Spinning jenny

Encyclopedia

The spinning jenny is a multi-spool

spinning frame

. It was invented c. 1764 by James Hargreaves

in Stanhill, Oswaldtwistle

, Lancashire

in England. The device reduced the amount of work needed to produce yarn

, with a worker able to work eight or more spools at once. This grew to 120 as technology advanced.

The Spinning Jenny is attributed to James Hargreaves

The Spinning Jenny is attributed to James Hargreaves

. He was born in Oswaldtwistle

, near Blackburn, around 1720. Blackburn, was a town with a population of about 5,000, known for the production of "Blackburn greys," cloths of linen warp and cotton weft. They were usually sent to London to be printed.

At the time cotton production could not keep up with demand, and Hargreaves spent some time considering how to improve the process. The flying shuttle

had increased yarn demand by the weavers by doubling their productivity, and now the spinning jenny could supply that demand by increasing the spinners' productivity even more. The machine produced coarse yarn.

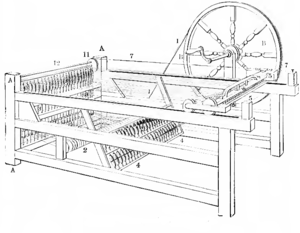

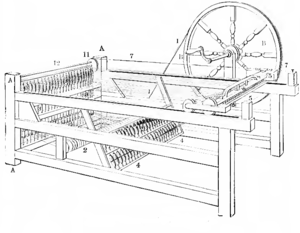

The idea was developed as a metal frame with eight wooden spindles at one end. A set of eight roving

The idea was developed as a metal frame with eight wooden spindles at one end. A set of eight roving

s was attached to a beam on that frame. The rovings when extended passed through two horizontal bars of wood that could be clasped together. These bars could be drawn along the top of the frame by the spinners left hand thus extending the thread. The spinner used his right hand to rapidly turn a wheel which caused all the spindles to revolve, and the thread to be spun. When the bars were returned, the thread wound onto the spindle. A pressing wire (faller) was used to guide the threads onto the right place on the spindle.

cloth. That industry, centred in the east and south in towns such as Norwich

, jealously protected their product. Cotton processing was tiny: in 1701 only 1985868 pounds (900,774.6 kg) of cotton-wool was imported into England, and by 1730 this had fallen to 1545472 pounds (701,014.3 kg). This was due to commercial legislation to protect the woollen industry. Cheap calico prints, imported by the East India Company

from "Hindustan

", had become popular. In 1700 an Act of Parliament was passed to prevent the importation of dyed or printed calicoes from India, China or Persia. This caused grey cloth (calico that hadn't been finished - dyed or printed) to be imported instead, and these were printed in Southern England with the popular patterns. Also, Lancashire businessmen produced grey cloth with linen warp and cotton weft, which they sent to London to be finished. Cotton-wool imports recovered and by 1720 were almost back to their 1701 levels. Again the woollen manufacturers, in true protectionist

style, claimed that this was taking away jobs from workers in [Coventry]]. Another law was passed, to fine anyone caught wearing any printed or stained calico; muslins, neckcloths and fustians were exempted. It was this exemption that the Lancashire Manufactures exploited.

The use of coloured cotton weft, with linen warp was permitted in the 1736 Manchester Act. There now was an artificial demand for woven cloth. In 1764, 3870392 pounds (1,755,580.3 kg) of cotton-wool was imported.

s, and before the turnpikes

. The only way to transport goods such as calicos, broadcloth or cotton-wool was by packhorse. Strings of packhorses travelled along a network of bridleways. A merchant would be away from home most of the year, carrying his takings in cash in his saddlebag. Later a series of chapmen

would work for the merchant, taking his wares to wholesalers and previous clients in other town, with them would go sample books.

Before 1720, the handloom weaver would spend part of each day visiting neighbours buying any weft they had. Carding and spinning could be the only income for that dwelling, or just part of it. The family might farm a few acres and card spin and weave wool and cotton. It took 3 carders to provide the roving for one spinner, and up to three spinners to provide the yarn for one weaver. The process was continuous, and done by both sexes, from the youngest to the oldest. The weaver would go, once a week to the market with his wares and offer them for sale.

A change came about 1740 when fustian masters would give out raw cotton and warps to the weavers and return to collect the finished cloth. The weaver would organise the carding, spinning and weaving to the masters specification. The master would now dye or print the grey cloth, and take it to the distant shopkeepers. Ten years later this had changed and the fustiamn masters were middle men, who collected the grey cloth and took it to the market in Manchester where it was sold onto the merchants who organised the finishing.

To handweave a 12 pounds (5.4 kg) piece of eighteenpenny weft took 14 days and paid 36 shillings in all. Of this nine shillings was paid for the spinning, and nine for the carding. So by 1750, we see a rudimentary manufacturing system feeding into a marketing system.

And it was in 1738 that John Kay

started to introduce improvements to the loom. He improved the reed, and then invented the raceboard, the shuttleboxes and the picker which together allowed one weaver to double his throughput. This is commonly called the fly-shuttle. It met with violent opposition and he fled from Lancashire to Leeds. Though the workers thought this was a threat to their jobs, it was adopted and the pressure was on to speed up carding and spinning.

The shortage of spinning capacity to feed the new and more efficient looms provided the motivation to develop more productive spinning techniques such as the spinning jenny, and triggered the start of the Industrial Revolution

.

in 1768. This was a centre for the hosiery industry, and knitted silks, cottons and wool. There he set up shop producing jennies in secret for one Mr. Shipley, with the assistance of a joiner

named Thomas James. He and Thomas James set up a textile business in Mill Street. On 12 July 1770, he took out a patent (no. 962) on his invention, the Spinning Jenny—a machine for spinning drawing and twisting cotton. By this time a number of spinners in Lancashire were already using copies of the machine, and Hargreaves sent notice that he was taking legal action against them. The manufacturers met, and offered Hargreaves £3000. He at first demanded £7000, and at last stood out for £4000, but the case eventually fell apart when it was learned he had already sold several in the past.

The spinning jenny succeeded because it held more than one ball of yarn, therefore making more yarn in a shorter amount of time while reducing the overall cost. The spinning jenny wouldn't have been such a success if the flying shuttle

hadn't been there with it in the textile factories. Its success was limited in that it still required the rovings to be prepared on a wheel, and even this was limited by the need to card by hand. It continued in common use in the cotton and fustian industry until about 1810. The spinning jenny was superseded by the spinning mule

. The jenny was adapted for the process of slubbing, being the basis of the Slubbing Billy.

The name is variously said to derive from this tale. The Registers of Church Kirk show that Hargreaves had several daughters, but none named Jenny (neither was his wife). A more likely explanation of the name is that 'Jenny' was an abbreviation of 'engine'.

Thomas Highs

of Leigh has also claimed to be the inventor and the story is repeated using his wife's name.

Thomas Earnshaw invented a spinning device of a similar description - but destroyed it fearing he might be taking bread out of the mouths of the poor.

Spool

Spool can mean one of the following:*Spool, a usually low-flanged or unflanged cylinder on which thread, wire, cable, paper, film, or tape is wound for distribution or use....

spinning frame

Spinning wheel

A spinning wheel is a device for spinning thread or yarn from natural or synthetic fibers. Spinning wheels appeared in Asia, probably in the 11th century, and very gradually replaced hand spinning with spindle and distaff...

. It was invented c. 1764 by James Hargreaves

James Hargreaves

James Hargreaves was a weaver, carpenter and an inventor in Lancashire, England. He is credited with inventing the spinning Jenny in 1764....

in Stanhill, Oswaldtwistle

Oswaldtwistle

Oswaldtwistle is a town within the Hyndburn borough of Lancashire, England. It lies on the course of the Leeds and Liverpool Canal, east-southeast of Blackburn and is contiguous to Accrington.-History:...

, Lancashire

Lancashire

Lancashire is a non-metropolitan county of historic origin in the North West of England. It takes its name from the city of Lancaster, and is sometimes known as the County of Lancaster. Although Lancaster is still considered to be the county town, Lancashire County Council is based in Preston...

in England. The device reduced the amount of work needed to produce yarn

Yarn

Yarn is a long continuous length of interlocked fibres, suitable for use in the production of textiles, sewing, crocheting, knitting, weaving, embroidery and ropemaking. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or...

, with a worker able to work eight or more spools at once. This grew to 120 as technology advanced.

History

James Hargreaves

James Hargreaves was a weaver, carpenter and an inventor in Lancashire, England. He is credited with inventing the spinning Jenny in 1764....

. He was born in Oswaldtwistle

Oswaldtwistle

Oswaldtwistle is a town within the Hyndburn borough of Lancashire, England. It lies on the course of the Leeds and Liverpool Canal, east-southeast of Blackburn and is contiguous to Accrington.-History:...

, near Blackburn, around 1720. Blackburn, was a town with a population of about 5,000, known for the production of "Blackburn greys," cloths of linen warp and cotton weft. They were usually sent to London to be printed.

At the time cotton production could not keep up with demand, and Hargreaves spent some time considering how to improve the process. The flying shuttle

Flying shuttle

The flying shuttle was one of the key developments in weaving that helped fuel the Industrial Revolution. It was patented by John Kay in 1733. Only one weaver was needed to control its lever-driven motion. Before the shuttle, a single weaver could not weave a fabric wider than arms length. Beyond...

had increased yarn demand by the weavers by doubling their productivity, and now the spinning jenny could supply that demand by increasing the spinners' productivity even more. The machine produced coarse yarn.

Components

Roving

A roving is a long and narrow bundle of fibre. It is usually used to spin woollen yarn. A roving can be created by carding the fibre, and it is then drawn into long strips. Because it is carded, the fibres are not parallel, though drawing it into strips may line the fibres up a bit...

s was attached to a beam on that frame. The rovings when extended passed through two horizontal bars of wood that could be clasped together. These bars could be drawn along the top of the frame by the spinners left hand thus extending the thread. The spinner used his right hand to rapidly turn a wheel which caused all the spindles to revolve, and the thread to be spun. When the bars were returned, the thread wound onto the spindle. A pressing wire (faller) was used to guide the threads onto the right place on the spindle.

The politics of cotton

In the seventeenth century, England was famous for its woollen and worstedWorsted

Worsted , is the name of a yarn, the cloth made from this yarn, and a yarn weight category. The name derives from the village of Worstead in the English county of Norfolk...

cloth. That industry, centred in the east and south in towns such as Norwich

Norwich

Norwich is a city in England. It is the regional administrative centre and county town of Norfolk. During the 11th century, Norwich was the largest city in England after London, and one of the most important places in the kingdom...

, jealously protected their product. Cotton processing was tiny: in 1701 only 1985868 pounds (900,774.6 kg) of cotton-wool was imported into England, and by 1730 this had fallen to 1545472 pounds (701,014.3 kg). This was due to commercial legislation to protect the woollen industry. Cheap calico prints, imported by the East India Company

East India Company

The East India Company was an early English joint-stock company that was formed initially for pursuing trade with the East Indies, but that ended up trading mainly with the Indian subcontinent and China...

from "Hindustan

Hindustan

Hindustan or Indostan, literal translation "Land of River Sindhu ", is one of the popular names of South Asia. It can also mean "the land of the Hindus"...

", had become popular. In 1700 an Act of Parliament was passed to prevent the importation of dyed or printed calicoes from India, China or Persia. This caused grey cloth (calico that hadn't been finished - dyed or printed) to be imported instead, and these were printed in Southern England with the popular patterns. Also, Lancashire businessmen produced grey cloth with linen warp and cotton weft, which they sent to London to be finished. Cotton-wool imports recovered and by 1720 were almost back to their 1701 levels. Again the woollen manufacturers, in true protectionist

Protectionism

Protectionism is the economic policy of restraining trade between states through methods such as tariffs on imported goods, restrictive quotas, and a variety of other government regulations designed to allow "fair competition" between imports and goods and services produced domestically.This...

style, claimed that this was taking away jobs from workers in [Coventry]]. Another law was passed, to fine anyone caught wearing any printed or stained calico; muslins, neckcloths and fustians were exempted. It was this exemption that the Lancashire Manufactures exploited.

The use of coloured cotton weft, with linen warp was permitted in the 1736 Manchester Act. There now was an artificial demand for woven cloth. In 1764, 3870392 pounds (1,755,580.3 kg) of cotton-wool was imported.

The economics of Northern England in 1750

This was the England before the canalCanal

Canals are man-made channels for water. There are two types of canal:#Waterways: navigable transportation canals used for carrying ships and boats shipping goods and conveying people, further subdivided into two kinds:...

s, and before the turnpikes

Turnpike trust

Turnpike trusts in the United Kingdom were bodies set up by individual Acts of Parliament, with powers to collect road tolls for maintaining the principal highways in Britain from the 17th but especially during the 18th and 19th centuries...

. The only way to transport goods such as calicos, broadcloth or cotton-wool was by packhorse. Strings of packhorses travelled along a network of bridleways. A merchant would be away from home most of the year, carrying his takings in cash in his saddlebag. Later a series of chapmen

Chapmen

A chapman was an itinerant dealer or hawker in early modern Britain.-Etymology:Old English céapmann was the regular term for "dealer, seller", cognate to the synonymous Dutch koopman....

would work for the merchant, taking his wares to wholesalers and previous clients in other town, with them would go sample books.

Before 1720, the handloom weaver would spend part of each day visiting neighbours buying any weft they had. Carding and spinning could be the only income for that dwelling, or just part of it. The family might farm a few acres and card spin and weave wool and cotton. It took 3 carders to provide the roving for one spinner, and up to three spinners to provide the yarn for one weaver. The process was continuous, and done by both sexes, from the youngest to the oldest. The weaver would go, once a week to the market with his wares and offer them for sale.

A change came about 1740 when fustian masters would give out raw cotton and warps to the weavers and return to collect the finished cloth. The weaver would organise the carding, spinning and weaving to the masters specification. The master would now dye or print the grey cloth, and take it to the distant shopkeepers. Ten years later this had changed and the fustiamn masters were middle men, who collected the grey cloth and took it to the market in Manchester where it was sold onto the merchants who organised the finishing.

To handweave a 12 pounds (5.4 kg) piece of eighteenpenny weft took 14 days and paid 36 shillings in all. Of this nine shillings was paid for the spinning, and nine for the carding. So by 1750, we see a rudimentary manufacturing system feeding into a marketing system.

And it was in 1738 that John Kay

John Kay

John Kay may refer to:*John Kay , English inventor of textile machinery, notably the flying shuttle*John Kay , English developer of textile machinery, notably the spinning frame *John Kay , Scottish caricaturist*Sir John Kay...

started to introduce improvements to the loom. He improved the reed, and then invented the raceboard, the shuttleboxes and the picker which together allowed one weaver to double his throughput. This is commonly called the fly-shuttle. It met with violent opposition and he fled from Lancashire to Leeds. Though the workers thought this was a threat to their jobs, it was adopted and the pressure was on to speed up carding and spinning.

The shortage of spinning capacity to feed the new and more efficient looms provided the motivation to develop more productive spinning techniques such as the spinning jenny, and triggered the start of the Industrial Revolution

Industrial Revolution

The Industrial Revolution was a period from the 18th to the 19th century where major changes in agriculture, manufacturing, mining, transportation, and technology had a profound effect on the social, economic and cultural conditions of the times...

.

Success

Hargreaves kept the machine secret for some time, but he produced a number for his own growing industry. The price of yarn fell, angering the large spinning community in Blackburn. Eventually they broke into his house and smashed his machines, forcing him to flee to NottinghamNottingham

Nottingham is a city and unitary authority in the East Midlands of England. It is located in the ceremonial county of Nottinghamshire and represents one of eight members of the English Core Cities Group...

in 1768. This was a centre for the hosiery industry, and knitted silks, cottons and wool. There he set up shop producing jennies in secret for one Mr. Shipley, with the assistance of a joiner

Joiner

A joiner differs from a carpenter in that joiners cut and fit joints in wood that do not use nails. Joiners usually work in a workshop since the formation of various joints generally requires non-portable machinery. A carpenter normally works on site...

named Thomas James. He and Thomas James set up a textile business in Mill Street. On 12 July 1770, he took out a patent (no. 962) on his invention, the Spinning Jenny—a machine for spinning drawing and twisting cotton. By this time a number of spinners in Lancashire were already using copies of the machine, and Hargreaves sent notice that he was taking legal action against them. The manufacturers met, and offered Hargreaves £3000. He at first demanded £7000, and at last stood out for £4000, but the case eventually fell apart when it was learned he had already sold several in the past.

The spinning jenny succeeded because it held more than one ball of yarn, therefore making more yarn in a shorter amount of time while reducing the overall cost. The spinning jenny wouldn't have been such a success if the flying shuttle

Flying shuttle

The flying shuttle was one of the key developments in weaving that helped fuel the Industrial Revolution. It was patented by John Kay in 1733. Only one weaver was needed to control its lever-driven motion. Before the shuttle, a single weaver could not weave a fabric wider than arms length. Beyond...

hadn't been there with it in the textile factories. Its success was limited in that it still required the rovings to be prepared on a wheel, and even this was limited by the need to card by hand. It continued in common use in the cotton and fustian industry until about 1810. The spinning jenny was superseded by the spinning mule

Spinning mule

The spinning mule was a machine used to spin cotton and other fibres in the mills of Lancashire and elsewhere from the late eighteenth to the early twentieth century. Mules were worked in pairs by a minder, with the help of two boys: the little piecer and the big or side piecer...

. The jenny was adapted for the process of slubbing, being the basis of the Slubbing Billy.

Origin and myth

The most common story told about the invention of the device and the origin of the Jenny in the machine's name is that a daughter (or his wife) named Jenny knocked over one of their own spinning wheels. The device kept working as normal, with the spindle now pointed upright. Hargreaves realized there was no particular reason the spindles had to be horizontal, as they always had been, and he could place them vertically in a row.The name is variously said to derive from this tale. The Registers of Church Kirk show that Hargreaves had several daughters, but none named Jenny (neither was his wife). A more likely explanation of the name is that 'Jenny' was an abbreviation of 'engine'.

Thomas Highs

Thomas Highs

Thomas Highs , of Leigh, Lancashire, was a reed-maker and manufacturer of cotton carding and spinning engines in the 1780s, during the Industrial Revolution...

of Leigh has also claimed to be the inventor and the story is repeated using his wife's name.

Thomas Earnshaw invented a spinning device of a similar description - but destroyed it fearing he might be taking bread out of the mouths of the poor.

See also

- LudditeLudditeThe Luddites were a social movement of 19th-century English textile artisans who protested – often by destroying mechanised looms – against the changes produced by the Industrial Revolution, which they felt were leaving them without work and changing their way of life...

- Cotton millCotton millA cotton mill is a factory that houses spinning and weaving machinery. Typically built between 1775 and 1930, mills spun cotton which was an important product during the Industrial Revolution....

- Spinning MuleSpinning muleThe spinning mule was a machine used to spin cotton and other fibres in the mills of Lancashire and elsewhere from the late eighteenth to the early twentieth century. Mules were worked in pairs by a minder, with the help of two boys: the little piecer and the big or side piecer...

- Textile manufacturingTextile manufacturingTextile manufacturing is a major industry. It is based in the conversion of three types of fibre into yarn, then fabric, then textiles. These are then fabricated into clothes or other artifacts. Cotton remains the most important natural fibre, so is treated in depth...

- Timeline of clothing and textiles technologyTimeline of clothing and textiles technologyTimeline of clothing and textiles technology.*Prehistory – spindle used to create yarn from fibres.* – loom.*c. 28000 BC – Sewing needles in use at Kostenki in Russia....

- Textile manufacture during the Industrial RevolutionTextile manufacture during the Industrial RevolutionThe industrial revolution changed the nature of work and society. Opinion varies as to the exact date, but it is estimated that the First Industrial Revolution took place between 1750 and 1850, and the second phase or Second Industrial Revolution between 1860 and 1900. The three key drivers in...

External links

- Essay from http://www.cottontown.org on Hargreaves and the spinning jenny.

- Essay from http://www.cottonttimes.co.uk on Highs and the spinning jenny.

- Source for alternate name of spinning ginny

- Spinning Jenny Summary