Voided biaxial slab

Encyclopedia

Voided biaxial slabs are reinforced concrete

slabs in which voids reduce the amount of concrete.

While concrete has been used for thousands of years, the use of reinforced concrete is a relatively recent invention, usually attributed to Joseph-Louis Lambot

in 1848. Joseph Monier

, a French gardener, patented a design for reinforced garden tubs in 1868, and later patented reinforced concrete beams and posts for railway and road guardrails.

The main obstacle with concrete constructions, in case of horizontal slabs, is the high weight, which limits the span

. For this reason major developments of reinforced concrete have focused on enhancing the span, either by reducing the weight or overcoming concrete's natural weakness in tension.

An early example is the Pantheon

in Rome

, build 125 AD. Although not reinforced, coffers were used to reduce the weight.

, invented by Freyssinet in 1928, is a method for overcoming concrete's natural weakness in tension, thereby enabling longer span.

For decades, several attempts have been made to create biaxial slabs with hollow cavities in order to reduce the weight. Most attempts have consisted of laying blocks of a less heavy material like expanded polystyrene between the bottom and top reinforcement, while other types included waffle slabs and grid slabs. Of these types, only waffle slabs can be regarded to have a certain use in the market. But the use will always be very limited due to reduced resistances towards shear, local punching and fire. The idea of placing large blocks of light material in the slab suffers from the same flaws, which is why the use of these systems has never gained acceptance and they are only used in a limited number of projects in Spanish-speaking countries.

, British Standards

or local norms.

All geometrical parameters of the slab can be described by a single parameter, the modulus named “a”.

Modulus and corresponding deck heights are manufactured in steps (modulus in steps of 25 mm, and effective heights in steps of 50 mm)

In principle, fixing of the ellipsoids can be made in numerous ways, but using only the reinforcement meshes reduces superfluous material consumption and allows for an optimal geometrical proportion between concrete, reinforcement and voids.

The voids are positioned in the middle of the cross section, where concrete has limited effect, while maintaining solid sections in top and bottom where high stresses can exist. Hence, the slab is fully functional with regards to both positive and negative bending.

just with less load corresponding to the reduced amount of concrete. Thorough investigations according to Eurocodes are made at universities in Germany, Netherlands and Denmark, concluding that a BubbleDeck slab acts like as a solid slab.

It is important to emphasize the differences in static calculations between different hollow slabs. While a true biaxial slab as the BubbleDeck system must be calculated as a solid slab, ribbed slab systems, like the U-boot system, consisting of a grid of orthogonal "I" beams, must be calculated as beams.

The BubbleDeck technology is directly incorporated in national standards, such as the CUR in the Netherlands.

For a BubbleDeck slab the shear resistance is proportional to the amount of concrete, as the special geometry shaped by the ellipsoidal voids acts like the famous Roman arch, hence enabling

all concrete to be effective. Notice, this is only valid when considering the BubbleDeck technology. Other types of voided biaxial slabs have reduced resistances towards shear, local punching and fire.

In practise, the reduced shear resistance will not lead to problems, as balls are simply left out where the shear is high, at columns and walls.

resistance is dependent on the temperature in the rebars and hence the transport of heat. As the top and bottom of the BubbleDeck slab is solid, and

the rebars are placed in this solid part, the fire resistance can be designed according to demands.

140-7:1998, ISO 717-1:1997 and ISO 717-2:1997 measuring impact and airborne sound. These tests show that 230 mm and thicker BubbleDeck slabs can meet the

national rules.

The BubbleDeck system fulfil these principles:

A two way spanning biaxial slab construction compared to a one way spanning deck (traditionally a hollow core):

As this floor type is made of complete prefab elements with no structural coherence, support moments are absent, resulting in increased material consumption.

A two way spanning voided biaxial slab construction, BubbleDeck, compared to older voided slab constructions:

8% of global CO2 emissions are due to cement production. 1 tonne of cement:

Due to the BubbleDeck technologys green gredentials, the use of the BubbleDeck system qualifies for LEED points in North America.

Suitable for the majority of new-build projects, also suspended ground floor slabs and alteration / refurbishing projects.

Acts directly like a seamless ceiling. Suitable for the majority of new-build projects.

The BubbleDeck technology can benefit most buildings. However, as it is a biaxial deck technology, the use will focus on biaxial slab designs.

Functional applicability: Residential living, offices, utility and industrial buildings. Used in offices, apartments, villas, hotels, schools, parking, hospitals, laboratories and factories.

As a consequence of the reduced load, it is possible to achieve larger spans than a solid slab. Depending of the design, spans of 20 to 40 times the deck height are possible. Cantilevers can be made 10 times the deck height. By incorporating PT cables, these spans can be further enhanced.

The effect of PT cables in a BubbleDeck slab is enhanced, because of the relative high deck height compared to the moment strength. This combination could seem like the perfect match for several applications.

On site the individual elements are then ‘stitched’ together with loose reinforcement simply laid centrally across the joints between elements. The splice bars are inserted loose above the pre-cast concrete layer between the bubbles, and purpose made mesh sheets tied across the top reinforcement mesh to join the elements

together. After the site finishing, concrete is poured and cured. This technique provides structural continuity across the entire floor slab – the joints between elements are then redundant without any structural effect – to create a seamless biaxial floor slab.

slab. This enhances the nature of the slim flat slab structure. The tubes can

either be placed in the bubble-lattice as prefab, or onsite before concreting.

Thermal heating/cooling in slabs can substantial reduce the energy consumption.

technology:

University, Utrecht in the Netherlands:

Vogaskoli, School in Reykjavik, Iceland:

Sogn Arena, Oslo in Norway:

City Hall and Offices, Glostrup in Denmark:

Between 2002 and 2008 full building regulation approval was issued to 12 no. UK & Channel Islands projects that have been successfully completed, including Salisbury Law Courts and 96 apartments in Le Coie Social rented flats together containing over 10000 sq ft (929 m²) of BubbleDeck floors. In 2007 one floor of two UK projects were partially completed due to reticence of one building control body following which another building control firm was prepared to approve. Irrespective of which the design & build contractor decided to switch to a conventional solid concrete slab structure. The British Board of Agrement undertook a full technical assessment of the BubbleDeck system which they have confirmed is acceptable, pending further production and site installation assessment. Since 2008 the BubbleDeck system continued to be marketed in UK and further buildings have recently been completed - where one wonders!

BubbleDeck was also nominated for the ”European Environmental Prize for Sustainable Development”

Reinforced concrete

Reinforced concrete is concrete in which reinforcement bars , reinforcement grids, plates or fibers have been incorporated to strengthen the concrete in tension. It was invented by French gardener Joseph Monier in 1849 and patented in 1867. The term Ferro Concrete refers only to concrete that is...

slabs in which voids reduce the amount of concrete.

While concrete has been used for thousands of years, the use of reinforced concrete is a relatively recent invention, usually attributed to Joseph-Louis Lambot

Joseph-Louis Lambot

Joseph-Louis Lambot , is the inventor of ferro-cement, which led to the development of what is now known as reinforced concrete...

in 1848. Joseph Monier

Joseph Monier

-Overview:Joseph Monier was a French gardener and one of the principal inventors of reinforced concrete....

, a French gardener, patented a design for reinforced garden tubs in 1868, and later patented reinforced concrete beams and posts for railway and road guardrails.

The main obstacle with concrete constructions, in case of horizontal slabs, is the high weight, which limits the span

Span (architecture)

Span is the distance between two intermediate supports for a structure, e.g. a beam or a bridge.A span can be closed by a solid beam or of a rope...

. For this reason major developments of reinforced concrete have focused on enhancing the span, either by reducing the weight or overcoming concrete's natural weakness in tension.

An early example is the Pantheon

Pantheon, Rome

The Pantheon ,Rarely Pantheum. This appears in Pliny's Natural History in describing this edifice: Agrippae Pantheum decoravit Diogenes Atheniensis; in columnis templi eius Caryatides probantur inter pauca operum, sicut in fastigio posita signa, sed propter altitudinem loci minus celebrata.from ,...

in Rome

Rome

Rome is the capital of Italy and the country's largest and most populated city and comune, with over 2.7 million residents in . The city is located in the central-western portion of the Italian Peninsula, on the Tiber River within the Lazio region of Italy.Rome's history spans two and a half...

, build 125 AD. Although not reinforced, coffers were used to reduce the weight.

Prestressed concrete

Prestressed concretePrestressed concrete

Prestressed concrete is a method for overcoming concrete's natural weakness in tension. It can be used to produce beams, floors or bridges with a longer span than is practical with ordinary reinforced concrete...

, invented by Freyssinet in 1928, is a method for overcoming concrete's natural weakness in tension, thereby enabling longer span.

Hollow-core slabs

In the 1950s, hollow-core slabs were invented. These are prefabricated, one-way spanning, concrete elements with hollow cylinders. Due to the prefabrication, these are inexpensive, and reduce building time, but can be used only in one-way spanning constructions, and must be supported by beams and/or fixed walls.Biaxial slabs

Due to the limitations in hollow-core slabs, primarily lack of structural integrity, inflexibility and reduced architectural possibilities, focus has been on biaxial slabs and ways to reduce the weight. Several methods have been introduced during the last decades, but with very limited success, due to major problems with shear capacity and fire resistance as well as impractical execution.For decades, several attempts have been made to create biaxial slabs with hollow cavities in order to reduce the weight. Most attempts have consisted of laying blocks of a less heavy material like expanded polystyrene between the bottom and top reinforcement, while other types included waffle slabs and grid slabs. Of these types, only waffle slabs can be regarded to have a certain use in the market. But the use will always be very limited due to reduced resistances towards shear, local punching and fire. The idea of placing large blocks of light material in the slab suffers from the same flaws, which is why the use of these systems has never gained acceptance and they are only used in a limited number of projects in Spanish-speaking countries.

BubbleDeck

In the 1990s, a new system was invented, eliminating the above problems. The so called BubbleDeck technology invented by Jørgen Breuning, locks ellipsoids between the top and bottom reinforcement meshes, thereby creating a natural cell structure, acting like a solid slab. For the first time a voided biaxial slab is created with the same capabilities as a solid slab, but with considerably less weight due to the elimination of superfluous concrete.U-boot

Some years ago an Italian engineer, Roberto Il Grande, developed a new system of lightenings, in order to decrease the transportation costs (and CO2 production). The name of the product is U-boot, and its biggest advantage is that it is stackable. The second innovation is the shape: U-boot creates a grid of orthogonal "I" beams, so the calculation of the reinforcement can be effected by any static engineer according to EurocodeEurocode

Eurocodes are a set of harmonized technical rules developed by the European Committee for Standardisation for the structural design of construction works in the European Union.The purposes of the Eurocodes are:...

, British Standards

British Standards

British Standards are the standards produced by BSI Group which is incorporated under a Royal Charter...

or local norms.

Airdeck

The Airdeck concept was patented in 2003 and comprises an inverted plastic injection moulded element which is vibrated into the lower slab during the production process by a robotic arm. The advantage of this system is that no retaining mesh is required to hold down the voiding elements during on site pouring of the second layer. As the boxes can be nested there are clear transport advantages versus other voiding systems. The static calculations are according to standard Eurocode 2 norms. http://www.airdeck.be]Polystyrene voiding blocks

A classic methodology for reducing weight of structural floors is the use of polystyrene blocks to reduce the amount of on-site concrete poured. This is a labour intensive and man dependant approach.Composition

The geometry of the voided biaxial deck (BubbleDeck slabs or short, BD) is identified by ellipsoids of a certain size, placed in a precise modular grid.All geometrical parameters of the slab can be described by a single parameter, the modulus named “a”.

Modulus and corresponding deck heights are manufactured in steps (modulus in steps of 25 mm, and effective heights in steps of 50 mm)

In principle, fixing of the ellipsoids can be made in numerous ways, but using only the reinforcement meshes reduces superfluous material consumption and allows for an optimal geometrical proportion between concrete, reinforcement and voids.

The voids are positioned in the middle of the cross section, where concrete has limited effect, while maintaining solid sections in top and bottom where high stresses can exist. Hence, the slab is fully functional with regards to both positive and negative bending.

Theory

In principle, BubbleDeck slabs acts like solid slabs. Designing is consequently like for solid slabs,just with less load corresponding to the reduced amount of concrete. Thorough investigations according to Eurocodes are made at universities in Germany, Netherlands and Denmark, concluding that a BubbleDeck slab acts like as a solid slab.

It is important to emphasize the differences in static calculations between different hollow slabs. While a true biaxial slab as the BubbleDeck system must be calculated as a solid slab, ribbed slab systems, like the U-boot system, consisting of a grid of orthogonal "I" beams, must be calculated as beams.

The BubbleDeck technology is directly incorporated in national standards, such as the CUR in the Netherlands.

Shear

The main difference between a solid slab and a voided biaxial slab refers to shear resistance. Due to the reduced concrete volume, the shear resistance will also be reduced.For a BubbleDeck slab the shear resistance is proportional to the amount of concrete, as the special geometry shaped by the ellipsoidal voids acts like the famous Roman arch, hence enabling

all concrete to be effective. Notice, this is only valid when considering the BubbleDeck technology. Other types of voided biaxial slabs have reduced resistances towards shear, local punching and fire.

In practise, the reduced shear resistance will not lead to problems, as balls are simply left out where the shear is high, at columns and walls.

Fire

As a BubbleDeck slab acts like a solid slab, the fire resistance is just a matter of the amount of concrete layer. The fireresistance is dependent on the temperature in the rebars and hence the transport of heat. As the top and bottom of the BubbleDeck slab is solid, and

the rebars are placed in this solid part, the fire resistance can be designed according to demands.

Sound

Tests have been carried out in Germany, UK and the Netherlands according to ISO 140-4:1998, ISO140-7:1998, ISO 717-1:1997 and ISO 717-2:1997 measuring impact and airborne sound. These tests show that 230 mm and thicker BubbleDeck slabs can meet the

national rules.

Seismic

There exits different approaches and opinions of design methods - but some general guiding principles are:- Low weight/stiffness ratio – influence of impact is proportional with weight

- Simplicity and symmetry and uniform extent – Lessen the impact effect Uniform and continuous distribution/flow of forces

- Monolithic, continuous and ductile structure

The BubbleDeck system fulfil these principles:

- Saves 35% weight compared to a corresponding solid slab – equal stiffnes

- Simple, monolithic behaviour, uniform and continuous distribution of Forces

- Max ductile structure - increased ductility due to increased strength/weight ratio

Approvals

- Dutch Standards: From November 2001, The BubbleDeck system is incorporated in the Dutch Standards (by CUR – Civieltechnisch Centrum Uitvoering Research en Regelgeving.

- UK Standards: The BubbleDeck system can be treated as a normal flat slab supported on columns (BS 8110) according to CRIC (Concrete Research & Innovation Centre under the Imperial College of Science, Technology & Medicine), 1997.

- Danish Standards: The BubbleDeck system can be calculated from recognized principles and within existing standards - Directorate of Building and Housing, Municipality of Copenhagen, 1996.

- German Standards: The BubbleDeck system can be used according to existing technical standards according to Deutsches Institut für Bautechnik, 1994.

Comparisons

A two way spanning voided biaxial slab construction compared to a traditional two way spanning non voided biaxial slab construction:- The reduced weight of the slab will typical result in a change in design to longer spans and/or reduced deck thickness. The overall concrete consumption can be reduced with up to 50% depending on design, as a consequence of reduced mass in slabs, vertical structure and foundation.

A two way spanning biaxial slab construction compared to a one way spanning deck (traditionally a hollow core):

- One way spanning decks are supported by a combination of walls and beams. This leads to rigid and inflexible structures. This type of structure should be used with care in seismic regions due to the risk of progressive collapse.

As this floor type is made of complete prefab elements with no structural coherence, support moments are absent, resulting in increased material consumption.

A two way spanning voided biaxial slab construction, BubbleDeck, compared to older voided slab constructions:

- Acts like a solid slab. Do not have the earlier problems with reduced resistances towards shear, local punching and fire.

In general

Different building types have different advantages, but general benefits include:- Design Freedom – flexible layout easily adapts to irregular & curved plan layouts.

- Reduced Dead Weight -35% removed allowing smaller foundation sizes.

- Longer spans between columns – up to 50% further than traditional structures.

- Downstand Beams eliminated – quicker & cheaper erection of walls and services.

- Load bearing walls eliminated – facilitating MMC with lightweight building envelopes.

- Reduced concrete usage – 1 kg recycled plastic replaces 100 kg of concrete.

- Environmentally Green and Sustainable – reduced energy & carbon emissions.

8% of global CO2 emissions are due to cement production. 1 tonne of cement:

- Releases 1 tonne of CO2

- Consumes 5 million BTU of energy

- Uses 2 tonnes of raw materials

Due to the BubbleDeck technologys green gredentials, the use of the BubbleDeck system qualifies for LEED points in North America.

Applications

The Biaxial deck can be implemented in three versions according to degree of prefabrication:- “Reinforcement modules”: Comprising prefabricated “bubble-lattice” sandwich elements to be placed on traditional formwork. Building time is reduced compared to conventional on site construction.

Suitable for the majority of new-build projects, also suspended ground floor slabs and alteration / refurbishing projects.

- “Filigree elements”: Where the bottom side of the 'bubble-lattice' unit is furnished with a pre-cast concrete layer which replaces the horizontal part of the formwork on the building site, optimizing both building time and quality by prefabrication.

Acts directly like a seamless ceiling. Suitable for the majority of new-build projects.

- “Finished elements”: Finished panels, complete precast slab elements. These can be used for limited areas such as balconies or staircases.

The BubbleDeck technology can benefit most buildings. However, as it is a biaxial deck technology, the use will focus on biaxial slab designs.

Functional applicability: Residential living, offices, utility and industrial buildings. Used in offices, apartments, villas, hotels, schools, parking, hospitals, laboratories and factories.

As a consequence of the reduced load, it is possible to achieve larger spans than a solid slab. Depending of the design, spans of 20 to 40 times the deck height are possible. Cantilevers can be made 10 times the deck height. By incorporating PT cables, these spans can be further enhanced.

The effect of PT cables in a BubbleDeck slab is enhanced, because of the relative high deck height compared to the moment strength. This combination could seem like the perfect match for several applications.

Execution

The overall floor area can be divided down into a series of planned individual elements, up to 3 m wide dependent upon site access, which are manufactured off-site using MMC techniques. These elements comprise the top and bottom reinforcement mesh, sized to suit the specific project, joined together with vertical lattice girders with the void formers trapped between the top and bottom mesh reinforcement to fix their optimum position. This is termed a ‘bubble-reinforcement’ sandwich, which is then cast into bottom layer of 60 mm pre-cast concrete, encasing the bottom mesh reinforcement, to provide permanent formwork within part of the overall finished slab depth.On site the individual elements are then ‘stitched’ together with loose reinforcement simply laid centrally across the joints between elements. The splice bars are inserted loose above the pre-cast concrete layer between the bubbles, and purpose made mesh sheets tied across the top reinforcement mesh to join the elements

together. After the site finishing, concrete is poured and cured. This technique provides structural continuity across the entire floor slab – the joints between elements are then redundant without any structural effect – to create a seamless biaxial floor slab.

Installations

The BubbleDeck concept simplifies the placement of installations like ducts and heating/cooling systems directly in theslab. This enhances the nature of the slim flat slab structure. The tubes can

either be placed in the bubble-lattice as prefab, or onsite before concreting.

Thermal heating/cooling in slabs can substantial reduce the energy consumption.

Examples

The possibilities of the concept are shown in the following examples of constructions made by the BubbleDecktechnology:

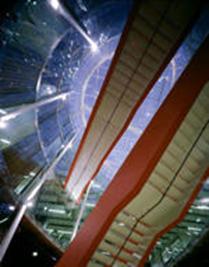

University, Utrecht in the Netherlands:

Vogaskoli, School in Reykjavik, Iceland:

Sogn Arena, Oslo in Norway:

City Hall and Offices, Glostrup in Denmark:

Between 2002 and 2008 full building regulation approval was issued to 12 no. UK & Channel Islands projects that have been successfully completed, including Salisbury Law Courts and 96 apartments in Le Coie Social rented flats together containing over 10000 sq ft (929 m²) of BubbleDeck floors. In 2007 one floor of two UK projects were partially completed due to reticence of one building control body following which another building control firm was prepared to approve. Irrespective of which the design & build contractor decided to switch to a conventional solid concrete slab structure. The British Board of Agrement undertook a full technical assessment of the BubbleDeck system which they have confirmed is acceptable, pending further production and site installation assessment. Since 2008 the BubbleDeck system continued to be marketed in UK and further buildings have recently been completed - where one wonders!

Prizes and awards

- The BubbleDeck technology have received several prizes and recognitions:

- The Dutch Building Prize, the Netherlands 1999

- The Industrial Environmental Prize, the Netherlands 1999

- The Stubeco Building Prize for Execution, the Netherlands 2000

- Innovation Award, the Netherlands 2000

- RIO Award, Germany 2003

- “Building of the Year” for Office buildings, Denmark 2004

- Jersey Construction Awards: “Best Use of Innovation”, Jersey 2005

BubbleDeck was also nominated for the ”European Environmental Prize for Sustainable Development”

See also

- ConcreteConcreteConcrete is a composite construction material, composed of cement and other cementitious materials such as fly ash and slag cement, aggregate , water and chemical admixtures.The word concrete comes from the Latin word...

- Reinforced concreteReinforced concreteReinforced concrete is concrete in which reinforcement bars , reinforcement grids, plates or fibers have been incorporated to strengthen the concrete in tension. It was invented by French gardener Joseph Monier in 1849 and patented in 1867. The term Ferro Concrete refers only to concrete that is...

- Building construction

- Construction engineeringConstruction engineeringConstruction engineering is a professional discipline that deals with the designing, planning, construction, and management of infrastructures such as highways, bridges, airports, railroads, buildings, dams, and utilities. Construction Engineers are unique such that they are a cross between civil...

- Structural engineeringStructural engineeringStructural engineering is a field of engineering dealing with the analysis and design of structures that support or resist loads. Structural engineering is usually considered a specialty within civil engineering, but it can also be studied in its own right....

- Filigree concreteFiligree concreteThe Filigree Wideslab method is a process for construction of concrete floor decks from two interconnected concrete placements, one precast in a factory, and the other done in the field. The method was developed during the late 1960s by Harry H...

- RebarRebarA rebar , also known as reinforcing steel, reinforcement steel, rerod, or a deformed bar, is a common steel bar, and is commonly used as a tensioning device in reinforced concrete and reinforced masonry structures holding the concrete in compression...