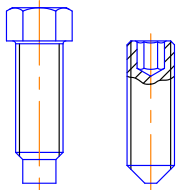

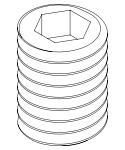

Set screw

Encyclopedia

Screw

A screw, or bolt, is a type of fastener characterized by a helical ridge, known as an external thread or just thread, wrapped around a cylinder. Some screw threads are designed to mate with a complementary thread, known as an internal thread, often in the form of a nut or an object that has the...

generally used to secure an object within or against another object. The most common examples are securing a pulley

Pulley

A pulley, also called a sheave or a drum, is a mechanism composed of a wheel on an axle or shaft that may have a groove between two flanges around its circumference. A rope, cable, belt, or chain usually runs over the wheel and inside the groove, if present...

or gear

Gear

A gear is a rotating machine part having cut teeth, or cogs, which mesh with another toothed part in order to transmit torque. Two or more gears working in tandem are called a transmission and can produce a mechanical advantage through a gear ratio and thus may be considered a simple machine....

to a shaft

Axle

An axle is a central shaft for a rotating wheel or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to its surroundings, with the wheels rotating around the axle. In the former case, bearings or bushings are provided at the mounting points where the axle...

. Set screws are most often headless (also called blind), meaning that the screw is fully threaded and has no head projecting past the major diameter of the screw thread

Screw thread

A screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a straight thread and the latter called a tapered thread...

. A blind set screw (known in the UK as a grub screw, quite possibly from its figurative resemblance to a soil-dwelling grub

Larva

A larva is a distinct juvenile form many animals undergo before metamorphosis into adults. Animals with indirect development such as insects, amphibians, or cnidarians typically have a larval phase of their life cycle...

) is almost always driven with an internal-wrenching drive, such as a hex socket (Allen), star (Torx), square socket (Robertson), or slot. The set screw passes through a threaded hole in the outer object and is tightened against the inner object to prevent it from moving relative to the outer object. It exerts compressional or clamp

Clamp (tool)

A clamp is a fastening device to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure...

ing force through the bottom tip that projects through the hole.

Torque resistance or transmission

Set screws are not always the best way to resist the torqueTorque

Torque, moment or moment of force , is the tendency of a force to rotate an object about an axis, fulcrum, or pivot. Just as a force is a push or a pull, a torque can be thought of as a twist....

of driven shafts, and so they are often used only for transmitting light loads. To reduce the chance of slipping and to increase load capacity, a detent

Detent

Detent is the term for a method, as well as the actual device, used to mechanically resist or arrest the rotation of a wheel, axle or spindle....

(often called a "flat") may be milled or ground at the part of the shaft where the set screw's point contacts. The detent, however, must be closely aligned with the threaded hole prior to fastening. The operator can often feel the screw push the flat into final alignment as he or she tightens the screw.

The use of keys and keyways instead of, or in combination with, set screws is common for applications requiring higher torque resistance or transmission. Splines offer yet more strength. But despite the light-load caveat, set screws often successfully hold against heavy-torque applications if the details are right. For example, endmill

Endmill

An endmill is a type of milling cutter, a cutting tool used in industrial milling applications. It is distinguished from the drill bit, in its application, geometry, and manufacture...

holders of the solid type typically use set screws holding against flats to fasten the endmill, and some truly aggressive loads are resisted.

For longer life, set screws are usually made of alloy steel and case hardened

Case hardening

Case hardening or surface hardening is the process of hardening the surface of a metal, often a low carbon steel, by infusing elements into the material's surface, forming a thin layer of a harder alloy...

. Hardened set screws often leave a plastic deformation, in the form of a circular or semicircular mark, in the shaft that the screw sets against. This has both pros and cons. On the pro side, such deformation increases the holding power (torque resistance) of the joint, as the screw is essentially "making its own detent" on a small but effective scale. On the con side, if one is aiming to have a blemish-free cosmetic finish on the part being set against, one must take actions to prevent the circular marks. In most set screw applications, the latter consideration is irrelevant.

Point types

Set screws appear with a variety of tip (point) types. The different shaped tips have different properties that engineers can utilize. If an engineer were to use a detent to ensure proper nesting of the screw, they might choose to use a cone point type of screw. One might often need to use a flat point when the screw must press perfectly flat against a surface. The most common type is the cup point. This type works well because the surface is rounded so that a small surface area is in contact, but it does not have extremely high stress at one point like that of a cone point. Durability studies show that the cup point offers superior resistance to wear while maintaining a strong grip. Knurled cup points offer the added advantage of a locking action (similar to that of a serrated lock washer) that prevents the screws from working loose in high-vibration applications (such as machinery that vibrates a lot while running).Common points include the following:

- Flat point

- Domed point

- Cone point

- Cup point

- Knurled cup point

- Extended point (pilot point, dog point)

Drive types

Set screws are made with a variety of drive styles, including the following:- Straight slot

- Hex socket

- Square socket

- External hex

- External square

- Bristol spline

History

The concept of set screws is many centuries old. Headless set screws have been around for a long time, with the straight slot being the oldest drive type (due to its ease of machiningMachining

Conventional machining is a form of subtractive manufacturing, in which a collection of material-working processes utilizing power-driven machine tools, such as saws, lathes, milling machines, and drill presses, are used with a sharp cutting tool to physical remove material to achieve a desired...

), but the demand for headless set screws experienced a marked increase in the first decade of the 20th century, when a penchant for better industrial safety, a campaign with the slogan "safety first", swept the industrialized nations of North America and Europe as a part of the larger Progressive Movement. This surge in safety consciousness was a backlash against the often-atrocious industrial safety standards (or, mostly, lack thereof) during the era of robber baron

Robber baron

A robber baron or robber knight was an unscrupulous and despotic nobility of the medieval period in Europe, for example, Berlichingen. It has slightly different meanings in different countries. In modern US parlance, the term is also used to describe unscrupulous industrialists...

captains of industry in the Gilded Age

Gilded Age

In United States history, the Gilded Age refers to the era of rapid economic and population growth in the United States during the post–Civil War and post-Reconstruction eras of the late 19th century. The term "Gilded Age" was coined by Mark Twain and Charles Dudley Warner in their book The Gilded...

. H.T. Hallowell, Sr., a U.S. industrialist whose corporation pioneered the commercialization of the hex socket

Hex key

A hex key, Allen key, or Allen wrench is a tool of hexagonal cross-section used to drive bolts and screws that have a hexagonal socket in the head .- Nomenclature :...

drive, noted in his memoir that line shaft

Line shaft

A line shaft is a power transmission system used extensively during the Industrial Revolution. Prior to the widespread use of electric motors small enough to be connected directly to each piece of machinery, line shafting was used to distribute power from a large central power source to machinery...

ing, which was positively ubiquitous in the industrial practice of the time, often had headed set screws (with external-wrenching square drive) holding the many pulleys to the line shafts, and collars holding the shafts from axial movement. Gear trains of exposed gears were also common at the time, and those, too, often used headed set screws, holding the gears to the shafts. His company's chief products at the time were shaft hangers and shaft collars of pressed-steel construction. The "safety craze" created a burgeoning demand for headless set screws on pulleys, gears, and collars to replace the headed ones, so that workers' clothing and fingers were less likely to catch on the exposed rotating screw head. It was this heightened demand that prompted Hallowell's firm to get into the screw-making business and to explore socket-head drive designs. With P.L. Robertson holding fresh patent rights on a practical-to-make

Design for manufacturability

Design for manufacturability - is the general engineering art of designing products in such a way that they are easy to manufacture. The basic idea exists in almost all engineering disciplines, but of course the details differ widely depending on the manufacturing technology...

square-socket drive, the firm soon pursued the hex socket drive.