Cavitation

Encyclopedia

Pressure

Pressure is the force per unit area applied in a direction perpendicular to the surface of an object. Gauge pressure is the pressure relative to the local atmospheric or ambient pressure.- Definition :...

that cause the formation of cavities where the pressure is relatively low.

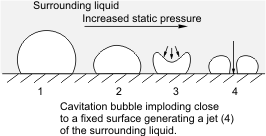

Cavitation is a significant cause of wear in some engineering contexts. When entering high pressure areas, cavitation bubbles that implode on a metal surface cause cyclic stress

Cyclic stress

Cyclic stress in engineering refers to an internal distribution of forces that changes over time in a repetitive fashion. As an example, consider one of the large wheels used to drive an aerial lift such as a ski lift. The wire cable wrapped around the wheel exerts a downward force on the wheel...

. This results in surface fatigue of the metal causing a type of wear also called "cavitation". The most common examples of this kind of wear are pump impellers and bends when a sudden change in the direction of liquid occurs. Cavitation is usually divided into two classes of behaviour: inertial (or transient) cavitation and non-inertial cavitation.

Inertial cavitation is the process where a void or bubble in a liquid rapidly collapses, producing a shock wave

Shock wave

A shock wave is a type of propagating disturbance. Like an ordinary wave, it carries energy and can propagate through a medium or in some cases in the absence of a material medium, through a field such as the electromagnetic field...

. Inertial cavitation occurs in nature in the strikes of mantis shrimp

Mantis shrimp

Mantis shrimp or stomatopods are marine crustaceans, the members of the order Stomatopoda. They are neither shrimp nor mantids, but receive their name purely from the physical resemblance to both the terrestrial praying mantis and the shrimp. They may reach in length, although exceptional cases of...

s and pistol shrimps, as well as in the vascular tissues of plants. In man-made objects, it can occur in control valves

Control valves

Control valves are valves used to control conditions such as flow, pressure, temperature, and liquid level by fully or partially opening or closing in response to signals received from controllers that compare a "setpoint" to a "process variable" whose value is provided by sensors that monitor...

, pumps, propellers and impeller

Impeller

An impeller is a rotor inside a tube or conduit used to increase the pressure and flow of a fluid.- Impellers in pumps :...

s.

Non inertial cavitation is the process in which a bubble in a fluid is forced to oscillate in size or shape due to some form of energy input, such as an acoustic field

Sound

Sound is a mechanical wave that is an oscillation of pressure transmitted through a solid, liquid, or gas, composed of frequencies within the range of hearing and of a level sufficiently strong to be heard, or the sensation stimulated in organs of hearing by such vibrations.-Propagation of...

. Such cavitation is often employed in ultrasonic cleaning

Ultrasonic cleaning

thumb|300px|Ultrasonic cleaner showing the removable basket in place, and a closeup of the light and timerAn ultrasonic cleaner is a cleaning device that uses ultrasound and an appropriate cleaning solvent to clean delicate items...

baths and can also be observed in pumps, propellers, etc.

Since the shock waves formed by cavitation are strong enough to significantly damage moving parts, cavitation is usually an undesirable phenomenon. It is specifically avoided in the design of machines such as turbines or propellers, and eliminating cavitation is a major field in the study of fluid dynamics

Fluid dynamics

In physics, fluid dynamics is a sub-discipline of fluid mechanics that deals with fluid flow—the natural science of fluids in motion. It has several subdisciplines itself, including aerodynamics and hydrodynamics...

.

Inertial cavitation

Inertial cavitation was first studied by Lord Rayleigh in the late 19th century, when he considered the collapse of a spherical void within a liquid. When a volume of liquid is subjected to a sufficiently low pressurePressure

Pressure is the force per unit area applied in a direction perpendicular to the surface of an object. Gauge pressure is the pressure relative to the local atmospheric or ambient pressure.- Definition :...

, it may rupture and form a cavity. This phenomenon is termed cavitation inception and may occur behind the blade of a rapidly rotating propeller or on any surface vibrating in the liquid with sufficient amplitude and acceleration. A fast-flowing river can cause cavitation on rock surfaces, particularly when there is a drop-off, such as on a waterfall.

Other ways of generating cavitation voids involve the local deposition of energy, such as an intense focused laser pulse (optic cavitation) or with an electrical discharge through a spark. Vapor gases evaporate into the cavity from the surrounding medium; thus, the cavity is not a perfect vacuum, but has a relatively low gas pressure. Such a low-pressure cavitation bubble in a liquid begins to collapse due to the higher pressure of the surrounding medium. As the bubble collapses, the pressure and temperature of the vapor within increases. The bubble eventually collapses to a minute fraction of its original size, at which point the gas within dissipates into the surrounding liquid via a rather violent mechanism, which releases a significant amount of energy in the form of an acoustic shock wave and as visible light. At the point of total collapse, the temperature of the vapor within the bubble may be several thousand kelvin

Kelvin

The kelvin is a unit of measurement for temperature. It is one of the seven base units in the International System of Units and is assigned the unit symbol K. The Kelvin scale is an absolute, thermodynamic temperature scale using as its null point absolute zero, the temperature at which all...

, and the pressure several hundred atmospheres.

Inertial cavitation can also occur in the presence of an acoustic field. Microscopic gas bubbles that are generally present in a liquid will be forced to oscillate due to an applied acoustic field. If the acoustic intensity is sufficiently high, the bubbles will first grow in size and then rapidly collapse. Hence, inertial cavitation can occur even if the rarefaction

Rarefaction

Rarefaction is the reduction of a medium's density, or the opposite of compression.A natural example of this is as a phase in a sound wave or phonon. Half of a sound wave is made up of the compression of the medium, and the other half is the decompression or rarefaction of the medium.Another...

in the liquid is insufficient for a Rayleigh

Rayleigh

Rayleigh may refer to:*Rayleigh scattering*Rayleigh–Jeans law*Rayleigh waves*Rayleigh , named after the son of Lord Rayleigh*Rayleigh criterion in angular resolution*Rayleigh distribution*Rayleigh fading...

-like void to occur. High-power ultrasonics

Ultrasonics

Ultrasonics is a term meaning the application of ultrasound. It is often used in industry as a shorthand term for any equipment employing ultrasonic principles....

usually utilize the inertial cavitation of microscopic vacuum bubbles for treatment of surfaces, liquids, and slurries.

The physical process of cavitation inception is similar to boiling

Boiling

Boiling is the rapid vaporization of a liquid, which occurs when a liquid is heated to its boiling point, the temperature at which the vapor pressure of the liquid is equal to the pressure exerted on the liquid by the surrounding environmental pressure. While below the boiling point a liquid...

. The major difference between the two is the thermodynamic paths that precede the formation of the vapor. Boiling occurs when the local vapor pressure

Vapor pressure

Vapor pressure or equilibrium vapor pressure is the pressure of a vapor in thermodynamic equilibrium with its condensed phases in a closed system. All liquids have a tendency to evaporate, and some solids can sublimate into a gaseous form...

of the liquid rises above its local ambient pressure and sufficient energy is present to cause the phase change to a gas. Cavitation inception occurs when the local pressure falls sufficiently far below the saturated vapor pressure, a value given by the tensile strength of the liquid at a certain temperature.

In order for cavitation inception to occur, the cavitation "bubbles" generally need a surface on which they can nucleate

Nucleation

Nucleation is the extremely localized budding of a distinct thermodynamic phase. Some examples of phases that may form by way of nucleation in liquids are gaseous bubbles, crystals or glassy regions. Creation of liquid droplets in saturated vapor is also characterized by nucleation...

. This surface can be provided by the sides of a container, by impurities

Impurity

Impurities are substances inside a confined amount of liquid, gas, or solid, which differ from the chemical composition of the material or compound.Impurities are either naturally occurring or added during synthesis of a chemical or commercial product...

in the liquid, or by small undissolved microbubbles within the liquid. It is generally accepted that hydrophobic

Hydrophobe

In chemistry, hydrophobicity is the physical property of a molecule that is repelled from a mass of water....

surfaces stabilize small bubbles. These pre-existing bubbles start to grow unbounded when they are exposed to a pressure below the threshold pressure, termed Blake's threshold.

The vapour pressure here differs from the meteorological definition of vapour pressure, which describes the partial pressure of water in the atmosphere at some value less than 100% saturation. Vapour pressure as relating to cavitation refers to the vapour pressure in equilibrium conditions and can therefore be more accurately defined as the equilibrium (or saturated) vapour pressure.

Noninertial cavitation

Noninertial cavitation is the process in which small bubbles in a liquid are forced to oscillate in the presence of an acoustic field, when the intensity of the acoustic field is insufficient to cause total bubble collapse. This form of cavitation causes significantly less erosion than inertial cavitation, and is often used for the cleaning of delicate materials, such as silicon wafers.Cavitation damage

Propeller

A propeller is a type of fan that transmits power by converting rotational motion into thrust. A pressure difference is produced between the forward and rear surfaces of the airfoil-shaped blade, and a fluid is accelerated behind the blade. Propeller dynamics can be modeled by both Bernoulli's...

s and pump

Pump

A pump is a device used to move fluids, such as liquids, gases or slurries.A pump displaces a volume by physical or mechanical action. Pumps fall into three major groups: direct lift, displacement, and gravity pumps...

s, cavitation causes a great deal of noise, damage to components, vibrations, and a loss of efficiency.

When the cavitation bubbles collapse, they force energetic liquid into very small volumes, thereby creating spots of high temperature and emitting shock waves, the latter of which are a source of noise. The noise created by cavitation is a particular problem for military submarine

Submarine

A submarine is a watercraft capable of independent operation below the surface of the water. It differs from a submersible, which has more limited underwater capability...

s, as it increases the chances of being detected by passive sonar.

Although the collapse of a cavity is a relatively low-energy event, highly localized collapses can erode metals, such as steel, over time. The pitting caused by the collapse of cavities produces great wear on components and can dramatically shorten a propeller or pump's lifetime.

After a surface is initially affected by cavitation, it tends to erode at an accelerating pace. The cavitation pits increase the turbulence of the fluid flow and create crevasses that act as nucleation sites for additional cavitation bubbles. The pits also increase the components' surface area and leave behind residual stresses. This makes the surface more prone to stress corrosion.

Hydrodynamic cavitation

Hydrodynamic cavitation describes the process of vaporisation, bubble generation and bubble implosion which occurs in a flowing liquid as a result of a decrease and subsequent increase in pressure. Cavitation will only occur if the pressure declines to some point below the saturated vapour pressure of the liquid. In pipe systems, cavitation typically occurs either as the result of an increase in the kinetic energy (through an area constriction) or an increase in the pipe elevation.Hydrodynamic cavitation can be produced by passing a liquid through a constricted channel at a specific velocity or by mechanical rotation through a liquid. In the case of the constricted channel and based on the specific (or unique) geometry of the system, the combination of pressure and kinetic energy can be created when the hydrodynamic cavitation cavern downstream of the local constriction generating high energy cavitation bubbles.

The process of bubble generation, subsequent growth and collapse of the cavitation bubbles results in very high energy densities, resulting in very high temperatures and pressures at the surface of the bubbles for a very short time. The overall liquid medium environment, therefore, remains at ambient conditions. When uncontrolled, cavitation is damaging; however, by controlling the flow of the cavitation the power is harnessed and non-destructive. Controlled cavitation can be used to enhance chemical reactions or propagate certain unexpected reactions because free radicals are generated in the process due to disassociation of vapours trapped in the cavitating bubbles .

Orifices and venturi are reported to be widely used for generating cavitation. A venturi, because of its smooth converging and diverging sections, has an inherent advantage, over the orifice, that it can generate a higher velocity at the throat for a given pressure drop across it. On the other hand, an orifice has an advantage that it can accommodate more number of holes (larger perimeter of holes) in a given cross sectional area of the pipe.

Hydrodynamic cavitation can improve industrial processes. For instance, cavitated corn slurry show higher yields in ethanol

Ethanol

Ethanol, also called ethyl alcohol, pure alcohol, grain alcohol, or drinking alcohol, is a volatile, flammable, colorless liquid. It is a psychoactive drug and one of the oldest recreational drugs. Best known as the type of alcohol found in alcoholic beverages, it is also used in thermometers, as a...

production compared to uncavitated corn slurry in dry milling facilities.

This is also used in the mineralization of bio-refractory compounds which otherwise would need extremely high temperature and pressure conditions since free radicals are generated in the process due to the dissociation of vapours trapped in the cavitating bubbles, which results in either the intensification of the chemical reaction or may even result in the propagation of certain reactions not possible under otherwise ambient conditions.

Chemical engineering applications

In industry, cavitation is often used to homogenizeHomogenization (chemistry)

Homogenization or homogenisation is any of several processes used to make a chemical mixture the same throughout.-Definition:Homogenization is intensive blending of mutually related substances or groups of mutually related substances to form a constant of different insoluble phases to obtain a...

, or mix and break down, suspended particles in a colloidal liquid compound such as paint mixtures or milk. Many industrial mixing machines are based upon this design principle. It is usually achieved through impeller design or by forcing the mixture through an annular opening that has a narrow entrance orifice with a much larger exit orifice. In the latter case, the drastic decrease in pressure as the liquid accelerates into a larger volume induces cavitation. This method can be controlled with hydraulic devices that control inlet orifice size, allowing for dynamic adjustment during the process, or modification for different substances. The surface of this type of mixing valve, against which surface the cavitation bubbles are driven causing their implosion, undergoes tremendous mechanical and thermal localized stress; they are therefore often constructed of super-hard or tough materials such as stainless steel

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

, Stellite

Stellite

Stellite alloy is a range of cobalt-chromium alloys designed for wear resistance. It may also contain tungsten or molybdenum and a small but important amount of carbon...

, or even polycrystalline diamond (PCD).

Cavitating water purification

Water purification

Water purification is the process of removing undesirable chemicals, materials, and biological contaminants from contaminated water. The goal is to produce water fit for a specific purpose...

devices have also been designed, in which the extreme conditions of cavitation can break down pollutants and organic molecules. Spectral analysis of light emitted in sonochemical reactions

Sonochemistry

In chemistry, the study of sonochemistry is concerned with understanding the effect of sonic waves and wave properties on chemical systems. The chemical effects of ultrasound do not come from adirect interaction with molecular species...

reveal chemical and plasma-based mechanisms of energy transfer. The light emitted from cavitation bubbles is termed sonoluminescence

Sonoluminescence

Sonoluminescence is the emission of short bursts of light from imploding bubbles in a liquid when excited by sound.-History:The effect was first discovered at the University of Cologne in 1934 as a result of work on sonar. H. Frenzel and H. Schultes put an ultrasound transducer in a tank of...

.

Hydrophobic chemicals are attracted underwater by cavitation as the pressure difference between the bubbles and the liquid water forces them to join together. This effect may assist in protein folding

Protein folding

Protein folding is the process by which a protein structure assumes its functional shape or conformation. It is the physical process by which a polypeptide folds into its characteristic and functional three-dimensional structure from random coil....

.

Biomedical application

Cavitation plays an important role for the destruction of kidney stoneKidney stone

A kidney stone, also known as a renal calculus is a solid concretion or crystal aggregation formed in the kidneys from dietary minerals in the urine...

s in shock wave lithotripsy

Lithotriptor

Extracorporeal shock wave lithotripsy is a non-invasive treatment of kidney stones and biliary calculi using an acoustic pulse....

. Currently, tests are being conducted as to whether cavitation can be used to transfer large molecules into biological cell

Cell (biology)

The cell is the basic structural and functional unit of all known living organisms. It is the smallest unit of life that is classified as a living thing, and is often called the building block of life. The Alberts text discusses how the "cellular building blocks" move to shape developing embryos....

s (sonoporation

Sonoporation

Sonoporation, or cellular sonication, is the use of sound for modifying the permeability of the cell plasma membrane. This technique is usually used in molecular biology and non-viral gene therapy in order to allow uptake of large molecules such as DNA into the cell, in a cell disruption process...

). Nitrogen cavitation is a method used in research to lyse

Lysis

Lysis refers to the breaking down of a cell, often by viral, enzymic, or osmotic mechanisms that compromise its integrity. A fluid containing the contents of lysed cells is called a "lysate"....

cell membranes while leaving organelles intact.

Cavitation plays a key role in non-thermal non-invasive fractionation of tissue for treatment of a variety of diseases. Cavitation also probably plays a role in HIFU, a thermal noninvasive treatment methodology for cancer

Cancer

Cancer , known medically as a malignant neoplasm, is a large group of different diseases, all involving unregulated cell growth. In cancer, cells divide and grow uncontrollably, forming malignant tumors, and invade nearby parts of the body. The cancer may also spread to more distant parts of the...

.

Ultrasound is sometimes used to increase bone formation, for instance post-surgical applications.

Ultrasound treatments and/or exposure can create cavitation that can potentially "result in a syndrome involving manifestations of nausea, headache, tinnitus, pain, dizziness, and fatigue.".

It has been suggested that the sound of "cracking" knuckles derives from the collapse of cavitation in the synovial fluid within the joint. Movements that cause cracking expand the joint space, thus reducing pressure to the point of cavitation. The gas dissolved in synovial fluid is primarily carbon dioxide. It remains controversial whether this is associated with clinically significant joint injury such as osteoarthritis.

Cleaning application

In industrial cleaning applications, cavitation has sufficient power to overcome the particle-to-substrate adhesion forces, loosening contaminants. The threshold pressure required to initiate cavitation is a strong function of the pulse width and the power input. This method works by generating controlled acoustic cavitation in the cleaning fluid, picking up and carrying contaminant particles away so that they do not reattach to the material being cleaned.Pumps and propellers

Major places where cavitation occurs are in pumps, on propellers, or at restrictions in a flowing liquid.As an impeller's (in a pump) or propeller's (as in the case of a ship or submarine) blades move through a fluid, low-pressure areas are formed as the fluid accelerates around and moves past the blades. The faster the blades move, the lower the pressure around it can become. As it reaches vapour pressure, the fluid vaporizes

Vaporization

Vaporization of an element or compound is a phase transition from the liquid or solid phase to gas phase. There are three types of vaporization: evaporation, boiling and sublimation....

and forms small bubble

Liquid bubble

A bubble is a globule of one substance in another, usually gas in a liquid.Due to the Marangoni effect, bubbles may remain intact when they reach the surface of the immersive substance.-Common examples:...

s of gas. This is cavitation. When the bubbles collapse later, they typically cause very strong local shock waves in the fluid, which may be audible and may even damage the blades.

Cavitation in pumps may occur in two different forms:

Suction cavitation

SuctionSuction

Suction is the flow of a fluid into a partial vacuum, or region of low pressure. The pressure gradient between this region and the ambient pressure will propel matter toward the low pressure area. Suction is popularly thought of as an attractive effect, which is incorrect since vacuums do not...

cavitation occurs when the pump suction is under a low-pressure/high-vacuum condition where the liquid turns into a vapour at the eye of the pump impeller. This vapour is carried over to the discharge side of the pump, where it no longer sees vacuum and is compressed back into a liquid by the discharge pressure. This imploding action occurs violently and attacks the face of the impeller. An impeller that has been operating under a suction cavitation condition can have large chunks of material removed from its face or very small bits of material removed, causing the impeller to look spongelike. Both cases will cause premature failure of the pump, often due to bearing failure. Suction cavitation is often identified by a sound like gravel or marbles in the pump casing.

In automotive applications, a clogged filter in a hydraulic system (power steering, power brakes) can cause suction cavitation making a noise that rises and falls in synch with engine RPM. It is fairly often a high pitched whine, like set of nylon gears not quite meshing correctly.

Discharge cavitation

Discharge cavitation occurs when the pump discharge pressure is extremely high, normally occurring in a pump that is running at less than 10% of its best efficiency point. The high discharge pressure causes the majority of the fluid to circulate inside the pump instead of being allowed to flow out the discharge. As the liquid flows around the impeller, it must pass through the small clearance between the impeller and the pump housing at extremely high velocityVelocity

In physics, velocity is speed in a given direction. Speed describes only how fast an object is moving, whereas velocity gives both the speed and direction of the object's motion. To have a constant velocity, an object must have a constant speed and motion in a constant direction. Constant ...

. This velocity causes a vacuum to develop at the housing wall (similar to what occurs in a venturi

Venturi effect

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section of pipe. The Venturi effect is named after Giovanni Battista Venturi , an Italian physicist.-Background:...

), which turns the liquid into a vapor. A pump that has been operating under these conditions shows premature wear of the impeller vane tips and the pump housing. In addition, due to the high pressure conditions, premature failure of the pump's mechanical seal and bearings can be expected. Under extreme conditions, this can break the impeller shaft.

Discharge cavitation in joint fluid is thought to cause the popping sound produced by bone joint cracking

Cracking joints

Cracking joints is the action of moving joints to produce a sharp cracking or popping sound. The most common form of this occurs during deliberate knuckle-cracking...

, for example by deliberately cracking one's knuckles.

Control valves

Cavitation can occur in control valvesControl valves

Control valves are valves used to control conditions such as flow, pressure, temperature, and liquid level by fully or partially opening or closing in response to signals received from controllers that compare a "setpoint" to a "process variable" whose value is provided by sensors that monitor...

. If the upstream pressure is just above the vapour pressure, then it is possible that the pressure will drop below the vapour pressure as the fluid flows through the valve. If the pressure recovers after the valve to a pressure that is once again above the vapor pressure, then cavitation will occur.

Cavitation on spillways

When water flows over a dam spillwaySpillway

A spillway is a structure used to provide the controlled release of flows from a dam or levee into a downstream area, typically being the river that was dammed. In the UK they may be known as overflow channels. Spillways release floods so that the water does not overtop and damage or even destroy...

, the irregularities on the spillway surface will cause small areas of flow separation in a high speed flow, and, in these regions, the pressure will be lowered. If the velocities are high enough the pressure may fall to below the local vapour pressure of the water and vapour bubbles will form. When these are carried downstream into high pressure region the bubble collapses giving rise to high pressures and possible cavitation damage.

Experimental investigations show that the damage on concrete

Concrete

Concrete is a composite construction material, composed of cement and other cementitious materials such as fly ash and slag cement, aggregate , water and chemical admixtures.The word concrete comes from the Latin word...

chute and tunnel spillways can start at clear water velocities of between 12 to 15 m/s, and, up to velocities of 20 m/s, it may be possible to protect the surface by streamlining the boundaries, improving the surface finishes or using resistant materials.

When some air is present in the water the resulting mixture is compressible and this damps the high pressure caused

by the bubble collapses. If the velocities near the spillway invert are sufficiently high, aerators (or aeration devices) must be introduced to prevent cavitation. Although these have been installed for some years, the mechanisms of air entrainment at the aerators and the slow movement of the air away from the spillway surface are still challenging.

The spillway aeration device design is based upon a small deflection of the spillway bed (or sidewall) such as a ramp and offset to deflect the high velocity flow away from the spillway surface. In the cavity formed below the nappe, a local subpressure beneath the nappe is produced by which air is sucked into the flow. The complete design includes the deflection device (ramp, offset) and the air supply system.

Cavitation in engines

Some larger diesel engineDiesel engine

A diesel engine is an internal combustion engine that uses the heat of compression to initiate ignition to burn the fuel, which is injected into the combustion chamber...

s suffer from cavitation due to high compression and undersized cylinder

Cylinder (engine)

A cylinder is the central working part of a reciprocating engine or pump, the space in which a piston travels. Multiple cylinders are commonly arranged side by side in a bank, or engine block, which is typically cast from aluminum or cast iron before receiving precision machine work...

walls. Vibrations of the cylinder wall induce alternating low and high pressure in the coolant against the cylinder wall. The result is pitting of the cylinder wall, which will eventually let cooling fluid leak into the cylinder and combustion gases to leak into the coolant.

It is possible to prevent this from happening with the use of chemical additives in the cooling fluid that form a protective layer on the cylinder wall. This layer will be exposed to the same cavitation, but rebuilds itself. Additionally a regulated overpressure in the cooling system (regulated and maintained by the coolant filler cap spring pressure) prevents the forming of cavitation.

From about the 1980s, new designs of smaller petrol (gasoline

Gasoline

Gasoline , or petrol , is a toxic, translucent, petroleum-derived liquid that is primarily used as a fuel in internal combustion engines. It consists mostly of organic compounds obtained by the fractional distillation of petroleum, enhanced with a variety of additives. Some gasolines also contain...

) engines also displayed cavitation phenomenon. One answer to the need for smaller and lighter engines was a smaller coolant volume and a correspondingly higher coolant velocity. This gave rise to rapid changes in flow velocity and therefore rapid changes of static pressure in areas of high heat transfer. Where resulting vapour bubbles collapsed against a surface, they had the effect of first disrupting protective oxide layers (of cast aluminium materials) and then repeatedly damaging the newly formed surface, preventing the action of some types of corrosion inhibitor (such as silicate based inhibitors). A final problem was the effect that increased material temperature had on the relative electrochemical reactivity of the base metal and its alloying constituents. The result was deep pits that could form and penetrate the engine head in a matter of hours when the engine was running at high load and high speed. These effects could largely be avoided by the use of organic corrosion inhibitors or (preferably) by designing the engine head in such a way as to avoid certain cavitation inducing conditions.

Geology

Some theories relating to diamondDiamond

In mineralogy, diamond is an allotrope of carbon, where the carbon atoms are arranged in a variation of the face-centered cubic crystal structure called a diamond lattice. Diamond is less stable than graphite, but the conversion rate from diamond to graphite is negligible at ambient conditions...

formation posit a possible rôle for cavitation—namely cavitiation in the kimberlite

Kimberlite

Kimberlite is a type of potassic volcanic rock best known for sometimes containing diamonds. It is named after the town of Kimberley in South Africa, where the discovery of an diamond in 1871 spawned a diamond rush, eventually creating the Big Hole....

pipes providing the extreme pressure needed to change pure carbon

Carbon

Carbon is the chemical element with symbol C and atomic number 6. As a member of group 14 on the periodic table, it is nonmetallic and tetravalent—making four electrons available to form covalent chemical bonds...

into the rare allotrope that is diamond.

Vascular plants

Cavitation occurs in the xylemXylem

Xylem is one of the two types of transport tissue in vascular plants. . The word xylem is derived from the Classical Greek word ξυλον , meaning "wood"; the best-known xylem tissue is wood, though it is found throughout the plant...

of vascular plants when the tension of water within the xylem becomes so great that dissolved air within the water expands to fill either the vessel elements or tracheid

Tracheid

Tracheids are elongated cells in the xylem of vascular plants that serve in the transport of water and mineral salts. Tracheids are one of two types of tracheary elements, vessel elements being the other. All tracheary elements develop a thick lignified cell wall, and at maturity the protoplast...

s. Plants are generally able to repair cavitated xylem in a number of ways. For plants less than 50 cm tall, root pressure can be sufficient to redissolve air. For larger plants, they must repair cavitation by importing solutes into the xylem via ray cells, or in tracheid

Tracheid

Tracheids are elongated cells in the xylem of vascular plants that serve in the transport of water and mineral salts. Tracheids are one of two types of tracheary elements, vessel elements being the other. All tracheary elements develop a thick lignified cell wall, and at maturity the protoplast...

s, via osmosis throughbordered pits

Plant cell

Plant cells are eukaryotic cells that differ in several key respects from the cells of other eukaryotic organisms. Their distinctive features include:...

; this causes water to enter as well, which can then redissolve the air. In some trees, the sound of the cavitation is clearly audible, particularly in summer, when the rate of evapotranspiration

Evapotranspiration

Evapotranspiration is a term used to describe the sum of evaporation and plant transpiration from the Earth's land surface to atmosphere. Evaporation accounts for the movement of water to the air from sources such as the soil, canopy interception, and waterbodies...

is highest, and can be used to determine the rate of cavitation. Deciduous trees shed leaves in the autumn partly because cavitation increases as temperatures decrease.

Marine life

Just as cavitation bubbles form on a fast-spinning boat propeller, they may also form on the tails and fins of aquatic animals. The effects of cavitation are especially important near the surface of the ocean, where the ambient water pressure is relatively low and cavitation is more likely to occur.For powerful swimming animals like dolphins and tuna

Tuna

Tuna is a salt water fish from the family Scombridae, mostly in the genus Thunnus. Tuna are fast swimmers, and some species are capable of speeds of . Unlike most fish, which have white flesh, the muscle tissue of tuna ranges from pink to dark red. The red coloration derives from myoglobin, an...

, cavitation may be detrimental, because it limits their maximum swimming speed. Even if they have the power to swim faster, dolphins may have to restrict their speed because collapsing cavitation bubbles on their tail are too painful. Cavitation also slows tuna, but for a different reason. Unlike dolphins, these fish do not feel the painful bubbles, because they have bony fins without nerve endings. Nevertheless, they cannot swim faster because the cavitation bubbles create a vapor film around their fins that limits their speed. Lesions have been found on tuna that are consistent with cavitation damage.

Cavitation is not always a limitation for sea life; some animals have found ways to use it to their advantage when hunting prey. The pistol shrimp snaps a specialized claw to create cavitation, which can kill small fish. The mantis shrimp

Mantis shrimp

Mantis shrimp or stomatopods are marine crustaceans, the members of the order Stomatopoda. They are neither shrimp nor mantids, but receive their name purely from the physical resemblance to both the terrestrial praying mantis and the shrimp. They may reach in length, although exceptional cases of...

(of the smasher variety) uses cavitation as well in order to stun, smash open, or kill the shellfish that it feasts upon. Their appendages do wear out as a result, which is not a problem because the animal moults every three months.

Coastal erosion

In the last half-decade, coastal erosion in the form of inertial cavitation has been generally accepted. Vapor pockets in an incoming wave are forced into cracks in the cliff being eroded, then the force of the wave compresses the vapor pockets until the bubble implodes, becoming liquid, giving off various forms of energy that blast apart the rock.Canada

- National Research Council—Institute for Ocean Technology Cavitation Tunnel, St. Johns, Newfoundland.

France

- "Tunnel de Cavitation" Ecole Navale, Lanveoc.

- "Grand Tunnel Hydrodynamique" Bassin d'Essais des Carènes, Val de Reuil.

Germany

- Multiple cavitation tunnels at the Versuchsanstalt für Wasserbau und Schiffbau, Berlin.

- Large Cavitation tunnel at Hamburg Ship Model Basin, Hamburg.

- Cavitation tunnel at the Schiffbau-Versuchsanstalt, Potsdam.

India

- Fluid Control Research Institute, Palakkad,Kerala. http://www.fcriindia.com

- Cavitation Tunnel of the Naval Science and Technology Labs at Visakhapatnam.

Iran

- Applied Hydrodynamics Laboratory, Iran University of Science and Technology, Narmak, Tehran.

- Marine Engineering Laboratory, Sharif University of Technology, Azadi Av., Tehran.

Italy

- Tunnel di Cavitazione, Istituto nazionale per studi ed esperienze di architettura navale (INSEAN)

- www.insean.it, RomaRoma- Places :Italy* Rome, the capital of Italy, is called Roma in Italian and some other languages* Roma Tre University, a university located in Rome, Italy, and founded in 1992...

- Tunnel di Cavitazione, Dipartimento di Ingegneria Navale e Tecnologie Marine, Università degli Studi di Genova

- Cavitating Pump Rotordynamic Test Facility, ALTA S.p.A., Pisa

- www.alta-space.com, PisaPisaPisa is a city in Tuscany, Central Italy, on the right bank of the mouth of the River Arno on the Tyrrhenian Sea. It is the capital city of the Province of Pisa...

Netherlands

- Large Cavitation Tunnel and High Speed Cavitation Tunnel at the Maritime Research InstituteMARIN (research)MARIN, the Maritime Research Institute Netherlands, is one of the leading institutes in the world for hydrodynamic research and maritime technology. The services incorporate a unique combination of simulation, model testing, full-scale measurements and training programmes. MARIN provides services...

, Wageningen.

Norway

- "Cavitation Lab" NTNU, The Norwegian University of Science and TechnologyNorwegian University of Science and TechnologyThe Norwegian University of Science and Technology , commonly known as NTNU, is located in Trondheim. NTNU is the second largest of the eight universities in Norway, and, as its name suggests, has the main national responsibility for higher education in engineering and technology...

, Trondheim.

Switzerland

- Tunnel de Cavitation au Laboratoire des Machines Hydrauliques (LMH), Ecole Polytechnique Federale de Lausanne (EPFL)

Ukraine

- The Cavitation Tunnel at Institute of Hydromechanics of National Academy of Sciences, Kiev

United States

- The Garfield Thomas Water Tunnel, The Pennsylvania State University, State College, PA.

- Naval Surface Warfare Center, Carderock Division 24" Variable Pressure Water Tunnel West Bethesda, MD

- Naval Surface Warfare Center, Carderock Division 36" Variable Pressure Water Tunnel West Bethesda, MD

- The William B. Morgan Large Cavitation Channel, part of NSWCCD Memphis, TN.

- MIT's variable pressure water tunnel.

- University of Minnesota's St. Anthony Falls Laboratory cavitation facilities.

See also

- The phenomenon known as supercavitationSupercavitationSupercavitation is the use of cavitation effects to create a bubble of gas inside a liquid large enough to encompass an object traveling through the liquid, greatly reducing the skin friction drag on the object and enabling achievement of very high speeds...

is used to allow objects to travel under water at high speed. - Supercavitation propeller

- SonoluminescenceSonoluminescenceSonoluminescence is the emission of short bursts of light from imploding bubbles in a liquid when excited by sound.-History:The effect was first discovered at the University of Cologne in 1934 as a result of work on sonar. H. Frenzel and H. Schultes put an ultrasound transducer in a tank of...

- Cavitation number

- Erosion corrosion of copper water tubesErosion corrosion of copper water tubesErosion corrosion, also known as impingement damage, is the combined effect of corrosion and erosion caused by rapid flowing turbulent water. It is probably the second most common cause of copper tube failures behind Type 1 pitting which is also known as Cold Water Pitting of Copper Tube.-Copper...

- Water hammerWater hammerWater hammer is a pressure surge or wave resulting when a fluid in motion is forced to stop or change direction suddenly . Water hammer commonly occurs when a valve is closed suddenly at an end of a pipeline system, and a pressure wave propagates in the pipe...

Further reading

- For cavitation in plants, see Plant Physiology by Taiz and Zeiger.

- For cavitation in the engineering field, visit http://www.corrosion-doctors.org/Forms-cavitation/cavitation.htm

- Kornfelt, M.: "On the destructive action of cavitation," Journal of applied Physics No.15, 1944.

- For hydrodynamic cavitation in the ethanol field, visit http://www.arisdyne.com and Ethanol Producer Magazine: "Tiny Bubbles to Make You Happy" http://www.ethanolproducer.com/article.jsp?article_id=5732&q=tiny%20bubbles&category_id=46

- S. Barnett; Nonthermal issues: Cavitation—Its nature, detection and measurement; Ultrasound in Medicine & Biology, Volume 24, Supplement 1, June 1998, Pages S11-S21

External links

- Cavitation and Bubble Dynamics by Christopher E. Brennen

- Fundamentals of Multiphase Flow by Christopher E. Brennen

- van der Waals-type CFD Modeling of Cavitation

- Single Cavitation Bubble in a Water Drop - Evolution, Liquid Jets, Shock Wave

- Cavitation limits the speed of dolphins

- Tiny Bubbles to Make You Happy