Product lifecycle management

Encyclopedia

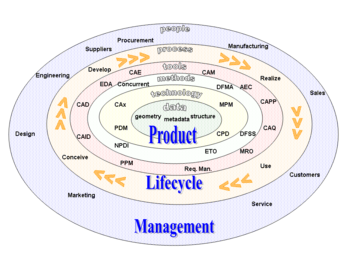

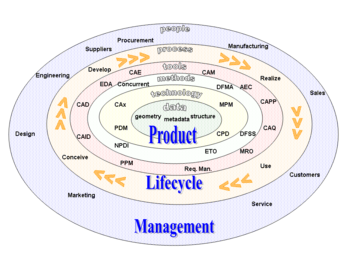

In industry, product lifecycle management (PLM) is the process of managing the entire lifecycle of a product from its conception, through design and manufacture, to service and disposal. PLM integrates people, data, processes and business systems and provides a product information backbone for companies and their extended enterprise.

Product lifecycle management (PLM) should be distinguished from 'Product life cycle management (marketing)' (PLCM). PLM describes the engineering aspect of a product, from managing descriptions and properties of a product through its development and useful life; whereas, PLCM refers to the commercial management of life of a product in the business market with respect to costs and sales measures.

Product lifecycle management is one of the four cornerstones of a corporation's information technology

structure. All companies need to manage communications and information with their customers (CRM-customer relationship management

), their suppliers (SCM-supply chain management

), their resources within the enterprise (ERP-enterprise resource planning

) and their planning (SDLC-systems development life cycle

). In addition, manufacturing engineering companies must also develop, describe, manage and communicate information about their products.

One form of PLM is called people-centric PLM. While traditional PLM tools have been deployed only on release or during the release phase, people-centric PLM targets the design phase.

As of 2009, ICT development (EU-funded PROMISE project 2004–2008) has allowed PLM to extend beyond traditional PLM and integrate sensor data and real time 'lifecycle event data' into PLM, as well as allowing this information to be made available to different players in the total lifecycle of an individual product (closing the information loop). This has resulted in the extension of PLM into closed-loop lifecycle management (CL2M).

Note: While application software is not required for PLM processes, the business complexity and rate of change requires organizations execute as rapidly as possible.

Systems engineering is focused on meeting all requirements, primary meeting customer needs, and coordinating the systems design process by involving all relevant disciplines. Product and portfolio management is focused on managing resource allocation, tracking progress vs. plan for projects in the new product development projects that are in process (or in a holding status). Portfolio management is a tool that assists management in tracking progress on new products and making trade-off decisions when allocating scarce resources. Product data management is focused on capturing and maintaining information on products and/or services through their development and useful life.

, CAM

and PDM

, but can be viewed as the integration of these tools with methods, people and the processes through all stages of a product’s life. It is not just about software technology but is also a business strategy.

For simplicity the stages described are shown in a traditional sequential engineering workflow.

For simplicity the stages described are shown in a traditional sequential engineering workflow.

The exact order of event and tasks will vary according to the product and industry in question but the main processes are:

The major key point events are:

The reality is however more complex, people and departments cannot perform their tasks in isolation and one activity cannot simply finish and the next activity start. Design is an iterative process, often designs need to be modified due to manufacturing constraints or conflicting requirements.

Where exactly a customer order fits into the time line depends on the industry type, whether the products are for example build to order, engineer to order, or assemble to order.

, Vice President for Product Engineering and Development. After introducing its compact Jeep Cherokee (XJ)

, the vehicle that launched the modern sport utility vehicle

(SUV) market, AMC began development of a new model, that later came out as the Jeep Grand Cherokee

. The first part in its quest for faster product development was computer-aided design

(CAD) software system that make engineers more productive. The second part in this effort was the new communication system that allowed conflicts to be resolved faster, as well as reducing costly engineering changes because all drawings and documents were in a central database. The product data management was so effective, that after AMC was purchased by Chrysler, the system was expanded throughout the enterprise connecting everyone involved in designing and building products. While an early adopter of PLM technology, Chrysler was able to become the auto industry's lowest-cost producer, recording development costs that were half of the industry average by the mid-1990s.

activities such as product portfolio management (PPM), particularly with regards to new product development

(NPD). There are several life-cycle models in industry to consider, but most are rather similar. What follows below is one possible life-cycle model; while it emphasizes hardware-oriented products, similar phases would describe any form of product or service, including non-technical or software-based products:

Parallel to the requirements specification the initial concept design work is carried out defining the aesthetics of the product together with its main functional aspects. For the industrial design

, Styling, work many different media are used from pencil and paper, clay models to 3D CAID computer-aided industrial design

software.

In some concepts, the investment of resources into research or analysis-of-options may be included in the conception phase – e.g. bringing the technology to a level of maturity sufficent to move to the next phase. However, life-cycle engineering is iterative. It is always possible that something doesn't work well in any phase enough to back up into a prior phase – perhaps all the way back to conception or research. There are many examples to draw from.

.

The main tool used for design and development is CAD. This can be simple 2D drawing / drafting or 3D parametric feature based solid/surface modeling. Such software includes technology such as Hybrid Modeling, Reverse Engineering

, KBE (knowledge-based engineering

), NDT (Nondestructive testing

), Assembly construction.

This step covers many engineering disciplines including: mechanical, electrical, electronic, software (embedded

), and domain-specific, such as architectural, aerospace, automotive, ... Along with the actual creation of geometry there is the analysis of the components and product assemblies. Simulation, validation and optimization tasks are carried out using CAE (computer-aided engineering

) software either integrated in the CAD package or stand-alone. These are used to perform tasks such as:- Stress analysis, FEA (finite element analysis); kinematics

; computational fluid dynamics

(CFD); and mechanical event simulation (MES). CAQ (computer-aided quality

) is used for tasks such as Dimensional tolerance (engineering)

analysis.

Another task performed at this stage is the sourcing of bought out components, possibly with the aid of procurement

systems.

software. This will also involve analysis tools for process simulation for operations such as casting, molding, and die press forming.

Once the manufacturing method has been identified CPM comes into play. This involves CAPE (computer-aided production engineering) or CAP/CAPP – (production planning) tools for carrying out factory, plant and facility layout and production simulation. For example: press-line simulation; and industrial ergonomics; as well as tool selection management.

Once components are manufactured their geometrical form and size can be checked against the original CAD data with the use of computer-aided inspection equipment and software.

Parallel to the engineering tasks, sales product configuration and marketing documentation work will be taking place. This could include transferring engineering data (geometry and part list data) to a web based sales configurator and other desktop publishing

systems.

/recycling

information. This involves using tools such as Maintenance, Repair and Operations Management (MRO

) software.

It is easy to forget that there is an end-of-life to every product. Whether it be disposal or destruction of material objects or information, this needs to be considered since it may not be free from ramifications.

A major part of PLM is the co-ordination of and management of product definition data. This includes managing engineering changes and release status of components; configuration product variations; document management; planning project resources and timescale and risk assessment.

For these tasks graphical, text and metadata such as product bills of materials

(BOMs) needs to be managed. At the engineering departments level this is the domain of PDM – (product data management

) software, at the corporate level EDM (enterprise data management) software, these two definitions tend to blur however but it is typical to see two or more data management systems within an organization. These systems are also linked to other corporate systems such as SCM, CRM, and ERP. Associated with these system are project management

Systems for project/program planning.

This central role is covered by numerous collaborative product development

tools which run throughout the whole lifecycle and across organizations. This requires many technology tools in the areas of conferencing, data sharing and data translation. The field being product visualization which includes technologies such as DMU (digital mock-up

), immersive virtual digital prototyping (virtual reality

) and photo-realistic imaging.

Despite the increased ease of use of PLM tools, cross-training all personnel on the entire PLM tool-set has not proven to be practical. Now, however, advances are being made to address ease of use for all participants within the PLM arena. One such advance is the availability of “role” specific user interfaces. Through tailorable UIs, the commands that are presented to users are appropriate to their function and expertise.

These techniques include:-

(British English: simultaneous engineering) is a workflow that, instead of working sequentially through stages, carries out a number of tasks in parallel. For example: starting tool design before the detailed designs of the product are finished, or starting on detail design solid models before the concept design surfaces models are complete. Although this does not necessarily reduce the amount of manpower required for a project, it does drastically reduce lead times and thus time to market.

Feature-based CAD systems have for many years allowed the simultaneous work on 3D solid model and the 2D drawing by means of two separate files, with the drawing looking at the data in the model; when the model changes the drawing will associatively update. Some CAD packages also allow associative copying of geometry between files. This allows, for example, the copying of a part design into the files used by the tooling designer. The manufacturing engineer can then start work on tools before the final design freeze; when a design changes size or shape the tool geometry will then update.

Concurrent engineering also has the added benefit of providing better and more immediate communication between departments, reducing the chance of costly, late design changes. It adopts a problem prevention method as compared to the problem solving and re-designing method of traditional sequential engineering.

Bottom–up design tends to focus on the capabilities of available real-world physical technology, implementing those solutions which this technology is most suited to. When these bottom–up solutions have real-world value, bottom–up design can be much more efficient than top–down design. The risk of bottom–up design is that it very efficiently provides solutions to low-value problems. The focus of bottom–up design is "what can we most efficiently do with this technology?" rather than the focus of top–down which is "What is the most valuable thing to do?"

A part-centric top–down design may eliminate some of the risks of top–down design. This starts with a layout model, often a simple 2D sketch defining basic sizes and some major defining parameters. Industrial design

, brings creative ideas to product development. Geometry from this is associatively copied down to the next level, which represents different subsystems of the product. The geometry in the sub-systems is then used to define more detail in levels below. Depending on the complexity of the product, a number of levels of this assembly are created until the basic definition of components can be identified, such as position and principal dimensions. This information is then associatively copied to component files. In these files the components are detailed; this is where the classic bottom–up assembly starts.

The top–down assembly is sometime known as a control structure. If a single file is used to define the layout and parameters for the review structure it is often known as a skeleton file.

Defense engineering traditionally develops the product structure from the top down. The system engineering process prescribes a functional decomposition of requirements and then physical allocation of product structure to the functions. This top down approach would normally have lower levels of the product structure developed from CAD data as a bottom–up structure or design.

techniques. Other components’ geometry can be seen and referenced within the CAD tool being used. The other components within the sub-assembly, may or may not have been constructed in the same system, their geometry being translated from other CPD

formats. Some assembly checking such as DMU

is also carried out using product visualization software.

Market growth estimates are in the 10% area.

Product lifecycle management (PLM) should be distinguished from 'Product life cycle management (marketing)' (PLCM). PLM describes the engineering aspect of a product, from managing descriptions and properties of a product through its development and useful life; whereas, PLCM refers to the commercial management of life of a product in the business market with respect to costs and sales measures.

Product lifecycle management is one of the four cornerstones of a corporation's information technology

Information technology

Information technology is the acquisition, processing, storage and dissemination of vocal, pictorial, textual and numerical information by a microelectronics-based combination of computing and telecommunications...

structure. All companies need to manage communications and information with their customers (CRM-customer relationship management

Customer relationship management

Customer relationship management is a widely implemented strategy for managing a company’s interactions with customers, clients and sales prospects. It involves using technology to organize, automate, and synchronize business processes—principally sales activities, but also those for marketing,...

), their suppliers (SCM-supply chain management

Supply chain management

Supply chain management is the management of a network of interconnected businesses involved in the ultimate provision of product and service packages required by end customers...

), their resources within the enterprise (ERP-enterprise resource planning

Enterprise resource planning

Enterprise resource planning systems integrate internal and external management information across an entire organization, embracing finance/accounting, manufacturing, sales and service, customer relationship management, etc. ERP systems automate this activity with an integrated software application...

) and their planning (SDLC-systems development life cycle

Systems Development Life Cycle

The systems development life cycle , or software development life cycle in systems engineering, information systems and software engineering, is a process of creating or altering information systems, and the models and methodologies that people use to develop these systems.In software engineering...

). In addition, manufacturing engineering companies must also develop, describe, manage and communicate information about their products.

One form of PLM is called people-centric PLM. While traditional PLM tools have been deployed only on release or during the release phase, people-centric PLM targets the design phase.

As of 2009, ICT development (EU-funded PROMISE project 2004–2008) has allowed PLM to extend beyond traditional PLM and integrate sensor data and real time 'lifecycle event data' into PLM, as well as allowing this information to be made available to different players in the total lifecycle of an individual product (closing the information loop). This has resulted in the extension of PLM into closed-loop lifecycle management (CL2M).

Benefits

Documented benefits of product lifecycle management include:- Reduced time to marketTime to marketIn commerce, time to market is the length of time it takes from a product being conceived until its being available for sale. TTM is important in industries where products are outmoded quickly...

- Improved product quality

- Reduced prototyping costs

- More accurate and timely request for quote generation

- Ability to quickly identify potential sales opportunities and revenue contributions

- Savings through the re-use of original data

- A frameworkConceptual frameworkA conceptual framework is used in research to outline possible courses of action or to present a preferred approach to an idea or thought. For example, the philosopher Isaiah Berlin used the "hedgehogs" versus "foxes" approach; a "hedgehog" might approach the world in terms of a single organizing...

for product optimization - Reduced waste

- Savings through the complete integration of engineering workflows..

- Documentation that can assist in proving compliance for RoHS or Title 21 CFR Part 11Title 21 CFR Part 11Title 21 CFR Part 11 of the Code of Federal Regulations deals with the Food and Drug Administration guidelines on electronic records and electronic signatures in the United States...

- Ability to provide contract manufacturers with access to a centralized product record

Areas of PLM

Within PLM there are five primary areas;- Systems engineeringSystems engineeringSystems engineering is an interdisciplinary field of engineering that focuses on how complex engineering projects should be designed and managed over the life cycle of the project. Issues such as logistics, the coordination of different teams, and automatic control of machinery become more...

(SE) - ProductProduct managementProduct management is an organizational lifecycle function within a company dealing with the planning, forecasting, or marketing of a product or products at all stages of the product lifecycle....

and portfolio managementProject Portfolio ManagementProject portfolio management is a term used by project managers and project management organizations, , to describe methods for analyzing and collectively managing a group of current or proposed projects based on numerous key characteristics...

(PPM) - Product designProduct design-Introduction:Product design is the process of creating a new product to be sold by a business or enterprise to its customers. It is concerned with the efficient and effective generation and development of ideas through a process that leads to new products.Product designers conceptualize and...

(CAx) - Manufacturing process managementManufacturing Process ManagementManufacturing process management is a collection of technologies and methods used to define how products are to be manufactured. MPM differs from ERP/MRP which is used to plan the ordering of materials and other resources, set manufacturing schedules, and compile cost data.A cornerstone of MPM is...

(MPM) - Product Data ManagementProduct Data ManagementProduct data management is the business function often within product lifecycle management that is responsible for the creation, management and publication of product data...

(PDM)

Note: While application software is not required for PLM processes, the business complexity and rate of change requires organizations execute as rapidly as possible.

Systems engineering is focused on meeting all requirements, primary meeting customer needs, and coordinating the systems design process by involving all relevant disciplines. Product and portfolio management is focused on managing resource allocation, tracking progress vs. plan for projects in the new product development projects that are in process (or in a holding status). Portfolio management is a tool that assists management in tracking progress on new products and making trade-off decisions when allocating scarce resources. Product data management is focused on capturing and maintaining information on products and/or services through their development and useful life.

Introduction to development process

The core of PLM (product lifecycle management) is in the creations and central management of all product data and the technology used to access this information and knowledge. PLM as a discipline emerged from tools such as CADComputer-aided design

Computer-aided design , also known as computer-aided design and drafting , is the use of computer technology for the process of design and design-documentation. Computer Aided Drafting describes the process of drafting with a computer...

, CAM

Computer-aided manufacturing

Computer-aided manufacturing is the use of computer software to control machine tools and related machinery in the manufacturing of workpieces. This is not the only definition for CAM, but it is the most common; CAM may also refer to the use of a computer to assist in all operations of a...

and PDM

Product Data Management

Product data management is the business function often within product lifecycle management that is responsible for the creation, management and publication of product data...

, but can be viewed as the integration of these tools with methods, people and the processes through all stages of a product’s life. It is not just about software technology but is also a business strategy.

The exact order of event and tasks will vary according to the product and industry in question but the main processes are:

- Conceive

- Specification

- Concept design

- Design

- Detailed design

- Validation and analysis (simulation)

- Tool design

- Realize

- Plan manufacturing

- Manufacture

- Build/Assemble

- Test (quality check)

- Service

- Sell and deliver

- Use

- Maintain and support

- Dispose

The major key point events are:

- Order

- Idea

- Kick-off

- Design freeze

- Launch

The reality is however more complex, people and departments cannot perform their tasks in isolation and one activity cannot simply finish and the next activity start. Design is an iterative process, often designs need to be modified due to manufacturing constraints or conflicting requirements.

Where exactly a customer order fits into the time line depends on the industry type, whether the products are for example build to order, engineer to order, or assemble to order.

History

Inspiration for the burgeoning business process now known as PLM came when American Motors Corporation (AMC) was looking for a way to speed up its product development process to compete better against its larger competitors in 1985, according to François CastaingFrançois Castaing

François J. Castaing is a 27-year veteran automotive executive with Renault, American Motors, and Chrysler. He is an engineering graduate from École Nationale Supérieure d'Arts et Métiers in Paris, and worked in Europe for Gordini and Renault before being named Vice President for Product...

, Vice President for Product Engineering and Development. After introducing its compact Jeep Cherokee (XJ)

Jeep Cherokee (XJ)

The Jeep Cherokee is a unibody compact SUV. It shared the name of the original full-size SJ model, but without a body-on-frame chassis, it set the stage for the modern SUV. Its innovative appearance and sales popularity spawned important imitators as other automakers began to notice that this...

, the vehicle that launched the modern sport utility vehicle

Sport utility vehicle

A sport utility vehicle is a generic marketing term for a vehicle similar to a station wagon, but built on a light-truck chassis. It is usually equipped with four-wheel drive for on- or off-road ability, and with some pretension or ability to be used as an off-road vehicle. Not all four-wheel...

(SUV) market, AMC began development of a new model, that later came out as the Jeep Grand Cherokee

Jeep Grand Cherokee

The Jeep Grand Cherokee is a Mid-size SUV produced by the Jeep division of Chrysler. While some other SUVs were manufactured with body on frame construction, the Jeep Grand Cherokee has always used a unibody chassis.- Development :...

. The first part in its quest for faster product development was computer-aided design

Computer-aided design

Computer-aided design , also known as computer-aided design and drafting , is the use of computer technology for the process of design and design-documentation. Computer Aided Drafting describes the process of drafting with a computer...

(CAD) software system that make engineers more productive. The second part in this effort was the new communication system that allowed conflicts to be resolved faster, as well as reducing costly engineering changes because all drawings and documents were in a central database. The product data management was so effective, that after AMC was purchased by Chrysler, the system was expanded throughout the enterprise connecting everyone involved in designing and building products. While an early adopter of PLM technology, Chrysler was able to become the auto industry's lowest-cost producer, recording development costs that were half of the industry average by the mid-1990s.

Phases of product lifecycle and corresponding technologies

Many software solutions have developed to organize and integrate the different phases of a product’s lifecycle. PLM should not be seen as a single software product but a collection of software tools and working methods integrated together to address either single stages of the lifecycle or connect different tasks or manage the whole process. Some software providers cover the whole PLM range while others a single niche application. Some applications can span many fields of PLM with different modules within the same data model. An overview of the fields within PLM is covered here. It should be noted however that the simple classifications do not always fit exactly, many areas overlap and many software products cover more than one area or do not fit easily into one category. It should also not be forgotten that one of the main goals of PLM is to collect knowledge that can be reused for other projects and to coordinate simultaneous concurrent development of many products. It is about business processes, people and methods as much as software application solutions. Although PLM is mainly associated with engineering tasks it also involves marketingMarketing

Marketing is the process used to determine what products or services may be of interest to customers, and the strategy to use in sales, communications and business development. It generates the strategy that underlies sales techniques, business communication, and business developments...

activities such as product portfolio management (PPM), particularly with regards to new product development

New product development

In business and engineering, new product development is the term used to describe the complete process of bringing a new product to market. A product is a set of benefits offered for exchange and can be tangible or intangible...

(NPD). There are several life-cycle models in industry to consider, but most are rather similar. What follows below is one possible life-cycle model; while it emphasizes hardware-oriented products, similar phases would describe any form of product or service, including non-technical or software-based products:

Imagine, specify, plan, innovate

The first stage in idea is the definition of its requirements based on customer, company, market and regulatory bodies’ viewpoints. From this specification of the products major technical parameters can be defined.Parallel to the requirements specification the initial concept design work is carried out defining the aesthetics of the product together with its main functional aspects. For the industrial design

Industrial design

Industrial design is the use of a combination of applied art and applied science to improve the aesthetics, ergonomics, and usability of a product, but it may also be used to improve the product's marketability and production...

, Styling, work many different media are used from pencil and paper, clay models to 3D CAID computer-aided industrial design

Computer-aided industrial design

Computer-aided industrial design is a subset of computer-aided design that includes software that directly helps in product development....

software.

In some concepts, the investment of resources into research or analysis-of-options may be included in the conception phase – e.g. bringing the technology to a level of maturity sufficent to move to the next phase. However, life-cycle engineering is iterative. It is always possible that something doesn't work well in any phase enough to back up into a prior phase – perhaps all the way back to conception or research. There are many examples to draw from.

Describe, define, develop, test, analyze and validate

This is where the detailed design and development of the product’s form starts, progressing to prototype testing, through pilot release to full product launch. It can also involve redesign and ramp for improvement to existing products as well as planned obsolescencePlanned obsolescence

Planned obsolescence or built-in obsolescence in industrial design is a policy of deliberately planning or designing a product with a limited useful life, so it will become obsolete or nonfunctional after a certain period of time...

.

The main tool used for design and development is CAD. This can be simple 2D drawing / drafting or 3D parametric feature based solid/surface modeling. Such software includes technology such as Hybrid Modeling, Reverse Engineering

Reverse engineering

Reverse engineering is the process of discovering the technological principles of a device, object, or system through analysis of its structure, function, and operation...

, KBE (knowledge-based engineering

Knowledge-based engineering

Knowledge-based engineering is a discipline with roots in computer-aided design and knowledge-based systems but has several definitions and roles depending upon the context. An early role was support tool for a design engineer generally within the context of product design...

), NDT (Nondestructive testing

Nondestructive testing

Nondestructive testing or Non-destructive testing is a wide group of analysis techniques used in science and industry to evaluate the properties of a material, component or system without causing damage....

), Assembly construction.

This step covers many engineering disciplines including: mechanical, electrical, electronic, software (embedded

Embedded system

An embedded system is a computer system designed for specific control functions within a larger system. often with real-time computing constraints. It is embedded as part of a complete device often including hardware and mechanical parts. By contrast, a general-purpose computer, such as a personal...

), and domain-specific, such as architectural, aerospace, automotive, ... Along with the actual creation of geometry there is the analysis of the components and product assemblies. Simulation, validation and optimization tasks are carried out using CAE (computer-aided engineering

Computer-aided engineering

Computer-aided engineering is the broad usage of computer software to aid in engineering tasks. It includes computer-aided design , computer-aided analysis , computer-integrated manufacturing , computer-aided manufacturing , material requirements planning , and computer-aided planning .- Overview...

) software either integrated in the CAD package or stand-alone. These are used to perform tasks such as:- Stress analysis, FEA (finite element analysis); kinematics

Kinematics

Kinematics is the branch of classical mechanics that describes the motion of bodies and systems without consideration of the forces that cause the motion....

; computational fluid dynamics

Computational fluid dynamics

Computational fluid dynamics, usually abbreviated as CFD, is a branch of fluid mechanics that uses numerical methods and algorithms to solve and analyze problems that involve fluid flows. Computers are used to perform the calculations required to simulate the interaction of liquids and gases with...

(CFD); and mechanical event simulation (MES). CAQ (computer-aided quality

Computer-aided quality

Computer-aided quality assurance is the engineering application of computers and computer controlled machines for the definition and inspection of the quality of products.This includes:*Measuring equipment management*Goods inward inspection...

) is used for tasks such as Dimensional tolerance (engineering)

Tolerance (engineering)

Engineering tolerance is the permissible limit or limits of variation in# a physical dimension,# a measured value or physical property of a material, manufactured object, system, or service,# other measured values ....

analysis.

Another task performed at this stage is the sourcing of bought out components, possibly with the aid of procurement

Procurement

Procurement is the acquisition of goods or services. It is favourable that the goods/services are appropriate and that they are procured at the best possible cost to meet the needs of the purchaser in terms of quality and quantity, time, and location...

systems.

Manufacture, make, build, procure, produce, sell and deliver

Once the design of the product’s components is complete the method of manufacturing is defined. This includes CAD tasks such as tool design; creation of CNC Machining instructions for the product’s parts as well as tools to manufacture those parts, using integrated or separate CAM computer-aided manufacturingComputer-aided manufacturing

Computer-aided manufacturing is the use of computer software to control machine tools and related machinery in the manufacturing of workpieces. This is not the only definition for CAM, but it is the most common; CAM may also refer to the use of a computer to assist in all operations of a...

software. This will also involve analysis tools for process simulation for operations such as casting, molding, and die press forming.

Once the manufacturing method has been identified CPM comes into play. This involves CAPE (computer-aided production engineering) or CAP/CAPP – (production planning) tools for carrying out factory, plant and facility layout and production simulation. For example: press-line simulation; and industrial ergonomics; as well as tool selection management.

Once components are manufactured their geometrical form and size can be checked against the original CAD data with the use of computer-aided inspection equipment and software.

Parallel to the engineering tasks, sales product configuration and marketing documentation work will be taking place. This could include transferring engineering data (geometry and part list data) to a web based sales configurator and other desktop publishing

Desktop publishing

Desktop publishing is the creation of documents using page layout software on a personal computer.The term has been used for publishing at all levels, from small-circulation documents such as local newsletters to books, magazines and newspapers...

systems.

Use, operate, maintain, support, sustain, phase-out, retire, recycle and disposal

The final phase of the lifecycle involves managing of in service information. Providing customers and service engineers with support information for repair and maintenance, as well as waste managementWaste management

Waste management is the collection, transport, processing or disposal,managing and monitoring of waste materials. The term usually relates to materials produced by human activity, and the process is generally undertaken to reduce their effect on health, the environment or aesthetics...

/recycling

Recycling

Recycling is processing used materials into new products to prevent waste of potentially useful materials, reduce the consumption of fresh raw materials, reduce energy usage, reduce air pollution and water pollution by reducing the need for "conventional" waste disposal, and lower greenhouse...

information. This involves using tools such as Maintenance, Repair and Operations Management (MRO

Maintenance, Repair and Operations

Maintenance, repair, and operations or maintenance, repair, and overhaul involves fixing any sort of mechanical or electrical device should it become out of order or broken...

) software.

It is easy to forget that there is an end-of-life to every product. Whether it be disposal or destruction of material objects or information, this needs to be considered since it may not be free from ramifications.

Communicate, manage and collaborate

None of the above phases can be seen in isolation. In reality a project does not run sequentially or in isolation of other product development projects. Information is flowing between different people and systems.A major part of PLM is the co-ordination of and management of product definition data. This includes managing engineering changes and release status of components; configuration product variations; document management; planning project resources and timescale and risk assessment.

For these tasks graphical, text and metadata such as product bills of materials

Bill of materials

A bill of materials is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, components, parts and the quantities of each needed to manufacture an end product...

(BOMs) needs to be managed. At the engineering departments level this is the domain of PDM – (product data management

Product Data Management

Product data management is the business function often within product lifecycle management that is responsible for the creation, management and publication of product data...

) software, at the corporate level EDM (enterprise data management) software, these two definitions tend to blur however but it is typical to see two or more data management systems within an organization. These systems are also linked to other corporate systems such as SCM, CRM, and ERP. Associated with these system are project management

Project management

Project management is the discipline of planning, organizing, securing, and managing resources to achieve specific goals. A project is a temporary endeavor with a defined beginning and end , undertaken to meet unique goals and objectives, typically to bring about beneficial change or added value...

Systems for project/program planning.

This central role is covered by numerous collaborative product development

Collaborative Product Development

Collaborative product development is a business strategy, work process and collection of software applications that facilitates different organizations to work together on the development of a product...

tools which run throughout the whole lifecycle and across organizations. This requires many technology tools in the areas of conferencing, data sharing and data translation. The field being product visualization which includes technologies such as DMU (digital mock-up

Digital mockup

Digital MockUp or DMU is a concept that allows the description of a product, usually in 3D, for its entire life cycle. Digital Mockup is enriched by all the activities that contribute to describing the product. The product design engineers, the manufacturing engineers, and the support engineers...

), immersive virtual digital prototyping (virtual reality

Virtual reality

Virtual reality , also known as virtuality, is a term that applies to computer-simulated environments that can simulate physical presence in places in the real world, as well as in imaginary worlds...

) and photo-realistic imaging.

User skills

The broad array of solutions that make up the tools used within a PLM solution-set (e.g., CAD, CAM, CAx...) were initially used by dedicated practitioners who invested time and effort to gain the required skills. Designers and engineers worked wonders with CAD systems, manufacturing engineers became highly skilled CAM users while analysts, administrators and managers fully mastered their support technologies. However, achieving the full advantages of PLM requires the participation of many people of various skills from throughout an extended enterprise, each requiring the ability to access and operate on the inputs and output of other participants.Despite the increased ease of use of PLM tools, cross-training all personnel on the entire PLM tool-set has not proven to be practical. Now, however, advances are being made to address ease of use for all participants within the PLM arena. One such advance is the availability of “role” specific user interfaces. Through tailorable UIs, the commands that are presented to users are appropriate to their function and expertise.

Product development processes and methodologies

A number of established methodologies have been adopted by PLM and been further advanced. Together with PLM digital engineering techniques, they have been advanced to meet company goals such as reduced time to market and lower production costs. Reducing lead times is a major factor as getting a product to market quicker than the competition will help with higher revenue and profit margins and increase market share.These techniques include:-

- Concurrent engineering workflow

- Industrial designIndustrial designIndustrial design is the use of a combination of applied art and applied science to improve the aesthetics, ergonomics, and usability of a product, but it may also be used to improve the product's marketability and production...

- Bottom–up design

- Top–down design

- Front-loading design workflow

- Design in context

- Modular design

- NPD new product developmentNew product developmentIn business and engineering, new product development is the term used to describe the complete process of bringing a new product to market. A product is a set of benefits offered for exchange and can be tangible or intangible...

- DFSS design for Six SigmaDesign for Six SigmaDesign for Six Sigma is a separate and emerging business-process management methodology related to traditional Six Sigma. While the tools and order used in Six Sigma require a process to be in place and functioning, DFSS has the objective of determining the needs of customers and the business, and...

- DFMA design for manufacture / assembly

- Digital simulation engineering

- Requirement-driven design

- Specification-managed validation

- Configuration managementConfiguration managementConfiguration management is a field of management that focuses on establishing and maintaining consistency of a system or product's performance and its functional and physical attributes with its requirements, design, and operational information throughout its life.For information assurance, CM...

Concurrent engineering workflow

Concurrent engineeringConcurrent engineering

Concurrent engineering is a work methodology based on the parallelization of tasks . It refers to an approach used in product development in which functions of design engineering, manufacturing engineering and other functions are integrated to reduce the elapsed time required to bring a new product...

(British English: simultaneous engineering) is a workflow that, instead of working sequentially through stages, carries out a number of tasks in parallel. For example: starting tool design before the detailed designs of the product are finished, or starting on detail design solid models before the concept design surfaces models are complete. Although this does not necessarily reduce the amount of manpower required for a project, it does drastically reduce lead times and thus time to market.

Feature-based CAD systems have for many years allowed the simultaneous work on 3D solid model and the 2D drawing by means of two separate files, with the drawing looking at the data in the model; when the model changes the drawing will associatively update. Some CAD packages also allow associative copying of geometry between files. This allows, for example, the copying of a part design into the files used by the tooling designer. The manufacturing engineer can then start work on tools before the final design freeze; when a design changes size or shape the tool geometry will then update.

Concurrent engineering also has the added benefit of providing better and more immediate communication between departments, reducing the chance of costly, late design changes. It adopts a problem prevention method as compared to the problem solving and re-designing method of traditional sequential engineering.

Bottom–up design

Bottom–up design (CAD-centric) occurs where the definition of 3D models of a product starts with the construction of individual components. These are then virtually brought together in sub-assemblies of more than one level until the full product is digitally defined. This is sometimes known as the review structure showing what the product will look like. The BOM contains all of the physical (solid) components; it may (but not also) contain other items required for the final product BOM such as paint, glue, oil and other materials commonly described as 'bulk items'. Bulk items typically have mass and quantities but are not usually modelled with geometry.Bottom–up design tends to focus on the capabilities of available real-world physical technology, implementing those solutions which this technology is most suited to. When these bottom–up solutions have real-world value, bottom–up design can be much more efficient than top–down design. The risk of bottom–up design is that it very efficiently provides solutions to low-value problems. The focus of bottom–up design is "what can we most efficiently do with this technology?" rather than the focus of top–down which is "What is the most valuable thing to do?"

Top–down design

Top–down design is focused on high-level functional requirements, with relatively less focus on existing implementation technology. A top level spec is decomposed into lower and lower level structures and specifications, until the physical implementation layer is reached. The risk of a top–down design is that it will not take advantage of the most efficient applications of current physical technology, especially with respect to hardware implementation. Top–down design sometimes results in excessive layers of lower-level abstraction and inefficient performance when the Top–down model has followed an abstraction path which does not efficiently fit available physical-level technology. The positive value of top–down design is that it preserves a focus on the optimum solution requirements.A part-centric top–down design may eliminate some of the risks of top–down design. This starts with a layout model, often a simple 2D sketch defining basic sizes and some major defining parameters. Industrial design

Industrial design

Industrial design is the use of a combination of applied art and applied science to improve the aesthetics, ergonomics, and usability of a product, but it may also be used to improve the product's marketability and production...

, brings creative ideas to product development. Geometry from this is associatively copied down to the next level, which represents different subsystems of the product. The geometry in the sub-systems is then used to define more detail in levels below. Depending on the complexity of the product, a number of levels of this assembly are created until the basic definition of components can be identified, such as position and principal dimensions. This information is then associatively copied to component files. In these files the components are detailed; this is where the classic bottom–up assembly starts.

The top–down assembly is sometime known as a control structure. If a single file is used to define the layout and parameters for the review structure it is often known as a skeleton file.

Defense engineering traditionally develops the product structure from the top down. The system engineering process prescribes a functional decomposition of requirements and then physical allocation of product structure to the functions. This top down approach would normally have lower levels of the product structure developed from CAD data as a bottom–up structure or design.

Both-ends-against-the-middle design

Both-ends-against-the-middle (BEATM) design is a design process that endeavors to combine the best features of top–down design, and bottom–up design into one process. A BEATM design process flow may begin with an emergent technology which suggests solutions which may have value, or it may begin with a top–down view of an important problem which needs a solution. In either case the key attribute of BEATM design methodology is to immediately focus at both ends of the design process flow: a top–down view of the solution requirements, and a bottom–up view of the available technology which may offer promise of an efficient solution. The BEATM design process proceeds from both ends in search of an optimum merging somewhere between the top–down requirements, and bottom–up efficient implementation. In this fashion, BEATM has been shown to genuinely offer the best of both methodologies. Indeed some of the best success stories from either top–down or bottom–up have been successful because of an intuitive, yet unconscious use of the BEATM methodology. When employed consciously, BEATM offers even more powerful advantages.Front loading design and workflow

Front loading is taking top–down design to the next stage. The complete control structure and review structure, as well as downstream data such as drawings, tooling development and CAM models, are constructed before the product has been defined or a project kick-off has been authorized. These assemblies of files constitute a template from which a family of products can be constructed. When the decision has been made to go with a new product, the parameters of the product are entered into the template model and all the associated data is updated. Obviously predefined associative models will not be able to predict all possibilities and will require additional work. The main principle is that a lot of the experimental/investigative work has already been completed. A lot of knowledge is built into these templates to be reused on new products. This does require additional resources “up front” but can drastically reduce the time between project kick-off and launch. Such methods do however require organizational changes, as considerable engineering efforts are moved into “offline” development departments. It can be seen as an analogy to creating a concept car to test new technology for future products, but in this case the work is directly used for the next product generation.Design in context

Individual components cannot be constructed in isolation. CAD and CaiD models of components are designed within the context of part or all of the product being developed. This is achieved using assembly modellingAssembly modelling

Assembly modelling is technology and methods used by computer-aided design and product visualization computer software systems to handle multiple files that represent components within a product. The components within an assembly are represented as solid or surface models.The designer generally has...

techniques. Other components’ geometry can be seen and referenced within the CAD tool being used. The other components within the sub-assembly, may or may not have been constructed in the same system, their geometry being translated from other CPD

Collaborative Product Development

Collaborative product development is a business strategy, work process and collection of software applications that facilitates different organizations to work together on the development of a product...

formats. Some assembly checking such as DMU

Digital mockup

Digital MockUp or DMU is a concept that allows the description of a product, usually in 3D, for its entire life cycle. Digital Mockup is enriched by all the activities that contribute to describing the product. The product design engineers, the manufacturing engineers, and the support engineers...

is also carried out using product visualization software.

Product and process lifecycle management (PPLM)

Product and process lifecycle management (PPLM) is an alternate genre of PLM in which the process by which the product is made is just as important as the product itself. Typically, this is the life sciences and advanced specialty chemicals markets. The process behind the manufacture of a given compound is a key element of the regulatory filing for a new drug application. As such, PPLM seeks to manage information around the development of the process in a similar fashion that baseline PLM talks about managing information around development of the product.Market size

Total spending on PLM software and services was estimated in 2006 to be above $15 billion a year.Market growth estimates are in the 10% area.

See also

- System lifecycleSystem lifecycleThe system lifecycle in systems engineering is an examination of a system or proposed system that addresses all phases of its existence to include system conception, design and development, production and/or construction, distribution, operation, maintenance and support, retirement, phase-out and...

- Application lifecycle managementApplication lifecycle managementApplication Lifecycle Management is a continuous process of managing the life of an application through governance, development and maintenance...

- Building lifecycle managementBuilding lifecycle managementBuilding lifecycle management or BLM is the adaptation of product lifecycle management -like techniques to the design, construction, and management of buildings. Building lifecycle management requires accurate and extensive building information modeling .-See also:*Computerized Maintenance...

- Collaborative product developmentCollaborative Product DevelopmentCollaborative product development is a business strategy, work process and collection of software applications that facilitates different organizations to work together on the development of a product...

- Cradle to Cradle Design

- Concept carConcept carA concept vehicle or show vehicle is a car made to showcase new styling and or new technology. They are often shown at motor shows to gauge customer reaction to new and radical designs which may or may not have a chance of being produced....

- Extending product life cycles

- Industrial designIndustrial designIndustrial design is the use of a combination of applied art and applied science to improve the aesthetics, ergonomics, and usability of a product, but it may also be used to improve the product's marketability and production...

- ISO 10303ISO 10303ISO 10303 is an ISO standard for the computer-interpretable representation and exchange of product manufacturing information. Its official title is: Automation systems and integration — Product data representation and exchange...

– Standard for the Exchange of Product model data - Mass productionMass productionMass production is the production of large amounts of standardized products, including and especially on assembly lines...

- New product developmentNew product developmentIn business and engineering, new product development is the term used to describe the complete process of bringing a new product to market. A product is a set of benefits offered for exchange and can be tangible or intangible...

(NPD) - Product life cycle management (marketing)

- Product managementProduct managementProduct management is an organizational lifecycle function within a company dealing with the planning, forecasting, or marketing of a product or products at all stages of the product lifecycle....

- User-centered designUser-centered designIn broad terms, user-centered design or pervasive usability is a design philosophy and a process in which the needs, wants, and limitations of end users of a product are given extensive attention at each stage of the design process...

- Product data recordProduct Data RecordThe product record, or product data record, is an information technology management concept used to refer to data associated with the entire lifecycle of a product from its conception, through design and manufacture, to service and disposal...