Nondestructive testing

Encyclopedia

Nondestructive testing or Non-destructive testing (NDT) is a wide group of analysis techniques used in science and industry to evaluate the properties of a material, component or system without causing damage.

The terms Nondestructive examination (NDE), Nondestructive inspection (NDI), and Nondestructive evaluation (NDE) are also commonly used to describe this technology.

Because NDT does not permanently alter the article being inspected, it is a highly-valuable technique that can save both money and time in product evaluation, troubleshooting, and research. Common NDT methods include ultrasonic, magnetic-particle

, liquid penetrant, radiographic

, remote visual inspection (RVI), eddy-current testing

, and low coherence interferometry

.

NDT is a commonly-used tool in forensic engineering

, mechanical engineering

, electrical engineering

, civil engineering

, systems engineering

, aeronautical engineering, medicine

, and art

.

, sound

, and inherent properties of materials to examine samples. This includes some kinds of microscopy

to examine external surfaces in detail, although sample preparation techniques for metallography

, optical microscopy

and electron microscopy

are generally destructive as the surfaces must be made smooth through polishing or the sample must be electron transparent in thickness. The inside of a sample can be examined with penetrating electromagnetic radiation, such as X-rays or 3D X-rays

for volumetric inspection. Sound waves are utilized in the case of ultrasonic testing. Contrast between a defect and the bulk of the sample may be enhanced for visual examination by the unaided eye by using liquids to penetrate fatigue

cracks. One method (liquid penetrant testing) involves using dyes, fluorescent or non-fluorescing, in fluids for non-magnetic materials, usually metals. Another commonly used method for magnetic materials involves using a liquid suspension of fine iron particles applied to a part while it is in an externally applied magnetic field (magnetic-particle testing

).

Thermoelectric effect

(or use of the Seebeck effect) uses thermal properties of an alloy to quickly and easily characterize many alloys. The chemical test

, or chemical spot test method, utilizes application of sensitive chemicals that can indicate the presence of individual alloying elements.

In manufacturing, welds

In manufacturing, welds

are commonly used to join two or more metal surfaces. Because these connections may encounter loads and fatigue

during product lifetime, there is a chance that they may fail if not created to proper specification. For example, the base metal must reach a certain temperature during the welding process, must cool at a specific rate, and must be welded with compatible materials or the joint may not be strong enough to hold the surfaces together, or cracks may form in the weld causing it to fail. The typical welding defects, lack of fusion of the weld to the base metal, cracks or porosity inside the weld, and variations in weld density, could cause a structure to break or a pipeline to rupture.

Welds may be tested using NDT techniques such as industrial radiography

or industrial CT scanning

using X-rays or gamma rays, ultrasonic testing, liquid penetrant testing or via eddy current

. In a proper weld, these tests would indicate a lack of cracks in the radiograph, show clear passage of sound through the weld and back, or indicate a clear surface without penetrant captured in cracks.

Welding techniques may also be actively monitored with acoustic emission techniques before production to design the best set of parameters to use to properly join two materials.

in a liquid-fuel rocket, can also cost millions of dollars. Engineers will commonly model these structures as coupled second-order systems, approximating dynamic structure components with springs

, mass

es, and dampers

. These sets of differential equations can be used to derive a transfer function that models the behavior of the system.

In NDT, the structure undergoes a dynamic input, such as the tap of a hammer or a controlled impulse. Key properties, such as displacement

or acceleration

at different points of the structure, are measured as the corresponding output. This output is recorded and compared to the corresponding output given by the transfer function and the known input. Differences may indicate an inappropriate model (which may alert engineers to unpredicted instabilities or performance outside of tolerances), failed components, or an inadequate control system

.

As a system, the human body

As a system, the human body

is difficult to model as a complete transfer function

. Elements of the body, however, such as bone

s or molecules, have a known response to certain radiographic inputs, such as x-ray

s or magnetic resonance

. Coupled with the controlled introduction of a known element, such as digested barium

, radiography can be used to image parts or functions of the body by measuring and interpreting the response to the radiographic input. In this manner, many bone fracture

s and diseases

may be detected and localized in preparation for treatment. X-rays may also be used to examine the interior of mechanical systems in manufacturing using NDT techniques, as well.

(Source: Hellier, 2001) Note the number of advancements made during the WWII era, a time when industrial quality control was growing in importance.

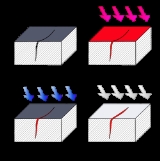

NDT is divided into various methods of nondestructive testing, each based on a particular scientific principle. These methods may be further subdivided into various techniques. The various methods and techniques, due to their particular natures, may lend themselves especially well to certain applications and be of little or no value at all in other applications. Therefore choosing the right method and technique is an important part of the performance of NDT.

NDT is divided into various methods of nondestructive testing, each based on a particular scientific principle. These methods may be further subdivided into various techniques. The various methods and techniques, due to their particular natures, may lend themselves especially well to certain applications and be of little or no value at all in other applications. Therefore choosing the right method and technique is an important part of the performance of NDT.

In US standards and codes, while a very similar definition of qualification is included in ASNT SNT-TC-1A, certification is simply defined as: "Written testimony of qualification".

In the United States employer based schemes are the norm, however central certification schemes exist as well. The most notable is ASNT Level III (established in 1976-1977), which is organized by the American Society for Nondestructive Testing

for Level 3 NDT personnel. NAVSEA 250-1500 is another US central certification scheme, specifically developed for use in the naval nuclear program.

Central certification is more widely used in the European Union, where certifications are issued by accredited bodies

(independent organizations conforming to ISO 17024 and accredited by a national accreditation authority like UKAS). The Pressure Equipment Directive

(97/23/EEC) actually enforces central personnel certification for the initial testing of steam boilers and some categories of pressure vessel

s and piping

. European Standards harmonized with this directive specify personnel certification to EN 473. Certifications issued by a national NDT society which is a member of the European Federation of NDT (EFNDT) are mutually acceptable by the other member societies under a multilateral recognition agreement.

Canada also implements an ISO 9712 central certification scheme, which is administered by Natural Resources Canada

, a government department.

The aerospace

sector worldwide sticks to employer based schemes. In America it is based mostly on AIA-NAS-410 and in the European Union on the equivalent and very similar standard EN 4179

Indication : The response or evidence from an examination, such as a blip on the screen of an instrument. Indications are classified as true or false. False indications are those caused by factors not related to the principles of the testing method or by improper implementation of the method, like film damage in radiography, electrical interference in ultrasonic testing etc. True indications are further classified as relevant and non relevant. Relevant indications are those caused by flaws. Non relevant indications are those caused by known features of the tested object, like gaps, threads, case hardening etc.

Interpretation : Determining if an indication is of a type to be investigated. For example, in electromagnetic testing, indications from metal loss are considered flaws because they should usually be investigated, but indications due to variations in the material properties may be harmless and nonrelevant.

Flaw : A type of discontinuity that must be investigated to see if it is rejectable. For example, porosity in a weld or metal loss.

Evaluation : Determining if a flaw is rejectable. For example, is porosity in a weld larger than acceptable by code?

Defect : A flaw that is rejectable — i.e. does not meet acceptance criteria. Defects are generally removed or repaired.

Penetrant testing : Non-destructive test typically comprising a penetrant, a method of excess removal and a developer to produce a visible indication of surface-breaking discontinuities.

The terms Nondestructive examination (NDE), Nondestructive inspection (NDI), and Nondestructive evaluation (NDE) are also commonly used to describe this technology.

Because NDT does not permanently alter the article being inspected, it is a highly-valuable technique that can save both money and time in product evaluation, troubleshooting, and research. Common NDT methods include ultrasonic, magnetic-particle

Magnetic-particle inspection

Magnetic particle inspection is a non-destructive testing process for detecting surface and slightly subsurface discontinuities in ferroelectric materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The piece can be magnetized by direct...

, liquid penetrant, radiographic

Radiographic testing

Radiographic Testing , or industrial radiography, is a nondestructive testing method of inspecting materials for hidden flaws by using the ability of short wavelength electromagnetic radiation to penetrate various materials.Either an X-ray machine or a radioactive source can be used as a source...

, remote visual inspection (RVI), eddy-current testing

Eddy-current testing

Eddy-current testing uses electromagnetic induction to detect flaws in conductive materials. There are several limitations, among them: only conductive materials can be tested, the surface of the material must be accessible, the finish of the material may cause bad readings, the depth of...

, and low coherence interferometry

Optical interferometry

Optical interferometry combines two or more light waves in an opticalinstrument in such a way that interference occurs between them.Early interferometers used white light sources and also monochromatic light from atomic sources...

.

NDT is a commonly-used tool in forensic engineering

Forensic engineering

Forensic engineering is the investigation of materials, products, structures or components that fail or do not operate or function as intended, causing personal injury or damage to property. The consequences of failure are dealt with by the law of product liability. The field also deals with...

, mechanical engineering

Mechanical engineering

Mechanical engineering is a discipline of engineering that applies the principles of physics and materials science for analysis, design, manufacturing, and maintenance of mechanical systems. It is the branch of engineering that involves the production and usage of heat and mechanical power for the...

, electrical engineering

Electrical engineering

Electrical engineering is a field of engineering that generally deals with the study and application of electricity, electronics and electromagnetism. The field first became an identifiable occupation in the late nineteenth century after commercialization of the electric telegraph and electrical...

, civil engineering

Civil engineering

Civil engineering is a professional engineering discipline that deals with the design, construction, and maintenance of the physical and naturally built environment, including works like roads, bridges, canals, dams, and buildings...

, systems engineering

Systems engineering

Systems engineering is an interdisciplinary field of engineering that focuses on how complex engineering projects should be designed and managed over the life cycle of the project. Issues such as logistics, the coordination of different teams, and automatic control of machinery become more...

, aeronautical engineering, medicine

Medicine

Medicine is the science and art of healing. It encompasses a variety of health care practices evolved to maintain and restore health by the prevention and treatment of illness....

, and art

Art

Art is the product or process of deliberately arranging items in a way that influences and affects one or more of the senses, emotions, and intellect....

.

Methods

NDT methods may rely upon use of electromagnetic radiationElectromagnetic radiation

Electromagnetic radiation is a form of energy that exhibits wave-like behavior as it travels through space...

, sound

Sound

Sound is a mechanical wave that is an oscillation of pressure transmitted through a solid, liquid, or gas, composed of frequencies within the range of hearing and of a level sufficiently strong to be heard, or the sensation stimulated in organs of hearing by such vibrations.-Propagation of...

, and inherent properties of materials to examine samples. This includes some kinds of microscopy

Microscopy

Microscopy is the technical field of using microscopes to view samples and objects that cannot be seen with the unaided eye...

to examine external surfaces in detail, although sample preparation techniques for metallography

Metallography

Metallography is the study of the physical structure and components of metals, typically using microscopy.Ceramic and polymeric materials may also be prepared using metallographic techniques, hence the terms ceramography, plastography and, collectively, materialography.-Preparing metallographic...

, optical microscopy

Optical microscope

The optical microscope, often referred to as the "light microscope", is a type of microscope which uses visible light and a system of lenses to magnify images of small samples. Optical microscopes are the oldest design of microscope and were possibly designed in their present compound form in the...

and electron microscopy

Electron microscope

An electron microscope is a type of microscope that uses a beam of electrons to illuminate the specimen and produce a magnified image. Electron microscopes have a greater resolving power than a light-powered optical microscope, because electrons have wavelengths about 100,000 times shorter than...

are generally destructive as the surfaces must be made smooth through polishing or the sample must be electron transparent in thickness. The inside of a sample can be examined with penetrating electromagnetic radiation, such as X-rays or 3D X-rays

Industrial CT Scanning

Industrial CT scanning is a process which uses X-ray equipment to produce three-dimensional representations of components both externally and internally. Industrial CT scanning has been used in many areas of industry for internal inspection of components...

for volumetric inspection. Sound waves are utilized in the case of ultrasonic testing. Contrast between a defect and the bulk of the sample may be enhanced for visual examination by the unaided eye by using liquids to penetrate fatigue

Fatigue (material)

'In materials science, fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. The nominal maximum stress values are less than the ultimate tensile stress limit, and may be below the yield stress limit of the material.Fatigue occurs...

cracks. One method (liquid penetrant testing) involves using dyes, fluorescent or non-fluorescing, in fluids for non-magnetic materials, usually metals. Another commonly used method for magnetic materials involves using a liquid suspension of fine iron particles applied to a part while it is in an externally applied magnetic field (magnetic-particle testing

Magnetic-particle inspection

Magnetic particle inspection is a non-destructive testing process for detecting surface and slightly subsurface discontinuities in ferroelectric materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The piece can be magnetized by direct...

).

Thermoelectric effect

Thermoelectric effect

The thermoelectric effect is the direct conversion of temperature differences to electric voltage and vice-versa. A thermoelectric device creates a voltage when there is a different temperature on each side. Conversely, when a voltage is applied to it, it creates a temperature difference...

(or use of the Seebeck effect) uses thermal properties of an alloy to quickly and easily characterize many alloys. The chemical test

Chemical test

In chemistry, a chemical test is a qualitative or quantitative procedure designed to prove the existence of, or to quantify, a chemical compound or chemical group with the aid of a specific reagent...

, or chemical spot test method, utilizes application of sensitive chemicals that can indicate the presence of individual alloying elements.

Weld verification

Welding

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material that cools to become a strong joint, with pressure sometimes...

are commonly used to join two or more metal surfaces. Because these connections may encounter loads and fatigue

Fatigue (material)

'In materials science, fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. The nominal maximum stress values are less than the ultimate tensile stress limit, and may be below the yield stress limit of the material.Fatigue occurs...

during product lifetime, there is a chance that they may fail if not created to proper specification. For example, the base metal must reach a certain temperature during the welding process, must cool at a specific rate, and must be welded with compatible materials or the joint may not be strong enough to hold the surfaces together, or cracks may form in the weld causing it to fail. The typical welding defects, lack of fusion of the weld to the base metal, cracks or porosity inside the weld, and variations in weld density, could cause a structure to break or a pipeline to rupture.

Welds may be tested using NDT techniques such as industrial radiography

Industrial radiography

Industrial Radiography is the use of ionizing radiation to view objects in a way that cannot be seen otherwise. It is not to be confused with the use of ionizing radiation to change or modify objects; radiography's purpose is strictly viewing. Industrial radiography has grown out of engineering,...

or industrial CT scanning

Industrial CT Scanning

Industrial CT scanning is a process which uses X-ray equipment to produce three-dimensional representations of components both externally and internally. Industrial CT scanning has been used in many areas of industry for internal inspection of components...

using X-rays or gamma rays, ultrasonic testing, liquid penetrant testing or via eddy current

Eddy current

Eddy currents are electric currents induced in conductors when a conductor is exposed to a changing magnetic field; due to relative motion of the field source and conductor or due to variations of the field with time. This can cause a circulating flow of electrons, or current, within the body of...

. In a proper weld, these tests would indicate a lack of cracks in the radiograph, show clear passage of sound through the weld and back, or indicate a clear surface without penetrant captured in cracks.

Welding techniques may also be actively monitored with acoustic emission techniques before production to design the best set of parameters to use to properly join two materials.

Structural mechanics

Structures can be complex systems that undergo different loads during their lifetime. Some complex structures, such as the turbomachineryTurbomachinery

Turbomachinery, in mechanical engineering, describes machines that transfer energy between a rotor and a fluid, including both turbines and compressors. While a turbine transfers energy from a fluid to a rotor, a compressor transfers energy from a rotor to a fluid...

in a liquid-fuel rocket, can also cost millions of dollars. Engineers will commonly model these structures as coupled second-order systems, approximating dynamic structure components with springs

Spring (device)

A spring is an elastic object used to store mechanical energy. Springs are usually made out of spring steel. Small springs can be wound from pre-hardened stock, while larger ones are made from annealed steel and hardened after fabrication...

, mass

Mass

Mass can be defined as a quantitive measure of the resistance an object has to change in its velocity.In physics, mass commonly refers to any of the following three properties of matter, which have been shown experimentally to be equivalent:...

es, and dampers

Dashpot

A dashpot is a mechanical device, a damper which resists motion via viscous friction. The resulting force is proportional to the velocity, but acts in the opposite direction, slowing the motion and absorbing energy. It is commonly used in conjunction with a spring...

. These sets of differential equations can be used to derive a transfer function that models the behavior of the system.

In NDT, the structure undergoes a dynamic input, such as the tap of a hammer or a controlled impulse. Key properties, such as displacement

Displacement (vector)

A displacement is the shortest distance from the initial to the final position of a point P. Thus, it is the length of an imaginary straight path, typically distinct from the path actually travelled by P...

or acceleration

Acceleration

In physics, acceleration is the rate of change of velocity with time. In one dimension, acceleration is the rate at which something speeds up or slows down. However, since velocity is a vector, acceleration describes the rate of change of both the magnitude and the direction of velocity. ...

at different points of the structure, are measured as the corresponding output. This output is recorded and compared to the corresponding output given by the transfer function and the known input. Differences may indicate an inappropriate model (which may alert engineers to unpredicted instabilities or performance outside of tolerances), failed components, or an inadequate control system

Control system

A control system is a device, or set of devices to manage, command, direct or regulate the behavior of other devices or system.There are two common classes of control systems, with many variations and combinations: logic or sequential controls, and feedback or linear controls...

.

Radiography in medicine

Human body

The human body is the entire structure of a human organism, and consists of a head, neck, torso, two arms and two legs.By the time the human reaches adulthood, the body consists of close to 100 trillion cells, the basic unit of life...

is difficult to model as a complete transfer function

Transfer function

A transfer function is a mathematical representation, in terms of spatial or temporal frequency, of the relation between the input and output of a linear time-invariant system. With optical imaging devices, for example, it is the Fourier transform of the point spread function i.e...

. Elements of the body, however, such as bone

Bone

Bones are rigid organs that constitute part of the endoskeleton of vertebrates. They support, and protect the various organs of the body, produce red and white blood cells and store minerals. Bone tissue is a type of dense connective tissue...

s or molecules, have a known response to certain radiographic inputs, such as x-ray

X-ray

X-radiation is a form of electromagnetic radiation. X-rays have a wavelength in the range of 0.01 to 10 nanometers, corresponding to frequencies in the range 30 petahertz to 30 exahertz and energies in the range 120 eV to 120 keV. They are shorter in wavelength than UV rays and longer than gamma...

s or magnetic resonance

Magnetic resonance imaging

Magnetic resonance imaging , nuclear magnetic resonance imaging , or magnetic resonance tomography is a medical imaging technique used in radiology to visualize detailed internal structures...

. Coupled with the controlled introduction of a known element, such as digested barium

Barium swallow

A barium swallow is a medical imaging procedure used to examine the upper GI tract, which includes the esophagus and, to a lesser extent, the stomach.-Principle:...

, radiography can be used to image parts or functions of the body by measuring and interpreting the response to the radiographic input. In this manner, many bone fracture

Bone fracture

A bone fracture is a medical condition in which there is a break in the continuity of the bone...

s and diseases

Cancer

Cancer , known medically as a malignant neoplasm, is a large group of different diseases, all involving unregulated cell growth. In cancer, cells divide and grow uncontrollably, forming malignant tumors, and invade nearby parts of the body. The cancer may also spread to more distant parts of the...

may be detected and localized in preparation for treatment. X-rays may also be used to examine the interior of mechanical systems in manufacturing using NDT techniques, as well.

Notable events in early industrial NDT

- 1854 Hartford, ConnecticutConnecticutConnecticut is a state in the New England region of the northeastern United States. It is bordered by Rhode Island to the east, Massachusetts to the north, and the state of New York to the west and the south .Connecticut is named for the Connecticut River, the major U.S. river that approximately...

: a boiler at the Fales and Gray Car works explodes, killing 21 people and seriously injuring 50. Within a decade, the State of Connecticut passes a law requiring annual inspection (in this case visual) of boilers. - 1880 - 1920 The "Oil and Whiting" method of crack detection is used in the railroad industry to find cracks in heavy steel parts. (A part is soaked in thinned oil, then painted with a white coating that dries to a powder. Oil seeping out from cracks turns the white powder brown, allowing the cracks to be detected.) This was the precursor to modern liquid penetrant tests.

- 1895 Wilhelm Conrad RöntgenWilhelm Conrad RöntgenWilhelm Conrad Röntgen was a German physicist, who, on 8 November 1895, produced and detected electromagnetic radiation in a wavelength range today known as X-rays or Röntgen rays, an achievement that earned him the first Nobel Prize in Physics in 1901....

discovers what are now known as X-rays. In his first paper he discusses the possibility of flaw detection. - 1920 Dr. H. H. Lester begins development of industrial radiography for metals.

- 1924 — Lester uses radiography to examine castings to be installed in a Boston Edison Company steam pressure power plant http://www.robots4welding.com/articles.php?tag=615.

- 1926 The first electromagnetic eddy current instrument is available to measure material thicknesses.

- 1927 - 1928 Magnetic induction system to detect flaws in railroad track developed by Dr. Elmer Sperry and H.C. Drake.

- 1929 Magnetic particle methods and equipment pioneered (A.V. DeForest and F.B. Doane.)

- 1930s Robert F. Mehl demonstrates radiographic imaging using gamma radiation from Radium, which can examine thicker components than the low-energy X-ray machines available at the time.

- 1935 - 1940 Liquid penetrant tests developed (Betz, Doane, and DeForest)

- 1935 - 1940s Eddy currentEddy currentEddy currents are electric currents induced in conductors when a conductor is exposed to a changing magnetic field; due to relative motion of the field source and conductor or due to variations of the field with time. This can cause a circulating flow of electrons, or current, within the body of...

instruments developed (H.C. Knerr, C. Farrow, Theo Zuschlag, and Fr. F. Foerster). - 1940 - 1944 Ultrasonic test method developed in USA by Dr. Floyd Firestone.

- 1950 The Schmidt HammerSchmidt hammerA Schmidt hammer, also known as a Swiss hammer or a rebound hammer, is a device to measure the elastic properties or strength of concrete or rock, mainly surface hardness and penetration resistance.It was invented by Ernst Schmidt, a Swiss engineer....

(also known as "Swiss Hammer") is invented. The instrument uses the world’s first patented non-destructive testing method for concrete. - 1950 J. Kaiser introduces acoustic emission as an NDT method.

(Source: Hellier, 2001) Note the number of advancements made during the WWII era, a time when industrial quality control was growing in importance.

Applications

NDT is used in a variety of settings that covers a wide range of industrial activity.- Automotive

- EngineEngineAn engine or motor is a machine designed to convert energy into useful mechanical motion. Heat engines, including internal combustion engines and external combustion engines burn a fuel to create heat which is then used to create motion...

parts - FrameChassisA chassis consists of an internal framework that supports a man-made object. It is analogous to an animal's skeleton. An example of a chassis is the underpart of a motor vehicle, consisting of the frame with the wheels and machinery.- Vehicles :In the case of vehicles, the term chassis means the...

- Engine

- AviationAviationAviation is the design, development, production, operation, and use of aircraft, especially heavier-than-air aircraft. Aviation is derived from avis, the Latin word for bird.-History:...

/ AerospaceAerospaceAerospace comprises the atmosphere of Earth and surrounding space. Typically the term is used to refer to the industry that researches, designs, manufactures, operates, and maintains vehicles moving through air and space...

- AirframeAirframeThe airframe of an aircraft is its mechanical structure. It is typically considered to include fuselage, wings and undercarriage and exclude the propulsion system...

s- Spaceframes

- Powerplants

- Propellers

- Reciprocating EngineReciprocating engineA reciprocating engine, also often known as a piston engine, is a heat engine that uses one or more reciprocating pistons to convert pressure into a rotating motion. This article describes the common features of all types...

s - Gas turbine engines

- RocketRocketA rocket is a missile, spacecraft, aircraft or other vehicle which obtains thrust from a rocket engine. In all rockets, the exhaust is formed entirely from propellants carried within the rocket before use. Rocket engines work by action and reaction...

ry

- Airframe

- ConstructionConstructionIn the fields of architecture and civil engineering, construction is a process that consists of the building or assembling of infrastructure. Far from being a single activity, large scale construction is a feat of human multitasking...

- StructureStructureStructure is a fundamental, tangible or intangible notion referring to the recognition, observation, nature, and permanence of patterns and relationships of entities. This notion may itself be an object, such as a built structure, or an attribute, such as the structure of society...

s - BridgeBridgeA bridge is a structure built to span physical obstacles such as a body of water, valley, or road, for the purpose of providing passage over the obstacle...

s - Cover MeterCover meterA cover meter is an instrument to locate rebars and measure the exact concrete cover. Rebar detectors are less sophisticated devices that can only locate metallic objects below the surface...

- Structure

- Maintenance, repair and operationsMaintenance, Repair and OperationsMaintenance, repair, and operations or maintenance, repair, and overhaul involves fixing any sort of mechanical or electrical device should it become out of order or broken...

- BridgeBridgeA bridge is a structure built to span physical obstacles such as a body of water, valley, or road, for the purpose of providing passage over the obstacle...

s

- Bridge

- ManufacturingManufacturingManufacturing is the use of machines, tools and labor to produce goods for use or sale. The term may refer to a range of human activity, from handicraft to high tech, but is most commonly applied to industrial production, in which raw materials are transformed into finished goods on a large scale...

- Machine parts

- CastingCastingIn metalworking, casting involves pouring liquid metal into a mold, which contains a hollow cavity of the desired shape, and then allowing it to cool and solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process...

s and ForgingsForgeA forge is a hearth used for forging. The term "forge" can also refer to the workplace of a smith or a blacksmith, although the term smithy is then more commonly used.The basic smithy contains a forge, also known as a hearth, for heating metals...

- Industrial plants such as NuclearNuclear engineeringNuclear engineering is the branch of engineering concerned with the application of the breakdown as well as the fusion of atomic nuclei and/or the application of other sub-atomic physics, based on the principles of nuclear physics...

, PetrochemicalPetrochemicalPetrochemicals are chemical products derived from petroleum. Some chemical compounds made from petroleum are also obtained from other fossil fuels, such as coal or natural gas, or renewable sources such as corn or sugar cane....

, PowerPower stationA power station is an industrial facility for the generation of electric energy....

, RefineriesOil refineryAn oil refinery or petroleum refinery is an industrial process plant where crude oil is processed and refined into more useful petroleum products, such as gasoline, diesel fuel, asphalt base, heating oil, kerosene, and liquefied petroleum gas...

, Pulp and PaperPulp and paper industryThe global pulp and paper industry is dominated by North American , northern European and East Asian countries...

, Fabrication shopsFabrication (metal)Fabrication as an industrial term refers to building metal structures by cutting, bending, and assembling. The cutting part of fabrication is via sawing, shearing, or chiseling ; torching with handheld torches ; and via CNC cutters...

, Mine processingMiningMining is the extraction of valuable minerals or other geological materials from the earth, from an ore body, vein or seam. The term also includes the removal of soil. Materials recovered by mining include base metals, precious metals, iron, uranium, coal, diamonds, limestone, oil shale, rock...

and their Risk Based InspectionRisk based inspectionRisk Based Inspection is a risk based approach to prioritizing and planning inspection used in engineering industries, and predominant in the oil and gas industries. This type of inspection planning analyses the probability and consequence of failure of an asset to calculate its risk of failure...

programmes.- Pressure vesselPressure vesselA pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.The pressure differential is dangerous and many fatal accidents have occurred in the history of their development and operation. Consequently, their design,...

s - Storage tankStorage tankA storage tank is a container, usually for holding liquids, sometimes for compressed gases . The term can be used for reservoirs , and for manufactured containers. The usage of the word tank for reservoirs is common or universal in Indian English, American English and moderately common in British...

s - WeldsWeldingWelding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material that cools to become a strong joint, with pressure sometimes...

- BoilerBoilerA boiler is a closed vessel in which water or other fluid is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications.-Materials:...

s - Heat exchangerHeat exchangerA heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact...

s - TurbineTurbineA turbine is a rotary engine that extracts energy from a fluid flow and converts it into useful work.The simplest turbines have one moving part, a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades, or the blades react to the flow, so that they move and...

bores - In-plant PipingPipingWithin industry, piping is a system of pipes used to convey fluids from one location to another. The engineering discipline of piping design studies the efficient transport of fluid....

- Pressure vessel

- Miscellaneous

- PipelinesPipeline transportPipeline transport is the transportation of goods through a pipe. Most commonly, liquids and gases are sent, but pneumatic tubes that transport solid capsules using compressed air are also used....

- In-line InspectionPiggingPigging in the context of pipelines refers to the practice of using pipeline inspection gauges or 'pigs' to perform various maintenance operations on a pipeline. This is done without stopping the flow of the product in the pipeline....

using "pigs" - Pipeline integrity managementPipeline integrity managementThe concept of pipeline integrity management became especially important as a result of the Pipeline Safety Improvement Act of 2002 signed by President Bush on December, 12 2002.-History:...

- Leak DetectionLeak DetectionPipeline networks are the most economic and safest pipeline transport for mineral oil, gases and other fluid products. As a means of long-distance transport, pipelines have to fulfill high demands of safety, reliability and efficiency. Most pipelines, regardless of what they transport, are designed...

- In-line Inspection

- Railways

- Rail InspectionRail inspectionRail inspection is the practice of examining rail tracks for flaws that could lead to catastrophic failures. According to the United States Federal Railroad Administration Office of Safety Analysis, track defects are the second leading cause of accidents on railways in the United States. The...

- Wheel Inspection

- Rail Inspection

- Tubular NDTTubular NDTTubular NDT is the application of various technologies to detect anomalies such as corrosion and manufacturing defects in metallic tubes. Tubing can be found in such equipment as boilers and heat exchangers. To carry out an examination "in situ" Tubular NDT (nondestructive testing) is the...

, for Tubing material - Corrosion Under Insulation (CUI)

- Amusement parkAmusement parkthumb|Cinderella Castle in [[Magic Kingdom]], [[Disney World]]Amusement and theme parks are terms for a group of entertainment attractions and rides and other events in a location for the enjoyment of large numbers of people...

rides - Submarines and other Naval warships

- Medical imagingMedical imagingMedical imaging is the technique and process used to create images of the human body for clinical purposes or medical science...

applications (see also Medical physicsMedical physicsMedical physics is the application of physics to medicine. It generally concerns physics as applied to medical imaging and radiotherapy, although a medical physicist may also work in many other areas of healthcare...

)

- Pipelines

Methods and techniques

- Acoustic emission testing (AE or AT)

- Blue Etch Anodize (BEA)

- Dye penetrant inspectionDye penetrant inspectionDye penetrant inspection , also called liquid penetrant inspection or penetrant testing , is a widely applied and low-cost inspection method used to locate surface-breaking defects in all non-porous materials...

Liquid penetrant testing (PT or LPI) - Electromagnetic testingElectromagnetic testingElectromagnetic Testing , as a form of nondestructive testing, is the process of inducing electric currents or magnetic fields or both inside a test object and observing the electromagnetic response...

(ET)- Alternating current field measurementAlternating Current Field MeasurementAlternating Current Field Measurement is an electromagnetic technique for detection and sizing of surface breaking cracks. It works on all metals and, not requiring direct, electrical contact, works through coatings.-Use:...

(ACFM) - Alternating current potential drop measurement (ACPD)

- BarkhausenBarkhausen effectThe Barkhausen effect is a name given to the noise in the magnetic output of a ferromagnet when the magnetizing force applied to it is changed...

testing - Direct current potential drop measurement (DCPD)

- Eddy-current testingEddy-current testingEddy-current testing uses electromagnetic induction to detect flaws in conductive materials. There are several limitations, among them: only conductive materials can be tested, the surface of the material must be accessible, the finish of the material may cause bad readings, the depth of...

(ECT) - Magnetic flux leakageMagnetic flux leakageMagnetic flux leakage is a magnetic method of nondestructive testing that is used to detect corrosion and pitting in steel structures, most commonly pipelines and storage tanks. The basic principle is that a powerful magnet is used to magnetize the steel. At areas where there is corrosion or...

testing (MFL) for pipelines, tank floors, and wire rope - Magnetic-particle inspectionMagnetic-particle inspectionMagnetic particle inspection is a non-destructive testing process for detecting surface and slightly subsurface discontinuities in ferroelectric materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The piece can be magnetized by direct...

(MT or MPI) - Remote field testingRemote field testingRemote field testing is an electromagnetic method of nondestructive testing whose main application is finding defects in steel pipes and tubes. RFT may also referred to as RFEC or RFET...

(RFT)

- Alternating current field measurement

- EllipsometryEllipsometryEllipsometry is an optical technique for the investigation of the dielectric properties of thin films....

- Guided wave testingGuided wave testingGuided Wave testing is one of latest methods in the field ofnon-destructive evaluation. The methodemploys mechanical stress waves that propagate along an elongatedstructure while guided by its boundaries. This allows the...

(GWT) - Hardness testing

- Impulse excitation techniqueImpulse excitation technique-Practical:The impulse excitation technique is a nondestructive test method that uses natural frequency, dimensions and mass of a test-piece to determine Young's modulus, Shear modulus, Poisson's ratio and damping coefficient....

(IET) - Infrared and thermal testingInfrared and thermal testingInfrared and thermal testing is one of many Nondestructive testing techniques designated by the American Society for Nondestructive Testing . Infrared Thermography is the science of measuring and mapping surface temperatures....

(IR)- Thermographic inspectionThermographic inspectionThermographic inspection refers to the nondestructive testing of parts, materials or systems through the imaging of the thermal patterns at the object's surface. Strictly speaking, the term thermography alone, refers to all thermographic inspection techniques regardless of the physical phenomena...

- Thermographic inspection

- Laser testing

- Electronic speckle pattern interferometryElectronic speckle pattern interferometryElectronic Speckle Pattern Interferometry , also known as TV Holography, is a technique which uses laser light, together with video detection, recording and processing to visualise static and dynamic displacements of components with optically rough surfaces...

- Holographic interferometryHolographic interferometryHolographic interferometry is a technique which enables static and dynamic displacements of objects with optically rough surfaces to be measured to optical interferometric precision . These measurements can be applied to stress, strain and vibration analysis, as well as to non-destructive testing...

- Low coherence interferometry

- ProfilometryProfilometerProfilometer is a measuring instrument used to measure a surface's profile, in order to quantify its roughness.While the historical notion of a profilometer was a device similar to a phonograph that measures a surface as the surface is moved relative to the contact profilometer's stylus, this...

- ShearographyShearographyShearography or speckle pattern shearing interferometry is a measuring and testing method similar to holographic interferometry. It uses coherent light or coherent soundwaves to provide information about the quality of different materials in nondestructive testing, strain measurement, and vibration...

- Electronic speckle pattern interferometry

- Leak testing (LT) or Leak detectionLeak DetectionPipeline networks are the most economic and safest pipeline transport for mineral oil, gases and other fluid products. As a means of long-distance transport, pipelines have to fulfill high demands of safety, reliability and efficiency. Most pipelines, regardless of what they transport, are designed...

- Absolute pressure leak testing (pressure change)

- Bubble testing

- Halogen diode leak testing

- Hydrogen leak testingHydrogen leak testingHydrogen leak testing is the normal way in which a hydrogen pressure vessel or installation is checked for leaks or flaws. There are various tests....

- Mass spectrometer leak testing

- Tracer-gas leak testing methodTracer-gas leak testing methodTracer-gas leak testing method is a nondestructive testing method.-Types:Several tracer-gas leak testing methods exist among which the methods of choice are:* Helium mass spectrometer or helium leak detection, providing the highest sensitivity...

Helium, Hydrogen and refrigerant gases

- Magnetic resonance imagingMagnetic resonance imagingMagnetic resonance imaging , nuclear magnetic resonance imaging , or magnetic resonance tomography is a medical imaging technique used in radiology to visualize detailed internal structures...

(MRI) and NMR spectroscopyNMR spectroscopyNuclear magnetic resonance spectroscopy, most commonly known as NMR spectroscopy, is a research technique that exploits the magnetic properties of certain atomic nuclei to determine physical and chemical properties of atoms or the molecules in which they are contained... - Near-infrared spectroscopy (NIRS)

- Optical microscopyOptical microscopeThe optical microscope, often referred to as the "light microscope", is a type of microscope which uses visible light and a system of lenses to magnify images of small samples. Optical microscopes are the oldest design of microscope and were possibly designed in their present compound form in the...

- Positive Material Identification (PMI)

- Radiographic testingRadiographic testingRadiographic Testing , or industrial radiography, is a nondestructive testing method of inspecting materials for hidden flaws by using the ability of short wavelength electromagnetic radiation to penetrate various materials.Either an X-ray machine or a radioactive source can be used as a source...

(RT) (see also Industrial radiographyIndustrial radiographyIndustrial Radiography is the use of ionizing radiation to view objects in a way that cannot be seen otherwise. It is not to be confused with the use of ionizing radiation to change or modify objects; radiography's purpose is strictly viewing. Industrial radiography has grown out of engineering,...

and RadiographyRadiographyRadiography is the use of X-rays to view a non-uniformly composed material such as the human body. By using the physical properties of the ray an image can be developed which displays areas of different density and composition....

)- Computed radiographyComputed radiographyComputed Radiography uses very similar equipment to conventional radiography except that in place of a film to create the image, an imaging plate made of photostimulable phosphor is used. The imaging plate housed in a special cassette and placed under the body part or object to be examined and...

- Digital radiography (real-time)

- Neutron radiographic testing (NR)

- SCAR (Small Controlled Area Radiography)

- X-ray computed tomography (CT)

- Computed radiography

- Scanning electron microscopyScanning electron microscopeA scanning electron microscope is a type of electron microscope that images a sample by scanning it with a high-energy beam of electrons in a raster scan pattern...

- Surface Temper Etch (Nital Etch)

- Ultrasonic testing (UT)

- ART (Acoustic Resonance Technology)ART (Acoustic Resonance Technology)Acoustic Resonance Technology is an acoustic inspection technology developed by Det Norske Veritas over the past 20 years. ART exploits the phenomenon of half-wave resonance, whereby a suitably excited resonant target exhibits longitudinal resonances at certain frequencies characteristic of the...

- Electro Magnetic Acoustic TransducerElectro Magnetic Acoustic TransducerElectromagnetic acoustic transducer is a transducer for non-contact sound generation and reception using electromagnetic mechanisms. EMAT is an ultrasonic nondestructive testing method where couplant is not needed since the sound is directly generated in the material underneath the transducer...

(EMAT) (non-contact) - Laser ultrasonicsLaser ultrasonicsLaser-ultrasonics uses lasers to generate and detect ultrasonic waves. It is a non-contact technique used to measure materials thickness, detect flaws and materials characterization...

(LUT) - Internal rotary inspection systemInternal rotary inspection systemInternal rotary inspection system is an ultrasonic method for the nondestructive testing of pipes and tubes. The IRIS probe is inserted into a tube that is flooded with water, and the probe is pulled out slowly as the data is displayed and recorded...

(IRIS) ultrasonics for tubes - Phased array ultrasonicsPhased array ultrasonicsPhased Array ultrasonics is an advanced method of ultrasonic testing that has applications in medical imaging and industrial nondestructive testing. In medicine a common application of phased array is the imaging of the heart...

- Time of flight diffraction ultrasonicsTime of flight diffraction ultrasonicsTime of Flight Diffraction method of Ultrasonic inspection is a very sensitive and accurate method for nondestructive testing of welds for defects. TOFD originated from tip diffraction techniques which were first published by Silk and Liddington in 1975 which paved the way for TOFD. Later works...

(TOFD) - Time of Flight Ultrasonic Determination of 3D Elastic ConstantsTime of Flight Ultrasonic Determination of 3D Elastic ConstantsThe three dimensional elastic constants of materials can be measured using the ultrasonic immersion method. This was pioneered by xx and xx from the National Physical Laboratory in the 19xxs. It has mainly been used for polymer composite materials...

(TOF)

- ART (Acoustic Resonance Technology)

- Visual inspection (VT)

- Pipeline video inspectionPipeline video inspectionPipeline video inspection is a form of telepresence used to visually inspect the interiors of pipelines. A common application is to determine the condition of small diameter sewer lines and household connection pipes....

- Pipeline video inspection

- Corroscan/C-scan

- IRIS - Internal Rotary Inspection SystemInternal rotary inspection systemInternal rotary inspection system is an ultrasonic method for the nondestructive testing of pipes and tubes. The IRIS probe is inserted into a tube that is flooded with water, and the probe is pulled out slowly as the data is displayed and recorded...

- 3D Computed Tomography

- Industrial CT ScanningIndustrial CT ScanningIndustrial CT scanning is a process which uses X-ray equipment to produce three-dimensional representations of components both externally and internally. Industrial CT scanning has been used in many areas of industry for internal inspection of components...

- Industrial CT Scanning

- Heat Exchanger Life Assessment System

- RTJ Flange Special Ultrasonic Testing

Personnel training, qualification and certification

Successful and consistent application of nondestructive testing techniques depends heavily on personnel training, experience and integrity. Personnel involved in application of industrial NDT methods and interpretation of results should be certified, and in some industrial sectors certification is enforced by law or by the applied codes and standards.Definitions

The following definitions for qualification and certification are given in ISO 9712 and EN 473:- Certification: "Procedure, used by the certification body to confirm that the qualification requirements for a method, level and sector have been fulfilled, leading to the issuing of a certificate".

- Qualification: "Demonstration of physical attributes, knowledge, skill, training and experience required to properly perform NDT tasks".

In US standards and codes, while a very similar definition of qualification is included in ASNT SNT-TC-1A, certification is simply defined as: "Written testimony of qualification".

Training

Non-Destructive Testing (NDT) training is provided for people working in many industries. It is generally necessary that the candidate successfully completes a theoretical and practical training program, as well as have performed several hundred hours of practical application of the particular method they wish to be trained in. At this point, they may pass a certification examination. Further, NDT training has recently become available online. WorldSpec.org is one of the innovative companies that helped pioneer this new "era" in NDT Training.Certification schemes

There are two approaches in personnel certification:- Employer Based Certification: Under this concept the employer compiles their own Written Practice. The written practice defines the responsibilities of each level of certification, as implemented by the company, and describes the training, experience and examination requirements for each level of certification. In industrial sectors the written practices are usually based on recommended practice SNT-TC-1A of the American Society for Nondestructive TestingAmerican Society for Nondestructive TestingThe American Society for Nondestructive Testing, Inc. or ASNT is a technical society for nondestructive testing professionals. ASNT evolved from The American Industrial Radium and X-Ray Society which was founded in 1941. Its headquarters is located in Columbus, OH, and there are 70 local sections...

. ANSI standard CP-189 outlines requirements for any written practice that conforms to the standard. - Personal Central Certification: The concept of central certification is that an NDT operator can obtain certification from a central certification authority, that is recognized by most employers, third parties and/or government authorities. Industrial standards for central certification schemes include ISO 9712, EN 473. and ACCP. Certification under these standards involves training, work experience under supervision and passing a written and practical examination set up by the independent certification authority.

In the United States employer based schemes are the norm, however central certification schemes exist as well. The most notable is ASNT Level III (established in 1976-1977), which is organized by the American Society for Nondestructive Testing

American Society for Nondestructive Testing

The American Society for Nondestructive Testing, Inc. or ASNT is a technical society for nondestructive testing professionals. ASNT evolved from The American Industrial Radium and X-Ray Society which was founded in 1941. Its headquarters is located in Columbus, OH, and there are 70 local sections...

for Level 3 NDT personnel. NAVSEA 250-1500 is another US central certification scheme, specifically developed for use in the naval nuclear program.

Central certification is more widely used in the European Union, where certifications are issued by accredited bodies

Personnel certification body

A personnel certification body is an organization that administers individual credentials. A personnel certification body develops criteria against which an individual needs to demonstrate competencies and ensures these criteria are held by applicants before certifying them.Most personnel...

(independent organizations conforming to ISO 17024 and accredited by a national accreditation authority like UKAS). The Pressure Equipment Directive

Pressure Equipment Directive

The Pressure Equipment Directive 97/23/EC of the EU sets out the standards for the design and fabrication of pressure equipment generally over one litre in volume and having a maximum pressure more than 0.5 bar gauge...

(97/23/EEC) actually enforces central personnel certification for the initial testing of steam boilers and some categories of pressure vessel

Pressure vessel

A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.The pressure differential is dangerous and many fatal accidents have occurred in the history of their development and operation. Consequently, their design,...

s and piping

Piping

Within industry, piping is a system of pipes used to convey fluids from one location to another. The engineering discipline of piping design studies the efficient transport of fluid....

. European Standards harmonized with this directive specify personnel certification to EN 473. Certifications issued by a national NDT society which is a member of the European Federation of NDT (EFNDT) are mutually acceptable by the other member societies under a multilateral recognition agreement.

Canada also implements an ISO 9712 central certification scheme, which is administered by Natural Resources Canada

Natural Resources Canada

The Department of Natural Resources , operating under the FIP applied title Natural Resources Canada , is the ministry of the government of Canada responsible for natural resources, energy, minerals and metals, forests, earth sciences, mapping and remote sensing...

, a government department.

The aerospace

Aerospace

Aerospace comprises the atmosphere of Earth and surrounding space. Typically the term is used to refer to the industry that researches, designs, manufactures, operates, and maintains vehicles moving through air and space...

sector worldwide sticks to employer based schemes. In America it is based mostly on AIA-NAS-410 and in the European Union on the equivalent and very similar standard EN 4179

Levels of certification

Most NDT personnel certification schemes listed above specify three "levels" of qualification and/or certification, usually designated as Level 1, Level 2 and Level 3 (although some codes specify roman numerals, like Level II). The roles and responsibilities of personnel in each level are generally as follows (there are slight differences or variations between different codes and standards):- Level 1 are technicianTechnicianA technician is a worker in a field of technology who is proficient in the relevant skills and techniques, with a relatively practical understanding of the theoretical principles. Experienced technicians in a specific tool domain typically have intermediate understanding of theory and expert...

s qualified to perform only specific calibrationCalibrationCalibration is a comparison between measurements – one of known magnitude or correctness made or set with one device and another measurement made in as similar a way as possible with a second device....

s and tests under close supervision and direction by higher level personnel. They can only report test results. Normally they work following specific work instructions for testing procedures and rejection criteria.

- Level 2 are engineers or experienced technicians who are able to set up and calibrate testing equipment, conduct the inspection according to codes and standards (instead of following work instructions) and compile work instructions for Level 1 technicians. They are also authorized to report, interpret, evaluate and document testing results. They can also supervise and train Level 1 technicians. In addition to testing methods, they must be familiar with applicable codes and standards and have some knowledge of the manufacture and service of tested products.

- Level 3 are usually specialized engineers or very experienced technicians. They can establish NDT techniques and procedures and interpret codes and standards. They also direct NDT laboratories and have central role in personnel certification. They are expected to have wider knowledge covering materials, fabrication and product technology.

Terminology

The standard US terminology for Nondestructive testing is defined in standard ASTM E-1316. Some definitions may be different in European standard EN 1330.Indication : The response or evidence from an examination, such as a blip on the screen of an instrument. Indications are classified as true or false. False indications are those caused by factors not related to the principles of the testing method or by improper implementation of the method, like film damage in radiography, electrical interference in ultrasonic testing etc. True indications are further classified as relevant and non relevant. Relevant indications are those caused by flaws. Non relevant indications are those caused by known features of the tested object, like gaps, threads, case hardening etc.

Interpretation : Determining if an indication is of a type to be investigated. For example, in electromagnetic testing, indications from metal loss are considered flaws because they should usually be investigated, but indications due to variations in the material properties may be harmless and nonrelevant.

Flaw : A type of discontinuity that must be investigated to see if it is rejectable. For example, porosity in a weld or metal loss.

Evaluation : Determining if a flaw is rejectable. For example, is porosity in a weld larger than acceptable by code?

Defect : A flaw that is rejectable — i.e. does not meet acceptance criteria. Defects are generally removed or repaired.

Penetrant testing : Non-destructive test typically comprising a penetrant, a method of excess removal and a developer to produce a visible indication of surface-breaking discontinuities.

Reliability and statistics

Defect detection tests are among the more commonly employed of non-destructive tests. The evaluation of NDT reliability commonly contains two statistical errors. First, most tests fail to define the objects that are called "sampling units" in statistics; it follows that the reliability of the tests cannot be established. Second, the literature usually misuses statistical terms in such a way as to make it sound as though sampling units are defined. These two errors may lead to incorrect estimates of probability of detection.See also

- Destructive testingDestructive testingIn destructive testing, tests are carried out to the specimen's failure, in order to understand a specimen's structural performance or material behaviour under different loads...

- InspectionInspectionAn inspection is, most generally, an organized examination or formal evaluation exercise. In engineering activities inspection involves the measurements, tests, and gauges applied to certain characteristics in regard to an object or activity...

- Maintenance testingMaintenance testingMaintenance testing is that testing which is performed to either identify equipment problems, diagnose equipment problems or to confirm that repair measures have been effective...

- Product certificationProduct certificationProduct certification or product qualification is the process of verifying that a certain product has passed performance tests and quality assurance tests or qualification requirements stipulated in contracts, regulations, or specifications...

- Quality controlQuality controlQuality control, or QC for short, is a process by which entities review the quality of all factors involved in production. This approach places an emphasis on three aspects:...

- Risk-based inspection

- Failure analysisFailure analysisFailure analysis is the process of collecting and analyzing data to determine the cause of a failure. It is an important discipline in many branches of manufacturing industry, such as the electronics industry, where it is a vital tool used in the development of new products and for the improvement...

- Forensic engineeringForensic engineeringForensic engineering is the investigation of materials, products, structures or components that fail or do not operate or function as intended, causing personal injury or damage to property. The consequences of failure are dealt with by the law of product liability. The field also deals with...

- Materials scienceMaterials scienceMaterials science is an interdisciplinary field applying the properties of matter to various areas of science and engineering. This scientific field investigates the relationship between the structure of materials at atomic or molecular scales and their macroscopic properties. It incorporates...

- Predictive maintenancePredictive maintenancePredictive maintenance techniques help determine the condition of in-service equipment in order to predict when maintenance should be performed...

- Reliability engineeringReliability engineeringReliability engineering is an engineering field, that deals with the study, evaluation, and life-cycle management of reliability: the ability of a system or component to perform its required functions under stated conditions for a specified period of time. It is often measured as a probability of...

- Stress testingStress testingStress testing is a form of testing that is used to determine the stability of a given system or entity. It involves testing beyond normal operational capacity, often to a breaking point, in order to observe the results...

- Terahertz nondestructive evaluationTerahertz nondestructive evaluationTerahertz nondestructive evaluation pertains to devices, and techniques of analysis occurring in the terahertz domain of electromagnetic radiation...

External links

- The International Committee for Non-Destructive Testing (ICNDT)

- European Federation for Non-Destructive Testing (EFNDT)

- American Society for Nondestructive Testing http://www.asnt.org

- NDT Education University of Iowa Repository for Nondestructive Education Material

- NDT.net, Nondestructive Online Journal

- NDT.org NDT Jobs, News, and Social Network

- NDTWiki.com, NonDestructive Testing wiki for professionals

- SimplyNDT.com NDT/NDE Employment Opportunities & Blog