Meat grinder

Encyclopedia

Meat

Meat is animal flesh that is used as food. Most often, this means the skeletal muscle and associated fat and other tissues, but it may also describe other edible tissues such as organs and offal...

, fish

Fish (food)

Fish is a food consumed by many species, including humans. The word "fish" refers to both the animal and to the food prepared from it. Fish has been an important source of protein for humans throughout recorded history.-Terminology:...

, vegetable

Vegetable

The noun vegetable usually means an edible plant or part of a plant other than a sweet fruit or seed. This typically means the leaf, stem, or root of a plant....

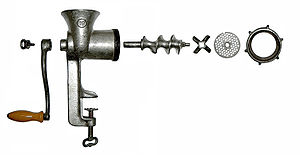

s or similar food. It replaces tools like the mincing knife, for example, which has been used to produce minced meat, filling etc. The producer puts the minced food into a funnel, which is placed on the top of the grinder. From there the material goes on a horizontal screw conveyor. This screw conveyor, that can be powered by a hand wheel or an electric motor, squashes and partially mixes the food. At the end of the screw conveyor there is a knife installed directly in front of the fixed hole plate. At this opening the minced meat comes out of the machine. The fineness of the meat depends on the size of the holes of the plate.

The meat grinder was invented by Karl Drais

Karl Drais

Karl Drais was a German inventor and invented the Laufmaschine , also later called the velocipede, draisine or "draisienne" , also nicknamed the dandy horse. This incorporated the two-wheeler principle that is basic to the bicycle and motorcycle and was the beginning of mechanized personal...

in the 19th century.

By changing the hole plate it is also possible to produce breadcrumbs or fill sausage casing. After the drop from the retainer, it is possible to change the hole plate. By removing the fixing screw the grinder can be disassembled completely for cleaning. Besides the domestic manually or motor operated grinders, there are also grinders for butchery (table- or shop-grinders for example) and for the food industry. Some large machines are able to produce several tons per hour.

For these machines the Typ C norm DIN EN 12331 "Food processing machinery - Mincing machines - Safety and hygiene requirements" from 2004-5 with the change from 2007-A2, is applied.

Mixer unit

A basic optional feature for larger grinders is the mixer unit. With this unit can be mixed different kinds of meat(for example beef or pork) with each other homogeneously and/or can be mixed the meat with additives, like salt or spices, before grinding it.Without such a mixer unit, the additives must be mixed into the meat after grinding it, which adversely affects the taste and appearance of most products.

Frozen meat grinder

Frozen meat grinders can process frozen blocks of meat, bacon and mechanically separated meatMechanically separated meat

Mechanically separated meat , a product also known as mechanically recovered/reclaimed meat or mechanically deboned meat , is a paste-like meat product produced by forcing beef, pork, turkey or chicken, under high pressure through a sieve or similar device to separate the bone from the edible meat...

up to –25 °C.

The frozen blocks can range from 90x50x15 cm to 90x50x20 cm, and the power can applies from 8.000 kg to 12.000 kg.

By the regular cutting the chopped meat can be processed through mixers and grinders, which reach an optimal addition in the cutter as well as a protection of the cutter and knives.

There are 2 different drive forms, a single rev-drive, which is ideal to grind frozen meat blocks, and a two rev-drive, which promises higher power by the application of a special meat worm.

The first cut takes place in the worm, who peels with his long pulled, sharpen meander/bend approximately 8 cm from the frozen meat and then to pass on for the next cut in the cutting set .

The lock protection prevents possible mechanical damages in too high burden/load, for example by a foreign body.