Tumble polishing

Encyclopedia

Tumble finishing, also known as tumbling or rumbling, is a technique for smoothing and polishing a rough surface on relatively small parts. In the field of metalworking

, a similar process called barreling, or barrel finishing, works upon the same principles.

For tumbling of rocks as a lapidary

For tumbling of rocks as a lapidary

technique, a plastic or rubber-lined barrel is loaded with a consignment of rocks, all of similar or the same hardness

, some abrasive

grit

, and a liquid lubricant

. Silicon carbide

grit is commonly used, and water is a universal lubricant. The barrel is then placed upon slowly rotating rails so that it rotates. The "optimal" speed of rotation depends on the size of the tumbler barrel and materials involved.

A well-chosen speed for stone polishing causes the rocks within the barrel to slide past each other, with the abrasive grit between them. The result of this depends on the coarseness of the abrasive, and the duration of the tumble.

Typically, a full tumble polish from rough rock to polish takes between 3–5 weeks, and is done in a minimum of 3 steps. Initially, the rocks are smoothed with a coarse grit (such as 60-90 mesh

). This is followed by washing and then a stage of finer grits (120-220 then 400-600 mesh), before the (optional) use of a pre-polishing compound (1200 grit), a washing cycle with detergent to remove any grit on the stones. The final step is a polishing stage using powdered polish, (such as cerium oxide

or tin oxide

), water, and often small plastic pellets that are designed to cushion the stones as they tumble (so as not to cause chipping) and carry the polish evenly across the stones. The precise tumbling time is determined by many factors, including the hardness of the rock and the degree of smoothing desired in the coarser steps. Some people will tumble stones with rough grit for two, three or even four weeks to get their desired shapes out of the stones.

Sometimes, stone "preforms" are used. This refers to cutting shapes from the rough rock, before tumbling. This gives more control over the final piece, so shapes such as a tear drop can be produced. The technique is still limited to rounded shapes. Preforms may use less time with the coarsest step, or skip it altogether.

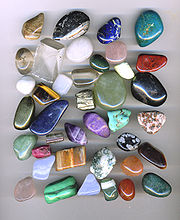

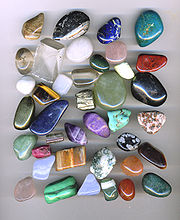

During the 1970s, small rock tumblers were a common hobby item, and jewelry decorated with tumbled semi-precious stones was very much in fashion. Likewise, dishes and decorative glass jars filled with tumbled stones (often including common rocks not suitable even for costume jewelry

) were frequently used as household ornaments.

, deburr, clean, radius, de-flash, descale, remove rust, polish, brighten, surface harden, prepare parts for further finishing, and break off die cast runners. The process is fairly simple: a horizontal barrel is filled with the parts which is then rotated. Variations of this process usually include media, water, or other lubricants. As the barrel is rotated the material rises until gravity causes the uppermost layer to landslide down to the other side. The barrel may also have vanes, typically made of rubber, which run along the inside of the barrel. As the barrel turns the vanes catch and lift the parts, which eventually slide down or fall.

In a wet processes a compound, lubricant, or barreling soap is added to aid the finishing process, prevent rusting, and to clean parts. A wide variety of media is available to achieved the desired finished product. Common media materials include: sand, granite chips, slag

, steel, ceramics, and synthetics. Moreover, these materials are available in a wide variety of shapes. Usually different shapes are used in the same load to reach into every geometry of the part.

Tumbling is an economical finishing process because large batches of parts can be run with little or no supervision by the operator. A full cycle can take anywhere from 6 to 24 hours with the barrel turning at 20 to 38 RPM. Tumbling is usually most efficient with the barrel half full. Some processes also use a filter system to allow parts or other materials in the cylinder to be separated.

The disadvantages of this process are that the abrasive action cannot be limited to only certain areas of the part, cycle times are long, and the process is noisy.

Centrifugal barrel tumbling uses a tumbling barrel at the end of a rotating arm to add centrifugal forces to the barreling process. This can accelerate the process 25 to 50 times.

mounts the workpieces onto spindles that rotate the parts opposite that of the media flow. This prevents the parts from interacting with each other and accelerates the cycle time, but extra time and cost are required to fixture the workpieces.

glass are also tumbled. No abrasive is used, to avoid clouding the glass; there is only water as a lubricant. The object of this tumbling is to remove the sharp edges from the glass, so that it may be handled safely. As little as 8 hours of tumbling may be sufficient for tumbled glass.

for recreational use, but it has the unfortunate effect of making their sides and faces somewhat uneven and thus making the dice less than fair.

These techniques, although they take a long time, involve very little operator intervention and thus are very cheap. Small tumblers (one pound capacity) are available and inexpensive for home/hobbyist use. At the other end of the scale, professionals can use very large barrels to do a lot of work at once. The main disadvantage of tumbling is its limited scope - stones will be smooth and have semi-random shapes (like pebbles from the beach), and metals need to be relatively simple shapes, with no fine work.

Metalworking

Metalworking is the process of working with metals to create individual parts, assemblies, or large scale structures. The term covers a wide range of work from large ships and bridges to precise engine parts and delicate jewelry. It therefore includes a correspondingly wide range of skills,...

, a similar process called barreling, or barrel finishing, works upon the same principles.

Stone

Lapidary

A lapidary is an artist or artisan who forms stone, mineral, gemstones, and other suitably durable materials into decorative items such as engraved gems, including cameos, or cabochons, and faceted designs...

technique, a plastic or rubber-lined barrel is loaded with a consignment of rocks, all of similar or the same hardness

Mohs scale of mineral hardness

The Mohs scale of mineral hardness characterizes the scratch resistance of various minerals through the ability of a harder material to scratch a softer material. It was created in 1812 by the German geologist and mineralogist Friedrich Mohs and is one of several definitions of hardness in...

, some abrasive

Abrasive

An abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away...

grit

Grit

Grit may refer to:* GRIT , also known as Arhgap32 or PX-RICS* Grit , a U.S. periodical founded as a newspaper in 1882* Grit , by Celtic fusion musician Martyn Bennett* Grit , by Norwegian rock band Madrugada...

, and a liquid lubricant

Lubricant

A lubricant is a substance introduced to reduce friction between moving surfaces. It may also have the function of transporting foreign particles and of distributing heat...

. Silicon carbide

Silicon carbide

Silicon carbide , also known as carborundum, is a compound of silicon and carbon with chemical formula SiC. It occurs in nature as the extremely rare mineral moissanite. Silicon carbide powder has been mass-produced since 1893 for use as an abrasive...

grit is commonly used, and water is a universal lubricant. The barrel is then placed upon slowly rotating rails so that it rotates. The "optimal" speed of rotation depends on the size of the tumbler barrel and materials involved.

A well-chosen speed for stone polishing causes the rocks within the barrel to slide past each other, with the abrasive grit between them. The result of this depends on the coarseness of the abrasive, and the duration of the tumble.

Typically, a full tumble polish from rough rock to polish takes between 3–5 weeks, and is done in a minimum of 3 steps. Initially, the rocks are smoothed with a coarse grit (such as 60-90 mesh

Mesh (scale)

Mesh material is often used in determining the particle size distribution of a granular material. For example, a sample from a truckload of peanuts may be placed atop a mesh with 5 mm openings. When the mesh is shaken, small broken pieces and dust pass through the mesh while whole peanuts are...

). This is followed by washing and then a stage of finer grits (120-220 then 400-600 mesh), before the (optional) use of a pre-polishing compound (1200 grit), a washing cycle with detergent to remove any grit on the stones. The final step is a polishing stage using powdered polish, (such as cerium oxide

Cerium oxide

Cerium oxide may refer to either of the following:*Cerium oxide, Ce2O3*Cerium oxide, CeO2...

or tin oxide

Tin oxide

Tin oxide may refer to:* Tin oxide , SnO* Tin dioxide , SnO2...

), water, and often small plastic pellets that are designed to cushion the stones as they tumble (so as not to cause chipping) and carry the polish evenly across the stones. The precise tumbling time is determined by many factors, including the hardness of the rock and the degree of smoothing desired in the coarser steps. Some people will tumble stones with rough grit for two, three or even four weeks to get their desired shapes out of the stones.

Sometimes, stone "preforms" are used. This refers to cutting shapes from the rough rock, before tumbling. This gives more control over the final piece, so shapes such as a tear drop can be produced. The technique is still limited to rounded shapes. Preforms may use less time with the coarsest step, or skip it altogether.

During the 1970s, small rock tumblers were a common hobby item, and jewelry decorated with tumbled semi-precious stones was very much in fashion. Likewise, dishes and decorative glass jars filled with tumbled stones (often including common rocks not suitable even for costume jewelry

Costume jewelry

Costume jewelry is jewelry manufactured as ornamentation to complement a particular fashionable costume or garment. Costume jewelry came into being in the 1930s as a cheap, disposable accessory meant to be worn with a specific outfit...

) were frequently used as household ornaments.

Metal

Metal tumbling is used to burnishBurnishing (metalworking)

Burnishing is the plastic deformation of a surface due to sliding contact with another object. Visually, burnishing smears the texture of a rough surface and makes it shinier...

, deburr, clean, radius, de-flash, descale, remove rust, polish, brighten, surface harden, prepare parts for further finishing, and break off die cast runners. The process is fairly simple: a horizontal barrel is filled with the parts which is then rotated. Variations of this process usually include media, water, or other lubricants. As the barrel is rotated the material rises until gravity causes the uppermost layer to landslide down to the other side. The barrel may also have vanes, typically made of rubber, which run along the inside of the barrel. As the barrel turns the vanes catch and lift the parts, which eventually slide down or fall.

In a wet processes a compound, lubricant, or barreling soap is added to aid the finishing process, prevent rusting, and to clean parts. A wide variety of media is available to achieved the desired finished product. Common media materials include: sand, granite chips, slag

Slag

Slag is a partially vitreous by-product of smelting ore to separate the metal fraction from the unwanted fraction. It can usually be considered to be a mixture of metal oxides and silicon dioxide. However, slags can contain metal sulfides and metal atoms in the elemental form...

, steel, ceramics, and synthetics. Moreover, these materials are available in a wide variety of shapes. Usually different shapes are used in the same load to reach into every geometry of the part.

Tumbling is an economical finishing process because large batches of parts can be run with little or no supervision by the operator. A full cycle can take anywhere from 6 to 24 hours with the barrel turning at 20 to 38 RPM. Tumbling is usually most efficient with the barrel half full. Some processes also use a filter system to allow parts or other materials in the cylinder to be separated.

The disadvantages of this process are that the abrasive action cannot be limited to only certain areas of the part, cycle times are long, and the process is noisy.

Specific types

Barrel burnishing is a type of barreling where no cutting action is desired. The goal is to reduce minute irregularities and produce a clean, smooth surface. The parts are usually tumbled against themselves or with steel balls, shot, rounded-end pins, or ballcones to achieve this. It is also usually a wet process, that uses water and a lubricant or cleaning agent, such as soap or cream of tartar. The barrel is not loaded more than half full and if media is used then a 2:1 ratio of media to parts is maintained to keep the parts from rubbing.Centrifugal barrel tumbling uses a tumbling barrel at the end of a rotating arm to add centrifugal forces to the barreling process. This can accelerate the process 25 to 50 times.

mounts the workpieces onto spindles that rotate the parts opposite that of the media flow. This prevents the parts from interacting with each other and accelerates the cycle time, but extra time and cost are required to fixture the workpieces.

Glass

Stained glass shards used for mosaicMosaic

Mosaic is the art of creating images with an assemblage of small pieces of colored glass, stone, or other materials. It may be a technique of decorative art, an aspect of interior decoration, or of cultural and spiritual significance as in a cathedral...

glass are also tumbled. No abrasive is used, to avoid clouding the glass; there is only water as a lubricant. The object of this tumbling is to remove the sharp edges from the glass, so that it may be handled safely. As little as 8 hours of tumbling may be sufficient for tumbled glass.

Other

Tumbling is used to polish and smooth diceDice

A die is a small throwable object with multiple resting positions, used for generating random numbers...

for recreational use, but it has the unfortunate effect of making their sides and faces somewhat uneven and thus making the dice less than fair.

These techniques, although they take a long time, involve very little operator intervention and thus are very cheap. Small tumblers (one pound capacity) are available and inexpensive for home/hobbyist use. At the other end of the scale, professionals can use very large barrels to do a lot of work at once. The main disadvantage of tumbling is its limited scope - stones will be smooth and have semi-random shapes (like pebbles from the beach), and metals need to be relatively simple shapes, with no fine work.