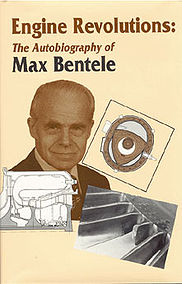

Max Bentele

Encyclopedia

Wankel engine

The Wankel engine is a type of internal combustion engine using an eccentric rotary design to convert pressure into a rotating motion instead of using reciprocating pistons. Its four-stroke cycle takes place in a space between the inside of an oval-like epitrochoid-shaped housing and a rotor that...

earned him the title, "Father of the Wankel Engine in the USA".

Bentele in Germany

Bentele had been fascinated with engineering at an early age and graduated from the Technical University of Stuttgart in the Fall of 1928 with a degree in mechanical and electrical engineering. Bentele spent his life up to the war years of World War IIWorld War II

World War II, or the Second World War , was a global conflict lasting from 1939 to 1945, involving most of the world's nations—including all of the great powers—eventually forming two opposing military alliances: the Allies and the Axis...

working on turbine

Turbine

A turbine is a rotary engine that extracts energy from a fluid flow and converts it into useful work.The simplest turbines have one moving part, a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades, or the blades react to the flow, so that they move and...

blade design for the Heinkel-Hirth, Germany

Germany

Germany , officially the Federal Republic of Germany , is a federal parliamentary republic in Europe. The country consists of 16 states while the capital and largest city is Berlin. Germany covers an area of 357,021 km2 and has a largely temperate seasonal climate...

's new jet engine

Jet engine

A jet engine is a reaction engine that discharges a fast moving jet to generate thrust by jet propulsion and in accordance with Newton's laws of motion. This broad definition of jet engines includes turbojets, turbofans, rockets, ramjets, pulse jets...

. Bentele excelled at this task, and after the war he managed one of Heinkel-Hirth's few remaining machine shops, this one virtually unscathed. He excelled at this job as well, and was approached to undertake the designing and manufacturing of much needed spare parts for Allied Jeep

Jeep

Jeep is an automobile marque of Chrysler . The first Willys Jeeps were produced in 1941 with the first civilian models in 1945, making it the oldest off-road vehicle and sport utility vehicle brand. It inspired a number of other light utility vehicles, such as the Land Rover which is the second...

s. It was this manufacturing and supply business that exemplified his talent.

Bentele in the United States

Bentele left his successful business at the request of the AmericansUnited States

The United States of America is a federal constitutional republic comprising fifty states and a federal district...

and British

United Kingdom

The United Kingdom of Great Britain and Northern IrelandIn the United Kingdom and Dependencies, other languages have been officially recognised as legitimate autochthonous languages under the European Charter for Regional or Minority Languages...

in order to study and repair damaged German

Germany

Germany , officially the Federal Republic of Germany , is a federal parliamentary republic in Europe. The country consists of 16 states while the capital and largest city is Berlin. Germany covers an area of 357,021 km2 and has a largely temperate seasonal climate...

jet aircraft

Jet aircraft

A jet aircraft is an aircraft propelled by jet engines. Jet aircraft generally fly much faster than propeller-powered aircraft and at higher altitudes – as high as . At these altitudes, jet engines achieve maximum efficiency over long distances. The engines in propeller-powered aircraft...

. Bentele successfully built twelve new aircrafts for such purposes and pleased the Americans. While it is believed that he was interrogated at this time, Bentele made contacts which ultimately brought him to the United States

United States

The United States of America is a federal constitutional republic comprising fifty states and a federal district...

for good. Bentele temporarily returned to Heinkel-Hirth in Germany

Germany

Germany , officially the Federal Republic of Germany , is a federal parliamentary republic in Europe. The country consists of 16 states while the capital and largest city is Berlin. Germany covers an area of 357,021 km2 and has a largely temperate seasonal climate...

and established a moped

Moped

Mopeds are a type of low-powered motorcycle designed to provide economical and relatively safe transport with minimal licensing requirements.Mopeds were once all equipped with bicycle-like pedals , but moped has been increasingly applied by governments to vehicles without pedals, based on their...

business there. It was also during this time that Bentele worked on turbine

Turbine

A turbine is a rotary engine that extracts energy from a fluid flow and converts it into useful work.The simplest turbines have one moving part, a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades, or the blades react to the flow, so that they move and...

and direct fuel injection engines for such companies as Bosch

Robert Bosch GmbH

Robert Bosch GmbH is a multinational engineering and electronics company headquartered in Gerlingen, near Stuttgart, Germany. It is the world's largest supplier of automotive components...

, L'Orange

L'Orange

"L'Orange" is a 1964 song recorded by French singer and songwriter Gilbert Bécaud. It was covered in 2003 by the contestants of the French third version of the TV reality show Star Academy, and achieved a great success in France and Belgium , where it topped the chart for several weeks...

, Daimler-Benz

Daimler-Benz

Daimler-Benz AG was a German manufacturer of automobiles, motor vehicles, and internal combustion engines; founded in 1926. An Agreement of Mutual Interest - which was valid until year 2000 - was signed on 1 May 1924 between Karl Benz's Benz & Cie., and Daimler Motoren Gesellschaft, which had...

, and the British Ministry of Supply. Shortly thereafter he immigrated to the United States

United States

The United States of America is a federal constitutional republic comprising fifty states and a federal district...

, where he was to work for Curtiss-Wright

Curtiss-Wright

The Curtiss-Wright Corporation was the largest aircraft manufacturer in the United States at the end of World War II, but has evolved to largely become a component manufacturer, specializing in actuators, aircraft controls, valves, and metalworking....

in developing new technologies.

Curtiss-Wright

Immediately after World War IIWorld War II

World War II, or the Second World War , was a global conflict lasting from 1939 to 1945, involving most of the world's nations—including all of the great powers—eventually forming two opposing military alliances: the Allies and the Axis...

, the Curtiss-Wright Corporation, the American aircraft manufacturing company directly descending from the Wright brothers

Wright brothers

The Wright brothers, Orville and Wilbur , were two Americans credited with inventing and building the world's first successful airplane and making the first controlled, powered and sustained heavier-than-air human flight, on December 17, 1903...

and industrial Glenn Curtiss

Glenn Curtiss

Glenn Hammond Curtiss was an American aviation pioneer and a founder of the U.S. aircraft industry. He began his career as a bicycle then motorcycle builder and racer, later also manufacturing engines for airships as early as 1906...

, became a defense contractor supplying aircraft and aircraft engines. In 1949, the ambitious Roy Hurley became president of the company and sought to acquire Bentele at any price. While Curtiss-Wright had been one of the top aircraft and aircraft engine producers in the world, the company was slow to adopt the new turbojet engine which began to dominate the market. There was simply no more possible tinkering that could be done to improve Curtiss's engines — a complete overhaul was necessary. Curtiss needed a new engine if it were to seriously compete for much needed government contracts which dominated the market.

Although Bentele did not have the proper government clearance — an issue which would seem to have hindered his ability — he worked to the fullest of his potential and brought results. In 1958, Hurley acquired Studebaker Packard, and it was soon discovered that German automobile and engine producer NSU

NSU Motorenwerke AG

NSU Motorenwerke AG, normally just NSU, was a German manufacturer of automobiles, motorcycles and pedal cycles, founded in 1873. It was acquired by Volkswagen Group in 1969...

had been working hard on a remarkable engine concept: the Wankel rotary engine of Felix Wankel

Felix Wankel

Felix Heinrich Wankel was a German mechanical engineer and inventor after whom the Wankel engine was named. He is the only twentieth century engineer to have designed an internal combustion engine which went into production.-Early life:Wankel was born in Lahr, Baden, in the upper Rhine Valley...

. Security surrounding this project was surprisingly lax for such a revolutionary invention, and it was even arranged for Bentele to study a model on his own, exploring the potential further development and production of such an engine at Curtiss-Wright. After a long weekend, Bentele emerged more than impressed with the project and was an admirer of a fellow mechanist Felix Wankel.

Bentele was one of several British, German and Swiss engineers that had recently been hired by C-W to broaden their engine line. Bentele, when he came to C-W, was assigned, as a “Chief Scientist,” to assist the large number of Engineering Section Heads that carried out the Design, Development, Testing, and Analysis for the various production and experimental engines in work at C-W. Bentele, who was well qualified to help solve existing problems, was soon unwelcome at the various Section Head offices. There were probably several reasons for this less than enthusiastic acceptance and some part of the cool reception had to be Bentele’s energetic approach . For one thing, this may not have been properly coordinated into the largely independent Engineering and Research Departments (Hurley, by his own admission, wa a “jackknife engineer” and did not come up through Engineering) and, for another, Bentele was not very modest when he went around to each office to review their technical problems and generally concluded, “in Germany, we did it this way,” which was interpreted as arrogant. Soon all doors were closed.

All save one. The youngest Section Head at Curtiss-Wright at that time, Charles Jones, was head of the Stress and Applied Mechanics Section, responsible for the structural integrity of C-W engines. Jones had a staff of 30 engineers, almost all with advanced degrees, but still had to put in an inordinate number of hours to keep up. He was delighted to have Bentele’s experience, similar to that of Jones’ but far more extensive, available to him. Bentele became a steady visitor, even before any Wankel issues came up. Therefore, it was quite natural for Bentele to ask Jones if he would try to develop the Wankel engine basic formulas (dimensions, dynamics, accelerations, velocities, vibrations, etc.) on weekends. Jones, already loaded on weekends, was intrigued and agreed. Within a few weekends Jones delivered the fformulae and analyses to Bentele.

Curtiss-Wright, led by Roy Hurley, determined that rotary technology would enable the comeback they needed. The Germans were very familiar and respectful of Bentele and he was a great asset to Curtiss-Wright. As luck would have it, NSU, who held patents and rights to the Wankel-derived engine in many countries at the time, failed to patent their engine in the United States, due to complex patent laws and their lawyer who was unfamiliar with these laws. Eventually, a deal was made that allowed Curtiss-Wright to gain a license on Wankel's technology, and was something that changed history. On October 21, 1958, Curtiss-Wright became the first company to purchase a license at the rate of $2.1 million and a 5% commission on all engines sold. Although Curtiss was forced to share major technological developments, Curtiss was the sole license holder of Wankel's little wonder in the United States.

In 1958 Bentele was asked by Hurley to review potential and, if promising, head the R&D program on the new Wankel rotary engine. When, Bentele shared with Jones that Hurley had asked him to review the prospects for the Wankel and, that he would depart for Germany and France (the Planche rotary compressor, experimenrts in France, etc.) to further check out related efforts and review work at the Wankel Institute, and he would like Jones to give up his present assignment and, working alone, and in secret, at an offsite location, make a theoretical evaluation of the engine’s requirements and potential. Jones agreed and, a month later, Jones handed Bentele a thick volume containing the calculations. Jones had predicted major performance factors including heat rejection, fuel efficiency, power, size, etc. and concluded that certain design changes to cooling, structure, bearings, dynamic inversion, etc. had to be made to the “proof of principle” rigs that Wankel and NSU had built and (briefly) run, before the concept would be effective.

The sealing elements were too delicate as run by Wankel but the basic principle of using a pressure actuated cylindrical pin at each apex of the rotor, was recognized, along with making the trochoid profile “oversized” by the radius of the apex seal tip was recognized as essential to seal in three planes and was retained unchanged but made heavier initially and later changed to more rugged C-W patented designs that still retained the cylindrical pin.

Shortly thereafter, the OK to proceed was given even though the license had not yet been sealed. A completely separate engineering unit was formed drawing the best from every department, all told that the work they did at the separate building was not to be discussed outside of that building.

Jones was assigned by Bentele to design the basic single rotor 60 cu. in. module, and later, a two rotor (w/ & w/o center bearing versions, which later became the workhorse for automotive, airplanes, silent “spy” aircraft, generator, automotive, inboard boat, etc. engines for C-w and the licensees that followed, in the U.S. and elsewhere) Other groups were assigned to scale the single rotor engine up by the square root of 10 for potentially 1000 Hp/rotor, make a 4 rotor/integral shaft w/ split gears and bearings version for marine use,

Bentele started from the ground up, running one of the most efficient research and development programs in the country, beginning with mathematical formulas and the solving of many problems even before physically touching the engine. Bentele determined what was needed and what was not, and was given full access to whatever accommodations he needed. Bentele's work on the engine was top secret, however word leaked to the public and it became common knowledge that Curtiss was developing a Wankel engine. The public was not familiar with the secretive engine, however rumors spread like wildfire regarding the engine's immense potential. When Curtiss went public with this information, NSU got angry, claiming that Bentele and Curtiss were trying to make it as though the Wankel was a product of American ingenuity and that they were denying any German involvement. This dispute was forgotten shortly thereafter.

As development continued throughout the early 1960s, Hurley and Curtiss were accused of fraudulent activity, as investors and stocks soared. However, there was no real product on the market yet at the time.

Father of the Wankel Engine in the USA

Bentele and his team studied the concepts of the Wankel rotary engine and started design of a prototype before the license was signed, settling on a 60 cubic inch (0.000984 m³) design using most of Wankel's original geometric sealing designs in the DKM54 model. In its first dynoDynamometer

A dynamometer or "dyno" for short, is a device for measuring force, moment of force , or power. For example, the power produced by an engine, motor or other rotating prime mover can be calculated by simultaneously measuring torque and rotational speed .A dynamometer can also be used to determine...

test in 1959, the new model, dubbed the IRC6, provided a spectacular performance of 100 bhp at 5500 rpm, which was impressive for such a small engine design (ref; SAE Paper 886D). Bentele and Jones then proceeded to design a custom cooling system that surpassed the NSU's with increased engine performance and reliability (ref. U.S. patent 3,007,460, 11/7/61, M. Bentele, C. Jones, and F.P. Sollinger). Extensive experimentation went on in nearly every aspect of the engine's design, per Bentele's orders, the process taking several years and continuing after Bentele had left C-W.. Output was gradually increased, as was general size of the engine and many other aspects as well. The late RC2-60 engine was tested in a 1966 Ford Mustang

Ford Mustang

The Ford Mustang is an automobile manufactured by the Ford Motor Company. It was initially based on the second generation North American Ford Falcon, a compact car. Introduced early on April 17, 1964, as a "1964½" model, the 1965 Mustang was the automaker's most successful launch since the Model A...

and performed well, providing similar performance to the Mustang

Ford Mustang

The Ford Mustang is an automobile manufactured by the Ford Motor Company. It was initially based on the second generation North American Ford Falcon, a compact car. Introduced early on April 17, 1964, as a "1964½" model, the 1965 Mustang was the automaker's most successful launch since the Model A...

's original V8 with less fuel consumption, noise and vibration, and physical size. The engine was also emission tested in a study by C-W and the University of Michigan (ref. SAE Paper 700074, D.E. Cole and C. Jones,SAE Trans., April 1974 ) in a Ford Galaxy; GM and AMC also tested rotary engines in their vehicles but did not publish findings.

In November 1962, Bentele and his teams developed a larger 425 hp ] four-rotor variant of the RC2-60 called the 4RC-6 for heavy duty (ref. SAE Paper 720468, " A Survey of Curtiss-Wright's 1958-1971 Rotating Combustion Engine Technological Developments," Detroit, 1972, Charles Jones) and potential aircraft use. It was the first multi-rotor Wankel engine built and was a true technological masterpiece.

Throughout most of his fulfilling career at Curtiss-Wright

Curtiss-Wright

The Curtiss-Wright Corporation was the largest aircraft manufacturer in the United States at the end of World War II, but has evolved to largely become a component manufacturer, specializing in actuators, aircraft controls, valves, and metalworking....

, which ended in May, 1967 when Bentele went to Avco-Lycoming, he was responsible for developing Wankel engine technology in more ways than anyone, perhaps even Dr. Wankel himself. And although Curtiss-Wright amassed a large number of patented Wankel engine designs and design improvements, none of these engines were ever produced for consumption by C-W due to complex corporate issues, but were used in commercially produced applications by licensees in the U.S. and abroad. Deere (Deere and Co. was given the license for the considerably nominal fee of $14 million, hoping to utilize such technology in its manufacture of farming and commercial equipment and tractors); nevertheless his work lives on in every Wankel engine produced around the world, as this technology was utilized by many manufacturers both in America and worldwide.

Impact

Bentele was a pioneer in life and his successes have shaped the world in which we live in today. His knowledge with regard to turbine jets were largely responsible for the successful eventual development of American jet airplanes which were to dominate the skies worldwide from nearly the instant they took to the air. His pivotal role in the Wankel rotary engine development program financially helped one of America's greatest corporations at the time, and more importantly helped the Wankel engine succeed in the world. Much of what we know today regarding these engines is inspired by him. Although the actual unique engine itself was designed by Felix Wankel, the commercial success and worldwide applications of these engines would not have been possible without the development of Bentele. In the 1950s and 1960s, such an engine was seen as remarkable and the way of the future. Today, the compact and efficient rotary engines have commercial applications in automobiles, notably in MazdaMazda

is a Japanese automotive manufacturer based in Fuchū, Aki District, Hiroshima Prefecture, Japan.In 2007, Mazda produced almost 1.3 million vehicles for global sales...

sports and racing cars (Mazda acquired a Wankel license in the late 1960s and early 1970s and spent many years refining the design), boat and marine craft, as well as in small custom airplanes built by enthusiasts and small aircraft companies.

Bentele revolutionized the field of corporate engineering, research and development, and was chair of the SAE

SAE International

SAE International is an organization for engineering professionals in the aerospace, automotive, and commercial vehicle industries. The Society is a standards development organization for the engineering of powered vehicles of all kinds, including cars, trucks, boats, aircraft, and others.SAE...

until his death on May 19, 2006. One of the most prestigious engineering awards given by the SAE is named for him.