Wool classing

Encyclopedia

Wool

Wool is the textile fiber obtained from sheep and certain other animals, including cashmere from goats, mohair from goats, qiviut from muskoxen, vicuña, alpaca, camel from animals in the camel family, and angora from rabbits....

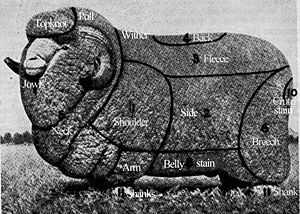

. This is carried out by examining the characteristics of the wool in its raw state. The characteristics which a wool classer would examine are:

Breed of the sheep: Shedding breeds will increase the risk of medulated and/or pigmented fibres. Any sheep likely to have dark fibres should be shorn last to avoid contamination. The age of the sheep will have a bearing on the fibre diameter and value of wool, too.

Chemical usage: Ensure that all rules have been followed.

Brands, seedy jowls and shanks: Must be removed from fleeces and broken.

Stain: Must be removed from bellies and fleeces and identified in a separate line.

Wool crimp: The number of bends per unit length along the wool fibre approximately indicates spinning capacity of the wool. fibre

Fiber

Fiber is a class of materials that are continuous filaments or are in discrete elongated pieces, similar to lengths of thread.They are very important in the biology of both plants and animals, for holding tissues together....

s with a fine crimp

Crimp

Crimp may refer to:*Crimp , a small hold with little surface area*Crimp , a bent corner of a card to facilitate cheating*Crimp , a deformity in metal used to make a join...

have many bends and usually have a small diameter. Such fibre can be spun into fine yarn

Yarn

Yarn is a long continuous length of interlocked fibres, suitable for use in the production of textiles, sewing, crocheting, knitting, weaving, embroidery and ropemaking. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or...

s, with great lengths of yarn for a given weight of wool, and greater market value. Fine fibres may be utilised in the production of fine garments such as men's suit

Suit (clothing)

In clothing, a suit is a set of garments made from the same cloth, consisting of at least a jacket and trousers. Lounge suits are the most common style of Western suit, originating in the United Kingdom as country wear...

s whereas the coarser fibres may be used for the production of carpet

Carpet

A carpet is a textile floor covering consisting of an upper layer of "pile" attached to a backing. The pile is generally either made from wool or a manmade fibre such as polypropylene,nylon or polyester and usually consists of twisted tufts which are often heat-treated to maintain their...

and other sturdy products. Crimp is measured in crimps per inch or crimps per centimetre. Average diameter or mean fibre diameter is measured in micrometres (microns). For generations, English wool-handlers categorized wool along the above lines estimating spinning capacity by eye and touch. This spread worldwide as the Bradford system

Bradford system

The Bradford system is a way to assess the quality of wool....

.

Wool Strength (also known as tensile strength

Tensile strength

Ultimate tensile strength , often shortened to tensile strength or ultimate strength, is the maximum stress that a material can withstand while being stretched or pulled before necking, which is when the specimen's cross-section starts to significantly contract...

) determines wool's ability to withstand processing. Weaker wools produce more waste in carding and spinning. Weaker wools may be used for production of felt

Felt

Felt is a non-woven cloth that is produced by matting, condensing and pressing woollen fibres. While some types of felt are very soft, some are tough enough to form construction materials. Felt can be of any colour, and made into any shape or size....

, or combined with other fibres, etc.

Wool colour

Color

Color or colour is the visual perceptual property corresponding in humans to the categories called red, green, blue and others. Color derives from the spectrum of light interacting in the eye with the spectral sensitivities of the light receptors...

: Indicates whether wool is able to be dye

Dye

A dye is a colored substance that has an affinity to the substrate to which it is being applied. The dye is generally applied in an aqueous solution, and requires a mordant to improve the fastness of the dye on the fiber....

d in light shades. Colour may be graded depending upon the natural colour, impurities and various stains present. Severely stained wool decreases prices dramatically. However, it is difficult to assess colour accurately without proper measurement, since some stains will wash out in the processing, whereas others are quite persistent.

The fleece

Wool

Wool is the textile fiber obtained from sheep and certain other animals, including cashmere from goats, mohair from goats, qiviut from muskoxen, vicuña, alpaca, camel from animals in the camel family, and angora from rabbits....

is skirted to remove excess frib, seed and burr etc. to leave the fleece as reasonably even as possible in good respects. The parts of wool taken from a sheep are graded separately. The fleece

Wool

Wool is the textile fiber obtained from sheep and certain other animals, including cashmere from goats, mohair from goats, qiviut from muskoxen, vicuña, alpaca, camel from animals in the camel family, and angora from rabbits....

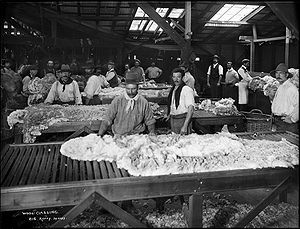

forming the bulk of the yield is placed with other fleece wool as the main line, other pieces such as the neck, belly and skirtings (inferior wool from edges) are sold for such purposes where the shorter wools are required (for example: fillings, carpets, insulation). Whilst in some places crimp may determine which grade the fleece will be placed into, this subjective assessment is not always reliable and processors prefer that wools are measured objectively by qualified laboratories. Some of the superfine wool growers do in shed wool testing, but this can only be used as a guide. This enables wool classers to place wool into lines of a consistent quality. A shedhand, known as a wool presser, places the wool into approved wool packs in a wool press to produce a bale of wool that must meet regulations concerning its fastenings, length, weight and branding if it is to be sold at auction in Australasia

Australasia

Australasia is a region of Oceania comprising Australia, New Zealand, the island of New Guinea, and neighbouring islands in the Pacific Ocean. The term was coined by Charles de Brosses in Histoire des navigations aux terres australes...

. All Merino fleece wool sold at auction in Australia is objectively measured for fibre diameter, yield (including the amount of vegetable matter), staple length, staple strength and sometimes colour.

Classers are also responsible for ensuring that a pre-shearing check is made to ensure that the wool and sheep areas are free of possible contaminants. They are to supervise shed staff during shearing and train any inexperienced hands. At the end of shearing classers have to provide full documentation concerning the clip.