Foil bearing

Encyclopedia

Fluid

In physics, a fluid is a substance that continually deforms under an applied shear stress. Fluids are a subset of the phases of matter and include liquids, gases, plasmas and, to some extent, plastic solids....

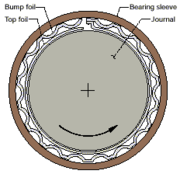

(usually air) pushes the foil away from the shaft so that there is no more contact. The shaft and foil are separated by the air's high pressure which is generated by the rotation which pulls gas into the bearing via viscosity effects. A high speed of the shaft with respect to the foil is required to initiate the air gap, and once this has been achieved, no wear occurs. Unlike aero or hydrostatic bearings, foil bearings require no external pressurisation system for the working fluid, so the hydrodynamic bearing is self-starting.

Development

Garrett AiResearch

Garrett AiResearch was a manufacturer of turboprop engines and turbochargers, and a pioneer in numerous aerospace technologies. It was previously known as Aircraft Tool and Supply Company, Garrett Supply Company, AiResearch Manufacturing Company, or simply AiResearch...

using independent R&D funds to serve military and space applications.Some early history is reported in They were first tested for commercial use in United Airlines

United Airlines

United Air Lines, Inc., is the world's largest airline with 86,852 employees United Air Lines, Inc., is the world's largest airline with 86,852 employees United Air Lines, Inc., is the world's largest airline with 86,852 employees (which includes the entire holding company United Continental...

Boeing 727

Boeing 727

The Boeing 727 is a mid-size, narrow-body, three-engine, T-tailed commercial jet airliner, manufactured by Boeing. The Boeing 727 first flew in 1963, and for over a decade more were built per year than any other jet airliner. When production ended in 1984 a total of 1,832 aircraft had been produced...

and Boeing 737

Boeing 737

The Boeing 737 is a short- to medium-range, twin-engine narrow-body jet airliner. Originally developed as a shorter, lower-cost twin-engine airliner derived from Boeing's 707 and 727, the 737 has developed into a family of nine passenger models with a capacity of 85 to 215 passengers...

cooling turbines in the early- and mid-1960s. Garrett AiResearch air cycle machine

Air cycle machine

An air cycle machine is the refrigeration unit of the environmental control system used in pressurized gas turbine-powered aircraft. Normally an aircraft has two or three of these ACM. Each ACM and its components are often referred as an Air Conditioning Pack.The air cycle cooling process uses...

foil bearings were first installed as original equipment in 1969 in the DC-10's environmental control systems

Environmental Control System

The environmental control system of an aircraft provides air supply, thermal control and cabin pressurization for the crew and passengers...

. Garrett AiResearch foil bearings were installed on all U.S. military aircraft to replace existing oil-lubricated rolling-contact bearings. The ability to operate at cryogenic gas temperatures as well as at very high temperatures gave foil bearings many other potential applications.

Current generation foil bearings with advanced coatings have greatly exceeded the limitations of earlier designs. Anti-wear coatings exist that allow over 100,000 start/stop cycles for typical applications. New third generation bearings can hold over 9,000 times their weight, at extremely high speeds.

Applications

TurbomachineryTurbomachinery

Turbomachinery, in mechanical engineering, describes machines that transfer energy between a rotor and a fluid, including both turbines and compressors. While a turbine transfers energy from a fluid to a rotor, a compressor transfers energy from a rotor to a fluid...

is the most common application because foil bearings operate at high speed. The main advantage of foil bearings is the elimination of the oil

Oil

An oil is any substance that is liquid at ambient temperatures and does not mix with water but may mix with other oils and organic solvents. This general definition includes vegetable oils, volatile essential oils, petrochemical oils, and synthetic oils....

systems required by traditional bearing designs. Other advantages are:

- Higher efficiency, due to a lower heat loss to friction; instead of fluid frictionFrictionFriction is the force resisting the relative motion of solid surfaces, fluid layers, and/or material elements sliding against each other. There are several types of friction:...

, the main source of heat is parasitic dragParasitic dragParasitic drag is drag caused by moving a solid object through a fluid medium . Parasitic drag is made up of many components, the most prominent being form drag... - Increased reliability

- Higher speed capability

- Quieter operation

- Wider operating temperatureOperating temperatureAn operating temperature is the temperature at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the device function and application context, and ranges from the minimum operating temperature to the...

range (40 KKelvinThe kelvin is a unit of measurement for temperature. It is one of the seven base units in the International System of Units and is assigned the unit symbol K. The Kelvin scale is an absolute, thermodynamic temperature scale using as its null point absolute zero, the temperature at which all...

to 2500 K) - High vibration and shock load capacity

- No scheduled maintenance

- No external support system

- Truly oil free where contamination is an issue

- Capable of operating above critical speedCritical speedIn solid mechanics, in the field of rotordynamics, the critical speed is the theoretical angular velocity which excites the natural frequency of a rotating object, such as a shaft, propeller, leadscrew, or gear. As the speed of rotation approaches the object's natural frequency, the object begins...

Areas of current research are:

- Higher load capacity

- Improved damping

- Improved coatings

The main disadvantages are:

- Lower capacity than roller or oil bearings

- Wear during start-up and stopping

- High speed required for operation