Plate heat exchanger

Encyclopedia

A plate heat exchanger is a type of heat exchanger

that uses metal plates to transfer heat

between two fluid

s. This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area

because the fluids spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature

change. Plate heat exchangers are now common and very small brazed versions are used in the hot-water sections of millions of combination boilers. The high heat transfer efficiency for such a small physical size has increased the domestic hot water (DHW) flowrate of combination boilers. The small plate heat exchanger has made a great impact in domestic heating and hot-water. Larger commercial versions use gaskets between the plates, smaller version tend to be brazed.

The concept behind a heat exchanger is the use of pipes or other containment vessels to heat or cool one fluid by transferring heat between it and another fluid. In most cases, the exchanger consists of a coiled pipe containing one fluid that passes through a chamber containing another fluid. The walls of the pipe are usually made of metal

, or another substance with a high thermal conductivity

, to facilitate the interchange, whereas the outer casing of the larger chamber is made of a plastic

or coated with thermal insulation

, to discourage heat from escaping from the exchanger.

The plate heat exchanger (PHE) was invented by Dr Richard Seligman in 1923 and revolutionised methods of indirect heating and cooling of fluids. Dr Richard Seligman founded APV

in 1910 as the Aluminium Plant & Vessel Company Limited, a specialist fabricating firm supplying welded vessels to the brewery and vegetable oil trades.

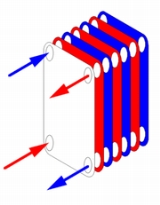

The plate heat exchanger (PHE) is a specialized design well suited to transferring heat between medium- and low-pressure fluids. Welded, semi-welded and brazed heat exchangers are used for heat exchange between high-pressure fluids or where a more compact product is required. In place of a pipe passing through a chamber, there are instead two alternating chambers, usually thin in depth, separated at their largest surface by a corrugated metal plate. The plates used in a plate and frame heat exchanger are obtained by one piece pressing of metal plates. Stainless steel is a commonly used metal for the plates because of its ability to withstand high temperatures, its strength, and its corrosion resistance. The plates are often spaced by rubber sealing gaskets which are cemented into a section around the edge of the plates. The plates are pressed to form troughs at right angles to the direction of flow of the liquid which runs through the channels in the heat exchanger. These troughs are arranged so that they interlink with the other plates which forms the channel with gaps of 1.3–1.5 mm between the plates.

The plate heat exchanger (PHE) is a specialized design well suited to transferring heat between medium- and low-pressure fluids. Welded, semi-welded and brazed heat exchangers are used for heat exchange between high-pressure fluids or where a more compact product is required. In place of a pipe passing through a chamber, there are instead two alternating chambers, usually thin in depth, separated at their largest surface by a corrugated metal plate. The plates used in a plate and frame heat exchanger are obtained by one piece pressing of metal plates. Stainless steel is a commonly used metal for the plates because of its ability to withstand high temperatures, its strength, and its corrosion resistance. The plates are often spaced by rubber sealing gaskets which are cemented into a section around the edge of the plates. The plates are pressed to form troughs at right angles to the direction of flow of the liquid which runs through the channels in the heat exchanger. These troughs are arranged so that they interlink with the other plates which forms the channel with gaps of 1.3–1.5 mm between the plates.

The plates produce an extremely large surface area, which allows for the fastest possible transfer. Making each chamber thin ensures that the majority of the volume of the liquid contacts the plate, again aiding exchange. The troughs also create and maintain a turbulent flow in the liquid to maximize heat transfer in the exchanger. A high degree of turbulence can be obtained at low flow rates and high heat transfer coefficient can then be achieved.

A plate heat exchanger consists of a series of thin, corrugated plates which are mentioned above. These plates are gasketed, welded or brazed together depending on the application of the heat exchanger. The plates are compressed together in a rigid frame to form an arrangement of parallel flow channels with alternating hot and cold fluids.

As compared to shell and tube heat exchangers, the temperature approach in a plate heat exchangers may be as low as 1 °C whereas shell and tube heat exchangers require an approach of 5 °C or more. For the same amount of heat exchanged, the size of the plate heat exchanger is smaller, because of the large heat transfer area afforded by the plates (the large area through which heat can travel). Expansion and reduction of the heat transfer area is possible in a plate heat exchanger.

An important aspect to take into account when evaluating a heat exchanger are the forms of corrugation within the heat exchanger. There are two types: intermating and chevron corrugations. In general, greater heat transfer enhancement is produced from chevrons for a given increase in pressure drop and are more commonly used than intermating corrugations.[1]

Q = UA∆Tm

where U is the overall heat transfer coefficient, A is the total plate area, and ∆Tm is the temperature difference. U is dependent upon the heat transfer coefficients in the hot and cold streams.[1]

Heat exchanger

A heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact...

that uses metal plates to transfer heat

Heat

In physics and thermodynamics, heat is energy transferred from one body, region, or thermodynamic system to another due to thermal contact or thermal radiation when the systems are at different temperatures. It is often described as one of the fundamental processes of energy transfer between...

between two fluid

Fluid

In physics, a fluid is a substance that continually deforms under an applied shear stress. Fluids are a subset of the phases of matter and include liquids, gases, plasmas and, to some extent, plastic solids....

s. This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area

Surface area

Surface area is the measure of how much exposed area a solid object has, expressed in square units. Mathematical description of the surface area is considerably more involved than the definition of arc length of a curve. For polyhedra the surface area is the sum of the areas of its faces...

because the fluids spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature

Temperature

Temperature is a physical property of matter that quantitatively expresses the common notions of hot and cold. Objects of low temperature are cold, while various degrees of higher temperatures are referred to as warm or hot...

change. Plate heat exchangers are now common and very small brazed versions are used in the hot-water sections of millions of combination boilers. The high heat transfer efficiency for such a small physical size has increased the domestic hot water (DHW) flowrate of combination boilers. The small plate heat exchanger has made a great impact in domestic heating and hot-water. Larger commercial versions use gaskets between the plates, smaller version tend to be brazed.

The concept behind a heat exchanger is the use of pipes or other containment vessels to heat or cool one fluid by transferring heat between it and another fluid. In most cases, the exchanger consists of a coiled pipe containing one fluid that passes through a chamber containing another fluid. The walls of the pipe are usually made of metal

Metal

A metal , is an element, compound, or alloy that is a good conductor of both electricity and heat. Metals are usually malleable and shiny, that is they reflect most of incident light...

, or another substance with a high thermal conductivity

Thermal conductivity

In physics, thermal conductivity, k, is the property of a material's ability to conduct heat. It appears primarily in Fourier's Law for heat conduction....

, to facilitate the interchange, whereas the outer casing of the larger chamber is made of a plastic

Plastic

A plastic material is any of a wide range of synthetic or semi-synthetic organic solids used in the manufacture of industrial products. Plastics are typically polymers of high molecular mass, and may contain other substances to improve performance and/or reduce production costs...

or coated with thermal insulation

Thermal insulation

Thermal insulation is the reduction of the effects of the various processes of heat transfer between objects in thermal contact or in range of radiative influence. Heat transfer is the transfer of thermal energy between objects of differing temperature...

, to discourage heat from escaping from the exchanger.

The plate heat exchanger (PHE) was invented by Dr Richard Seligman in 1923 and revolutionised methods of indirect heating and cooling of fluids. Dr Richard Seligman founded APV

APV

APV may refer to:* APV , or AP5, a selective NMDA receptor antagonist* Actuarial present value, a probability weighted present value often used in insurance* Adjusted present value, a variation of the net present value...

in 1910 as the Aluminium Plant & Vessel Company Limited, a specialist fabricating firm supplying welded vessels to the brewery and vegetable oil trades.

Design of plate and frame heat exchangers

The plates produce an extremely large surface area, which allows for the fastest possible transfer. Making each chamber thin ensures that the majority of the volume of the liquid contacts the plate, again aiding exchange. The troughs also create and maintain a turbulent flow in the liquid to maximize heat transfer in the exchanger. A high degree of turbulence can be obtained at low flow rates and high heat transfer coefficient can then be achieved.

A plate heat exchanger consists of a series of thin, corrugated plates which are mentioned above. These plates are gasketed, welded or brazed together depending on the application of the heat exchanger. The plates are compressed together in a rigid frame to form an arrangement of parallel flow channels with alternating hot and cold fluids.

As compared to shell and tube heat exchangers, the temperature approach in a plate heat exchangers may be as low as 1 °C whereas shell and tube heat exchangers require an approach of 5 °C or more. For the same amount of heat exchanged, the size of the plate heat exchanger is smaller, because of the large heat transfer area afforded by the plates (the large area through which heat can travel). Expansion and reduction of the heat transfer area is possible in a plate heat exchanger.

Evaluating plate heat exchangers

All plate heat exchangers look similar on the outside. The difference lies on the inside, in the details of the plate design and the sealing technologies used. Hence, when evaluating a plate heat exchanger, it is very important not only to explore the details of the product being supplied, but also to analyze the level of research and development carried out by the manufacturer and the post-commissioning service and spare parts availability.An important aspect to take into account when evaluating a heat exchanger are the forms of corrugation within the heat exchanger. There are two types: intermating and chevron corrugations. In general, greater heat transfer enhancement is produced from chevrons for a given increase in pressure drop and are more commonly used than intermating corrugations.[1]

Plate heat transfer equation

The total rate of heat transfer between the hot and cold fluids passing through a plate heat exchanger may be expressed as:Q = UA∆Tm

where U is the overall heat transfer coefficient, A is the total plate area, and ∆Tm is the temperature difference. U is dependent upon the heat transfer coefficients in the hot and cold streams.[1]

Books

- Hewitt, G, Shires, G, Bott, T 1994, Process Heat Transfer, CRC Press Inc, Florida.[1]

External links

- A list of published articles pertaining to plate heat exchangers

- A screening method for the optimal selection of plate heat exchanger configurations by J.M.Pinto and J.A.W.Gut, University of São PauloUniversity of São PauloUniversidade de São Paulo is a public university in the Brazilian state of São Paulo. It is the largest Brazilian university and one of the country's most prestigious...

, Brazil. - Seeking the optimal design of a typical plate heat exchanger (PHE) by Athanasios G. Kanaris, Aikaterini A. Mouza and Spiros V. Paras, Aristotle University of ThessalonikiAristotle University of ThessalonikiThe Aristotle University of Thessaloniki is the largest Greek university, and the largest university in the Balkans. It was named after the philosopher Aristotle, who was born in Stageira, Chalcidice, about 55 km east of Thessaloniki, in Central Macedonia...

.