Plain bearing

Encyclopedia

Bearing (mechanical)

A bearing is a device to allow constrained relative motion between two or more parts, typically rotation or linear movement. Bearings may be classified broadly according to the motions they allow and according to their principle of operation as well as by the directions of applied loads they can...

, comprising just a bearing surface

Bearing surface

A bearing surface is a mechanical engineering term that refers to the area of contact between two objects. It usually is used in reference to bolted joints and bearings, but can be applied to a wide variety of engineering applications....

and no rolling elements. Therefore the journal (i.e., the part of the shaft

Axle

An axle is a central shaft for a rotating wheel or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to its surroundings, with the wheels rotating around the axle. In the former case, bearings or bushings are provided at the mounting points where the axle...

in contact with the bearing) slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of flat surfaces designed to allow motion; e.g., a drawer and the slides it rests on or the ways on the bed of a lathe.

Plain bearings, in general, are the least expensive type of bearing. They are also compact and lightweight, and they have a high load-carrying capacity.

Design

- Journal (friction, radial or rotary) bearing: This is the most common type of plain bearing; it is simply a shaft rotating in a bearing.

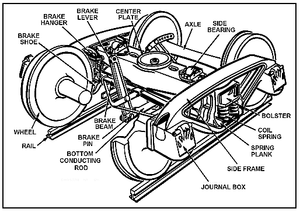

- In locomotive applications a journal bearing specifically referred to the plain bearing once used at the ends of the axleAxleAn axle is a central shaft for a rotating wheel or gear. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to its surroundings, with the wheels rotating around the axle. In the former case, bearings or bushings are provided at the mounting points where the axle...

s of railroad wheel sets, enclosed by journal boxes.

- In locomotive applications a journal bearing specifically referred to the plain bearing once used at the ends of the axle

- Linear bearing: This bearing provides linear motion; it may take the form of a circular bearing and shaft or any other two matching surfaces (e.g., a slide plateSlide plateA slide plate is linear bearing such as may be part of the expansion joints of bridges, high temperature horizontal ducts of water-tube boilers and other mechanical or structural engineering applications...

). - Thrust bearingThrust bearingA thrust bearing is a particular type of rotary bearing. Like other bearings they permit rotation between parts, but they are designed to support a high axial load while doing this.Thrust bearings come in several varieties....

: A thrust bearing provides a bearing surface for forces acting axialAxialAxial may mean:* Along the same line as an axis of rotation in geometry* A type of modal frame in music* One of several anatomical directions in an animal body* Axial age, the period from 800 to 200 BC in China, India and the western world...

to the shaft.

Integral

Integral plain bearings are built into the object of use. It is a hole that has been prepared into a bearing surface. Industrial integral bearings are usually made from cast ironCast iron

Cast iron is derived from pig iron, and while it usually refers to gray iron, it also identifies a large group of ferrous alloys which solidify with a eutectic. The color of a fractured surface can be used to identify an alloy. White cast iron is named after its white surface when fractured, due...

or babbitt and a hardened steel

Hardened steel

The term hardened steel is often used for a medium or high carbon steel that has been given the heat treatments of quenching followed by tempering. The quenching results in the formation of metastable martensite, the fraction of which is reduced to the desired amount during tempering. This is the...

shaft is used in the bearing.

Integral bearings are not as common because bushings are easy to accommodate and if they wear out then they are just replaced. Depending on the material an integral bearing may be less expensive but it cannot be replaced. If an integral bearing wears out then the item may be replaced or reworked to accept a bushing. Integral bearings were very common in 19th-century machinery but became progressively less common as interchangeable manufacture

Interchangeable parts

Interchangeable parts are parts that are, for practical purposes, identical. They are made to specifications that ensure that they are so nearly identical that they will fit into any device of the same type. One such part can freely replace another, without any custom fitting...

permeated the industry.

An example of a common integral plain bearing is the hinge

Hinge

A hinge is a type of bearing that connects two solid objects, typically allowing only a limited angle of rotation between them. Two objects connected by an ideal hinge rotate relative to each other about a fixed axis of rotation. Hinges may be made of flexible material or of moving components...

, which is both a thrust bearing and a journal bearing.

Bushing

A bushing, also known as a bush, is an independent plain bearing that is inserted into a housing to provide a bearing surfaceBearing surface

A bearing surface is a mechanical engineering term that refers to the area of contact between two objects. It usually is used in reference to bolted joints and bearings, but can be applied to a wide variety of engineering applications....

for rotary applications; this is the most common form of a plain bearing. Common designs include solid (sleeve and flanged), split, and clenched bushings. A sleeve, split, or clenched bushing is only a "sleeve" of material with an inner diameter (ID), outer diameter (OD), and length. The difference between the three types is that a solid sleeved bushing is solid all the way around, a split bushing has a cut along its length, and a clenched bearing is similar to a split bushing but with a clench across the cut. A flanged bushing is a sleeve bushing with a flange extending radially outward from the ID. The flange is used to positively locate the bushing when it is installed or to provide a thrust bearing surface.

Sleeve bearings of inch dimensions are almost exclusively dimensioned using the SAE

SAE International

SAE International is an organization for engineering professionals in the aerospace, automotive, and commercial vehicle industries. The Society is a standards development organization for the engineering of powered vehicles of all kinds, including cars, trucks, boats, aircraft, and others.SAE...

numbering system. The numbering system uses the format -XXYY-ZZ, where XX is the ID in sixteenths of an inch, YY is the OD in sixteenths of an inch, and ZZ is the length in eights of an inch. Metric sizes also exist.

A linear bushing is not usually pressed into a housing, but rather secured with a radial feature. Two such examples include two retaining ring

Retaining ring

A retaining ring is a fastener that holds components or assemblies onto a shaft or in a housing/bore when installed in a groove. Once installed, the exposed portion acts as a shoulder which retains the specific component or assembly....

s, or a ring that is molded onto the OD of the bushing that matches with a groove in the housing. This is usually a more durable way to retain the bushing, because the forces acting on the bushing could press it out.

The thrust form of a bushing is conventionally called a .

Two-piece

Two-piece plain bearings, known as full bearings in industrial machinery, are commonly used for larger diameters, such as crankshaftCrankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

bearings. The two halves are called shells. There are various systems used to keep the shells located. The most common method is a tab on the parting line

Parting line

A parting line in moldmaking is the place where two or more parts of the mold meet. At times, either because the mold halves do not meet with enough precision or because injection pressure is high, material will creep into the space between the molds. This material is generally called molding...

edge that correlates with a notch in the housing to prevent axial movement after installation. For large, thick shells a button stop or dowel pin is used. The button stop is screwed to the housing, while the dowel pin keys the two shells together. Another less common method uses a dowel pin that keys the shell to the housing through a hole or slot in the shell.

The distance from one parting edge to the other is slightly larger than the corresponding distance in the housing so that a light amount of pressure is required to install the bearing. This keeps the bearing in place as the two halves of the housing are installed. Finally, the shell's circumference is also slightly larger than the housing circumference so that when the two halves are bolted together the bearing crushes slightly. This creates a large amount of radial force around the entire bearing which keeps it from spinning. It also forms a good interface for heat to travel out of the bearings into the housing.

Materials

Plain bearings must be made from a material that is durable, low frictionFriction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and/or material elements sliding against each other. There are several types of friction:...

, low wear to the bearing and shaft, resistant to elevated temperatures, and corrosion resistant. Often the bearing is made up of at least two constituents, where one is soft and the other is hard. The hard constituent supports the load while the soft constituent supports the hard constituent. In general, the harder the surfaces in contact the lower the coefficient of friction and the greater the pressure required for the two to seize

Seize

Seize may refer to:*Seisin, legal possession*Seizing, a class of knots used to semi-permanently bind together two ropes*Seize , a British electronic band*The jamming of machine parts against each other, usually due to insufficient lubrication...

.

Babbitt

Babbitt is usually used in integral bearings. It is coated over the bore, usually to a thickness of 1 thou, depending on the diameter. Babbitt bearings are designed to not damage the journal during direct contact and to collect any contaminants in the lubrication.Bi-material

Bi-material bearings consist of two materials, a metal shell and a plastic bearing surface. Common combinations include a steel-backed PTFE-coated bronze and aluminum-backed FrelonFrelon (material)

Frelon is a polytetrafluoroethylene based material with other proprietary fillers to increase bearing characteristics, such as low wear, low friction, and high strength. It is chemically inert and self lubricating. It qualifies as a class III plain bearing...

. Steel-backed PTFE-coated bronze bearings are rated for more load than most other bi-metal bearings and are used for rotary and oscillating motions. Aluminum-backed frelon are commonly used in corrosive environments because the Frelon is chemically inert.

| Temperature range | P (max.) Pounds per square inch The pound per square inch or, more accurately, pound-force per square inch is a unit of pressure or of stress based on avoirdupois units... (MPa) Pascal (unit) The pascal is the SI derived unit of pressure, internal pressure, stress, Young's modulus and tensile strength, named after the French mathematician, physicist, inventor, writer, and philosopher Blaise Pascal. It is a measure of force per unit area, defined as one newton per square metre... ] | V (max.) | PV (max.) |

|

|---|---|---|---|---|

| Steel-backed PTFE-coated bronze | -328 – | 36000 psi (248 MPa) | 390 (2.0 m/s) | 51,000 (1.79 MPa m/s) |

| Aluminum-backed frelon | -400 – | 3000 psi (21 MPa) | 300 (1.52 m/s) | 20,000 (0.70 MPa m/s) |

Bronze

A common plain bearing design utilizes a hardened and polished steelSteel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

shaft and a softer bronze

Bronze

Bronze is a metal alloy consisting primarily of copper, usually with tin as the main additive. It is hard and brittle, and it was particularly significant in antiquity, so much so that the Bronze Age was named after the metal...

bushing. The bushing is replaced whenever it has worn too much.

Common bronze alloys used for bearings include: SAE 841, SAE 660 (CDA 932), SAE 863, and CDA 954.

| Temperature range | P (max.) Pounds per square inch The pound per square inch or, more accurately, pound-force per square inch is a unit of pressure or of stress based on avoirdupois units... (MPa) Pascal (unit) The pascal is the SI derived unit of pressure, internal pressure, stress, Young's modulus and tensile strength, named after the French mathematician, physicist, inventor, writer, and philosopher Blaise Pascal. It is a measure of force per unit area, defined as one newton per square metre... ] | V (max.) | PV (max.) |

|

|---|---|---|---|---|

| SAE 841 | 10 – | 2000 psi (14 MPa) | 1,200 (6.1 m/s) | 50,000 (1.75 MPa m/s) |

| SAE 660 | 10 – | 4000 psi (28 MPa) | 750 (3.8 m/s) | 75,000 (2.63 MPa m/s) |

| SAE 863 | 10 – | 4000 psi (28 MPa) | 225 (1.14 m/s) | 35,000 (1.23 MPa m/s) |

| CDA 954 | Less than 500 °F (260 °C) | 4500 psi (31 MPa) | 225 (1.14 m/s) | 125,000 (4.38 MPa m/s) |

Cast iron

A cast iron bearing is commonly used with a hardened steel shaft because the coefficient of friction is relatively low. The cast iron glazes over therefore wear becomes negligible.Graphite

In harsh environments, such as ovenOven

An oven is a thermally insulated chamber used for the heating, baking or drying of a substance. It is most commonly used for cooking. Kilns, and furnaces are special-purpose ovens...

s and dryer

Dryer

A dryer most commonly means:* Hair dryer* Hand dryer* Clothes dryer, also known as a tumble-dryer* Belt dryer* Cereal dryer, for food preservation* Desiccant, a substance that absorbs or adsorbs water...

s, a copper and graphite

Graphite

The mineral graphite is one of the allotropes of carbon. It was named by Abraham Gottlob Werner in 1789 from the Ancient Greek γράφω , "to draw/write", for its use in pencils, where it is commonly called lead . Unlike diamond , graphite is an electrical conductor, a semimetal...

alloy, commonly known by the trademarked name graphalloy

Graphalloy

Graphalloy is a group of metal impregnated graphite materials. The materials are commonly used for self-lubricating plain bearings or electrical contacts. They are proprietary materials owned by the Graphite Metallizing Corp.-Construction:...

, is used. The graphite

Graphite

The mineral graphite is one of the allotropes of carbon. It was named by Abraham Gottlob Werner in 1789 from the Ancient Greek γράφω , "to draw/write", for its use in pencils, where it is commonly called lead . Unlike diamond , graphite is an electrical conductor, a semimetal...

is a dry lubricant

Dry lubricant

Dry lubricants or solid lubricants are materials which despite being in the solid phase, are able to reduce friction between two surfaces sliding against each other without the need for a liquid media....

, therefore it is low friction and low maintenance. The copper adds strength, durability, and provides heat dissipation characteristics.

| Temperature range | P (max.) Pounds per square inch The pound per square inch or, more accurately, pound-force per square inch is a unit of pressure or of stress based on avoirdupois units... (MPa) Pascal (unit) The pascal is the SI derived unit of pressure, internal pressure, stress, Young's modulus and tensile strength, named after the French mathematician, physicist, inventor, writer, and philosopher Blaise Pascal. It is a measure of force per unit area, defined as one newton per square metre... ] | V (max.) | PV (max.) |

|

|---|---|---|---|---|

| Graphalloy Graphalloy Graphalloy is a group of metal impregnated graphite materials. The materials are commonly used for self-lubricating plain bearings or electrical contacts. They are proprietary materials owned by the Graphite Metallizing Corp.-Construction:... |

-450 F | 750 psi (5 MPa) | 75 (0.38 m/s) | 12,000 (0.42 MPa m/s) |

| Graphite | ? | ? | ? | ? |

Unalloyed graphite bearings are used in special applications, such as locations that are submerged in water.

Jewels

Known as jewel bearings, these bearings use jewelGemstone

A gemstone or gem is a piece of mineral, which, in cut and polished form, is used to make jewelry or other adornments...

s, such as sapphire

Sapphire

Sapphire is a gemstone variety of the mineral corundum, an aluminium oxide , when it is a color other than red or dark pink; in which case the gem would instead be called a ruby, considered to be a different gemstone. Trace amounts of other elements such as iron, titanium, or chromium can give...

, ruby

Ruby

A ruby is a pink to blood-red colored gemstone, a variety of the mineral corundum . The red color is caused mainly by the presence of the element chromium. Its name comes from ruber, Latin for red. Other varieties of gem-quality corundum are called sapphires...

, and garnet

Garnet

The garnet group includes a group of minerals that have been used since the Bronze Age as gemstones and abrasives. The name "garnet" may come from either the Middle English word gernet meaning 'dark red', or the Latin granatus , possibly a reference to the Punica granatum , a plant with red seeds...

.

Plastic

Solid plastic plain bearings are now increasingly popular due to dry-running lubrication-free behavior. Solid polymer plain bearings are low weight, corrosion resistant, and maintenance free. After research spanning decades, an accurate calculation of the service life of polymer plain bearings is possible today. Designing with solid polymer plain bearings is complicated by the wide range, and non-linearity, of coefficient of thermal expansion. These materials can heat rapidly when used in applications outside the recommended pV limits.Solid polymer type bearings are limited by the injection molding

Injection molding

Injection molding is a manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials. Material is fed into a heated barrel, mixed, and forced into a mold cavity where it cools and hardens to the configuration of the cavity...

process. Not all shapes are possible with this process and the shapes which are possible are limited to what is considered good design practice for injection molding. Plastic bearings are subject to the same design cautions as all other plastic parts: creep, high thermal expansion, softening (increased wear/reduced life) at elevated temperature, brittle fractures at cold temperatures, swelling due to moisture absorption. While most bearing-grade plastics/polymers are designed to reduce these design cautions, they still exist and should be carefully considered before specifying a solid polymer (plastic) type.

Plastic bearings are now everywhere from photocopy machines to the till

Cash register

A cash register or till is a mechanical or electronic device for calculating and recording sales transactions, and an attached cash drawer for storing cash...

s in the supermarket

Supermarket

A supermarket, a form of grocery store, is a self-service store offering a wide variety of food and household merchandise, organized into departments...

. Other applications include farm equipment

Farm equipment

Agricultural machinery is any kind of machinery used on a farm to help with farming. The best-known example of this kind is the tractor.-Soil cultivation:*Cultivator*Cultipacker*Chisel plow*Mulch tiller*Harrow**Spike harrow**Drag harrow...

, textile machinery, medical devices, food and packaging machines, car seating, marine equipment and many more.

Common plastics include nylon

Nylon

Nylon is a generic designation for a family of synthetic polymers known generically as polyamides, first produced on February 28, 1935, by Wallace Carothers at DuPont's research facility at the DuPont Experimental Station...

, polyacetal, polytetrafluoroethylene

Polytetrafluoroethylene

Polytetrafluoroethylene is a synthetic fluoropolymer of tetrafluoroethylene that finds numerous applications. PTFE is most well known by the DuPont brand name Teflon....

(PTFE), ultra-high-molecular-weight polyethylene (UHMWPE), rulon

Rulon

Rulon may refer to:Persons with the surname Rulon:*Kelly Rulon , 2004 Olympian in water poloPersons with the given name Rulon:*Rulon C...

, PEEK

PEEK

Polyether ether ketone is a colourless organic polymer thermoplastic used in engineering applications.-Synthesis:PEEK polymers are obtained by step-growth polymerization by the dialkylation of bisphenolate salts. Typical is the reaction of 4,4'-difluorobenzophenone with the disodium salt of...

, urethane

Polyurethane

A polyurethane is any polymer composed of a chain of organic units joined by carbamate links. Polyurethane polymers are formed through step-growth polymerization, by reacting a monomer with another monomer in the presence of a catalyst.Polyurethanes are...

, and vespel (a high-performance polyimide

Polyimide

Polyimide is a polymer of imide monomers. The structure of imide is as shown. Polyimides have been in mass production since 1955...

).

| Temperature range | P (max.) Pounds per square inch The pound per square inch or, more accurately, pound-force per square inch is a unit of pressure or of stress based on avoirdupois units... (MPa) Pascal (unit) The pascal is the SI derived unit of pressure, internal pressure, stress, Young's modulus and tensile strength, named after the French mathematician, physicist, inventor, writer, and philosopher Blaise Pascal. It is a measure of force per unit area, defined as one newton per square metre... ] | V (max.) | PV (max.) |

|

|---|---|---|---|---|

| Frelon | -400 F | 1500 (10 MPa) | 140 (0.71) (dry) | 10,000 (0.35) |

| Nylon | -20 – | 400 psi (3 MPa) | 360 (1.83 m/s) | 3,000 (0.11 MPa m/s) |

| MDS-filled nylon blend 1 | -40 – | 2000 psi (14 MPa) | 393 (2.0 m/s) | 3,400 (0.12 MPa m/s) |

| MDS-filled nylon blend 2 | -40 – | 300 psi (2 MPa) | 60 (0.30 m/s) | 3,000 (0.11 MPa m/s) |

| PEEK blend 1 | -148 – | 8500 psi (59 MPa) | 400 (2.0 m/s) | 3,500 (0.12 MPa m/s) |

| PEEK blend 2 | -148 – | 21750 psi (150 MPa) | 295 (1.50 m/s) | 37,700 (1.32 MPa m/s) |

| Polyacetal | -20 – | 1000 psi (7 MPa) | 1,000 (5.1 m/s) | 2,700 (0.09 MPa m/s) |

| PTFE | -350 – | 500 psi (3 MPa) | 100 (0.51 m/s) | 1,000 (0.04 MPa m/s) |

| Glass-filled PTFE | -350 – | 1000 psi (7 MPa) | 400 (2.0 m/s) | 11,000 (0.39 MPa m/s) |

| Rulon 641 | -400 – | 1000 psi (7 MPa) | 400 (2.0 m/s) | 10,000 (0.35 MPa m/s) |

| Rulon J | -400 – | 750 psi (5 MPa) | 400 (2.0 m/s) | 7,500 (0.26 MPa m/s) |

| Rulon LR | -400 – | 1000 psi (7 MPa) | 400 (2.0 m/s) | 10,000 (0.35 MPa m/s) |

| UHMWPE | -200 – | 1000 psi (7 MPa) | 100 (0.51 m/s) | 2,000 (0.07 MPa m/s) |

| MDS-filled urethane | -40 – | 700 psi (5 MPa) | 200 (1.02 m/s) | 11,000 (0.39 MPa m/s) |

| Vespel | -400 – | 4900 psi (34 MPa) | 3,000 (15.2 m/s) | 300,000 (10.5 MPa m/s) |

Others

- CeramicCeramicA ceramic is an inorganic, nonmetallic solid prepared by the action of heat and subsequent cooling. Ceramic materials may have a crystalline or partly crystalline structure, or may be amorphous...

bearings are very hard and sand and other grit which enter the bearing are simply ground to a fine powder which does not inhibit the operation of the bearing. - Lubrite

- Lignum vitaeLignum vitaeLignum vitae is a trade wood, also called guayacan or guaiacum, and in parts of Europe known as pockenholz, from trees of the genus Guaiacum. This wood was once very important for applications requiring a material with its extraordinary combination of strength, toughness and density...

is a self lubricating wood and in clocks it gives extremely long life.

Lubrication

The types of lubricationLubrication

Lubrication is the process, or technique employed to reduce wear of one or both surfaces in close proximity, and moving relative to each another, by interposing a substance called lubricant between the surfaces to carry or to help carry the load between the opposing surfaces. The interposed...

system can be categorized into three groups:

- Class I — bearings that require the application of a lubricant from an external source (e.g. oil, grease, etc.).

- Class II — Bearings that contain a lubricant within the walls of the bearing (e.g. bronze, Graphite, etc,). Typically these bearings require an outside lubricant to achieve maximum performance.

- Class III — bearings made of materials that are the lubricant. These bearings are typically considered "self-lubricating" and can run without an external lubricant.

Examples of the second type of bearing are Oilite

Oilite

Oilite is a bronze or iron alloy impregnated with an oil lubricant commonly used in bearing applications. The original Oilite and Oilite Plus are bronze alloys, but the related bearing alloys Super Oilite and Super Oilite 16 are iron based...

s and plastic bearings made from polyacetal; examples of the third type are metalized graphite bearings and PTFE bearings.

Most plain bearings have a plain inner surface, however some are grooved

Groove (machining)

In manufacturing or mechanical engineering a groove is a long and narrow indentation built into a material, generally for the purpose of allowing another material or part to move within the groove and be guided by it. Examples include:...

. The grooves help lubrication enter the bearing and cover the whole journal.

Self-lubricating plain bearings have a lubricant contained within the bearing walls. There are many forms of self-lubricating bearings. The first, and most common, are sintered

Sintering

Sintering is a method used to create objects from powders. It is based on atomic diffusion. Diffusion occurs in any material above absolute zero, but it occurs much faster at higher temperatures. In most sintering processes, the powdered material is held in a mold and then heated to a temperature...

metal bearings, which have porous walls. The porous walls draw oil in via capillary action

Capillary action

Capillary action, or capilarity, is the ability of a liquid to flow against gravity where liquid spontanously rise in a narrow space such as between the hair of a paint-brush, in a thin tube, or in porous material such as paper or in some non-porous material such as liquified carbon fiber, or in a...

and release the oil when pressure

Pressure

Pressure is the force per unit area applied in a direction perpendicular to the surface of an object. Gauge pressure is the pressure relative to the local atmospheric or ambient pressure.- Definition :...

or heat

Heat

In physics and thermodynamics, heat is energy transferred from one body, region, or thermodynamic system to another due to thermal contact or thermal radiation when the systems are at different temperatures. It is often described as one of the fundamental processes of energy transfer between...

is applied. Another form is a solid one-piece metal bushing with a figure eight groove channel on the ID that is filled with graphite. A similar bearing replaces the figure eight groove with holes that are plugged with graphite; this allows the bearing to be lubricated inside and out. The last form is a plastic bearing, which has the lubricant molded into the bearing. The lubricant is released as the bearing is run in.

There are three main types of lubrication: full-film condition, boundary condition, and dry condition. Full-film conditions are when the bearing's load is carried solely by a film of fluid lubricant and there is no contact between the two bearing surfaces. In mix or boundary conditions, load is carried partly by direct surface contact and partly by a film forming between the two. In a dry condition, the full load is carried by surface-to-surface contact.

Bearings that are made from bearing grade materials always run in the dry condition. The other two classes of plain bearings can run in all three conditions; the condition in which a bearing runs is dependent on the operating conditions, load, relative surface speed, clearance within the bearing, quality and quantity of lubricant, and temperature (affecting lubricant viscosity). If the plain bearing is not designed to run in the dry or boundary condition it will wear out and have a high coefficient of friction. Dry and boundary conditions may be experienced even in a fluid bearing when operating outside of its normal operating conditions; e.g., at startup and shutdown.

Fluid lubrication

Fluid lubrication results in a full-film or a boundary condition lubrication mode. A properly designed bearing system reduces friction by eliminating surface-to-surface contact between the journal and bearing through fluid dynamic effectsFluid dynamics

In physics, fluid dynamics is a sub-discipline of fluid mechanics that deals with fluid flow—the natural science of fluids in motion. It has several subdisciplines itself, including aerodynamics and hydrodynamics...

.

Fluid bearings can be hydrostatically or hydrodynamically lubricated. Hydrostatically lubricated bearings are lubricated by an external pump

Pump

A pump is a device used to move fluids, such as liquids, gases or slurries.A pump displaces a volume by physical or mechanical action. Pumps fall into three major groups: direct lift, displacement, and gravity pumps...

which always keeps a static amount of pressure. In a hydrodynamic bearing the pressure in the oil film is maintained by the rotation of the journal. Hydrostatic bearings enter a hydrodynamic state when the journal is rotating. Hydrostatic bearings almost always use oil

Oil

An oil is any substance that is liquid at ambient temperatures and does not mix with water but may mix with other oils and organic solvents. This general definition includes vegetable oils, volatile essential oils, petrochemical oils, and synthetic oils....

, while hydrodynamic bearings can use oil or grease

Grease (lubricant)

The term grease is used to describe semisolid lubricants. Although the word grease is also used to describe rendered fat of animals, in the context of lubrication, grease typically applies to a material consisting of a soap emulsified with mineral or vegetable oil...

. An example of a hydrostatic bearing is the heavily-loaded bearings (main

Main bearing

In a piston engine, the main bearings are the bearings on which the crankshaft rotates, usually plain or journal bearings.All engines have a minimum of two main bearings, one at each end of the crankshaft, and they may have as many as one more than the number of crank pins...

, connecting rod

Connecting rod

In a reciprocating piston engine, the connecting rod or conrod connects the piston to the crank or crankshaft. Together with the crank, they form a simple mechanism that converts linear motion into rotating motion....

big-end and camshaft

Camshaft

A camshaft is a shaft to which a cam is fastened or of which a cam forms an integral part.-History:An early cam was built into Hellenistic water-driven automata from the 3rd century BC. The camshaft was later described in Iraq by Al-Jazari in 1206. He employed it as part of his automata,...

) in an automobile engine, which are usually fed oil via a hole in the bearing.

Hydrodynamic bearings require greater care in design and operation than hydrostatic bearings. They are also more prone to initial wear because lubrication does not occur until there is rotation of the shaft. At low rotational speeds the lubrication may not attain complete separation between shaft and bushing. As a result, hydrodynamic bearings are often aided by secondary bearings which support the shaft during start and stop periods, protecting the fine tolerance machined surfaces of the journal bearing.

In the hydrodynamic state a lubrication "wedge" forms, which lifts the journal. The journal also slightly shifts horizontally in the direction of rotation. The location of the journal is measured by the attitude angle, which is angle formed between the horizontal and a line that crosses through the center of the journal and the center of the bearing. The attitude angle is dependent on the direction of rotation, oil pressure (in hydrostatic bearings), and electromagnetic forces (in electromagnetic equipment).

One disadvantage specific to fluid-lubricated journal bearings is oil whirl, also known as oil whip. Oil whirl is when a lubrication wedge cannot form, but instead "whirls" around the bearing. This leads to direct contact between the journal and the bearing, which quickly wears out the bearing. Moreover, the journal precesses in the opposite direction of rotation, causing the friction to increase.

One design used to minimize this problem is called the lemon bore or elliptical bore. In this design, shim

Shim

A shim is a thin and often tapered or wedged piece of material, used to fill small gaps or spaces between objects. Shims are typically used in order to support, adjust for better fit, or provide a level surface...

s are installed between the two halves of the bearing housing and then the bore is machined to size. After the shims are removed, the bore resembles a lemon shape, which decreases the clearance in one direction of the bore and increases the pre-load in that direction. The disadvantage of this design is its lower load carrying capacity, as compared to typical journal bearings. It is also still susceptible to oil whirl at high speeds, however its cost is relatively low.

Another design is the pressure dam or dammed groove, which has a shallow relief cut in the center of the bearing over the top half of the bearing. The groove abruptly stops in order to create a downward force to stabilize the journal. This design has a high load capacity and corrects most oil whirl situations. The disadvantage is that it only works in one direction. Offsetting the bearing halves does the same thing as the pressure dam. The only difference is the load capacity increases as the offset increases.

A more radical design is the tilting-pad design, which uses multiple pad that are designed to move with changing loads. It is usually used in very large applications.

Related components

Other components that are commonly used with plain bearings include:- Pillow blockPillow block bearingA pillow block, also known as a plummer block or bearing housing, is a pedestal used to provide support for a rotating shaft with the help of compatible bearings & various accessories...

: These are standardized bearing mounts designed to accept plain bearings. They are designed to mount to a flat surface. - Ring oilerRing oilerA ring oiler or oil ring is a form of oil-lubrication system for bearings.Ring oilers were used for medium-speed applications with moderate loads, during the first half of the 20th century. These represented the later years of the stationary steam engine, and the beginnings of the high-speed steam...

: A lubricating mechanism used in the first half of the 20th century for medium speed applications. - Stuffing boxStuffing boxA stuffing box is an assembly which is used to house a gland seal. It is used to prevent leakage of fluid, such as water or steam, between sliding or turning parts of machine elements.-Boats:...

: A sealing system used to keep fluid from leaking out of a pressurized system through the plain bearing.

External links

- Kinematic Models for Design Digital Library (KMODDL) - Movies and photos of hundreds of working mechanical-systems models at Cornell University. Also includes an e-book library of classic texts on mechanical design and engineering.