rings.

The boiler was the culmination of lessons learned with the Pacifics and was a prolific steam-raiser. All Leader boilers were constructed at Eastleigh

The boiler was the culmination of lessons learned with the Pacifics and was a prolific steam-raiser. All Leader boilers were constructed at Eastleigh

, and proved to be the least problematic area of the entire design. The boiler pressure was set at 280 psi (1.93 MPa) and each was fitted with four thermic siphons within the firebox to increase the rate of evaporation and improve water circulation. These were previously used to great effect on Bulleid's Merchant Navy

and West Country and Battle of Britain class designs.

The Leader had a "dry lining" firebox; it was not surrounded on top and sides by a "jacket" of water as in normal practice. It was constructed of welded steel and used firebricks instead of water for insulation, which was a novel but troublesome solution to dry-lining the firebox. These had the effect of reducing the grate area from 47 ft2 to 25.5 ft2 and concentrated the fire in a smaller area. The firehole door was offset to the left of the boiler backhead and was to provide difficulty for the fireman to add coal to the fire. The firebox was not initially equipped with a firebrick arch, although one was retro-fitted during the summer of 1950. The arch was problematic as it promoted the tendency for flames to enter the cab at high outputs, a situation made worse by the narrowing of the firebox area.

The smokebox

had an inherent problem in maintaining a constant vacuum

. This was a result of another Bulleid labour-saving innovation, a sliding hatch controlled from the front cab that enabled ash to be cleaned out through a chute onto the track when on the move. The problem lay with ash manifesting itself around the edges of the slide, allowing air to leak into the smokebox, therefore reducing the overall efficiency of the locomotive. The fierce blast from the exhaust also meant that ash and embers were ejected into the atmosphere, creating a potential lineside fire hazard.

For ease of maintenance, the boiler, firebox and smokebox were encased in steel sheeting that resembled a modern diesel locomotive

, a major departure from traditional steam locomotive design, allowing the engine to be cleaned using a carriage-washing plant. The locomotive was designed to carry 4 tons (4.06 tonnes) of coal and 4000 gallons (18,184.4 l) of water with the coal bunker covered by a tarpaulin to prevent water ingress into the fireman's cab. Entry into the locomotive was by way of ladders leading up to sliding doors although, due to the bogie design, the climb into the fireman's cab necessitated clambering over the oilbath casing.

in July 1947. British Railways inherited the Leader project upon nationalisation in 1948, which was far enough advanced to continue constructing the prototype, as Bulleid was still Chief Mechanical Engineer of the newly formed Southern Region of British Railways

. Although work on the other four locomotives stalled, the prototype Leader emerged from Brighton as locomotive No. 36001 in June 1949.

The other four members of the initial order made by the Southern Railway, Nos. 36002–5, were at varying stages of construction by the end of the development period. No. 36002 was almost complete, No. 36003 was without its outer casing, and Nos. 36004–5 were little more than sets of frames, although most of their major components had been constructed at Eastleigh and Brighton and were stored ready for fitting. With no prospect of further money being allocated by the Railway Executive for their completion, the unfinished locomotives were put into store at various depots around the former Southern Railway network pending a decision on their future.

were "conspicuous by the absence of praise" for the strengths of the Leader, namely the boiler, braking system and total adhesion provided by the two bogies. Several theories have been put forward regarding this state of affairs, the most plausible being that the more conservative members of the railway workforce at Brighton and the Railway Executive felt that the Leader was too revolutionary and were keen to maintain the status quo.

Following trials that lasted over a year, No. 36001 was shown to have several flaws, including heavy coal and water consumption, mechanical unreliability, untenable working conditions for both fireman and driver, loss of steam through the cylinder rings and uneven weight distribution on the bogies. After renewing the cylinder assembly, it was tested around Brighton

Following trials that lasted over a year, No. 36001 was shown to have several flaws, including heavy coal and water consumption, mechanical unreliability, untenable working conditions for both fireman and driver, loss of steam through the cylinder rings and uneven weight distribution on the bogies. After renewing the cylinder assembly, it was tested around Brighton

and Eastleigh

using an LNER Dynamometer car

, where good running was experienced at high costs in fuel and effort on the part of the fireman. The Leader was tested against the performance of a U class control locomotive and indicated that the brake release was too slow in service for use on tight schedules despite the brake application being noted as the best used on a Bulleid design.

Throughout No. 36001's trials, the firebrick lining provided a constant problem by continually collapsing into the fire. The firebricks were then replaced with cast iron

substitutes that melted in the intense heat of the firebox, which were in turn replaced by thicker 9 inches (22.9 cm) firebricks. Some of the firemen allotted to the Leader complained about cramped conditions in the centre cab of the locomotive, a situation made worse by flames entering the cab from the firebox at high outputs. It was an enclosed space that was constantly hot and the single fireman's entrance door on the side of the locomotive was left open during travel to promote ventilation. The door into the fireman's cab also attracted criticism, as it would have been blocked in the event of the locomotive overturning on that side, preventing the fireman's escape, so that members of the railway trade union ASLEF

threatened to stop their crews from operating the Leader.

The offset boiler and coal bunker caused the locomotive's centre of gravity to be shifted to one side. Experiments had to be undertaken to balance the locomotive by filling the linking corridor with large quantities of scrap metal, replaced in a re-design by a raised floor covering weighted material. These modifications resulted in the engine exceeding the total weight limit of 150 tons (151 tonnes), severely limiting the design's route availability during testing. A related problem was that despite being a tall locomotive, at 12 in 11 in (3.94 m), the cab ceilings were relatively low. The cab at the smokebox end of the locomotive suffered from the same excessive heat as did the fireman's cab. To circumvent this problem the locomotive was used in reverse, as the rear cab was next to the water tank and coal chute and therefore away from the hot gases circulating inside the smokebox.

Despite its problems, the locomotive displayed outstanding steaming characteristics and total traction from the two power bogies on its trial runs. When properly fired, the Leader was capable of keeping up with the schedules, even running ahead on occasions. However, operational difficulties when stopping for water tended to lose any time advantages gained and affected the published performance figures. Despite hauling test trains over the Central Section of the former Southern Railway, the Leader prototype was never used on a revenue-earning service because of the risk of failure of the valve gear and the adverse publicity this would cause for British Railways.

system where "C" refers to the number of driving axles – in this case three on each bogie. Since the design has six driving axles, the numbering would have been CC101–CC105 with the initial batch, the final number being the locomotive identifier.

, nor did it find favour internationally, with the Garratt

articulated locomotives providing a similar function for less maintenance. The whole concept was quietly dropped in 1951 after Bulleid left British Railways to become Chief Mechanical Engineer

of Córas Iompair Éireann

(where he produced CIÉ No. CC1

, a peat

-burning locomotive to a similar design) and all five were scrapped. The culmination of the project was a £178,865 5s 0d (£ as of ) bill for the taxpayer though, when the press reported the story as late as 1953, it was claimed that £500,000 (£ as of ) was wasted on the project. R. G. Jarvis

, who was placed in charge of the project after Bulleid's departure, insisted that the locomotive required an entire re-design to solve the problems of the original concept.

No members of the Leader class survived the 1950s and only the numberplates of No. 36001 and No. 36002 are known to exist. The numberplate for No. 36001 is located in the National Railway Museum

, although a locomotive builder's plate intended for the locomotive, but never fitted in service, was sold at auction in 2008. The Leader was a bold attempt at pushing back the boundaries of contemporary steam locomotive design and, if successful, would have prolonged the life of steam on Britain's Railways.

0-6-6-0

In Whyte notation, a 0-6-6-0 is a railroad steam locomotive that has two articulated sections, each with six coupled driving wheels, without any leading wheels or trailing wheels.-Equivalent classifications:Other equivalent classifications are:...

T articulated steam locomotive

Articulated locomotive

Articulated locomotive usually means a steam locomotive with one or more engine units which can move independent of the main frame. This is done to allow a longer locomotive to negotiate tighter curves...

, produced in the United Kingdom to the design of the innovative engineer Oliver Bulleid

Oliver Bulleid

Oliver Vaughan Snell Bulleid was a British railway and mechanical engineer best known as the Chief Mechanical Engineer of the Southern Railway between 1937 and the 1948 nationalisation, developing many well-known locomotives.- Early life and Great Northern Railway :He was born in Invercargill,...

. The Leader was an attempt to extend the life of steam traction by eliminating many of the operational drawbacks associated with existing steam locomotives. It was intended as a replacement for the ageing fleet of M7 class

LSWR M7 Class

The LSWR M7 class is a class of 0-4-4 passenger tank locomotive built between 1897 and 1911. The class was designed by Dugald Drummond for use on the intensive London network of the London and South Western Railway , and performed well in such tasks. Because of their utility, 105 were built and the...

tank engines still in operation on the Southern Railway (SR). Design work began in 1946 and development continued after the nationalisation of the railways in 1948, under the auspices of British Railways (BR).

The Leader project was part of Bulleid's desire to modernise the steam locomotive based on experience gained with the Southern Railway's fleet of electric stock. Bulleid considered that attitudes towards the labour-intensity of steam operation had changed during the post-war period, favouring dieselisation

Diesel locomotive

A diesel locomotive is a type of railroad locomotive in which the prime mover is a diesel engine, a reciprocating engine operating on the Diesel cycle as invented by Dr. Rudolf Diesel...

and electrification

Electric locomotive

An electric locomotive is a locomotive powered by electricity from overhead lines, a third rail or an on-board energy storage device...

. In an effort to demonstrate the continued potential of steam, Bulleid pushed forward the boundaries of steam-power, allowing it to compete with diesel and electric locomotives in terms of labour-saving and ease of operation.

The design incorporated many novel features, such as the use of thermic siphons, bogies and cabs at either end of the locomotive, resulting in its unique—for a steam locomotive—modern diesel-like appearance. Several of its innovations proved to be unsuccessful however, partly accounting for the project's cancellation in the early 1950s. Five Leader locomotives were begun, although only one was completed. The operational locomotive was trialled on the former Southern Railway network around Brighton

Brighton

Brighton is the major part of the city of Brighton and Hove in East Sussex, England on the south coast of Great Britain...

. Problems with the design, indifferent reports on performance and political pressure surrounding spiralling development costs, led to all locomotives of the class being scrapped by 1951.

Background

The basis of the Leader originated from a 1944 review of the Southern Railway's steam locomotive fleet, resulting in a Southern Railway design brief which called for a high-powered locomotive requiring little maintenance to replace the ageing fleet of M7 class tank engines. The brief also stipulated that the locomotive would be used on both passenger and freight trains, requiring high route availability. Bulleid proposed an initial design based on his SR Q1 class locomotive, which had proved easy to maintain in service. As the proposal progressed, Bulleid saw that certain tasks required with conventional steam locomotives could be eliminated by adopting some of the features of the contemporary Southern electric locomotives. However, one of the subsequent designs of a 0-4-4-00-4-4-0

In the Whyte notation for the classification of steam locomotive wheel arrangement, a 0-4-4-0 is a locomotive with no leading truck, two sets of four driving wheels, and no trailing truck. Examples of this type were constructed as Mallet, Meyer and Double Fairlie locomotives...

wheel arrangement had an unacceptably high axle-loading of 20 tons (20.4 tonnes), which increased the risk of damaging the Southern Railway's track. By developing the proposal further, Bulleid settled for a 0-6-6-0T design of bogied locomotive, which spread the weight more evenly over the rails and reduced the axle-loading.

Design

Boiler

A boiler is a closed vessel in which water or other fluid is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications.-Materials:...

or tender

Tender locomotive

A tender or coal-car is a special rail vehicle hauled by a steam locomotive containing the locomotive's fuel and water. Steam locomotives consume large quantities of water compared to the quantity of fuel, so tenders are necessary to keep the locomotive running over long distances. A locomotive...

obscuring his view. The need for a turntable

Turntable (railroad)

A railway turntable is a device for turning railroad rolling stock. When steam locomotives were still in wide use, many railroads needed a way to turn the locomotives around for return trips as their controls were often not configured for extended periods of running in reverse and in many...

to turn the locomotive around was therefore eliminated, although the initial designs were rejected by the operating department because of problems with welding technique. The accepted design included two 0-6-0

0-6-0

Under the Whyte notation for the classification of steam locomotives, 0-6-0 represents the wheel arrangement of no leading wheels, six powered and coupled driving wheels on three axles, and no trailing wheels...

steam bogies with weight-saving sleeve valve

Sleeve valve

The sleeve valve is a type of valve mechanism for piston engines, distinct from the usual poppet valve. Sleeve-valve engines saw use in a number of pre-World War II luxury cars and in USA in the Willys-Knight car and light truck...

s and chains to couple the driving axles. The boiler was offset to provide space for a communication corridor, allowing the driver to access both cabs without leaving the locomotive, an arrangement which led to later problems. The firebox, near the centre of the locomotive, was fed by the fireman from a third cab, linked to both driving cabs by the communication corridor. The entire ensemble was placed on a common frame and thus often referred to as an 0-6-6-0T.

The Leader prototype was constructed at Brighton railway works

Brighton railway works

Brighton railway works was one of the earliest railway-owned locomotive repair works, founded in 1840 by the London and Brighton Railway in Brighton, England, and thus pre-dating the more famous railway works at Crewe, Doncaster and Swindon...

, work beginning in 1946. An initial order for five locomotives was placed straight from the drawing board in 1946 and a further 31 were ordered in 1947, although, with nationalisation looming, this was merely a gesture. The latter order was cancelled after the Southern Railway was taken into public ownership, to allow trials to be carried out on the prototype.

Bogie and cylinder design

Each of the two bogies had three cylinders, with the driving wheels connected by chains enclosed in an oil-bath, based upon Bulleid's chain-driven valve gearBulleid chain-driven valve gear

The Bulleid chain-driven valve gear is a design of steam locomotive valve gear designed by Oliver Bulleid for use on his Pacific designs during the Second World War...

on his Pacific locomotives. The valve gear

Valve gear

The valve gear of a steam engine is the mechanism that operates the inlet and exhaust valves to admit steam into the cylinder and allow exhaust steam to escape, respectively, at the correct points in the cycle...

used the unusual sleeve valve

Sleeve valve

The sleeve valve is a type of valve mechanism for piston engines, distinct from the usual poppet valve. Sleeve-valve engines saw use in a number of pre-World War II luxury cars and in USA in the Willys-Knight car and light truck...

arrangement that was also tested on the ex-LB&SCR H1 class

LB&SCR H1 class

The London, Brighton and South Coast Railway H1 class was a class of 4-4-2 steam locomotives for express passenger work. They were designed by D. E. Marsh and were built by Messrs Kitson & Co...

Hartland Point in parallel with the construction of the first Leader locomotive. The Leader was the first steam locomotive to use a form of sleeve valve since Cecil Paget

Cecil Paget

Sir Cecil Walter Paget CMG, DSO , was a British locomotive engineer and railway administrator.Cecil Paget was the son of Sir George Ernest Paget, Chairman of the Midland Railway Company 1890-1911. He was born at Sutton Bonington, educated at Harrow and Pembroke College, Cambridge, and then joined...

's locomotive of 1908

Midland Railway Paget locomotive

The Midland Railway's Paget locomotive, No. 2299, was an experimental steam locomotive constructed at its Derby Works in 1908 to the design of the General Superintendent Cecil Paget ....

and the concurrent testing of the principle on Hartland Point hints at the rushed nature of the locomotive's conception. The locomotive sat on the unusual Bulleid-Firth-Brown

Boxpok

A Boxpok is a steam locomotive wheel that gains its strength through being made of a number of box sections rather than having traditional solid spokes . Being hollow, they allow better counterbalancing than conventional drivers, which is important for fast locomotives...

wheels, which were lighter, yet stronger, than the spoked equivalent.

The use of sleeve valves and oil baths to lubricate the moving parts of the engine units was inspired by contemporary internal combustion engine

Internal combustion engine

The internal combustion engine is an engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber. In an internal combustion engine, the expansion of the high-temperature and high -pressure gases produced by combustion apply direct force to some component of the engine...

practice. This included oscillating gear that gave a 25-degree axial movement to the sleeves, allowing even lubrication of the moving parts. However, this resulted in an over-complicated mechanism that was difficult to maintain, perpetuating the seizures it was meant to eradicate. This feature was removed from both bogies of the prototype as the trials progressed. Another innovative feature of the steam bogie assembly was the ability to interchange them when faults occurred, an easy operation for maintenance staff when compared to the complexities of overhauling a regular steam locomotive's motion.

The three cylinders of each bogie were cast in mono-block format, each surrounded by two annular inlet steam chests and a single large outlet steam chest. These had the added function of keeping the cylinder heated by hot steam to maintain the temperature and pressure of steam entering the cylinders. However, these castings were difficult to machine accurately. The steam-sealing arrangements needed for this system were also complex, with each of the six cylinders and valve sleeves requiring 24 sealing rings.

Boiler, firebox, smokebox and casing design

Eastleigh

Eastleigh is a railway town in Hampshire, England, and the main town in the Eastleigh borough which is part of Southampton Urban Area. The town lies between Southampton and Winchester, and is part of the South Hampshire conurbation...

, and proved to be the least problematic area of the entire design. The boiler pressure was set at 280 psi (1.93 MPa) and each was fitted with four thermic siphons within the firebox to increase the rate of evaporation and improve water circulation. These were previously used to great effect on Bulleid's Merchant Navy

SR Merchant Navy class

The SR Merchant Navy class , was a class of air-smoothed 4-6-2 Pacific steam locomotives designed for the Southern Railway of the United Kingdom by Oliver Bulleid...

and West Country and Battle of Britain class designs.

The Leader had a "dry lining" firebox; it was not surrounded on top and sides by a "jacket" of water as in normal practice. It was constructed of welded steel and used firebricks instead of water for insulation, which was a novel but troublesome solution to dry-lining the firebox. These had the effect of reducing the grate area from 47 ft2 to 25.5 ft2 and concentrated the fire in a smaller area. The firehole door was offset to the left of the boiler backhead and was to provide difficulty for the fireman to add coal to the fire. The firebox was not initially equipped with a firebrick arch, although one was retro-fitted during the summer of 1950. The arch was problematic as it promoted the tendency for flames to enter the cab at high outputs, a situation made worse by the narrowing of the firebox area.

The smokebox

Smokebox

A smokebox is one of the major basic parts of a Steam locomotive exhaust system. Smoke and hot gases pass from the firebox through tubes where they pass heat to the surrounding water in the boiler. The smoke then enters the smokebox, and is exhausted to the atmosphere through the chimney .To assist...

had an inherent problem in maintaining a constant vacuum

Vacuum

In everyday usage, vacuum is a volume of space that is essentially empty of matter, such that its gaseous pressure is much less than atmospheric pressure. The word comes from the Latin term for "empty". A perfect vacuum would be one with no particles in it at all, which is impossible to achieve in...

. This was a result of another Bulleid labour-saving innovation, a sliding hatch controlled from the front cab that enabled ash to be cleaned out through a chute onto the track when on the move. The problem lay with ash manifesting itself around the edges of the slide, allowing air to leak into the smokebox, therefore reducing the overall efficiency of the locomotive. The fierce blast from the exhaust also meant that ash and embers were ejected into the atmosphere, creating a potential lineside fire hazard.

For ease of maintenance, the boiler, firebox and smokebox were encased in steel sheeting that resembled a modern diesel locomotive

Diesel locomotive

A diesel locomotive is a type of railroad locomotive in which the prime mover is a diesel engine, a reciprocating engine operating on the Diesel cycle as invented by Dr. Rudolf Diesel...

, a major departure from traditional steam locomotive design, allowing the engine to be cleaned using a carriage-washing plant. The locomotive was designed to carry 4 tons (4.06 tonnes) of coal and 4000 gallons (18,184.4 l) of water with the coal bunker covered by a tarpaulin to prevent water ingress into the fireman's cab. Entry into the locomotive was by way of ladders leading up to sliding doors although, due to the bogie design, the climb into the fireman's cab necessitated clambering over the oilbath casing.

Construction

Construction of the first five Leader locomotives began at the Southern Railway's Brighton railway worksBrighton railway works

Brighton railway works was one of the earliest railway-owned locomotive repair works, founded in 1840 by the London and Brighton Railway in Brighton, England, and thus pre-dating the more famous railway works at Crewe, Doncaster and Swindon...

in July 1947. British Railways inherited the Leader project upon nationalisation in 1948, which was far enough advanced to continue constructing the prototype, as Bulleid was still Chief Mechanical Engineer of the newly formed Southern Region of British Railways

Southern Region of British Railways

The Southern Region was a region of British Railways from 1948. The region ceased to be an operating unit in its own right in the 1980s and was wound up at the end of 1992. The region covered south London, southern England and the south coast, including the busy commuter belt areas of Kent, Sussex...

. Although work on the other four locomotives stalled, the prototype Leader emerged from Brighton as locomotive No. 36001 in June 1949.

The other four members of the initial order made by the Southern Railway, Nos. 36002–5, were at varying stages of construction by the end of the development period. No. 36002 was almost complete, No. 36003 was without its outer casing, and Nos. 36004–5 were little more than sets of frames, although most of their major components had been constructed at Eastleigh and Brighton and were stored ready for fitting. With no prospect of further money being allocated by the Railway Executive for their completion, the unfinished locomotives were put into store at various depots around the former Southern Railway network pending a decision on their future.

Operational details

No. 36001 was immediately put into service trials using empty passenger carriage stock in the south-east of England. The official trial records kept at Brighton works reported varying degrees of success and failure on the runs undertaken. However, the results of the trials as reported to British Railways headquarters at MaryleboneMarylebone

Marylebone is an affluent inner-city area of central London, located within the City of Westminster. It is sometimes written as St. Marylebone or Mary-le-bone....

were "conspicuous by the absence of praise" for the strengths of the Leader, namely the boiler, braking system and total adhesion provided by the two bogies. Several theories have been put forward regarding this state of affairs, the most plausible being that the more conservative members of the railway workforce at Brighton and the Railway Executive felt that the Leader was too revolutionary and were keen to maintain the status quo.

Performance of No. 36001

Brighton

Brighton is the major part of the city of Brighton and Hove in East Sussex, England on the south coast of Great Britain...

and Eastleigh

Eastleigh

Eastleigh is a railway town in Hampshire, England, and the main town in the Eastleigh borough which is part of Southampton Urban Area. The town lies between Southampton and Winchester, and is part of the South Hampshire conurbation...

using an LNER Dynamometer car

Dynamometer car

A dynamometer car is a railroad maintenance of way car used for measuring various aspects of a locomotive's performance. Measurements include tractive effort , power, top speed, etc.-History:...

, where good running was experienced at high costs in fuel and effort on the part of the fireman. The Leader was tested against the performance of a U class control locomotive and indicated that the brake release was too slow in service for use on tight schedules despite the brake application being noted as the best used on a Bulleid design.

Throughout No. 36001's trials, the firebrick lining provided a constant problem by continually collapsing into the fire. The firebricks were then replaced with cast iron

Cast iron

Cast iron is derived from pig iron, and while it usually refers to gray iron, it also identifies a large group of ferrous alloys which solidify with a eutectic. The color of a fractured surface can be used to identify an alloy. White cast iron is named after its white surface when fractured, due...

substitutes that melted in the intense heat of the firebox, which were in turn replaced by thicker 9 inches (22.9 cm) firebricks. Some of the firemen allotted to the Leader complained about cramped conditions in the centre cab of the locomotive, a situation made worse by flames entering the cab from the firebox at high outputs. It was an enclosed space that was constantly hot and the single fireman's entrance door on the side of the locomotive was left open during travel to promote ventilation. The door into the fireman's cab also attracted criticism, as it would have been blocked in the event of the locomotive overturning on that side, preventing the fireman's escape, so that members of the railway trade union ASLEF

Associated Society of Locomotive Engineers and Firemen

The Associated Society of Locomotive Engineers and Firemen is the trade union representing railway workers in Great Britain who are train drivers or in the line of promotion to train driver....

threatened to stop their crews from operating the Leader.

The offset boiler and coal bunker caused the locomotive's centre of gravity to be shifted to one side. Experiments had to be undertaken to balance the locomotive by filling the linking corridor with large quantities of scrap metal, replaced in a re-design by a raised floor covering weighted material. These modifications resulted in the engine exceeding the total weight limit of 150 tons (151 tonnes), severely limiting the design's route availability during testing. A related problem was that despite being a tall locomotive, at 12 in 11 in (3.94 m), the cab ceilings were relatively low. The cab at the smokebox end of the locomotive suffered from the same excessive heat as did the fireman's cab. To circumvent this problem the locomotive was used in reverse, as the rear cab was next to the water tank and coal chute and therefore away from the hot gases circulating inside the smokebox.

Despite its problems, the locomotive displayed outstanding steaming characteristics and total traction from the two power bogies on its trial runs. When properly fired, the Leader was capable of keeping up with the schedules, even running ahead on occasions. However, operational difficulties when stopping for water tended to lose any time advantages gained and affected the published performance figures. Despite hauling test trains over the Central Section of the former Southern Railway, the Leader prototype was never used on a revenue-earning service because of the risk of failure of the valve gear and the adverse publicity this would cause for British Railways.

Southern Railway

When the project was under the auspices of the Southern Railway, No. 36001 would have been numbered CC101. Bulleid advocated a continental style of locomotive nomenclature, based upon his experiences at the French branch of Westinghouse Electric before the First World War and those of his tenure in the rail operating department during that conflict. The Southern Railway number followed an adaptation of the UIC classificationUIC classification

The UIC classification of locomotive axle arrangements describes the wheel arrangement of locomotives, multiple units and trams. It is set out in the International Union of Railways "Leaflet 650 - Standard designation of axle arrangement on locomotives and multiple-unit sets". It is used in much...

system where "C" refers to the number of driving axles – in this case three on each bogie. Since the design has six driving axles, the numbering would have been CC101–CC105 with the initial batch, the final number being the locomotive identifier.

British Railways

Operational livery was ex-works photographic grey with red and white lining. The British Railways "Cycling Lion" crest was also used though, after the works photograph, this was painted over without explanation. Numbering was the British Railways standard system, in the 36001 series. If the class had gone into full production, the locomotives would have been painted in British Railways mixed traffic/freight black livery with red, grey and cream lining. 36001 was initially painted in this livery but this preceded the official works photograph and was subsequently repainted in photographic grey livery.Operational assessment

Despite the high expectations attached to the Leader, it was not the motive power revolution that Bulleid intended it to be. No part of the Leader design was perpetuated on the British Railways Standard class locomotives by Robert RiddlesRobert Riddles

Robert Arthur "Robin" Riddles, CBE, MIMechE, MinstLE was a British locomotive engineer.-LNWR and LMS:Riddles was born in 1892 and entered the Crewe Works of the London and North Western Railway as a premium apprentice in 1909, completing his apprenticeship in 1913...

, nor did it find favour internationally, with the Garratt

Garratt

A Garratt is a type of steam locomotive that is articulated in three parts. Its boiler is mounted on the centre frame, and two steam engines are mounted on separate frames, one on each end of the boiler. Articulation permits larger locomotives to negotiate curves and lighter rails that might...

articulated locomotives providing a similar function for less maintenance. The whole concept was quietly dropped in 1951 after Bulleid left British Railways to become Chief Mechanical Engineer

Chief Mechanical Engineer

Chief Mechanical Engineer and Locomotive Superintendent are titles applied by British, Australian, and New Zealand railway companies to the person ultimately responsible to the board of the company for the building and maintaining of the locomotives and rolling stock...

of Córas Iompair Éireann

Córas Iompair Éireann

Córas Iompair Éireann , or CIÉ, is a statutory corporation of the Irish state, answerable to the Irish Government and responsible for most public transport in the Republic of Ireland and, jointly with its Northern Ireland counterpart, the Northern Ireland Transport Holding Company, between the...

(where he produced CIÉ No. CC1

CIÉ No. CC1

Córas Iompair Éireann No. CC1, generally known as the Turf Burner, was a prototype 0-6-6-0 articulated steam locomotive designed by Oliver Bulleid to burn turf and built at CIÉ's Inchicore Works in Dublin. CC1 shared some, but not all, of the characteristics of Bulleid's previous attempt to...

, a peat

Peat

Peat is an accumulation of partially decayed vegetation matter or histosol. Peat forms in wetland bogs, moors, muskegs, pocosins, mires, and peat swamp forests. Peat is harvested as an important source of fuel in certain parts of the world...

-burning locomotive to a similar design) and all five were scrapped. The culmination of the project was a £178,865 5s 0d (£ as of ) bill for the taxpayer though, when the press reported the story as late as 1953, it was claimed that £500,000 (£ as of ) was wasted on the project. R. G. Jarvis

R. G. Jarvis

Ronald G. Jarvis was a British locomotive engineer.Born 5 November 1911 in Harpenden, Jarvis apprenticed at Derby Works under H. G. Ivatt, alongside Oliver Bulleid. During the Second World War, he was sent to Turkey to oversee the construction of the TCDD 45151 Class , and then to India with...

, who was placed in charge of the project after Bulleid's departure, insisted that the locomotive required an entire re-design to solve the problems of the original concept.

No members of the Leader class survived the 1950s and only the numberplates of No. 36001 and No. 36002 are known to exist. The numberplate for No. 36001 is located in the National Railway Museum

National Railway Museum

The National Railway Museum is a museum in York forming part of the British National Museum of Science and Industry and telling the story of rail transport in Britain and its impact on society. It has won many awards, including the European Museum of the Year Award in 2001...

, although a locomotive builder's plate intended for the locomotive, but never fitted in service, was sold at auction in 2008. The Leader was a bold attempt at pushing back the boundaries of contemporary steam locomotive design and, if successful, would have prolonged the life of steam on Britain's Railways.

Further reading

- Ian Allan ABC of British Railways Locomotives, 1950 edition

- Carter, Ernest F.: Unusual Locomotives (Frederick Muller Ltd., 1960)

- Nock, O.S.: Southern Steam (Newton Abbot: David and Charles, 1972)

- Robertson, Kevin: Leader and Southern Experimental Steam (Stroud: Alan Sutton Publishing, 1990)

- Tufnell, Robert: Prototype Locomotives (Newton Abbot: David and Charles, 1985)