Battery holder

Encyclopedia

Battery (electricity)

An electrical battery is one or more electrochemical cells that convert stored chemical energy into electrical energy. Since the invention of the first battery in 1800 by Alessandro Volta and especially since the technically improved Daniell cell in 1836, batteries have become a common power...

. For dry cells, the holder must also make electrical contact with the battery terminals. For wet cells, cables are often connected to the battery terminals

Battery terminals

Battery terminals are the electrical contacts used to connect a load and/or charger to a single cell or multiple-cell battery. These terminals have a wide variety of designs, sizes, and features that are often not well documented....

, as is found in automobiles or emergency lighting equipment.

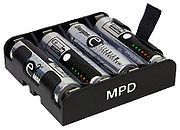

A battery holder is either a plastic case with the shape of the housing molded as a compartment or compartments that accepts a battery or batteries, or a separate plastic holder that is mounted with screws, eyelets, glue, double-sided tape, or other means. Battery holders may have a lid to retain and protect the batteries, or may be sealed to prevent damage to circuitry and components from battery leakage. Coiled spring wire or flat tabs that press against the battery terminals are the two most common methods of making the electrical connection inside a holder. External connections on battery holders are usually made by contacts with pins, surface mount feet, solder lugs, or wire leads.

Where the battery is expected to last over the life of the product, no holder is necessary, and a tab welded to the battery terminals can be directly soldered to a printed circuit board.

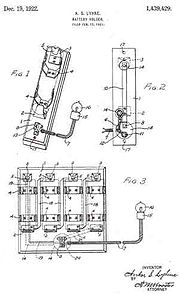

History

Flashlight

A flashlight is a hand-held electric-powered light source. Usually the light source is a small incandescent lightbulb or light-emitting diode...

s; patent no. 617592 dated March 1898 is for an early metal flashlight that accepted D batteries.

D battery

A D battery is a size of dry cell. A D cell is cylindrical with electrical contacts at each end; the positive end having a nub or bump...

The introduction of polypropylene

Polypropylene

Polypropylene , also known as polypropene, is a thermoplastic polymer used in a wide variety of applications including packaging, textiles , stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes...

in the 1950s and miniature batteries by Eveready

Energizer Holdings

Energizer Holdings is an American manufacturer of batteries and personal care products, headquartered in Town and Country, Missouri. Its most well known brands are Energizer and Eveready batteries, Schick, Wilkinson Sword and Edge shaving products, Playtex feminine hygiene and baby products, and...

allowed for the use of small plastic battery holders. These are still common in toys, decorations, and lighted or blinking items. In 1957, electric wrist watch

Watch

A watch is a small timepiece, typically worn either on the wrist or attached on a chain and carried in a pocket, with wristwatches being the most common type of watch used today. They evolved in the 17th century from spring powered clocks, which appeared in the 15th century. The first watches were...

es gained popularity with the public.

Battery holders developed in parallel with batteries over time; as battery package sizes shrunk so did the holders. In the 1980s, the first circuit board mounting lithium coin cell battery holders appeared in the form of patent no. 4487820 by the battery holder manufacturer MPD.

The electronics industry now uses many surface mounted lithium

Lithium

Lithium is a soft, silver-white metal that belongs to the alkali metal group of chemical elements. It is represented by the symbol Li, and it has the atomic number 3. Under standard conditions it is the lightest metal and the least dense solid element. Like all alkali metals, lithium is highly...

battery holders or sockets. CR2/3A, CR1/2AA and CR123A batteries

Lithium battery

Lithium batteries are disposable batteries that have lithium metal or lithium compounds as an anode. Depending on the design and chemical compounds used, lithium cells can produce voltages from 1.5 V to about 3.7 V, over twice the voltage of an ordinary zinc–carbon battery or alkaline battery...

began in camera applications, but expanded into new markets like alarm systems, hand held computers, and keyfobs.

Design considerations

Product design

-Introduction:Product design is the process of creating a new product to be sold by a business or enterprise to its customers. It is concerned with the efficient and effective generation and development of ideas through a process that leads to new products.Product designers conceptualize and...

. A designer must select between a battery holder molded into the product case or made as a separate part. For many products regulations and product safety standards affect the battery holder selection.

Most current battery holders are made with polypropylene

Polypropylene

Polypropylene , also known as polypropene, is a thermoplastic polymer used in a wide variety of applications including packaging, textiles , stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes...

or nylon

Nylon

Nylon is a generic designation for a family of synthetic polymers known generically as polyamides, first produced on February 28, 1935, by Wallace Carothers at DuPont's research facility at the DuPont Experimental Station...

bodies rated for 80-100°C. Lithium coin cell holders are made with high temperature PBT, nylon or LCP bodies because they normally are circuit board mounted and require wave soldering

Wave soldering

Wave soldering is a large-scale soldering process by which electronic components are soldered to a printed circuit board to form an electronic assembly. The name is derived from the use of waves of molten solder to attach metal components to the PCB...

at 180-240°C or reflow soldering

Reflow soldering

Reflow soldering is a process in which a solder paste is used to temporarily attach one or several electrical components to their contact pads, after which the entire assembly is subjected to controlled heat, which melts the solder, permanently connecting the joint...

at 260-300°C.

Battery contacts

Contact resistance

The term contact resistance refers to the contribution to the total resistance of a material which comes from the electrical leads and connections as opposed to the intrinsic resistance, which is an inherent property, independent of the measurement method...

are the most important part of the design and require serious consideration. Since batteries are nickel plated, it is recommended the contacts be nickel plated

Electroless nickel plating

Electroless nickel plating is an auto-catalytic chemical technique used to deposit a layer of nickel-phosphorus or nickel-boron alloy on a solid workpiece, such as metal or plastic. The process relies on the presence of a reducing agent, for example hydrated sodium hypophosphite which reacts with...

to prevent galvanic corrosion between dissimilar metals. Battery contacts may be fixed contacts, flexible contacts, or some combination of the two.

Fixed contacts are inexpensive but prone to loss of electrical connection. Combination of fixed and flexible contacts are a better solution, but this is subject to an open circuit upon movement in the direction away from the fixed position; the spring contact compresses and allows the battery to move away from the fixed contact. A flexible contact allows for slight expansion of the cell on discharge, as internal chemicals increase in volume. Flexible contacts with multiple fingers touching the anode

Anode

An anode is an electrode through which electric current flows into a polarized electrical device. Mnemonic: ACID ....

and cathode

Cathode

A cathode is an electrode through which electric current flows out of a polarized electrical device. Mnemonic: CCD .Cathode polarity is not always negative...

allow for movement in multiple directions without losing electrical connection.

Features like polarity, or reverse battery, protection can be part of the design. The contact for the anode side can be recessed behind plastic and receive a battery nub common on Alkaline batteries. Another method is a plastic channel to receive a battery post or terminal. In July 2010, Microsoft

Microsoft

Microsoft Corporation is an American public multinational corporation headquartered in Redmond, Washington, USA that develops, manufactures, licenses, and supports a wide range of products and services predominantly related to computing through its various product divisions...

announced its plans to partner with several other companies, including Duracell and MPD, to utilize its patent no. 2007/0275299 A1, which is a new kind of polarity protection in which a battery can be inserted into a battery holder in either orientation and still operate properly. Although other technologies have existed which could do this, they were expensive or caused a passive energy drain on the battery, whereas this solution is purely mechanical and affordable to produce.

Battery types such as the 9-volt have snap-on contacts.

Battery holders for zinc-air batteries

Zinc-air battery

Zinc–air batteries , and zinc–air fuel cells, are electro-chemical batteries powered by oxidizing zinc with oxygen from the air. These batteries have high energy densities and are relatively inexpensive to produce...

must not be completely air-tight since approximately 1 litre of air is required per ampere-hour of discharge per cell. The battery holder may include a valve integrated with the device power switch to allow air to be admitted when the device is switched on.

Environmental effects

There is a lot of uncertainty as to the effects of battery holders and batteries on the environment. The debate is evolving alongside developments in environmental awareness, such as concerns over global warmingGlobal warming

Global warming refers to the rising average temperature of Earth's atmosphere and oceans and its projected continuation. In the last 100 years, Earth's average surface temperature increased by about with about two thirds of the increase occurring over just the last three decades...

and e-waste. There are concerns that devices, such as cell phones and iPods, are heavily contributing to this through their use of soldered in batteries, which could be made removable and therefore replaceable. This could improve the life of each unit while reducing the amount of e-waste generated.

See also

- Alkaline batteryAlkaline batteryAlkaline batteries are a type of primary batteries dependent upon the reaction between zinc and manganese dioxide . A rechargeable alkaline battery allows reuse of specially designed cells....

- Lithium batteryLithium batteryLithium batteries are disposable batteries that have lithium metal or lithium compounds as an anode. Depending on the design and chemical compounds used, lithium cells can produce voltages from 1.5 V to about 3.7 V, over twice the voltage of an ordinary zinc–carbon battery or alkaline battery...

- Alkaline

- LithiumLithiumLithium is a soft, silver-white metal that belongs to the alkali metal group of chemical elements. It is represented by the symbol Li, and it has the atomic number 3. Under standard conditions it is the lightest metal and the least dense solid element. Like all alkali metals, lithium is highly...

- list of battery sizes

- Battery nomenclatureBattery nomenclatureStandard battery nomenclature describes portable dry cell batteries that are interchangeable in physical dimensions and electrical characteristics between manufacturers. The long history of disposable dry cells means that many different manufacturer-specific and national standards were used to...

- Battery terminalsBattery terminalsBattery terminals are the electrical contacts used to connect a load and/or charger to a single cell or multiple-cell battery. These terminals have a wide variety of designs, sizes, and features that are often not well documented....

, an alternative method of connecting batteries