Tatara (furnace)

Encyclopedia

Japan

Japan is an island nation in East Asia. Located in the Pacific Ocean, it lies to the east of the Sea of Japan, China, North Korea, South Korea and Russia, stretching from the Sea of Okhotsk in the north to the East China Sea and Taiwan in the south...

ese furnace

Furnace

A furnace is a device used for heating. The name derives from Latin fornax, oven.In American English and Canadian English, the term furnace on its own is generally used to describe household heating systems based on a central furnace , and sometimes as a synonym for kiln, a device used in the...

used for smelting

Smelting

Smelting is a form of extractive metallurgy; its main use is to produce a metal from its ore. This includes iron extraction from iron ore, and copper extraction and other base metals from their ores...

iron

Iron

Iron is a chemical element with the symbol Fe and atomic number 26. It is a metal in the first transition series. It is the most common element forming the planet Earth as a whole, forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust...

and steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

.

The word originally meant just foot bellows

Bellows

A bellows is a device for delivering pressurized air in a controlled quantity to a controlled location.Basically, a bellows is a deformable container which has an outlet nozzle. When the volume of the bellows is decreased, the air escapes through the outlet...

, but its use was later extended to the whole furnace. The two Chinese characters used when the word has the original meaning are 踏鞴 and, besides as tatara, they can be also read as fumifuigo, or foot bellows.

The word later came to mean also the entire building housing the furnace.

The steel, or , used in the forging of Japanese swords by contemporary Japanese forge masters like Kihara Akira and Gassan Sadatoshi is still smelted in a tatara. One of the few remaining tatara is the Nittoho tatara in Shimane Prefecture

Shimane Prefecture

is a prefecture of Japan located in the Chūgoku region on Honshū island. The capital is Matsue. It is the second least populous prefecture in Japan, after its eastern neighbor Tottori. The prefecture has an area elongated from east to west facing the Chūgoku Mountain Range on the south side and to...

, Japan.

The smelting

Smelting

Smelting is a form of extractive metallurgy; its main use is to produce a metal from its ore. This includes iron extraction from iron ore, and copper extraction and other base metals from their ores...

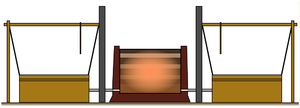

process used is different from that of the modern mass production of steel. A clay

Clay

Clay is a general term including many combinations of one or more clay minerals with traces of metal oxides and organic matter. Geologic clay deposits are mostly composed of phyllosilicate minerals containing variable amounts of water trapped in the mineral structure.- Formation :Clay minerals...

vessel about 1.1 meters (4 feet) tall, 3 meters (12 feet) long, and 1.1 meters (4 feet wide) is constructed. This is the tatara. After the clay tub has dried, it is fired until dry. A charcoal fire is started from soft pine charcoal

Charcoal

Charcoal is the dark grey residue consisting of carbon, and any remaining ash, obtained by removing water and other volatile constituents from animal and vegetation substances. Charcoal is usually produced by slow pyrolysis, the heating of wood or other substances in the absence of oxygen...

, then the smelter will wait for the fire to reach the correct temperature. At that point, he will direct the addition of ironsand

Ironsand

Ironsand is a type of sand with heavy concentrations of the metal iron. It is typically dark grey or blackish in colour.It comprises mainly magnetite, Fe3O4, and as such is attracted to magnets....

, known as satetsu. This will be layered in with more charcoal and more ironsand over the next 72 hours. 4 or 5 people need to constantly work on this process.

It takes about a week to build the tatara and complete the iron conversion to steel. When the process is done, they will break the clay tub and take out the steel bloom, known as a kera. At the end of the process, the tatara will have consumed about 10 tons of satetsu and 12 tons of charcoal, leaving about 2.5 tons of tamahagane.

The Nittoho Tatara

In 1977, the Japanese Society for Preservation of Japanese Art Swords (Nittoho), together with the Japanese government's Agency for Cultural Affairs and Hitachi Works, built in Shimane PrefectureShimane Prefecture

is a prefecture of Japan located in the Chūgoku region on Honshū island. The capital is Matsue. It is the second least populous prefecture in Japan, after its eastern neighbor Tottori. The prefecture has an area elongated from east to west facing the Chūgoku Mountain Range on the south side and to...

the so-called Nittoho Tatara to provide the steel necessary for the production of Japanese swords. The Nittoho Tatara is managed jointly with Yasugi Works, a subsidiary company of Hitachi Metals, and is operational only during the winter.