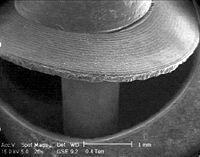

Diaphragm seal

Encyclopedia

.png)

Seal (mechanical)

A mechanical seal is a device which helps join systems or mechanisms together by preventing leakage , containing pressure, or excluding contamination...

allows pressure

Pressure

Pressure is the force per unit area applied in a direction perpendicular to the surface of an object. Gauge pressure is the pressure relative to the local atmospheric or ambient pressure.- Definition :...

effects to cross the barrier but not the material being contained.

Common uses for diaphragm seals are to protect pressure sensor

Pressure sensor

A pressure sensor measures pressure, typically of gases or liquids. Pressure is an expression of the force required to stop a fluid from expanding, and is usually stated in terms of force per unit area. A pressure sensor usually acts as a transducer; it generates a signal as a function of the...

s from the fluid

Fluid

In physics, a fluid is a substance that continually deforms under an applied shear stress. Fluids are a subset of the phases of matter and include liquids, gases, plasmas and, to some extent, plastic solids....

whose pressure is being measured.

Materials

Since diaphragm seals need to be highly flexible, elastomers are commonly used, and include a wide variety of both general purpose and speciality rubbers. Elastomers are limited to low pressure applications and those that are chemically compatible with the various plastics and rubbers used.Metal diaphragms of stainless steel (several grades), Carpenter 20, Hastelloy, Monel, Inconel, tantalum, titanium and several other metals are in common use where high pressure ratings and specific chemical compatibility are required. Flanged assemblies or flush welded versions are available.

Applications

Diaphragm seals (also known as chemical seals or gauge guards) are also used to protect a process fluid from the pressure sensor. Examples of this use are:- Sanitary processes (food, pharmaceuticals, etc.) where allowing process fluid to accumulate in the pressure port of the sensor would compromise the purity of the fluid (such as milk getting into the pressure port of a pressure gauge and spoiling)

- Very pure process fluids, where the metal surface of the pressure sensor might contaminate the fluid (such as copper ions from brass leaching into ultra pure water.)

- Pneumatic systems where small changes in pressures must be eliminated, such as those controlling air bearings.

Seal Failure

Cracking

Cracking may refer to:* Cracking, the formation of a fracture or partial fracture in a solid material* Fluid catalytic cracking, a catalytic process widely used in oil refineries for cracking large hydrocarbon molecules into smaller molecules...

. Ozone cracking

Ozone cracking

Cracks can be formed in many different elastomers by ozone attack, and the characteristic form of attack of vulnerable rubbers is known as ozone cracking...

can occur in many elastomers for example used in pneumatic systems. If the gas contaminates the air supply, then many rubber diaphragms are at risk from the problem.

See also

- Diaphragm (mechanics)Diaphragm (mechanics)In mechanics, a diaphragm is a sheet of a semi-flexible material anchored at its periphery and most often round in shape. It serves either as a barrier between two chambers, moving slightly up into one chamber or down into the other depending on differences in pressure, or as a device that...

- Polymer degradationPolymer degradationPolymer degradation is a change in the properties—tensile strength, colour, shape, etc.—of a polymer or polymer-based product under the influence of one or more environmental factors such as heat, light or chemicals such as acids, alkalis and some salts...

- Ozone crackingOzone crackingCracks can be formed in many different elastomers by ozone attack, and the characteristic form of attack of vulnerable rubbers is known as ozone cracking...