Automatic lathe

Encyclopedia

An automatic lathe is a lathe

(usually a metalworking lathe

) whose actions are controlled automatically

. Although all electronically controlled (CNC

) lathes are automatic, they are usually not called by that name, as explained under "General nomenclature". The first kinds of automatic lathes were mechanically automated ones, from the 1870s until the advent of NC and CNC in the 1950s and 1960s. CNC has not yet entirely displaced mechanically automated machines; in fact, it may still be many decades before that happens. The latter type of machine tool is no longer being newly built, but many existing examples remain in service.

technology, the natural language

terminology used to name automatic lathes, at least in English, is not hierarchical in quite the way that a manufacturing layperson might expect. Retronym

y (and, in other respects, lack of retronymy) have shaped the nomenclature. However, it is easy enough to understand once a bit of history is known (as explained below).

The term "automatic lathe" is still most often used in manufacturing in its earlier sense, referring to automated lathes of non-CNC

types. The first kinds of automatic lathes were mechanically automated ones (whose control is via cam

s or tracers and pantograph

s). Thus, before electronic automation

via numerical control

, programmable logic controller

s, and so on, the "automatic" in the term "automatic machine tool" always referred implicitly to mechanical automation.

The earliest mechanically automated lathes were geometric lathe

s. These included Rose engine lathe

s and others. In industrial contexts during the Machine Age

, the term "automatic lathe" referred to mechanical screw machines and chuckers (discussed below), of which a large variety of types, brands, and models were built.

Since the maturation of CNC, the implicit dichotomy of "manual versus automatic" still exists, but because CNC is so ubiquitous, the term "automatic" has lost some of its distinguishing power. All CNC machine tools are automatic, but (perhaps therefore) the usage of the machining industries does not routinely call them by that term. The term "automatic", when it is used at all, still usually refers implicitly to cam-operated machines. Thus a "plain old" 2-axis CNC lathe is not referred to as an "automatic lathe" (even though it is, literally speaking, automatic). However, within the machining subspecialty of Swiss-style CNC turning centers, the word "automatic" is often used freely for cam-op and CNC alike.

Small- to medium-sized cam-operated automatic lathes were (and still are) usually called screw machines or automatic screw machines. These machines work on parts that (as a rough guide only) are usually less than 80 millimetres (3.1 in) in diameter

and less than 300 millimetres (11.8 in) long. Screw machines almost invariably do bar work, which means that an entire length of bar stock

(anywhere from 1 to 4 m (3.3 to 13.1 ft) in length) passes through the spindle

and is gripped by the chuck

(which is usually a collet chuck

). As the part is being machined, the entire length of bar stock is turning with the spindle. When the part is done, it is "parted off" from the bar, the chuck un-clamps, the bar is fed forward, and the chuck then closes again, ready for the next cycle. The bar-feeding can happen by various means, including pulling-finger tools that grab the bar and pull or roller bar feed that pushes the bar from behind.

Larger cam-operated automatic lathes were (and still are) usually called automatic chucking lathes, automatic lathes, automatic chuckers, automatics, or chuckers. The "chucker" part of the name comes from the fact that the workpieces are usually discrete blanks, held in a bin called a "magazine", and each one takes a turn at being chucked

(gripped by the machine for being worked on) and cut. (This is analogous to the way that each round of ammunition in the magazine of a semi-automatic pistol gets its turn at being chambered.) The blanks are either individual forgings or castings, or they are pre-sawed pieces of billet

. However, some members of this family of machine tools turn bar work or work on centers

(for example, the Fay automatic lathe

). Regarding bar work of large diameter (for example, 150 millimetres (5.9 in) or more), it is merely an academic point whether it is called "screw machine work" or just "automatic work".

Screw machines, being the class of automatic lathes for small- to medium-sized parts, are used in the high-volume manufacture of a vast variety of turned components.

Screw machines, being the class of automatic lathes for small- to medium-sized parts, are used in the high-volume manufacture of a vast variety of turned components.

The name screw machine is somewhat of a misnomer, because screw machines spend much of their time making things that are not screw

s and that in many cases are not even threaded

. However, the archetypal use for which screw machines were named was screw-making.

The definition of the term screw machine has changed with changing technology. Any use of the term prior to the 1840s, if it occurred, would have referred ad hoc to any machine tool used to produce screws, that is, there would have been no established differentiation from the term screw-cutting lathe

. When turret lathe

s were developed in the 1840s, the term screw machine was applied to them in overlapping usage with the term turret lathe. In 1860, when some of the movements, such as turret indexing, were mechanically automated, the term automatic screw machine was applied, and the term hand screw machine or manual screw machine was retronym

ously applied to the earlier machines. Within 15 years, the entire part-cutting cycle had been mechanically automated, and machines of the 1860 type were retronymously called semi-automatic. From that time on, machines with fully automated cycles were usually called automatic screw machines, and eventually, in the usage of most people in the machining industries, the term screw machine no longer was used to refer to manual or semi-automatic turret lathes, having become reserved for one class of machine, the fully mechanically automated type. This narrow meaning of screw machine remained stable from about the 1890s until the 1950s. (Brown & Sharpe

continued to call some of their hand-operated turret lathe models "screw machines", but most machinists reserved the term for automatics.) Within this class called screw machines there were variations, such as single-spindle

versus multispindle, horizontal-turret versus vertical-turret, etc.

With the advent of NC, screw machines diverged into two classes, mechanical and NC. This distinction continues today with mechanical screw machines and CNC screw machines. However, in shop-floor jargon, the term screw machine by itself is still often understood in context to imply a mechanical screw machine, so the retronym mechanical screw machine is not consistently used.

was a variant that specialized in turning work on centers

. While a screw machine is limited to around 80 millimetres (3.1 in) practice, automatic chuckers are available that can handle up to 300 millimetres (11.8 in) chucks. The chucks are air-operated

. Many of these machines are multispindle (more than one main spindle).

Well-known brands of such machines have included National-Acme, New Britain, New Britain-Gridley, Acme-Gridley, Davenport, Bullard Mult-Au-Matic (a vertical multispindle variant), Thomas Ryder and Son, and others.

Automatic chuckers are a class of machine tool that relatively few machinists get a chance to work with. Thus some of these models and brands are obscure outside of narrow industry niches, such as OEM

parts suppliers to the automotive industry

. They are limited in their economic niches to high-volume production of large parts, which tends to occur only at relatively few companies (compared to smaller work that may be done by countless small businesses). The market for such machine tools generally does not include the neighborhood job shop or tool and die shop

.

A related characteristic of cam-operated chuckers is that they are fading into history faster than most other non-CNC machine tool classes. This is because the few companies that have them tend to be forced to continually adapt to the latest state of the art (which today is all CNC) in order to compete and thus survive. Cam-op chuckers may end up in scrap yards more easily than other types of non-CNC machine tools. Unlike with "Grandpa's South Bend

lathe" or "Dad's old Bridgeport knee mill", virtually no one can afford to keep and use them for sentimental reasons alone. As has happened with most nondigital commercial typesetting

machinery (such as old Linotype machine

s), it seems likely that within a few decades the only examples of these machines still extant will be a few museum pieces and a few obscure pockets of abandoned inventory. This is not because they are "primitive" by any means—in fact, they are mechanical marvels with ingenious design and high build quality. The change simply reflects the fact that CNC and CAD/CAM have become so advanced and flexible that it will be hard to compete with them.

In the hierarchy of manufacturing machines, the screw machine sits at the top when large product volumes are needed. An engine lathe sits at the bottom, taking the least amount of time to set up but the most amount of skilled labor and time to actually produce a part. A turret lathe has traditionally been one step above an engine lathe, needing greater set-up time but being able to produce a higher volume of product and usually requiring a lower-skilled operator once the set-up process is complete. Screw machines may require an extensive set-up, but once they are running, a single operator can monitor the operation of several machines.

The advent of the CNC lathe (or more properly, CNC turning center) has blurred these distinct levels of production to some extent. The CNC turning center most appropriately fits in the mid-range of production, replacing the turret lathe. However, it is often possible to produce a single component with a CNC turning center more quickly than can be done with an engine lathe. To some extent too, the CNC turning center has stepped into the region traditionally occupied by the (mechanical) screw machine. CNC screw machines do this to an even greater degree, but they are expensive. In some cases they are vital, yet in others a mechanical machine can match or beat overall performance and profitability. It is not unusual for cam-op automatic lathes to beat CNCs on cycle time. CNC offers many benefits, not least CAD/CAM integration, but the CNC itself usually does not give any inherent speed advantage within the context of an automatic lathe cycle in terms of speeds and feeds or tool-changing speed. There are many variables involved in answering the question of which is best for a particular part at a particular company. (Overhead

is part of the calculation—not least because most cam-op machines are long since paid for, whereas a late-model CNC machine has hefty monthly payments). Businesses relying on cam-op machines are still competing

even in today's CNC-filled environment; they just need to be vigilant and smart about keeping it that way.

An automatic lathe may have a single spindle or multiple spindles. Each spindle contains a bar or blank of material that is being machined simultaneously. A common configuration is six spindles. The cage that holds these six bars of material indexes

An automatic lathe may have a single spindle or multiple spindles. Each spindle contains a bar or blank of material that is being machined simultaneously. A common configuration is six spindles. The cage that holds these six bars of material indexes

after each machining operation is complete. The indexing is reminiscent of a Gatling gun

.

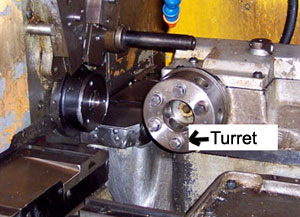

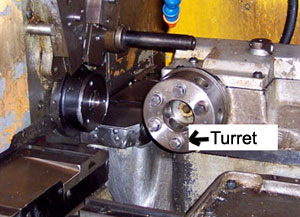

Each station may have multiple tools that cut the material in sequence. The tools are usually arranged in several axes, such as turret (rotary indexing), horizontal slide (linear indexing), and vertical slide (linear indexing). The linear groups are called "gangs". The operation of all these tools is similar to that on a turret lathe.

By way of example: a bar of material is fed forward through the spindle. The face of the bar is machined (facing operation). The outside of the bar is machined to shape (turning

operation). The bar is drill

ed or bored, and finally, the part is cut off (parting operation).

In a single-spindle machine, these four operations would most likely be performed sequentially, with four cross-slides each coming into position in turn to perform their operation. In a multi-spindle machine, each station corresponds to a stage in the production sequence through which each piece is then cycled, all operations occurring simultaneously, but on different pieces of work, in the manner of an assembly line

.

. A form tool has the form or contour of the final part but in reverse, so it cuts the material leaving the desired component shape. This contrasts to a single-point tool, which cuts on one point at a time and the shape of the component is dictated by the motion of the tool rather than its shape.

can rapidly cut or roll-form threads on outside diameters. A non-releasing tap holder with a tap can quickly cut inside diameters but it requires single spindle machines to reverse into high speed in order for the tap to be removed from the work. Threading and tapping speed (low speed) is typically 1/5 the high speed.

in the end of a cap screw.

The history of automatic lathes in industrial contexts began with screw machines, and that history can only be truly understood within the context of screw making in general. Thus the discussion below begins with a simple overview of screw making in prior centuries, and how it evolved into 19th-, 20th-, and 21st-century practice.

Humans have been making screws since ancient times. For most of those centuries, screw making generally involved custom cutting of the threads of each screw by hand (via whittling

or filing

). Other ancient methods involved wrapping wire

around a mandrel (such as a stick or metal rod) or carving a tree branch that had been spirally wrapped by a vine.

Various machine element

s that potentially lent themselves to screw making (such as the lathe

, the leadscrew

, the slide rest, gear

s, slide rests geared direct to spindles, and "change gear" gear trains) were developed over the centuries, with some of those elements being quite ancient. Various sparks of inventive power during the Middle Ages

and Renaissance

combined some of these elements into screw-making machines that presaged the industrial era to follow. For example, various medieval inventors whose names are lost to history clearly worked on the problem, as shown by Wolfegg Castle's Medieval Housebook (written circa 1475–1490), and Leonardo da Vinci

and Jacques Besson

left us with drawings of screw-cutting machines from the 1500s; not all of these designs are known to have been built, but clearly similar machines were a reality during Besson's lifetime. However, it was not until the era of 1760-1800 that these various elements were brought together successfully to create (in contemporaneous parallel) two new types of machine tool: the screw-cutting lathe

(for low-volume, toolroom

-style production of machine screws, with easy selection of various pitches) and the first high-volume-production, specialized, single-purpose machine tools for the production of screws, which were created to produce wood screws [meaning screws made of metal for use in wood] at high volume and low unit price

. Screw-cutting lathes fed into the just-dawning evolution of modern machine shop practice, whereas the wood-screw-making machines fed into the just-dawning evolution of the modern hardware industry, that is, the concept of one factory supplying the needs of thousands of customers, who consumed screws in growing quantities for carpentry

, cabinet making

, and other trades, but did not make the hardware themselves (purchasing it instead from capital-intensive specialist makers for lower unit cost than they could achieve on their own). These two classes of machine tools simultaneously took the various classes of screws and moved them, for the first time, from the category of expensive, hand-made, seldom-used objects into the category of affordable, often-interchangeable

commodity

. (The interchangeability developed gradually, from intra-company to inter-company to national to international).

Between 1800 and 1840, on the machine-screw side, it became common practice to build all of the relevant screw-cutting machine elements into engine lathes, so the term "screw-cutting lathe" ceased to stand in contradistinction to other metalworking lathe types as a "special" kind of lathe. Meanwhile, on the wood-screw side, hardware manufacturers had developed for their own in-house use the first fully automatic [mechanically automated] special-purpose machine tools for the making of screws. The 1760-1840 development arc was a tremendous technological advance, but later advancements would make screws even cheaper and more prevalent yet again. These began in the 1840s with the adaptation of the engine lathe with a turret-head toolholder to create the turret lathe

. This development greatly reduced the time, effort, and skill needed from the machine operator to produce each machine screw. Single-pointing was forgone in favor of die head

cutting for such medium- and high-volume repetitive production. Then, in the 1870s, the turret lathe's part-cutting cycle (sequence of movements) was automated by being put under cam

control, in a way very similar to how music boxes

and player piano

s can play a tune automatically. According to Rolt (1965), the first person to develop such a machine was Christopher Miner Spencer

, a New England

inventor. Charles Vander Woerd may have contemporarily independently invented a machine similar to Spencer's. However, the wood-screw-making machines of the 1840s and 1850s [special-purpose factory production machine tools as opposed to small-machine-shop machine tools], such as those developed by Cullen Whipple of the New England Screw Company and Thomas J. Sloan of the American Screw Company, had anticipated the machines of Spencer and Vander Woerd in various ways, albeit approaching the problem of automated screw production from a different commercial angle. All of the above machine tools (i.e., screw-cutting lathes; suitably equipped engine lathes and bench lathes; turret lathes; turret-lathe-derived screw machines; and wood-screw-factory screw machines) were sometimes called "screw machines" during this era (logically enough, given that they were machines tailored to screw making). The nomenclatural evolution whereby the term "screw machine" is often used more narrowly than that is discussed above.

Spencer patented his idea in 1873; unfortunately, his patent attorney failed to protect the most significant part, the cam drum, which Spencer called the "brain wheel". Therefore many other people quickly took up the idea. Later important developers of fully automatic lathes (large and small) included S. L. Worsley, who developed a single-spindle machine for Brown & Sharpe

; Edwin C. Henn, Reinhold Hakewessel, and George O. Gridley, who developed multiple-spindle variants and who were involved with a succession of corporations (Acme, National, National-Acme, Windsor Machine Company, Acme-Gridley, New Britain-Gridley); Edward P. Bullard Jr, who led the development of the Bullard Mult-Au-Matic; F.C. Fay and Otto A. Schaum, who developed the Fay automatic lathe

; Ralph Flanders

and his brother Ernest, who further refined the Fay lathe and who developed the automatic screw thread grinder; and many others. Meanwhile, engineers in Switzerland were also developing clever new manually and automatically controlled lathes during this same era. The technological developments in America and Switzerland flowed rapidly into other industrialized countries (via routes such as machine tool export

s; trade journal

articles and advertisements; trade shows

, from world's fair

s to regional events; and the turnover

and emigration

of engineers, setup hands, and operators). There, local innovators also developed further creative tooling for the machines and built clone machine models.

The development of numerical control was the next major leap in the history of automatic lathes—and it is also what changed the paradigm of what the "manual versus automatic" distinction even meant. Beginning in the 1950s, NC lathes began to take over the jobs that formerly were done by manual lathes and cam-op screw machines, although the displacement of the older technology by CNC has been a long, gradual arc that even today is not a total eclipse. By the 1980s, true CNC screw machines (as opposed to simpler CNC lathes), Swiss-style and non-Swiss, had begun to make serious inroads into the realm of cam-op screw machines. Similarly, CNC chuckers were developed, eventually evolving even into CNC rotary transfer machines. Very few people outside of automotive manufacturing are familiar with these machine tools, because they simply have no economic reason to come into contact with this segment of the machine tool industry. Today CNC lathes and their offspring (turn-mills, mill-turns, rotary transfers) are technological wonders with a blizzard of axes and accessories under CNC control. Their sophistication, accuracy and precision

, metal-removal speed, tool-changing speed, degree of automation, and degree of networking

with the rest of the enterprise are formidable.

Lathe

A lathe is a machine tool which rotates the workpiece on its axis to perform various operations such as cutting, sanding, knurling, drilling, or deformation with tools that are applied to the workpiece to create an object which has symmetry about an axis of rotation.Lathes are used in woodturning,...

(usually a metalworking lathe

Lathe (metal)

A metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of...

) whose actions are controlled automatically

Automation

Automation is the use of control systems and information technologies to reduce the need for human work in the production of goods and services. In the scope of industrialization, automation is a step beyond mechanization...

. Although all electronically controlled (CNC

Numerical control

Numerical control refers to the automation of machine tools that are operated by abstractly programmed commands encoded on a storage medium, as opposed to controlled manually via handwheels or levers, or mechanically automated via cams alone...

) lathes are automatic, they are usually not called by that name, as explained under "General nomenclature". The first kinds of automatic lathes were mechanically automated ones, from the 1870s until the advent of NC and CNC in the 1950s and 1960s. CNC has not yet entirely displaced mechanically automated machines; in fact, it may still be many decades before that happens. The latter type of machine tool is no longer being newly built, but many existing examples remain in service.

General nomenclature

Because of the historical path of development of machine toolMachine tool

A machine tool is a machine, typically powered other than by human muscle , used to make manufactured parts in various ways that include cutting or certain other kinds of deformation...

technology, the natural language

Natural language

In the philosophy of language, a natural language is any language which arises in an unpremeditated fashion as the result of the innate facility for language possessed by the human intellect. A natural language is typically used for communication, and may be spoken, signed, or written...

terminology used to name automatic lathes, at least in English, is not hierarchical in quite the way that a manufacturing layperson might expect. Retronym

Retronym

A retronym is a type of neologism that provides a new name for an object or concept to differentiate the original form or version of it from a more recent form or version. The original name is most often augmented with an adjective to account for later developments of the object or concept itself...

y (and, in other respects, lack of retronymy) have shaped the nomenclature. However, it is easy enough to understand once a bit of history is known (as explained below).

The term "automatic lathe" is still most often used in manufacturing in its earlier sense, referring to automated lathes of non-CNC

Numerical control

Numerical control refers to the automation of machine tools that are operated by abstractly programmed commands encoded on a storage medium, as opposed to controlled manually via handwheels or levers, or mechanically automated via cams alone...

types. The first kinds of automatic lathes were mechanically automated ones (whose control is via cam

Cam

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion or vice-versa. It is often a part of a rotating wheel or shaft that strikes a lever at one or more points on its circular path...

s or tracers and pantograph

Pantograph

A pantograph is a mechanical linkage connected in a special manner based on parallelograms so that the movement of one pen, in tracing an image, produces identical movements in a second pen...

s). Thus, before electronic automation

Automation

Automation is the use of control systems and information technologies to reduce the need for human work in the production of goods and services. In the scope of industrialization, automation is a step beyond mechanization...

via numerical control

Numerical control

Numerical control refers to the automation of machine tools that are operated by abstractly programmed commands encoded on a storage medium, as opposed to controlled manually via handwheels or levers, or mechanically automated via cams alone...

, programmable logic controller

Programmable logic controller

A programmable logic controller or programmable controller is a digital computer used for automation of electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or light fixtures. PLCs are used in many industries and machines...

s, and so on, the "automatic" in the term "automatic machine tool" always referred implicitly to mechanical automation.

The earliest mechanically automated lathes were geometric lathe

Geometric lathe

A geometric lathe was used for making ornamental patterns on the plates used in printing bank notes and postage stamps. It is sometimes called a Guilloché lathe. It was developed early in the nineteenth century when efforts were introduced to combat forgery, and is an adaptation of an ornamental...

s. These included Rose engine lathe

Rose engine lathe

A rose engine lathe is a specialized kind of geometric lathe. The headstock rocks back and forth with a rocking motion or along the spindle axis in a pumping motion, controlled by a rubber moving against a rosette or cam-like pattern mounted on the spindle, while the lathe spindle rotates...

s and others. In industrial contexts during the Machine Age

Machine Age

The Machine Age is a term associated mostly with the early 20th century, sometimes also including the late 19th century. An approximate dating would be about 1880 to 1945. Considered to be at a peak in the time between the first and second world wars, it forms a late part of the Industrial Age...

, the term "automatic lathe" referred to mechanical screw machines and chuckers (discussed below), of which a large variety of types, brands, and models were built.

Since the maturation of CNC, the implicit dichotomy of "manual versus automatic" still exists, but because CNC is so ubiquitous, the term "automatic" has lost some of its distinguishing power. All CNC machine tools are automatic, but (perhaps therefore) the usage of the machining industries does not routinely call them by that term. The term "automatic", when it is used at all, still usually refers implicitly to cam-operated machines. Thus a "plain old" 2-axis CNC lathe is not referred to as an "automatic lathe" (even though it is, literally speaking, automatic). However, within the machining subspecialty of Swiss-style CNC turning centers, the word "automatic" is often used freely for cam-op and CNC alike.

Small- to medium-sized cam-operated automatic lathes were (and still are) usually called screw machines or automatic screw machines. These machines work on parts that (as a rough guide only) are usually less than 80 millimetres (3.1 in) in diameter

Diameter

In geometry, a diameter of a circle is any straight line segment that passes through the center of the circle and whose endpoints are on the circle. The diameters are the longest chords of the circle...

and less than 300 millimetres (11.8 in) long. Screw machines almost invariably do bar work, which means that an entire length of bar stock

Bar stock

Bar stock, also colloquially known as billet, is a common form of raw purified metal, used by industry to manufacture metal parts and products....

(anywhere from 1 to 4 m (3.3 to 13.1 ft) in length) passes through the spindle

Spindle (tool)

In machine tools, a spindle is a rotating axis of the machine, which often has a shaft at its heart. The shaft itself is called a spindle, but also, in shop-floor practice, the word often is used metonymically to refer to the entire rotary unit, including not only the shaft itself, but its bearings...

and is gripped by the chuck

Chuck (engineering)

A chuck is a specialized type of clamp used to hold an object, usually an object with radial symmetry, especially a cylindrical object. It is most commonly used to hold a rotating tool or a rotating workpiece...

(which is usually a collet chuck

Collet

A collet is a holding device—specifically, a subtype of chuck—that forms a collar around the object to be held and exerts a strong clamping force on the object when it is tightened, usually via a tapered outer collar. It may be used to hold a workpiece or a tool.A collet is a sleeve with a ...

). As the part is being machined, the entire length of bar stock is turning with the spindle. When the part is done, it is "parted off" from the bar, the chuck un-clamps, the bar is fed forward, and the chuck then closes again, ready for the next cycle. The bar-feeding can happen by various means, including pulling-finger tools that grab the bar and pull or roller bar feed that pushes the bar from behind.

Larger cam-operated automatic lathes were (and still are) usually called automatic chucking lathes, automatic lathes, automatic chuckers, automatics, or chuckers. The "chucker" part of the name comes from the fact that the workpieces are usually discrete blanks, held in a bin called a "magazine", and each one takes a turn at being chucked

Chuck (engineering)

A chuck is a specialized type of clamp used to hold an object, usually an object with radial symmetry, especially a cylindrical object. It is most commonly used to hold a rotating tool or a rotating workpiece...

(gripped by the machine for being worked on) and cut. (This is analogous to the way that each round of ammunition in the magazine of a semi-automatic pistol gets its turn at being chambered.) The blanks are either individual forgings or castings, or they are pre-sawed pieces of billet

Bar stock

Bar stock, also colloquially known as billet, is a common form of raw purified metal, used by industry to manufacture metal parts and products....

. However, some members of this family of machine tools turn bar work or work on centers

Lathe center

A lathe center, often shortened to center, is a tool that has been ground to a point as to accurately position a workpiece about an axis...

(for example, the Fay automatic lathe

Fay automatic lathe

The Fay automatic lathe was an automatic lathe tailored to cutting workpieces that were mounted on centers . It could also do chucking work...

). Regarding bar work of large diameter (for example, 150 millimetres (5.9 in) or more), it is merely an academic point whether it is called "screw machine work" or just "automatic work".

Screw machine

Screw machine nomenclature

Speaking with reference to the normal definition of the term screw machine, all screw machines are fully automated, whether mechanically (via cams) or by CNC (computerized control), which means that once they are set up and started running, they continue running and producing parts with very little human intervention. This has been true since the 1870s. Mechanical automation came first, beginning in the 1870s; computerized control (via first NC and then CNC) came later, beginning in the 1950s.The name screw machine is somewhat of a misnomer, because screw machines spend much of their time making things that are not screw

Screw

A screw, or bolt, is a type of fastener characterized by a helical ridge, known as an external thread or just thread, wrapped around a cylinder. Some screw threads are designed to mate with a complementary thread, known as an internal thread, often in the form of a nut or an object that has the...

s and that in many cases are not even threaded

Screw thread

A screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a straight thread and the latter called a tapered thread...

. However, the archetypal use for which screw machines were named was screw-making.

The definition of the term screw machine has changed with changing technology. Any use of the term prior to the 1840s, if it occurred, would have referred ad hoc to any machine tool used to produce screws, that is, there would have been no established differentiation from the term screw-cutting lathe

Screw-cutting lathe

A screw-cutting lathe is a machine capable of cutting very accurate screw threads via single-point screw-cutting, which is the process of guiding the linear motion of the tool bit in a precisely known ratio to the rotating motion of the workpiece...

. When turret lathe

Turret lathe

The turret lathe is a form of metalworking lathe that is used for repetitive production of duplicate parts, which by the nature of their cutting process are usually interchangeable...

s were developed in the 1840s, the term screw machine was applied to them in overlapping usage with the term turret lathe. In 1860, when some of the movements, such as turret indexing, were mechanically automated, the term automatic screw machine was applied, and the term hand screw machine or manual screw machine was retronym

Retronym

A retronym is a type of neologism that provides a new name for an object or concept to differentiate the original form or version of it from a more recent form or version. The original name is most often augmented with an adjective to account for later developments of the object or concept itself...

ously applied to the earlier machines. Within 15 years, the entire part-cutting cycle had been mechanically automated, and machines of the 1860 type were retronymously called semi-automatic. From that time on, machines with fully automated cycles were usually called automatic screw machines, and eventually, in the usage of most people in the machining industries, the term screw machine no longer was used to refer to manual or semi-automatic turret lathes, having become reserved for one class of machine, the fully mechanically automated type. This narrow meaning of screw machine remained stable from about the 1890s until the 1950s. (Brown & Sharpe

Brown & Sharpe

Brown & Sharpe is a division of Hexagon Metrology, Inc., a multinational corporation focused mainly on metrological tools and technology. During the 19th and 20th centuries, Brown & Sharpe was one of the most well-known and influential firms in the machine tool industry...

continued to call some of their hand-operated turret lathe models "screw machines", but most machinists reserved the term for automatics.) Within this class called screw machines there were variations, such as single-spindle

Spindle (tool)

In machine tools, a spindle is a rotating axis of the machine, which often has a shaft at its heart. The shaft itself is called a spindle, but also, in shop-floor practice, the word often is used metonymically to refer to the entire rotary unit, including not only the shaft itself, but its bearings...

versus multispindle, horizontal-turret versus vertical-turret, etc.

With the advent of NC, screw machines diverged into two classes, mechanical and NC. This distinction continues today with mechanical screw machines and CNC screw machines. However, in shop-floor jargon, the term screw machine by itself is still often understood in context to imply a mechanical screw machine, so the retronym mechanical screw machine is not consistently used.

Automatic chucker

An automatic chucking machine is very similar to an automatic screw machine, except it handles larger work, which due to its size is more often chucking work and less often bar work. The Fay automatic latheFay automatic lathe

The Fay automatic lathe was an automatic lathe tailored to cutting workpieces that were mounted on centers . It could also do chucking work...

was a variant that specialized in turning work on centers

Lathe center

A lathe center, often shortened to center, is a tool that has been ground to a point as to accurately position a workpiece about an axis...

. While a screw machine is limited to around 80 millimetres (3.1 in) practice, automatic chuckers are available that can handle up to 300 millimetres (11.8 in) chucks. The chucks are air-operated

Pneumatic tool

A pneumatic tool or air tools is a tool driven by a gas, usually compressed air supplied by a gas compressor. Pneumatic tools can also be driven by compressed carbon dioxide stored in small cylinders allowing for portability...

. Many of these machines are multispindle (more than one main spindle).

Well-known brands of such machines have included National-Acme, New Britain, New Britain-Gridley, Acme-Gridley, Davenport, Bullard Mult-Au-Matic (a vertical multispindle variant), Thomas Ryder and Son, and others.

Automatic chuckers are a class of machine tool that relatively few machinists get a chance to work with. Thus some of these models and brands are obscure outside of narrow industry niches, such as OEM

Original Equipment Manufacturer

An original equipment manufacturer, or OEM, manufactures products or components that are purchased by a company and retailed under that purchasing company's brand name. OEM refers to the company that originally manufactured the product. When referring to automotive parts, OEM designates a...

parts suppliers to the automotive industry

Automotive industry

The automotive industry designs, develops, manufactures, markets, and sells motor vehicles, and is one of the world's most important economic sectors by revenue....

. They are limited in their economic niches to high-volume production of large parts, which tends to occur only at relatively few companies (compared to smaller work that may be done by countless small businesses). The market for such machine tools generally does not include the neighborhood job shop or tool and die shop

Tool and die maker

Tool and die makers are workers in the manufacturing industry who make jigs, fixtures, dies, molds, machine tools, cutting tools , gauges, and other tools used in manufacturing processes...

.

A related characteristic of cam-operated chuckers is that they are fading into history faster than most other non-CNC machine tool classes. This is because the few companies that have them tend to be forced to continually adapt to the latest state of the art (which today is all CNC) in order to compete and thus survive. Cam-op chuckers may end up in scrap yards more easily than other types of non-CNC machine tools. Unlike with "Grandpa's South Bend

South Bend Lathe Works

South Bend Lathe is a brand of machine tools. Today's South Bend Lathe corporation is the successor to the original South Bend Lathe Works, an American machine tool–building firm that for many decades was one of the most important builders of metalworking lathes in the U.S...

lathe" or "Dad's old Bridgeport knee mill", virtually no one can afford to keep and use them for sentimental reasons alone. As has happened with most nondigital commercial typesetting

Typesetting

Typesetting is the composition of text by means of types.Typesetting requires the prior process of designing a font and storing it in some manner...

machinery (such as old Linotype machine

Linotype machine

The Linotype typesetting machine is a "line casting" machine used in printing. The name of the machine comes from the fact that it produces an entire line of metal type at once, hence a line-o'-type, a significant improvement over manual typesetting....

s), it seems likely that within a few decades the only examples of these machines still extant will be a few museum pieces and a few obscure pockets of abandoned inventory. This is not because they are "primitive" by any means—in fact, they are mechanical marvels with ingenious design and high build quality. The change simply reflects the fact that CNC and CAD/CAM have become so advanced and flexible that it will be hard to compete with them.

Choice of machines and control type

Mechanical screw machines have been replaced to some extent by CNC lathes (turning centers) and CNC screw machines. However, they are still commonly in operation, and for high-volume production of turned components it is still often true that nothing is as cost-efficient as a mechanical screw machine.In the hierarchy of manufacturing machines, the screw machine sits at the top when large product volumes are needed. An engine lathe sits at the bottom, taking the least amount of time to set up but the most amount of skilled labor and time to actually produce a part. A turret lathe has traditionally been one step above an engine lathe, needing greater set-up time but being able to produce a higher volume of product and usually requiring a lower-skilled operator once the set-up process is complete. Screw machines may require an extensive set-up, but once they are running, a single operator can monitor the operation of several machines.

The advent of the CNC lathe (or more properly, CNC turning center) has blurred these distinct levels of production to some extent. The CNC turning center most appropriately fits in the mid-range of production, replacing the turret lathe. However, it is often possible to produce a single component with a CNC turning center more quickly than can be done with an engine lathe. To some extent too, the CNC turning center has stepped into the region traditionally occupied by the (mechanical) screw machine. CNC screw machines do this to an even greater degree, but they are expensive. In some cases they are vital, yet in others a mechanical machine can match or beat overall performance and profitability. It is not unusual for cam-op automatic lathes to beat CNCs on cycle time. CNC offers many benefits, not least CAD/CAM integration, but the CNC itself usually does not give any inherent speed advantage within the context of an automatic lathe cycle in terms of speeds and feeds or tool-changing speed. There are many variables involved in answering the question of which is best for a particular part at a particular company. (Overhead

Overhead (business)

In business, overhead or overhead expense refers to an ongoing expense of operating a business...

is part of the calculation—not least because most cam-op machines are long since paid for, whereas a late-model CNC machine has hefty monthly payments). Businesses relying on cam-op machines are still competing

Competition (economics)

Competition in economics is a term that encompasses the notion of individuals and firms striving for a greater share of a market to sell or buy goods and services...

even in today's CNC-filled environment; they just need to be vigilant and smart about keeping it that way.

Design

Indexing (motion)

Indexing in reference to motion is moving into a new position or location quickly and easily but also precisely. After a machine part has been indexed, its location is known to within a few hundredths of a millimeter , or often even to within a few thousandths of a millimeter , despite the fact...

after each machining operation is complete. The indexing is reminiscent of a Gatling gun

Gatling gun

The Gatling gun is one of the best known early rapid-fire weapons and a forerunner of the modern machine gun. It is well known for its use by the Union forces during the American Civil War in the 1860s, which was the first time it was employed in combat...

.

Each station may have multiple tools that cut the material in sequence. The tools are usually arranged in several axes, such as turret (rotary indexing), horizontal slide (linear indexing), and vertical slide (linear indexing). The linear groups are called "gangs". The operation of all these tools is similar to that on a turret lathe.

By way of example: a bar of material is fed forward through the spindle. The face of the bar is machined (facing operation). The outside of the bar is machined to shape (turning

Turning

Turning is the process whereby a single point cutting tool is parallel to the surface. It can be done manually, in a traditional form of lathe, which frequently requires continuous supervision by the operator, or by using a computer controlled and automated lathe which does not. This type of...

operation). The bar is drill

Drill bit

Drill bits are cutting tools used to create cylindrical holes. Bits are held in a tool called a drill, which rotates them and provides torque and axial force to create the hole. Specialized bits are also available for non-cylindrical-shaped holes....

ed or bored, and finally, the part is cut off (parting operation).

In a single-spindle machine, these four operations would most likely be performed sequentially, with four cross-slides each coming into position in turn to perform their operation. In a multi-spindle machine, each station corresponds to a stage in the production sequence through which each piece is then cycled, all operations occurring simultaneously, but on different pieces of work, in the manner of an assembly line

Assembly line

An assembly line is a manufacturing process in which parts are added to a product in a sequential manner using optimally planned logistics to create a finished product much faster than with handcrafting-type methods...

.

Form tools

For the machining of complex shapes, it is common to use form tools. This contrasts with the cutting that is performed on an engine lathe where the cutting tool is usually a single-point toolTool bit

The term tool bit generally refers to a non-rotary cutting tool used in metal lathes, shapers, and planers. Such cutters are also often referred to by the set-phrase name of single-point cutting tool. The cutting edge is ground to suit a particular machining operation and may be resharpened or...

. A form tool has the form or contour of the final part but in reverse, so it cuts the material leaving the desired component shape. This contrasts to a single-point tool, which cuts on one point at a time and the shape of the component is dictated by the motion of the tool rather than its shape.

Threading

Unlike on a lathe, single-point threading is rarely if ever performed; it is too time-consuming for the short cycle times that are typical of screw machines. A self-releasing die headDie head

A die head is a threading die that is used in the high volume production of threaded components.Die heads are commonly used on lathes, turret lathes, screw machines and CNC lathes. They may be used for either cutting a thread or rolling a thread...

can rapidly cut or roll-form threads on outside diameters. A non-releasing tap holder with a tap can quickly cut inside diameters but it requires single spindle machines to reverse into high speed in order for the tap to be removed from the work. Threading and tapping speed (low speed) is typically 1/5 the high speed.

Rotary broaching

Rotary broaching is another common operation. The broach holder is mounted stationary while its internal live spindle and end cutting broach tool are driven by the workpiece. As the broach is fed into or around the workpiece, the broach's contact points are constantly changing, easily creating the desired form. The most common form made this way is a hexagonal socketHex key

A hex key, Allen key, or Allen wrench is a tool of hexagonal cross-section used to drive bolts and screws that have a hexagonal socket in the head .- Nomenclature :...

in the end of a cap screw.

History

The history of geometric lathes is discussed elsewhere, and concerns such applications as engraving and printing (especially of paper currency), jewelry making, and artistic pursuits.The history of automatic lathes in industrial contexts began with screw machines, and that history can only be truly understood within the context of screw making in general. Thus the discussion below begins with a simple overview of screw making in prior centuries, and how it evolved into 19th-, 20th-, and 21st-century practice.

Humans have been making screws since ancient times. For most of those centuries, screw making generally involved custom cutting of the threads of each screw by hand (via whittling

Whittling

Whittling is the art of carving shapes typically out of raw wood or bone with a knife.Whittling is typically performed with a light, small-bladed knife, usually a pocket knife. Specialised whittling knives are available as well...

or filing

File (tool)

A file is a metalworking and woodworking tool used to cut fine amounts of material from a workpiece. It most commonly refers to the hand tool style, which takes the form of a steel bar with a case hardened surface and a series of sharp, parallel teeth. Most files have a narrow, pointed tang at one...

). Other ancient methods involved wrapping wire

Wire

A wire is a single, usually cylindrical, flexible strand or rod of metal. Wires are used to bear mechanical loads and to carry electricity and telecommunications signals. Wire is commonly formed by drawing the metal through a hole in a die or draw plate. Standard sizes are determined by various...

around a mandrel (such as a stick or metal rod) or carving a tree branch that had been spirally wrapped by a vine.

Various machine element

Machine element

Machine elements are basic mechanical parts used as the building blocks of most machines. Most are standardized to common sizes, but customs are also common for specialized applications.-Types:*Shafts**Couplings*Keys*Splines*Bearings**Roller bearings...

s that potentially lent themselves to screw making (such as the lathe

Lathe

A lathe is a machine tool which rotates the workpiece on its axis to perform various operations such as cutting, sanding, knurling, drilling, or deformation with tools that are applied to the workpiece to create an object which has symmetry about an axis of rotation.Lathes are used in woodturning,...

, the leadscrew

Leadscrew

A leadscrew , also known as a power screw or translation screw, is a screw designed to translate turning motion into linear motion...

, the slide rest, gear

Gear

A gear is a rotating machine part having cut teeth, or cogs, which mesh with another toothed part in order to transmit torque. Two or more gears working in tandem are called a transmission and can produce a mechanical advantage through a gear ratio and thus may be considered a simple machine....

s, slide rests geared direct to spindles, and "change gear" gear trains) were developed over the centuries, with some of those elements being quite ancient. Various sparks of inventive power during the Middle Ages

Middle Ages

The Middle Ages is a periodization of European history from the 5th century to the 15th century. The Middle Ages follows the fall of the Western Roman Empire in 476 and precedes the Early Modern Era. It is the middle period of a three-period division of Western history: Classic, Medieval and Modern...

and Renaissance

Renaissance

The Renaissance was a cultural movement that spanned roughly the 14th to the 17th century, beginning in Italy in the Late Middle Ages and later spreading to the rest of Europe. The term is also used more loosely to refer to the historical era, but since the changes of the Renaissance were not...

combined some of these elements into screw-making machines that presaged the industrial era to follow. For example, various medieval inventors whose names are lost to history clearly worked on the problem, as shown by Wolfegg Castle's Medieval Housebook (written circa 1475–1490), and Leonardo da Vinci

Leonardo da Vinci

Leonardo di ser Piero da Vinci was an Italian Renaissance polymath: painter, sculptor, architect, musician, scientist, mathematician, engineer, inventor, anatomist, geologist, cartographer, botanist and writer whose genius, perhaps more than that of any other figure, epitomized the Renaissance...

and Jacques Besson

Jacques Besson

Jacques Besson was a French Protestant inventor, mathematician, and philosopher, chiefly remembered for his popular treatise on machines Theatrum Instrumentorum , which saw many reprints in different languages.-Life:...

left us with drawings of screw-cutting machines from the 1500s; not all of these designs are known to have been built, but clearly similar machines were a reality during Besson's lifetime. However, it was not until the era of 1760-1800 that these various elements were brought together successfully to create (in contemporaneous parallel) two new types of machine tool: the screw-cutting lathe

Screw-cutting lathe

A screw-cutting lathe is a machine capable of cutting very accurate screw threads via single-point screw-cutting, which is the process of guiding the linear motion of the tool bit in a precisely known ratio to the rotating motion of the workpiece...

(for low-volume, toolroom

Toolroom

The term toolroom can refer to three related concepts. The concepts have evolved over the past two centuries as technology itself has evolved.- Storing tools :...

-style production of machine screws, with easy selection of various pitches) and the first high-volume-production, specialized, single-purpose machine tools for the production of screws, which were created to produce wood screws [meaning screws made of metal for use in wood] at high volume and low unit price

Unit price

Average prices represent, quite simply, total sales revenue divided by total units sold. Many products, however, are sold in multiple variants, such as bottle sizes. In these cases, managers face a challenge: they must determine “comparable” units. Average prices can be calculated by weighting...

. Screw-cutting lathes fed into the just-dawning evolution of modern machine shop practice, whereas the wood-screw-making machines fed into the just-dawning evolution of the modern hardware industry, that is, the concept of one factory supplying the needs of thousands of customers, who consumed screws in growing quantities for carpentry

Carpentry

A carpenter is a skilled craftsperson who works with timber to construct, install and maintain buildings, furniture, and other objects. The work, known as carpentry, may involve manual labor and work outdoors....

, cabinet making

Cabinet making

Cabinet making is the practice of using various woodworking skills to create cabinets, shelving and furniture.Cabinet making involves techniques such as creating appropriate joints, dados, bevels, chamfers and shelving systems, the use of finishing tools such as routers to create decorative...

, and other trades, but did not make the hardware themselves (purchasing it instead from capital-intensive specialist makers for lower unit cost than they could achieve on their own). These two classes of machine tools simultaneously took the various classes of screws and moved them, for the first time, from the category of expensive, hand-made, seldom-used objects into the category of affordable, often-interchangeable

Interchangeable parts

Interchangeable parts are parts that are, for practical purposes, identical. They are made to specifications that ensure that they are so nearly identical that they will fit into any device of the same type. One such part can freely replace another, without any custom fitting...

commodity

Commodity

In economics, a commodity is the generic term for any marketable item produced to satisfy wants or needs. Economic commodities comprise goods and services....

. (The interchangeability developed gradually, from intra-company to inter-company to national to international).

Between 1800 and 1840, on the machine-screw side, it became common practice to build all of the relevant screw-cutting machine elements into engine lathes, so the term "screw-cutting lathe" ceased to stand in contradistinction to other metalworking lathe types as a "special" kind of lathe. Meanwhile, on the wood-screw side, hardware manufacturers had developed for their own in-house use the first fully automatic [mechanically automated] special-purpose machine tools for the making of screws. The 1760-1840 development arc was a tremendous technological advance, but later advancements would make screws even cheaper and more prevalent yet again. These began in the 1840s with the adaptation of the engine lathe with a turret-head toolholder to create the turret lathe

Turret lathe

The turret lathe is a form of metalworking lathe that is used for repetitive production of duplicate parts, which by the nature of their cutting process are usually interchangeable...

. This development greatly reduced the time, effort, and skill needed from the machine operator to produce each machine screw. Single-pointing was forgone in favor of die head

Die head

A die head is a threading die that is used in the high volume production of threaded components.Die heads are commonly used on lathes, turret lathes, screw machines and CNC lathes. They may be used for either cutting a thread or rolling a thread...

cutting for such medium- and high-volume repetitive production. Then, in the 1870s, the turret lathe's part-cutting cycle (sequence of movements) was automated by being put under cam

Cam

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion or vice-versa. It is often a part of a rotating wheel or shaft that strikes a lever at one or more points on its circular path...

control, in a way very similar to how music boxes

Musical box

A music box is a 19th century automatic musical instrument that produces sounds by the use of a set of pins placed on a revolving cylinder or disc so as to pluck the tuned teeth of a steel comb. They were developed from musical snuff boxes of the 18th century and called carillons à musique...

and player piano

Player piano

A player piano is a self-playing piano, containing a pneumatic or electro-mechanical mechanism that operates the piano action via pre-programmed music perforated paper, or in rare instances, metallic rolls. The rise of the player piano grew with the rise of the mass-produced piano for the home in...

s can play a tune automatically. According to Rolt (1965), the first person to develop such a machine was Christopher Miner Spencer

Christopher Miner Spencer

Christopher Miner Spencer was an American inventor, from Manchester, Connecticut, who invented the Spencer repeating rifle, one of the earliest models of lever-action rifle, a steam powered "horseless carriage", and several other inventions...

, a New England

New England

New England is a region in the northeastern corner of the United States consisting of the six states of Maine, New Hampshire, Vermont, Massachusetts, Rhode Island, and Connecticut...

inventor. Charles Vander Woerd may have contemporarily independently invented a machine similar to Spencer's. However, the wood-screw-making machines of the 1840s and 1850s [special-purpose factory production machine tools as opposed to small-machine-shop machine tools], such as those developed by Cullen Whipple of the New England Screw Company and Thomas J. Sloan of the American Screw Company, had anticipated the machines of Spencer and Vander Woerd in various ways, albeit approaching the problem of automated screw production from a different commercial angle. All of the above machine tools (i.e., screw-cutting lathes; suitably equipped engine lathes and bench lathes; turret lathes; turret-lathe-derived screw machines; and wood-screw-factory screw machines) were sometimes called "screw machines" during this era (logically enough, given that they were machines tailored to screw making). The nomenclatural evolution whereby the term "screw machine" is often used more narrowly than that is discussed above.

Spencer patented his idea in 1873; unfortunately, his patent attorney failed to protect the most significant part, the cam drum, which Spencer called the "brain wheel". Therefore many other people quickly took up the idea. Later important developers of fully automatic lathes (large and small) included S. L. Worsley, who developed a single-spindle machine for Brown & Sharpe

Brown & Sharpe

Brown & Sharpe is a division of Hexagon Metrology, Inc., a multinational corporation focused mainly on metrological tools and technology. During the 19th and 20th centuries, Brown & Sharpe was one of the most well-known and influential firms in the machine tool industry...

; Edwin C. Henn, Reinhold Hakewessel, and George O. Gridley, who developed multiple-spindle variants and who were involved with a succession of corporations (Acme, National, National-Acme, Windsor Machine Company, Acme-Gridley, New Britain-Gridley); Edward P. Bullard Jr, who led the development of the Bullard Mult-Au-Matic; F.C. Fay and Otto A. Schaum, who developed the Fay automatic lathe

Fay automatic lathe

The Fay automatic lathe was an automatic lathe tailored to cutting workpieces that were mounted on centers . It could also do chucking work...

; Ralph Flanders

Ralph Flanders

Ralph Edward Flanders was an American mechanical engineer, industrialist and Republican U.S. Senator from the state of Vermont. He grew up on subsistence farms in Vermont and Rhode Island, became an apprentice first as a machinist, then as a draftsman, before training as a mechanical engineer...

and his brother Ernest, who further refined the Fay lathe and who developed the automatic screw thread grinder; and many others. Meanwhile, engineers in Switzerland were also developing clever new manually and automatically controlled lathes during this same era. The technological developments in America and Switzerland flowed rapidly into other industrialized countries (via routes such as machine tool export

Export

The term export is derived from the conceptual meaning as to ship the goods and services out of the port of a country. The seller of such goods and services is referred to as an "exporter" who is based in the country of export whereas the overseas based buyer is referred to as an "importer"...

s; trade journal

Trade journal

A trade magazine, also called a professional magazine, is a magazine published with the intention of target marketing to a specific industry or type of trade. The collective term for this area of publishing is the trade press....

articles and advertisements; trade shows

Trade fair

A trade fair is an exhibition organized so that companies in a specific industry can showcase and demonstrate their latest products, service, study activities of rivals and examine recent market trends and opportunities...

, from world's fair

World's Fair

World's fair, World fair, Universal Exposition, and World Expo are various large public exhibitions held in different parts of the world. The first Expo was held in The Crystal Palace in Hyde Park, London, United Kingdom, in 1851, under the title "Great Exhibition of the Works of Industry of All...

s to regional events; and the turnover

Turnover (employment)

In a human resources context, turnover or staff turnover or labour turnover is the rate at which an employer gains and loses employees. Simple ways to describe it are "how long employees tend to stay" or "the rate of traffic through the revolving door." Turnover is measured for individual companies...

and emigration

Emigration

Emigration is the act of leaving one's country or region to settle in another. It is the same as immigration but from the perspective of the country of origin. Human movement before the establishment of political boundaries or within one state is termed migration. There are many reasons why people...

of engineers, setup hands, and operators). There, local innovators also developed further creative tooling for the machines and built clone machine models.

The development of numerical control was the next major leap in the history of automatic lathes—and it is also what changed the paradigm of what the "manual versus automatic" distinction even meant. Beginning in the 1950s, NC lathes began to take over the jobs that formerly were done by manual lathes and cam-op screw machines, although the displacement of the older technology by CNC has been a long, gradual arc that even today is not a total eclipse. By the 1980s, true CNC screw machines (as opposed to simpler CNC lathes), Swiss-style and non-Swiss, had begun to make serious inroads into the realm of cam-op screw machines. Similarly, CNC chuckers were developed, eventually evolving even into CNC rotary transfer machines. Very few people outside of automotive manufacturing are familiar with these machine tools, because they simply have no economic reason to come into contact with this segment of the machine tool industry. Today CNC lathes and their offspring (turn-mills, mill-turns, rotary transfers) are technological wonders with a blizzard of axes and accessories under CNC control. Their sophistication, accuracy and precision

Accuracy and precision

In the fields of science, engineering, industry and statistics, the accuracy of a measurement system is the degree of closeness of measurements of a quantity to that quantity's actual value. The precision of a measurement system, also called reproducibility or repeatability, is the degree to which...

, metal-removal speed, tool-changing speed, degree of automation, and degree of networking

Computer network

A computer network, often simply referred to as a network, is a collection of hardware components and computers interconnected by communication channels that allow sharing of resources and information....

with the rest of the enterprise are formidable.