Shape Memory Polymer

Encyclopedia

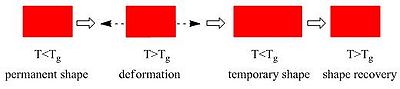

Shape-memory polymers are polymeric smart materials that have the ability to return from a deformed state (temporary shape) to their original (permanent) shape induced by an external stimulus (trigger), such as temperature change.

, light or solution. As well as polymers in general, SMPs also cover a wide property-range from stable to biodegradable

, from soft to hard, and from elastic to rigid, depending on the structural units that constitute the SMP. SMPs include thermoplastic

and thermoset (covalently cross-linked) polymeric materials. SMPs are known to be able to store up to three different shapes in memory.

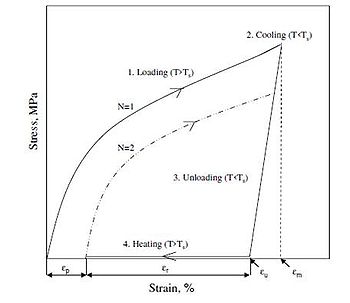

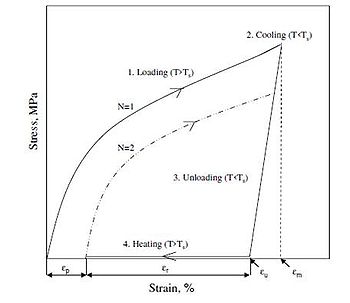

Two important quantities that are used to describe shape-memory effects are the strain recovery rate (Rr) and strain fixity rate (Rf). The strain recovery rate describes the ability of the material to memorize its permanent shape, while the strain fixity rate describes the ability of switching segments to fix the mechanical deformation.

where N is the cycle number, εm is the maximum strain imposed on the material, and εp(N) and εp(N-1) are the strains of the sample in two successive cycles in the stress-free state before yield stress is applied.

Shape-memory effect can be described briefly as the following mathematical model:

where Eg is the glassy modulus, Er is the rubbery modulus, fIR is viscous flow strain and fα is strain for t >> tr.

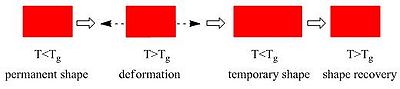

Polymers exhibiting a shape-memory effect have both a visible, current (temporary) form and a stored (permanent) form. Once the latter has been manufactured by conventional methods, the material is changed into another, temporary form by processing through heating, deformation, and finally, cooling. The polymer maintains this temporary shape until the shape change into the permanent form is activated by a predetermined external stimulus. The secret behind these materials lies in their molecular network structure, which contains at least two separate phases. The phase showing the highest thermal transition, Tperm, is the temperature that must be exceeded to establish the physical crosslinks responsible for the permanent shape. The switching segments, on the other hand, are the segments with the ability to soften past a certain transition temperature (Ttrans) and are responsible for the temporary shape. In some cases this is the glass transition temperature (Tg) and others the melting temperature (Tm). Exceeding Ttrans (while remaining below Tperm) activates the switching by softening these switching segments and thereby allowing the material to resume its original (permanent) form. Below Ttrans, flexibility of the segments is at least partly limited. If Tm is chosen for programming the SMP, strain-induced crystallization of the switching segment can be initiated when it is stretched above Tm and subsequently cooled below Tm These crystallites form covalent netpoints which prevent the polymer from reforming its usual coiled structure. The hard to soft segment ratio is often between 5/95 and 95/5, but ideally this ratio is between 20/80 and 80/20. The shape-memory polymers are effectively viscoelastic and many models and analysis methods exist.

Polymers exhibiting a shape-memory effect have both a visible, current (temporary) form and a stored (permanent) form. Once the latter has been manufactured by conventional methods, the material is changed into another, temporary form by processing through heating, deformation, and finally, cooling. The polymer maintains this temporary shape until the shape change into the permanent form is activated by a predetermined external stimulus. The secret behind these materials lies in their molecular network structure, which contains at least two separate phases. The phase showing the highest thermal transition, Tperm, is the temperature that must be exceeded to establish the physical crosslinks responsible for the permanent shape. The switching segments, on the other hand, are the segments with the ability to soften past a certain transition temperature (Ttrans) and are responsible for the temporary shape. In some cases this is the glass transition temperature (Tg) and others the melting temperature (Tm). Exceeding Ttrans (while remaining below Tperm) activates the switching by softening these switching segments and thereby allowing the material to resume its original (permanent) form. Below Ttrans, flexibility of the segments is at least partly limited. If Tm is chosen for programming the SMP, strain-induced crystallization of the switching segment can be initiated when it is stretched above Tm and subsequently cooled below Tm These crystallites form covalent netpoints which prevent the polymer from reforming its usual coiled structure. The hard to soft segment ratio is often between 5/95 and 95/5, but ideally this ratio is between 20/80 and 80/20. The shape-memory polymers are effectively viscoelastic and many models and analysis methods exist.

In the transition from the glassy state to a rubber-elastic state by thermal activation, the rotations around segment bonds become increasingly unimpeded. This allows chains to assume other possibly, energetically equivalent conformations with a small amount of disentangling. As a result, the majority of SMPs will form compact, random coils because this conformation is entropically favored over a stretched conformation.

Polymers in this elastic state with number average molecular weight greater than 20,000 stretch in the direction of an applied external force. If the force is applied for a short time, the entanglement of polymer chains with their neighbors will prevent large movement of the chain and the sample recovers its original conformation upon removal of the force. If the force is applied for a longer period of time, however, a relaxation process takes place whereby a plastic, irreversible deformation of the sample takes place due to the slipping and disentangling of the polymer chains.

To prevent the slipping and flow of polymer chains, cross-linking can be used, both chemical and physical.

s, polyurethanes with ionic or mesogenic components made by prepolymer

method. Other block copolymers also show the shape-memory effect, such as, block copolymer of polyethylene terephthalate

(PET) and polyethyleneoxide

(PEO), block copolymers containing polystyrene

and poly(1,4-butadiene), and an ABA triblock copolymer made from poly(2-methyl-2-oxazoline) and polytetrahydrofuran

.

(POSS) also have shape-memory effect.

. The network polymer can be synthesized by either polymerization with multifunctional (3 or more) crosslinker or by subsequent crosslinking of a linear or branched polymer. They form insoluble materials which swell in certain solvents.

, glycerin or dimethyl 5-isopthalates as a crosslinking agent. The addition of 1.5 wt% maleic anhydride increased in shape recovery from 35% to 65% and tensile strength from 3 to 5 MPa.

s, some thermoplastic

polymers, most notably PEEK

, can be used as well.

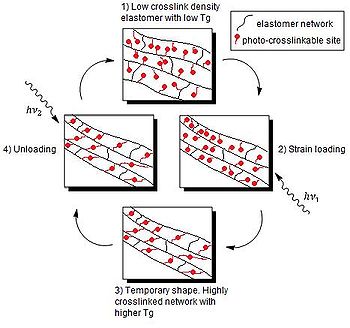

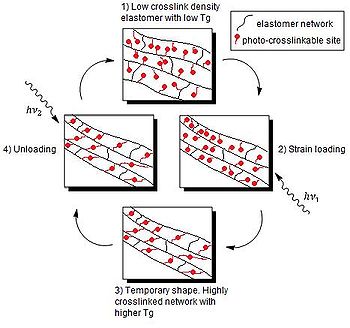

Light-activated shape-memory polymers (LASMP) use processes of photo-crosslinking and photo-cleaving to change Tg. Photo-crosslinking is achieved by using one wavelength of light, while a second wavelength of light reversibly cleaves the photo-crosslinked bonds. The effect achieved is that the material may be reversibly switched between an elastomer

Light-activated shape-memory polymers (LASMP) use processes of photo-crosslinking and photo-cleaving to change Tg. Photo-crosslinking is achieved by using one wavelength of light, while a second wavelength of light reversibly cleaves the photo-crosslinked bonds. The effect achieved is that the material may be reversibly switched between an elastomer

and a rigid polymer. Light does not change the temperature, only the cross-linking density within the material. For example, it has been reported that polymers containing cinnamic groups can be fixed into predetermined shapes by UV light illumination (> 260 nm) and then recover their original shape when exposed to UV light of a different wavelength (< 260 nm). Examples of photoresponsive switches include cinnamic acid

and cinnamylidene acetic acid.

and sulfuric acid

, with the purpose of improving the interfacial bonding between the polymers and the conductive fillers. The shape-memory effect in these types of SMPs have been shown to be dependent on the filler content and the degree of surface modification of the MWNTs, with the surface modified versions exhibiting good energy conversion efficiency and improved mechanical properties.

Another technique being investigated involves the use of surface-modified super-paramagnetic nanoparticles. When introduced into the polymer matrix, remote actuation of shape transitions is possible. An example of this involves the use of oligo (e-capolactone)dimethacrylate/butyl acrylate composite with between 2 and 12% magnetite

nanoparticles. Nickel

and hybrid fibers have also been used with some degree of success.

Shape-memory polymers differ from shape memory alloys by their glass transition or melting transition from a hard to a soft phase which is responsible for the shape-memory effect. In shape-memory alloys martensitic

/austenitic

transitions are responsible for the shape-memory effect.

There are numerous advantages that make SMPs more attractive than shape memory alloys. They have a high capacity for elastic deformation (up to 200% in most cases), much lower cost, lower density, a broad range of application temperatures which can be tailored, easy processing, and potential biocompatibility and biodegradability.

.

s with potential applications as, e.g., intravenous cannula, self-adjusting orthodontic wires and selectively pliable tools for small scale surgical procedures where currently metal-based shape-memory alloys such as Nitinol are widely used. Another application of SMP in the medical field could be its use in implants: for example minimally invasive, trough small incisions or natural orifices, implantation of a device in its small temporary shape. Shape-memory technologies have shown great promise for cardiovascular stents, since they allow a small stent to be inserted along a vein or artery and then expanded to prop it open. After activating the shape memory by temperature increase or mechanical stress, it would assume its permanent shape. Certain classes of shape-memory polymers possess an additional property: biodegradability. This offers the option to develop temporary implants. In the case of biodegradable polymers, after the implant has fulfilled its intended use, e.g. healing/tissue regeneration has occurred, the material degrades into substances which can be eliminated by the body. Thus full functionality would be restored without the necessity for a second surgery to remove the implant (to avoid inflammation). Examples of this development are vascular stent

s and surgical sutures. When used in surgical sutures, the shape-memory property of SMPs enables wound closure with self-adjusting optimal tension, which avoids tissue damage due to overtightened sutures and does support healing and regeneration.

Properties of shape-memory polymers

SMPs can retain two or sometimes three shapes, and the transition between those is induced by temperature. In addition to temperature change, the shape change of SMPs can also be triggered by an electric or magnetic fieldMagnetic field

A magnetic field is a mathematical description of the magnetic influence of electric currents and magnetic materials. The magnetic field at any given point is specified by both a direction and a magnitude ; as such it is a vector field.Technically, a magnetic field is a pseudo vector;...

, light or solution. As well as polymers in general, SMPs also cover a wide property-range from stable to biodegradable

Synthetic biodegradable polymer

Many opportunities exist for the application of synthetic biodegradable polymers in the biomedical area particularly in the fields of tissue engineering and controlled drug delivery. Degradation is important in biomedicine for many reasons...

, from soft to hard, and from elastic to rigid, depending on the structural units that constitute the SMP. SMPs include thermoplastic

Thermoplastic

Thermoplastic, also known as a thermosoftening plastic, is a polymer that turns to a liquid when heated and freezes to a very glassy state when cooled sufficiently...

and thermoset (covalently cross-linked) polymeric materials. SMPs are known to be able to store up to three different shapes in memory.

Two important quantities that are used to describe shape-memory effects are the strain recovery rate (Rr) and strain fixity rate (Rf). The strain recovery rate describes the ability of the material to memorize its permanent shape, while the strain fixity rate describes the ability of switching segments to fix the mechanical deformation.

where N is the cycle number, εm is the maximum strain imposed on the material, and εp(N) and εp(N-1) are the strains of the sample in two successive cycles in the stress-free state before yield stress is applied.

Shape-memory effect can be described briefly as the following mathematical model:

where Eg is the glassy modulus, Er is the rubbery modulus, fIR is viscous flow strain and fα is strain for t >> tr.

Triple-shape memory

While most traditional shape-memory polymers can only hold a permanent and temporary shape, recent technological advances have allowed the introduction of triple-shape-memory materials. Much as a traditional double-shape-memory polymer will change from a temporary shape back to a permanent shape at a particular temperature, triple-shape-memory polymers will switch from one temporary shape to another at the first transition temperature, and then back to the permanent shape at another, higher activation temperature. This is usually achieved by combining two double-shape-memory polymers with different glass transition temperatures.Description of the thermally induced shape-memory effect

Thermodynamics of the shape-memory effect

In the amorphous state, polymer chains assume a completely random distribution within the matrix. W represents the probability of a strongly coiled conformation, which is the conformation with maximum entropy, and is the most likely state for an amorphous linear polymer chain. This relationship is represented mathematically as k = ln W, where k is the Boltzmann constant.In the transition from the glassy state to a rubber-elastic state by thermal activation, the rotations around segment bonds become increasingly unimpeded. This allows chains to assume other possibly, energetically equivalent conformations with a small amount of disentangling. As a result, the majority of SMPs will form compact, random coils because this conformation is entropically favored over a stretched conformation.

Polymers in this elastic state with number average molecular weight greater than 20,000 stretch in the direction of an applied external force. If the force is applied for a short time, the entanglement of polymer chains with their neighbors will prevent large movement of the chain and the sample recovers its original conformation upon removal of the force. If the force is applied for a longer period of time, however, a relaxation process takes place whereby a plastic, irreversible deformation of the sample takes place due to the slipping and disentangling of the polymer chains.

To prevent the slipping and flow of polymer chains, cross-linking can be used, both chemical and physical.

Linear block copolymers

Representative shape-memory polymers in this category are polyurethanePolyurethane

A polyurethane is any polymer composed of a chain of organic units joined by carbamate links. Polyurethane polymers are formed through step-growth polymerization, by reacting a monomer with another monomer in the presence of a catalyst.Polyurethanes are...

s, polyurethanes with ionic or mesogenic components made by prepolymer

Prepolymer

The term pre-polymer refers to a monomer or system of monomers that have been reacted to an intermediate molecular weight state. This material is capable of further polymerization by reactive groups to a fully cured high molecular weight state. As such, mixtures of reactive polymers with un-reacted...

method. Other block copolymers also show the shape-memory effect, such as, block copolymer of polyethylene terephthalate

Polyethylene terephthalate

Polyethylene terephthalate , commonly abbreviated PET, PETE, or the obsolete PETP or PET-P, is a thermoplastic polymer resin of the polyester family and is used in synthetic fibers; beverage, food and other liquid containers; thermoforming applications; and engineering resins often in combination...

(PET) and polyethyleneoxide

Polyethylene glycol

Polyethylene glycol is a polyether compound with many applications from industrial manufacturing to medicine. It has also been known as polyethylene oxide or polyoxyethylene , depending on its molecular weight, and under the tradename Carbowax.-Available forms:PEG, PEO, or POE refers to an...

(PEO), block copolymers containing polystyrene

Polystyrene

Polystyrene ) also known as Thermocole, abbreviated following ISO Standard PS, is an aromatic polymer made from the monomer styrene, a liquid hydrocarbon that is manufactured from petroleum by the chemical industry...

and poly(1,4-butadiene), and an ABA triblock copolymer made from poly(2-methyl-2-oxazoline) and polytetrahydrofuran

Polytetrahydrofuran

Polytetrahydrofuran, also called poly glycol or poly, is a chemical compound with formula n2 or HO-n-OH...

.

Other thermoplastic polymers

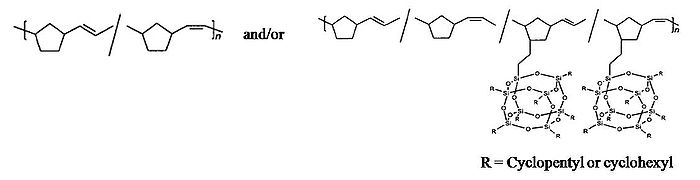

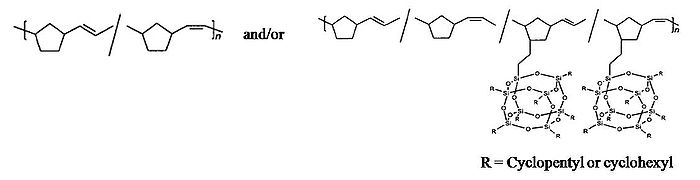

A linear, amorphous polynorbornene (Norsorex, developed by CdF Chemie/Nippon Zeon) or organic-inorganic hybrid polymers consisting of polynorbornene units that are partially substituted by polyhedral oligosilsesquioxaneSilsesquioxane

200px|thumbnail|right|Figure 1: Silsesquioxane Cage StructureA silsesquioxane is a compound with the empirical chemical formula RSiO3/2 where Si is the element silicon, O is oxygen and R is either hydrogen or an alkyl, alkene, aryl, arylene group.These materials can be used as a support for...

(POSS) also have shape-memory effect.

Chemically crosslinked SMPs

The main limitation of physically crosslinked polymers for the shape-memory application is irreversible deformation during memory programming due to the creepCreep

Creep may refer to:* CREEP, the Committee for the Re-Election of the President, associated with the Watergate scandal of U.S. president Nixon's administration....

. The network polymer can be synthesized by either polymerization with multifunctional (3 or more) crosslinker or by subsequent crosslinking of a linear or branched polymer. They form insoluble materials which swell in certain solvents.

Crosslinked polyurethane

This material can be made by using excess diisocyanate or by using a crosslinker such as glycerin, trimethylol propane. Introduction of covalent crosslinking improves in creep, increase in recovery temperature and recovery window.PEO based crosslinked SMPs

The PEO-PET block copolymers can be crosslinked by using maleic anhydrideMaleic anhydride

Maleic anhydride is an organic compound with the formula C2H22O. It is the acid anhydride of maleic acid and in its pure state it is a colourless or white solid with an acrid odour....

, glycerin or dimethyl 5-isopthalates as a crosslinking agent. The addition of 1.5 wt% maleic anhydride increased in shape recovery from 35% to 65% and tensile strength from 3 to 5 MPa.

| Hard phase | Crosslinker | Tr (°C) | Rf(5)(%) | Rf(5)(%) |

|---|---|---|---|---|

| PET | Glycerol/dimethyl 5-sulfoisopthalate | 11–30 | 90–95 | 60–70 |

| PET | Maleic anhydride | 8–13 | 91–93 | 60 |

| AA/MAA copolymer | N,N'-methylene-bis-acrylamide | 90 | 99 | |

| MAA/N-vinyl-2-pyrrolidone | Ethyleneglycol dimethacrylate | 90 | 99 | |

| PMMA/N-vinyl-2-pyrrolidone | Ethyleneglycol dimethacrylate | 45, 100 | 99 |

Thermoplastic shape-memory

While shape-memory effects are traditionally limited to thermosetting plasticThermosetting plastic

A thermosetting plastic, also known as a thermoset, is polymer material that irreversibly cures. The cure may be done through heat , through a chemical reaction , or irradiation such as electron beam processing.Thermoset materials are usually liquid or malleable prior to curing and designed to be...

s, some thermoplastic

Thermoplastic

Thermoplastic, also known as a thermosoftening plastic, is a polymer that turns to a liquid when heated and freezes to a very glassy state when cooled sufficiently...

polymers, most notably PEEK

PEEK

Polyether ether ketone is a colourless organic polymer thermoplastic used in engineering applications.-Synthesis:PEEK polymers are obtained by step-growth polymerization by the dialkylation of bisphenolate salts. Typical is the reaction of 4,4'-difluorobenzophenone with the disodium salt of...

, can be used as well.

Light-induced SMPs

Elastomer

An elastomer is a polymer with the property of viscoelasticity , generally having notably low Young's modulus and high yield strain compared with other materials. The term, which is derived from elastic polymer, is often used interchangeably with the term rubber, although the latter is preferred...

and a rigid polymer. Light does not change the temperature, only the cross-linking density within the material. For example, it has been reported that polymers containing cinnamic groups can be fixed into predetermined shapes by UV light illumination (> 260 nm) and then recover their original shape when exposed to UV light of a different wavelength (< 260 nm). Examples of photoresponsive switches include cinnamic acid

Cinnamic acid

Cinnamic acid is a white crystalline organic acid, which is slightly soluble in water.It is obtained from oil of cinnamon, or from balsams such as storax. It is also found in shea butter and is the best indication of its environmental history and post-extraction conditions...

and cinnamylidene acetic acid.

Electro-active SMPs

The use of electricity to activate the shape-memory effect of polymers is desirable for applications where it would not be possible to use heat and is another active area of research. Some current efforts use conducting SMP composites with carbon nanotubes. short carbon fibers (SCFs). carbon black, metallic Ni powder. These conducting SMPs are produced by chemically surface-modifying multi-walled carbon nanotubes (MWNTs) in a mixed solvent of nitric acidNitric acid

Nitric acid , also known as aqua fortis and spirit of nitre, is a highly corrosive and toxic strong acid.Colorless when pure, older samples tend to acquire a yellow cast due to the accumulation of oxides of nitrogen. If the solution contains more than 86% nitric acid, it is referred to as fuming...

and sulfuric acid

Sulfuric acid

Sulfuric acid is a strong mineral acid with the molecular formula . Its historical name is oil of vitriol. Pure sulfuric acid is a highly corrosive, colorless, viscous liquid. The salts of sulfuric acid are called sulfates...

, with the purpose of improving the interfacial bonding between the polymers and the conductive fillers. The shape-memory effect in these types of SMPs have been shown to be dependent on the filler content and the degree of surface modification of the MWNTs, with the surface modified versions exhibiting good energy conversion efficiency and improved mechanical properties.

Another technique being investigated involves the use of surface-modified super-paramagnetic nanoparticles. When introduced into the polymer matrix, remote actuation of shape transitions is possible. An example of this involves the use of oligo (e-capolactone)dimethacrylate/butyl acrylate composite with between 2 and 12% magnetite

Magnetite

Magnetite is a ferrimagnetic mineral with chemical formula Fe3O4, one of several iron oxides and a member of the spinel group. The chemical IUPAC name is iron oxide and the common chemical name is ferrous-ferric oxide. The formula for magnetite may also be written as FeO·Fe2O3, which is one part...

nanoparticles. Nickel

Nickel

Nickel is a chemical element with the chemical symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel belongs to the transition metals and is hard and ductile...

and hybrid fibers have also been used with some degree of success.

Shape-memory polymers vs. shape-memory alloys

| SMPs | SMAs | |

|---|---|---|

| Density (g/cm3) | 0.9–1.1 | 6–8 |

| Extent of deformation |

up to 800% | <8% |

| Required stress for deformation (MPa) |

1–3 | 50–200 |

| Stress generated upon recovery (MPa) |

1–3 | 150–300 |

| Transition temperatures (°C) |

−10..100 | −10..100 |

| Recovery speed | 1s – minutes |

<1s |

| Processing conditions |

<200 °C low pressure |

>1000 °C high pressure |

| Costs | <$10/lb | ~$250/lb |

Shape-memory polymers differ from shape memory alloys by their glass transition or melting transition from a hard to a soft phase which is responsible for the shape-memory effect. In shape-memory alloys martensitic

Martensite

Martensite, named after the German metallurgist Adolf Martens , most commonly refers to a very hard form of steel crystalline structure, but it can also refer to any crystal structure that is formed by displacive transformation. It includes a class of hard minerals occurring as lath- or...

/austenitic

Austenite

Austenite, also known as gamma phase iron, is a metallic non-magnetic allotrope of iron or a solid solution of iron, with an alloying element. In plain-carbon steel, austenite exists above the critical eutectoid temperature of ; other alloys of steel have different eutectoid temperatures...

transitions are responsible for the shape-memory effect.

There are numerous advantages that make SMPs more attractive than shape memory alloys. They have a high capacity for elastic deformation (up to 200% in most cases), much lower cost, lower density, a broad range of application temperatures which can be tailored, easy processing, and potential biocompatibility and biodegradability.

Industrial applications

One of the first conceived industrial applications was in robotics where shape-memory (SM) foams were used to provide initial soft pretension in gripping. These SM foams could be subsequently hardened by cooling making a shape adaptive grip. Since this time the materials have seen widespread usage in e.g. the building industry (foam which expands with warmth to seal window frames), sports wear (helmets, judo and karate suits) and in some cases with thermochromic additives for ease of thermal profile observation. Polyurethane SMPs are also applied as an autochoke element for engines.Medical applications

Most medical applications of SMP have yet to be developed, but devices with SMP are now beginning to hit the market. Recently, this technology has expanded to applications in orthopedic surgeryOrthopedic surgery

Orthopedic surgery or orthopedics is the branch of surgery concerned with conditions involving the musculoskeletal system...

.

Potential medical applications

SMPs are smart materialSmart material

Smart materials or designed materials are materials that have one or more properties that can be significantly changed in a controlled fashion by external stimuli, such as stress, temperature, moisture, pH, electric or magnetic fields....

s with potential applications as, e.g., intravenous cannula, self-adjusting orthodontic wires and selectively pliable tools for small scale surgical procedures where currently metal-based shape-memory alloys such as Nitinol are widely used. Another application of SMP in the medical field could be its use in implants: for example minimally invasive, trough small incisions or natural orifices, implantation of a device in its small temporary shape. Shape-memory technologies have shown great promise for cardiovascular stents, since they allow a small stent to be inserted along a vein or artery and then expanded to prop it open. After activating the shape memory by temperature increase or mechanical stress, it would assume its permanent shape. Certain classes of shape-memory polymers possess an additional property: biodegradability. This offers the option to develop temporary implants. In the case of biodegradable polymers, after the implant has fulfilled its intended use, e.g. healing/tissue regeneration has occurred, the material degrades into substances which can be eliminated by the body. Thus full functionality would be restored without the necessity for a second surgery to remove the implant (to avoid inflammation). Examples of this development are vascular stent

Stent

In the technical vocabulary of medicine, a stent is an artificial 'tube' inserted into a natural passage/conduit in the body to prevent, or counteract, a disease-induced, localized flow constriction. The term may also refer to a tube used to temporarily hold such a natural conduit open to allow...

s and surgical sutures. When used in surgical sutures, the shape-memory property of SMPs enables wound closure with self-adjusting optimal tension, which avoids tissue damage due to overtightened sutures and does support healing and regeneration.