Honeycomb structures

Encyclopedia

Honeycomb

A honeycomb is a mass of hexagonal waxcells built by honey bees in their nests to contain their larvae and stores of honey and pollen.Beekeepers may remove the entire honeycomb to harvest honey...

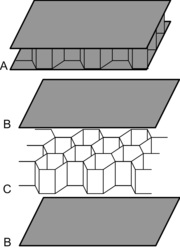

to allow the minimization of the amount of used material to reach minimal weight and minimal material cost. The geometry of honeycomb structures can vary widely but the common feature of all such structures is an array of hollow cells separated by thin vertical walls. The cells are often column

Column

A column or pillar in architecture and structural engineering is a vertical structural element that transmits, through compression, the weight of the structure above to other structural elements below. For the purpose of wind or earthquake engineering, columns may be designed to resist lateral forces...

ar and hexagonal in shape. A honeycomb shaped structure provides a material with minimal density and relative high out-of-plane compression properties and out-of-plane shear properties.

Introduction

Natural honeycomb structures include beehiveBeehive

A beehive is a structure in which bees live and raise their young.Beehive may also refer to:Buildings and locations:* Bee Hive, Alabama, a neighborhood in Alabama* Beehive , a wing of the New Zealand Parliament Buildings...

s, honeycomb weathering

Honeycomb weathering

Honeycomb weathering, also known as fretting, cavernous weathering, alveoli/alveolar weathering, stone lattice, stone lace or miniature tafoni weathering is a type of salt weathering common on coastal and semi-arid granites, sandstones and limestones...

in rocks, tripe

Tripe

Tripe is a type of edible offal from the stomachs of various farm animals.-Beef tripe:...

, and bone

Bone

Bones are rigid organs that constitute part of the endoskeleton of vertebrates. They support, and protect the various organs of the body, produce red and white blood cells and store minerals. Bone tissue is a type of dense connective tissue...

.

Man-made honeycomb structures include sandwich composites

Sandwich structured composite

A sandwich-structured composite is a special class of composite materials that is fabricated by attaching two thin but stiff skins to a lightweight but thick core...

with honeycomb cores. An example of a honeycomb structure is shown in the adjacent figure. Man-made honeycomb structures are manufactured by using a variety of different materials, depending on the intended application and required characteristics, from paper

Paper

Paper is a thin material mainly used for writing upon, printing upon, drawing or for packaging. It is produced by pressing together moist fibers, typically cellulose pulp derived from wood, rags or grasses, and drying them into flexible sheets....

or thermoplastics, used for low strength and stiffness for low load applications, to high strength and stiffness for high performance applications, from aluminum or fiber reinforced plastics. The strength of laminated or sandwich panels depends on the size of the panel, facing material used and the number or density of the honeycomb cells within it. Honeycomb composites are used widely in many industries, from aerospace industries, automotive and furniture to packaging and logistics.

The material takes its name from its visual resemblance to a bee's honeycomb

Honeycomb

A honeycomb is a mass of hexagonal waxcells built by honey bees in their nests to contain their larvae and stores of honey and pollen.Beekeepers may remove the entire honeycomb to harvest honey...

- a hexagonal sheet structure.

History

The hexagonal comb of the honeybee has been admired and wondered about from ancient times on. The first man-made honeycomb is said to have been manufactured by DaedalusDaedalus

In Greek mythology, Daedalus was a skillful craftsman and artisan.-Family:...

from gold by lost wax casting more than 3000 years ago. Marcus Varro reports that the Greek geometricians Euclid

Euclid

Euclid , fl. 300 BC, also known as Euclid of Alexandria, was a Greek mathematician, often referred to as the "Father of Geometry". He was active in Alexandria during the reign of Ptolemy I...

and Zenodorus

Zenodorus (mathematician)

- Life and work :Little is known about the life of Zenodorus, although he may have befriended Philonides and made two trips to Athens, as described in Philonides' biography...

found that the hexagon shape makes most efficient use of space and building materials. The interior structure and hidden chambers of the Roman Pantheon

Pantheon, Rome

The Pantheon ,Rarely Pantheum. This appears in Pliny's Natural History in describing this edifice: Agrippae Pantheum decoravit Diogenes Atheniensis; in columnis templi eius Caryatides probantur inter pauca operum, sicut in fastigio posita signa, sed propter altitudinem loci minus celebrata.from ,...

dome is an early example of a honeycomb structure.

Galileo Galilei

Galileo Galilei

Galileo Galilei , was an Italian physicist, mathematician, astronomer, and philosopher who played a major role in the Scientific Revolution. His achievements include improvements to the telescope and consequent astronomical observations and support for Copernicanism...

discusses in 1638 the resistance of hollow solids: "Art, and nature even more, makes use of these in thousands of operations in which robustness is increased without adding weight, as is seen in the bones of birds and in many stalks that are light and very resistant to bending and breaking”.

Robert Hook discovers in 1665 that the natural cellular structure of cork is similar to the hexagonal honeybee comb. and Charles Darwin

Charles Darwin

Charles Robert Darwin FRS was an English naturalist. He established that all species of life have descended over time from common ancestry, and proposed the scientific theory that this branching pattern of evolution resulted from a process that he called natural selection.He published his theory...

states in 1859 that "the comb of the hive-bee, as far as we can see, is absolutely perfect in economizing labour and wax”.

First paper honeycomb structures might have been made by the Chinese

China

Chinese civilization may refer to:* China for more general discussion of the country.* Chinese culture* Greater China, the transnational community of ethnic Chinese.* History of China* Sinosphere, the area historically affected by Chinese culture...

2000 years ago for ornaments, but no reference for this has been found. Paper honeycombs and the expansion production process has been invented in Halle/Saale in Germany by Hans Heilbrun in 1901 for decorative applications. First honeycomb structures from corrugated metal sheets had been proposed for bee keeping in 1890. For the same purpose, as foundation sheets to harvest more honey, a honeycomb moulding process using a paper paste glue mixture had been patented in 1878. The three today still used basic honeycomb production techniques: expansion, corrugation and moulding where already developed by 1901 for non-sandwich applications.

Honeycomb core

A honeycomb core is a material used as a central layer materialMaterial

Material is anything made of matter, constituted of one or more substances. Wood, cement, hydrogen, air and water are all examples of materials. Sometimes the term "material" is used more narrowly to refer to substances or components with certain physical properties that are used as inputs to...

in sandwich structured composite

Sandwich structured composite

A sandwich-structured composite is a special class of composite materials that is fabricated by attaching two thin but stiff skins to a lightweight but thick core...

structures. The concept was first explained in detail and published by Hugo Junkers

Hugo Junkers

Hugo Junkers was an innovative German engineer, as his many patents in varied areas show...

. He proposed and patented the first honeycomb cores for aircraft application in 1915. He described in detail his concept to replace the fabric covered aircraft structures by metal sheets and reasoned that a metal sheet can also be loaded in compression if it is supported at very small intervals by arranging side by side a series of square or rectangular cells or triangular or hexagonal hollow bodies. The problem of bonding a continuous skin to cellular cores led Junkers later to the open corrugated structure, which could be riveted or welded together.

The first use of honeycomb structures for structural applications had been independently proposed for building application and published already in 1914. In 1934 Edward G. Budd

Edward G. Budd

Edward Gowen Budd was an American inventor and businessman.Budd was born in Delaware in 1870. He studied engineering in Philadelphia in 1888, and in 1899 he took his knowledge of pressed steel to the railroad industry...

patented a welded steel honeycomb sandwich panel from corrugated metal sheets and Claude Dornier aimed 1937 to solve the core-skin bonding problem by rolling or pressing a skin which is in a plastic state into the core cell walls.

The first successful structural adhesive bonding of honeycomb sandwich structures was achieved by Norman de Bruyne

Norman de Bruyne

Norman Adrian de Bruyne FRS was born in Punta Arenas Chile on November 8, 1904, baptized on March 19, 1905 at the Anglican Church St. James Church, by the Rev. Edwin Aspinall. His father was Dutch and his mother English. He grew up in England, studied science at the University of Cambridge and...

of Aero Research Limited

Aero Research Limited

Aero Research Limited was a British company that pioneered several new adhesives, intended initially for the aeronautical industry.Formed in 1934 by Norman de Bruyne at Duxford, Cambridgeshire from an earlier company of his, the Cambridgeshire Aeroplane Construction Company, ARL started a...

, who patented an adhesive with the right viscosity to form resin fillets on the honeycomb core in 1938.

A summary of the important developments in the history of honeycomb technology is given below:

- 60 BC Diodorus SiculusDiodorus SiculusDiodorus Siculus was a Greek historian who flourished between 60 and 30 BC. According to Diodorus' own work, he was born at Agyrium in Sicily . With one exception, antiquity affords no further information about Diodorus' life and doings beyond what is to be found in his own work, Bibliotheca...

reports a golden honeycomb manufactured by DaedalusDaedalusIn Greek mythology, Daedalus was a skillful craftsman and artisan.-Family:...

via lost wax castingLost wax castingLost-wax casting sometimes called by the French name of cire perdue is the process by which a metal sculpture is cast from an artist's sculpture. Intricate works can be achieved by this method, primarily depending on the carver's skills...

. - 36 BC Marcus Varro reports most efficient use of space and building materials by hexagonal shape.

- 126 The Pantheon was rebuilt in Rome using a honeycomb structure to support its dome.

- 1638 Galileo GalileiGalileo GalileiGalileo Galilei , was an Italian physicist, mathematician, astronomer, and philosopher who played a major role in the Scientific Revolution. His achievements include improvements to the telescope and consequent astronomical observations and support for Copernicanism...

discusses hollow solids and their increase of resistance without adding weight. - 1665 Robert Hook discovers that the natural cellular structure of cork is similar to the hexagonal honeybee comb.

- 1859 Charles DarwinCharles DarwinCharles Robert Darwin FRS was an English naturalist. He established that all species of life have descended over time from common ancestry, and proposed the scientific theory that this branching pattern of evolution resulted from a process that he called natural selection.He published his theory...

states that the comb of the hive-bee is absolutely perfect in economizing labour and wax. - 1877 F. H. Küstermann invents a honeycomb moulding process using a paper paste glue mixture.

- 1890 Julius Steigel invents the honeycomb production process from corrugated metal sheets.

- 1901 Hans Heilbrun invents the hexagonal paper honeycombs and the expansion production process.

- 1914 R. Höfler and S. Renyi patent the first use of honeycomb structures for structural applications.

- 1915 Hugo JunkersHugo JunkersHugo Junkers was an innovative German engineer, as his many patents in varied areas show...

patents the first honeycomb cores for aircraft application. - 1931 George Thomson proposes to use decorative expended paper honeycombs for lightweight plasterboard panels.

- 1934 Edward G. BuddEdward G. BuddEdward Gowen Budd was an American inventor and businessman.Budd was born in Delaware in 1870. He studied engineering in Philadelphia in 1888, and in 1899 he took his knowledge of pressed steel to the railroad industry...

patents welded steel honeycomb sandwich panel from currguated metal sheets. - 1937 Claude Dornier patents a honeycomb sandwich panel with skins pressed in a plastic state into the core cell walls.

- 1938 Norman de BruyneNorman de BruyneNorman Adrian de Bruyne FRS was born in Punta Arenas Chile on November 8, 1904, baptized on March 19, 1905 at the Anglican Church St. James Church, by the Rev. Edwin Aspinall. His father was Dutch and his mother English. He grew up in England, studied science at the University of Cambridge and...

patents the structural adhesive bonding of honeycomb sandwich structures. - 1941 John D. Lincoln proposes the use expanded paper honeycombs for aircraft radomes

- 1948 Roger Steele applies the expansion production process using fiber reinforced composite sheets.

- 1969 Boeing 747 uses extensively fire-resistant honeycombs from Hexcel Composites using DuPont's Nomex aramid fiber paper.

- 1980's Thermoplastic honeycombs produced by extrusion processes are introduced.

Manufacture

The three traditional honeycomb production techniques: expansion, corrugation and moulding where all already developed by 1901 for non-sandwich applications. For decorative applications the expanded honeycomb production reached a remarkable degree of automation already in the first decade of the 20th century.Today honeycomb cores are manufactured via the expansion process and the corrugation process from composite materials such as glass-reinforced plastic

Glass-reinforced plastic

Fiberglass , is a fiber reinforced polymer made of a plastic matrix reinforced by fine fibers of glass. It is also known as GFK ....

(also known as fiberglass), carbon fiber reinforced plastic, Nomex

Nomex

Nomex is a registered trademark for flame resistant meta-aramid material developed in the early 1960s by DuPont and first marketed in 1967.- Properties:...

aramide paper reinforced plastic, or from a metal (usually aluminum).

Thermoplastic honeycomb cores (usually from polypropylene

Polypropylene

Polypropylene , also known as polypropene, is a thermoplastic polymer used in a wide variety of applications including packaging, textiles , stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes...

) are usually made by extrusion processed via a block of extruded profiles or extruded tubes from which the honeycomb sheets is sliced.

Recently a new process to produce thermoplastic honeycombs has been implemented, allowing a continuous in-line production with direct lamination of skin to cost efficient sandwich panel production.

Today, a wide variety of materials can be formed into a honeycomb composite. For example paperboard

Paperboard

Paperboard is a thick paper based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker than paper. According to ISO standards, paperboard is a paper with a basis weight above 224 g/m2, but there are exceptions. Paperboard can be single...

honeycomb is used in paper pallet

Paper pallet

Paper pallets are shipping or display pallets made from paperboard.-Construction:Paper shipping pallets come in corrugated fiberboard, partial wood decks or engineered with laminated paperboard...

s and package cushioning

Cushioning

Package cushioning is used to help protect fragile items during shipment. It is common for a transport package to be dropped, kicked, and impacted: These events may produce potentially damaging shocks. Transportation vibration from conveyors, trucks, railroads, or aircraft can also damage some...

, blocking and bracing.

Applications

Composite honeycomb structures have been used in numerous engineering and scientific applications.An early example of an aircraft built using honeycomb cores was the North American XB-70 Valkyrie.

| Application area | Industry | Company/Product |

|---|---|---|

| Racing shells | Sport | Vespoli Vespoli Vespoli USA is a manufacturer of racing shells for rowing. It was founded by former Georgetown University rower, Olympian, and World Rowing Champion Mike Vespoli in 1980. It is located on the Quinnipiac River in New Haven, Connecticut, United States.-History:... , Janousek Racing Boats |

| Aerospace manufacturing | Aerospace | Hexcel Hexcel Hexcel is a materials company incorporated in Delaware and headquartered in Stamford, Connecticut that manufactures advanced composite materials and structural parts... , Neomet Ltd. |

| Gliders | Aerospace | Schleicher ASW 19 Schleicher ASW 19 |-References:*****... , Solar Impulse Project |

| Helicopters | Aerospace | Kamov Ka-25 Kamov Ka-25 |-See also:-Bibliography:* Gunston, Bill. “The Osprey Encyclopaedia of Russian Aircraft 1875–1995”. London, Osprey. 1995. ISBN 1 85532 405 9-External links:* http://www.aviation.ru/Ka/#25* http://www.aviastar.org/helicopters_eng/ka-25.php... , Bell 533 Bell 533 -Bibliography:* Bell Helicopter. TRECOM Technical Report 63-42, "Summary Report, High-Performance-Helicopter Program, Phase I", U.S. Army Transportation Research Command, September 1963.... , Westland Lynx Westland Lynx The Westland Lynx is a British multi-purpose military helicopter designed and built by Westland Helicopters at its factory in Yeovil. Originally intended as a utility craft for both civil and naval usage, military interest led to the development of both battlefield and naval variants... |

| Jet aircraft | Aerospace | General Dynamics/Grumman F-111B General Dynamics/Grumman F-111B The General Dynamics/Grumman F-111B was developed as a long-range carrier-based interceptor follow-on to the F-4 Phantom II. It was developed in the 1960s by General Dynamics in conjunction with Grumman for the United States Navy as part of the joint Tactical Fighter Experimental with the United... , F-111 Aardvark |

| Rocket substructure | Aerospace | Saturn V Instrument Unit Saturn V Instrument Unit The Saturn V Instrument Unit is a ring-shaped structure fitted to the top of the Saturn V rocket's third stage and the Saturn IB's second stage . It was immediately below the SLA panels that contained the Lunar Module. The Instrument Unit contains the guidance system for the Saturn V rocket... , Mars Exploration Rover Mars Exploration Rover NASA's Mars Exploration Rover Mission is an ongoing robotic space mission involving two rovers, Spirit and Opportunity, exploring the planet Mars... , S-520 S-520 S-520 is the designation of a Japanese sounding rocket.The S-520 is a powerful single-stage rocket which is optionally equipped with three-axis attitude control and a recovery system... |

| LED technology | Lighting | SmartSlab SmartSlab SmartSlab is an LED technology invented in 1999 by Tom Barker. The SmartSlab technology uses a hexagonal pixel in a structural composite honeycomb so that it is possible for displays to be integrated into architecture.... |

| Loudspeaker technology | Audio | Loudspeaker#Driver design, Woofer Woofer Woofer is the term commonly used for a loudspeaker driver designed to produce low frequency sounds, typically from around 40 hertz up to about a kilohertz or higher. The name is from the onomatopoeic English word for a dog's bark, "woof"... |

| Telescope mirror structure | Aerospace | Hubble Space Telescope Hubble Space Telescope The Hubble Space Telescope is a space telescope that was carried into orbit by a Space Shuttle in 1990 and remains in operation. A 2.4 meter aperture telescope in low Earth orbit, Hubble's four main instruments observe in the near ultraviolet, visible, and near infrared... |

| Automobile structure | Automotive | Panther Solo Panther Solo The Panther Solo is a mid-engined sports car that was made by the British company Panther Car Company. It was available as a two-seat coupé, with the option of additional rear seats to make it a 2+2... , Dome F105 Dome F105 The Dome F105 was an unraced Formula One car designed and built by the Japanese motorsport constructor, Dome.-Concept and construction:Dome was founded in 1975 by brothers Minoru and Shoichi Hayashi, who had built their first racing car ten years earlier... , Bluebird-Proteus CN7 Bluebird-Proteus CN7 The Bluebird-Proteus CN7 was a technologically advanced wheel-driven land speed record-breaking car, driven by Donald Campbell, built in 1960 and rebuilt in 1962.- Design :... , Ferrari F50 Ferrari F50 The Ferrari F50 is a mid-engined range-topping sports car made by Ferrari. The F50 was introduced in 1995 to celebrate the company's 50th anniversary. The car is a two door, two seat convertible with a removable hardtop... |

| Snowboards | Sports | Snowboard Snowboard Snowboards are boards, usually with a width the length of one's foot, with the ability to glide on snow. Snowboards are differentiated from monoskis by the stance of the user... |

More recent developments show that honeycomb structures are also advantageous in applications involving nanohole arrays in anodized alumina, microporous arrays in polymer

Polymer

A polymer is a large molecule composed of repeating structural units. These subunits are typically connected by covalent chemical bonds...

thin film

Thin film

A thin film is a layer of material ranging from fractions of a nanometer to several micrometers in thickness. Electronic semiconductor devices and optical coatings are the main applications benefiting from thin film construction....

s, activated carbon

Activated carbon

Activated carbon, also called activated charcoal, activated coal or carbo activatus, is a form of carbon that has been processed to make it extremely porous and thus to have a very large surface area available for adsorption or chemical reactions.The word activated in the name is sometimes replaced...

honeycombs, and photonic band gap honeycomb structures.

Aerodynamics

A honeycomb meshMesh

Mesh consists of semi-permeable barrier made of connected strands of metal, fiber, or other flexible/ductile material. Mesh is similar to web or net in that it has many attached or woven strands.-Types of mesh:...

is often used in aerodynamics

Aerodynamics

Aerodynamics is a branch of dynamics concerned with studying the motion of air, particularly when it interacts with a moving object. Aerodynamics is a subfield of fluid dynamics and gas dynamics, with much theory shared between them. Aerodynamics is often used synonymously with gas dynamics, with...

to reduce or to create wind turbulence

Turbulence

In fluid dynamics, turbulence or turbulent flow is a flow regime characterized by chaotic and stochastic property changes. This includes low momentum diffusion, high momentum convection, and rapid variation of pressure and velocity in space and time...

. It is also used to obtain a standard profile in a wind tunnel

Wind tunnel

A wind tunnel is a research tool used in aerodynamic research to study the effects of air moving past solid objects.-Theory of operation:Wind tunnels were first proposed as a means of studying vehicles in free flight...

(temperature, flow speed). A major factor in choosing the right mesh is the length ratio (length vs honeycomb cell diameter) L/d.

Length ratio < 1:

Honeycomb meshes of low length ratio can be used on vehicles front grille

Grille

A grille or grill is an opening of several slits side by side in a wall or metal sheet or other barrier, usually to let air or water enter and/or leave but keep larger objects including people and animals in or out.-Spelling:In the United States, "grille" is used to differentiate the automotive...

. Beside the esthetic reasons, these meshes are used as screens to get a uniform profile and to reduce turbulences intensity.

Length ratio >> 1:

Basically, those honeycombs reduce lateral turbulence and eddies

Eddy (fluid dynamics)

In fluid dynamics, an eddy is the swirling of a fluid and the reverse current created when the fluid flows past an obstacle. The moving fluid creates a space devoid of downstream-flowing fluid on the downstream side of the object...

of the flow. Early wind tunnels used them with no screens. Unfortunately, this method introduced high turbulence intensity in the test section. Most modern tunnels use both honeycomb and screens.

While aluminium honeycombs are common use in the industry, other materials are offered for specific applications. People using metal structures should take care of removing burrs as they can introduce additional turbulences. Polycarbonate

Polycarbonate

PolycarbonatePhysical PropertiesDensity 1.20–1.22 g/cm3Abbe number 34.0Refractive index 1.584–1.586FlammabilityV0-V2Limiting oxygen index25–27%Water absorption – Equilibrium0.16–0.35%Water absorption – over 24 hours0.1%...

structures are a low-cost alternative.

The honeycombed, screened center of this open-circuit air intake for Langley's first wind tunnel ensured a steady, nonturbulent flow of air. Two mechanics pose near the entrance end of the actual tunnel, where air was pulled into the test section through a honeycomb arrangement to smoothen the flow.

Honeycomb is not the only cross-section available in order to reduce eddies in an airflow. Square, rectangular, circular and hexagonal cross-sections are other choices available, although honeycomb is generally the preferred choice.