Dairy

Encyclopedia

Milk

Milk is a white liquid produced by the mammary glands of mammals. It is the primary source of nutrition for young mammals before they are able to digest other types of food. Early-lactation milk contains colostrum, which carries the mother's antibodies to the baby and can reduce the risk of many...

—mostly from cows

Cattle

Cattle are the most common type of large domesticated ungulates. They are a prominent modern member of the subfamily Bovinae, are the most widespread species of the genus Bos, and are most commonly classified collectively as Bos primigenius...

or goat

Goat

The domestic goat is a subspecies of goat domesticated from the wild goat of southwest Asia and Eastern Europe. The goat is a member of the Bovidae family and is closely related to the sheep as both are in the goat-antelope subfamily Caprinae. There are over three hundred distinct breeds of...

s, but also from buffalo, sheep, horses or camel

Camel

A camel is an even-toed ungulate within the genus Camelus, bearing distinctive fatty deposits known as humps on its back. There are two species of camels: the dromedary or Arabian camel has a single hump, and the bactrian has two humps. Dromedaries are native to the dry desert areas of West Asia,...

s —for human consumption. A dairy is typically located on a dedicated dairy farm or section of a multi-purpose farm that is concerned with the harvesting of milk.

Terminology differs between countries. For example, in the United States

United States

The United States of America is a federal constitutional republic comprising fifty states and a federal district...

, a farm building where milk is harvested is often called a milking parlor. In New Zealand

New Zealand

New Zealand is an island country in the south-western Pacific Ocean comprising two main landmasses and numerous smaller islands. The country is situated some east of Australia across the Tasman Sea, and roughly south of the Pacific island nations of New Caledonia, Fiji, and Tonga...

such a building is historically known as the milking shed - although in recent years there has been a progressive change to call such a building a farm dairy.

In some countries, especially those with small numbers of animals being milked, as well as harvesting the milk from an animal, the dairy may also process the milk into butter

Butter

Butter is a dairy product made by churning fresh or fermented cream or milk. It is generally used as a spread and a condiment, as well as in cooking applications, such as baking, sauce making, and pan frying...

, cheese

Cheese

Cheese is a generic term for a diverse group of milk-based food products. Cheese is produced throughout the world in wide-ranging flavors, textures, and forms....

and yogurt, for example. This is a traditional method of producing specialist milk products, especially in Europe. In the United States a dairy can also be a place that processes, distributes and sells dairy product

Dairy product

Dairy products are generally defined as foods produced from cow's or domestic buffalo's milk. They are usually high-energy-yielding food products. A production plant for such processing is called a dairy or a dairy factory. Raw milk for processing comes mainly from cows, and, to a lesser extent,...

s, or a room, building or establishment where milk is stored and processed into milk products, such as butter

Butter

Butter is a dairy product made by churning fresh or fermented cream or milk. It is generally used as a spread and a condiment, as well as in cooking applications, such as baking, sauce making, and pan frying...

or cheese

Cheese

Cheese is a generic term for a diverse group of milk-based food products. Cheese is produced throughout the world in wide-ranging flavors, textures, and forms....

. In New Zealand English

New Zealand English

New Zealand English is the dialect of the English language used in New Zealand.The English language was established in New Zealand by colonists during the 19th century. It is one of "the newest native-speaker variet[ies] of the English language in existence, a variety which has developed and...

the singular use of the word dairy almost exclusively refers to the corner convenience store

Convenience store

A convenience store, corner store, corner shop, commonly called a bodega in Spanish-speaking areas of the United States, is a small store or shop in a built up area that stocks a range of everyday items such as groceries, toiletries, alcoholic and soft drinks, and may also offer money order and...

, or superette

Superette

A Superette, is a compact food market "convenience store" or "mini-mart".The term is most commonly used in the North Island of New Zealand, but also to a lesser extent in Northern New England, Newfoundland and Labrador, and elsewhere as an alternative name for a "convenience store" or...

. This usage is historical as such stores were a common place for the public to buy milk products.

As an attributive, the word dairy refers to milk-based products, derivatives and processes, and the animals and workers involved in their production: for example dairy cattle

Dairy cattle

Dairy cattle are cattle cows bred for the ability to produce large quantities of milk, from which dairy products are made. Dairy cows generally are of the species Bos taurus....

, dairy goat. A dairy farm produces milk and a dairy factory

Factory

A factory or manufacturing plant is an industrial building where laborers manufacture goods or supervise machines processing one product into another. Most modern factories have large warehouses or warehouse-like facilities that contain heavy equipment used for assembly line production...

processes it into a variety of dairy products. These establishments constitute the dairy industry, a component of the food industry

Food industry

The food production is a complex, global collective of diverse businesses that together supply much of the food energy consumed by the world population...

.

History

Milk producing animals have been domesticated for thousands of years. Initially, they were part of the subsistence farming that nomads engaged in. As the community moved about the country, their animals accompanied them. Protecting and feeding the animals were a big part of the symbiotic relationship between the animals and the herdHerd

Herd refers to a social grouping of certain animals of the same species, either wild or domestic, and also to the form of collective animal behavior associated with this or as a verb, to herd, to its control by another species such as humans or dogs.The term herd is generally applied to mammals,...

ers.

In the more recent past, people in agricultural societies

Agriculture

Agriculture is the cultivation of animals, plants, fungi and other life forms for food, fiber, and other products used to sustain life. Agriculture was the key implement in the rise of sedentary human civilization, whereby farming of domesticated species created food surpluses that nurtured the...

owned dairy animals that they milked for domestic and local (village) consumption, a typical example of a cottage industry. The animals might serve multiple purposes (for example, as a draught animal for pulling a plough

Plough

The plough or plow is a tool used in farming for initial cultivation of soil in preparation for sowing seed or planting. It has been a basic instrument for most of recorded history, and represents one of the major advances in agriculture...

as a youngster, and at the end of its useful life as meat

Meat

Meat is animal flesh that is used as food. Most often, this means the skeletal muscle and associated fat and other tissues, but it may also describe other edible tissues such as organs and offal...

). In this case the animals were normally milked by hand and the herd size was quite small, so that all of the animals could be milked in less than an hour—about 10 per milker. These tasks were performed by a dairymaid (dairywoman) or dairyman. The word dairy harkens back to Middle English dayerie, deyerie, from deye (female servant or dairymaid) and further back to Old English dæge (kneader of bread).

With industrialisation

Industrial Revolution

The Industrial Revolution was a period from the 18th to the 19th century where major changes in agriculture, manufacturing, mining, transportation, and technology had a profound effect on the social, economic and cultural conditions of the times...

and urbanisation, the supply of milk became a commercial industry, with specialised breeds of cattle being developed for dairy, as distinct from beef

Beef

Beef is the culinary name for meat from bovines, especially domestic cattle. Beef can be harvested from cows, bulls, heifers or steers. It is one of the principal meats used in the cuisine of the Middle East , Australia, Argentina, Brazil, Europe and the United States, and is also important in...

or draught animals. Initially, more people were employed as milkers, but it soon turned to mechanisation

Mechanization

Mechanization or mechanisation is providing human operators with machinery that assists them with the muscular requirements of work or displaces muscular work. In some fields, mechanization includes the use of hand tools...

with machines designed to do the milking.

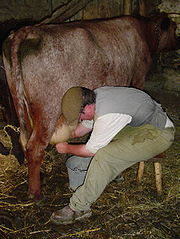

Milking

Milking is the act of removing milk from the mammary glands of an animal, typically cows , water buffalo, goats, sheep and more rarely camels, horses and donkeys. Milking may be done by hand or by machine.-Hand milking:...

and the processing

Food processing

Food processing is the set of methods and techniques used to transform raw ingredients into food or to transform food into other forms for consumption by humans or animals either in the home or by the food processing industry...

took place close together in space and time: on a dairy farm

Dairy farming

Dairy farming is a class of agricultural, or an animal husbandry, enterprise, for long-term production of milk, usually from dairy cows but also from goats and sheep, which may be either processed on-site or transported to a dairy factory for processing and eventual retail sale.Most dairy farms...

. People milked the animals by hand; on farms where only small numbers are kept, hand-milking may still be practiced. Hand-milking is accomplished by grasping the teats (often pronounced tit or tits) in the hand and expressing milk either by squeezing the fingers progressively, from the udder

Udder

An udder is an organ formed of the mammary glands of female quadruped mammals, especially ruminants such as cattle, goats, sheep and deer. The udder is a single mass hanging beneath the animal, consisting of pairs of mammary glands...

end to the tip, or by squeezing the teat between thumb and index finger, then moving the hand downward from udder towards the end of the teat. The action of the hand or fingers is designed to close off the milk duct at the udder (upper) end and, by the movement of the fingers, close the duct progressively to the tip to express the trapped milk. Each half or quarter of the udder is emptied one milk-duct capacity at a time.

The stripping action is repeated, using both hands for speed. Both methods result in the milk that was trapped in the milk duct being squirted out the end into a bucket that is supported between the knees (or rests on the ground) of the milker, who usually sits on a low stool.

Traditionally the cow, or cows, would stand in the field

Field (agriculture)

In agriculture, the word field refers generally to an area of land enclosed or otherwise and used for agricultural purposes such as:* Cultivating crops* Usage as a paddock or, generally, an enclosure of livestock...

or paddock while being milked. Young stock, heifer

Cattle

Cattle are the most common type of large domesticated ungulates. They are a prominent modern member of the subfamily Bovinae, are the most widespread species of the genus Bos, and are most commonly classified collectively as Bos primigenius...

s, would have to be trained to remain still to be milked. In many countries, the cows were tethered to a post and milked. The problem with this method is that it relies on quiet, tractable beasts, because the hind end of the cow is not restrained.

In 1937, it was found that bovine somatotropin

Bovine somatotropin

Bovine somatotropin , or BGH, is a chain of amino acids produced by the cow's pituitary gland. Like other hormones, it is produced in small quantities and is used in regulating metabolic processes...

(bST or bovine growth hormone) would increase the yield of milk. Monsanto Company developed a synthetic (recombinant) version of this hormone (rBST). In February 1994, rBST was approved by the Food and Drug Administration (FDA) for use in the U.S. It has become common in the U.S., but not elsewhere, to inject it into milch kine dairy cows to increase their production by up to 15%.

However, there are claims that this practice can have negative consequences for the animals themselves.

A European Union

European Union

The European Union is an economic and political union of 27 independent member states which are located primarily in Europe. The EU traces its origins from the European Coal and Steel Community and the European Economic Community , formed by six countries in 1958...

scientific commission was asked to report on the incidence of mastitis

Mastitis in dairy cattle

Mastitis in dairy cattle is the persistent, inflammatory reaction of the udder tissue. This potentially fatal mammary gland infection is the most common disease in dairy cattle in the United States. It is also the most costly to the dairy industry...

and other disorders in dairy cows, and on other aspects of the welfare of dairy cows. The commission's statement, subsequently adopted by the European Union, stated that the use of rBST substantially increased health problems with cows, including foot problems, mastitis and injection site reactions, impinged on the welfare of the animals and caused reproductive disorders. The report concluded that on the basis of the health and welfare of the animals, rBST should not be used. Health Canada

Health Canada

Health Canada is the department of the government of Canada with responsibility for national public health.The current Minister of Health is Leona Aglukkaq, a Conservative Member of Parliament appointed to the position by Prime Minister Stephen Harper.-Branches, regions and agencies:Health Canada...

prohibited the sale of rBST in 1999; the recommendations of external committees were that, despite not finding a significant health risk to humans, the drug presented a threat to animal health and, for this reason, could not be sold in Canada

Canada

Canada is a North American country consisting of ten provinces and three territories. Located in the northern part of the continent, it extends from the Atlantic Ocean in the east to the Pacific Ocean in the west, and northward into the Arctic Ocean...

.

Structure of the industry

While most countries produce their own milk products, the structure of the dairy industry varies in different parts of the world. In major milk-producing countries most milk is distributed through wholesale markets. In Ireland and Australia, for example, farmers' co-operatives own many of the large-scale processors, while in the United States many farmers and processors do business through individual contracts. In the United States, the country's 196 farmers' cooperatives sold 86% of milk in the U.S. in 2002, with five cooperatives accounting for half that. This was down from 2,300 cooperatives in the 1940s. In developing countries, the past practice of farmers marketing milk in their own neighborhoods are changing rapidly. Notable developments include considerable foreign investment in the dairy industry and a growing role for dairy cooperatives. Output of milk is growing rapidly in such countries and presents a major source of income growth for many farmers.As in many other branches of the food industry, dairy processing in the major dairy producing countries has become increasingly concentrated, with fewer but larger and more efficient plants operated by fewer workers. This is notably the case in the United States, Europe, Australia and New Zealand. In 2009, charges of anti-trust violations have been made against major dairy industry players in the United States.

Government intervention in milk markets was common in the 20th century. A limited anti-trust exemption was created for U.S. dairy cooperatives by the Capper-Volstead Act

Capper-Volstead Act

Capper-Volstead Act , the Co-operative Marketing Associations Act was adopted by the United States Congress on February 18, 1922. It gave “associations” of persons producing agricultural products certain exemptions from antitrust laws...

of 1922. In the 1930s, some U.S. states adopted price controls, and Federal Milk Marketing Orders started under the Agricultural Marketing Agreement Act of 1937 and continue in the 2000s. The Federal Milk Price Support Program began in 1949. The Northeast Dairy Compact

Northeast Dairy Compact

The Northeast [Interstate] Dairy Compact was an interstate compact created by the New England states and approved by Congress, most recently in , § 147 , the purpose of which was to regulate the wholesale price of fluid milk in the member states and take other actions to preserve the economic...

regulated wholesale milk prices in New England from 1997 to 2001.

Plants producing liquid milk and products with short shelf life, such as yogurts, creams and soft cheeses, tend to be located on the outskirts of urban centres close to consumer markets. Plants manufacturing items with longer shelf life, such as butter, milk powders, cheese and whey powders, tend to be situated in rural areas closer to the milk supply. Most large processing plants tend to specialise in a limited range of products. Exceptionally, however, large plants producing a wide range of products are still common in Eastern Europe, a holdover from the former centralized, supply-driven concept of the market.

As processing plants grow fewer and larger, they tend to acquire bigger, more automated and more efficient equipment. While this technological tendency keeps manufacturing costs lower, the need for long-distance transportation often increases the environmental impact.

Milk production is irregular, depending on cow biology. Producers must adjust the mix of milk which is sold in liquid form vs. processed foods (such as butter and cheese) depending on changing supply and demand.

Operation of the dairy farm

When it became necessary to milk larger numbers of cows, the cows would be brought to a shedShed

A shed is typically a simple, single-storey structure in a back garden or on an allotment that is used for storage, hobbies, or as a workshop....

or barn that was set up with bail

Bail

Traditionally, bail is some form of property deposited or pledged to a court to persuade it to release a suspect from jail, on the understanding that the suspect will return for trial or forfeit the bail...

s (stall

Stall (enclosure)

A stall is a small enclosure of some kind, usually less enclosed than a room.-Market stall:A market stall is usually an immobile temporary structure erected by merchants to display and shelter their merchandise...

s) where the cows could be confined while they were milked. One person could milk more cows this way, as many as 20 for a skilled worker. But having cows standing about in the yard and shed waiting to be milked is not good for the cow, as she needs as much time in the paddock grazing as is possible. It is usual to restrict the twice-daily milking to a maximum of an hour and a half each time. It makes no difference whether one milks 10 or 1000 cows, the milking time should not exceed a total of about three hours each day for any cow.

As herd

Herd

Herd refers to a social grouping of certain animals of the same species, either wild or domestic, and also to the form of collective animal behavior associated with this or as a verb, to herd, to its control by another species such as humans or dogs.The term herd is generally applied to mammals,...

sizes increased there was more need to have efficient milking machines, sheds, milk-storage facilities (vat

Bulk tank

In dairy farming a bulk milk cooling tank is a large storage tank for cooling and holding milk at a cold temperature until it can be picked up by a milk hauler....

s), bulk-milk transport and shed cleaning capabilities and the means of getting cows from paddock to shed and back.

Farmers found that cows would abandon their grazing area and walk towards the milking area when the time came for milking. This is not surprising as, in the flush of the milking season, cows presumably get very uncomfortable with udders engorged with milk, and the place of relief for them is the milking shed.

As herd numbers increased so did the problems of animal health

Animal Health

Animal Health is the UK government's executive agency primarily responsible for ensuring that farmed animals in Great Britain are healthy, disease-free and well looked after....

. In New Zealand

New Zealand

New Zealand is an island country in the south-western Pacific Ocean comprising two main landmasses and numerous smaller islands. The country is situated some east of Australia across the Tasman Sea, and roughly south of the Pacific island nations of New Caledonia, Fiji, and Tonga...

two approaches to this problem have been used. The first was improved veterinary medicine

Veterinary medicine

Veterinary Medicine is the branch of science that deals with the prevention, diagnosis and treatment of disease, disorder and injury in non-human animals...

s (and the government regulation of the medicines) that the farmer could use. The other was the creation of veterinary clubs where groups of farmers would employ a veterinarian

Veterinary medicine

Veterinary Medicine is the branch of science that deals with the prevention, diagnosis and treatment of disease, disorder and injury in non-human animals...

(vet) full-time and share those services throughout the year. It was in the vet's interest to keep the animals healthy and reduce the number of calls from farmers, rather than to ensure that the farmer needed to call for service and pay regularly.

Most dairy farmers milk their cows with absolute regularity at a minimum of twice a day, with some high-producing herds milking up to four times a day to lessen the weight of large volumes of milk in the udder of the cow. This daily milking routine goes on for about 300 to 320 days per year that the cow stays in milk. Some small herds are milked once a day for about the last 20 days of the production cycle but this is not usual for large herds. If a cow is left unmilked just once she is likely to reduce milk-production almost immediately and the rest of the season may see her dried off (giving no milk) and still consuming feed for no production. However, once-a-day milking is now being practised more widely in New Zealand for profit and lifestyle reasons. This is effective because the fall in milk yield is at least partially offset by labour and cost savings from milking once per day. This compares to some intensive farm systems in the United States

United States

The United States of America is a federal constitutional republic comprising fifty states and a federal district...

that milk three or more times per day due to higher milk yields per cow and lower marginal labor costs.

Farmers who are contracted to supply liquid milk for human consumption (as opposed to milk for processing into butter

Butter

Butter is a dairy product made by churning fresh or fermented cream or milk. It is generally used as a spread and a condiment, as well as in cooking applications, such as baking, sauce making, and pan frying...

, cheese

Cheese

Cheese is a generic term for a diverse group of milk-based food products. Cheese is produced throughout the world in wide-ranging flavors, textures, and forms....

, and so on—see milk

Milk

Milk is a white liquid produced by the mammary glands of mammals. It is the primary source of nutrition for young mammals before they are able to digest other types of food. Early-lactation milk contains colostrum, which carries the mother's antibodies to the baby and can reduce the risk of many...

) often have to manage their herd

Herd

Herd refers to a social grouping of certain animals of the same species, either wild or domestic, and also to the form of collective animal behavior associated with this or as a verb, to herd, to its control by another species such as humans or dogs.The term herd is generally applied to mammals,...

so that the contracted number of cows are in milk the year round, or the required minimum milk output is maintained. This is done by mating cows outside their natural mating time so that the period when each cow in the herd is giving maximum production is in rotation throughout the year.

Northern hemisphere farmers who keep cows in barns almost all the year usually manage their herds to give continuous production of milk so that they get paid all year round. In the southern hemisphere the cooperative

Cooperative

A cooperative is a business organization owned and operated by a group of individuals for their mutual benefit...

dairying systems allow for two months on no productivity because their systems are designed to take advantage of maximum grass and milk production in the spring and because the milk processing plants pay bonuses in the dry (winter) season to carry the farmers through the mid-winter break from milking. It also means that cows have a rest from milk production when they are most heavily pregnant. Some year-round milk farms are penalised financially for over-production at any time in the year by being unable to sell their overproduction at current prices.

Artificial insemination

Artificial insemination

Artificial insemination, or AI, is the process by which sperm is placed into the reproductive tract of a female for the purpose of impregnating the female by using means other than sexual intercourse or natural insemination...

(AI) is common in all high-production herds.

Industrial processing

Dairy plants process the raw milk they receive from farmers so as to extend its marketable life. Two main types of processes are employed: heat treatment to ensure the safety of milk for human consumption and to lengthen its shelf-life, and dehydrating dairy products such as butter, hard cheese and milk powders so that they can be stored.

Cream and butter

Today, milk is separated by huge machines in bulk into cream and skim milk. The cream is processed to produce various consumer products, depending on its thickness, its suitability for culinary uses and consumer demand, which differs from place to place and country to country.Some cream is dried and powdered, some is condensed (by evaporation

Evaporation

Evaporation is a type of vaporization of a liquid that occurs only on the surface of a liquid. The other type of vaporization is boiling, which, instead, occurs on the entire mass of the liquid....

) mixed with varying amounts of sugar

Sugar

Sugar is a class of edible crystalline carbohydrates, mainly sucrose, lactose, and fructose, characterized by a sweet flavor.Sucrose in its refined form primarily comes from sugar cane and sugar beet...

and canned. Most cream from New Zealand and Australian factories is made into butter

Butter

Butter is a dairy product made by churning fresh or fermented cream or milk. It is generally used as a spread and a condiment, as well as in cooking applications, such as baking, sauce making, and pan frying...

. This is done by churning

Churning (butter)

Churning is the process of shaking up whole milk to make butter, and various forms of butter churn have been used for the purpose. In Europe from the Middle Ages until the Industrial Revolution, this was generally as simple as a barrel with a plunger in it, which was moved by hand...

the cream until the fat globules coagulate and form a monolithic mass. This butter mass is washed and, sometimes, salted to improve keeping qualities. The residual buttermilk

Buttermilk

Buttermilk refers to a number of dairy drinks. Originally, buttermilk was the liquid left behind after churning butter out of cream. It also refers to a range of fermented milk drinks, common in warm climates where unrefrigerated fresh milk otherwise sours quickly...

goes on to further processing. The butter is packaged (25 to 50 kg boxes) and chilled for storage and sale. At a later stage these packages are broken down into home-consumption sized packs.

Skimmed milk

The product left after the cream is removed is called skim, or skimmed, milk.To make a consumable liquid a portion of cream is returned to the skim milk to make low fat milk (semi-skimmed) for human consumption. By varying the amount of cream returned, producers can make a variety of low-fat milks to suit their local market. Other products, such as calciumCalcium

Calcium is the chemical element with the symbol Ca and atomic number 20. It has an atomic mass of 40.078 amu. Calcium is a soft gray alkaline earth metal, and is the fifth-most-abundant element by mass in the Earth's crust...

, vitamin D

Vitamin D

Vitamin D is a group of fat-soluble secosteroids. In humans, vitamin D is unique both because it functions as a prohormone and because the body can synthesize it when sun exposure is adequate ....

, and flavouring, are also added to appeal to consumers.

Casein

CaseinCasein

Casein is the name for a family of related phosphoprotein proteins . These proteins are commonly found in mammalian milk, making up 80% of the proteins in cow milk and between 60% and 65% of the proteins in human milk....

is the predominant phosphoprotein

Phosphoprotein

Phosphoproteins are proteins that are physically bonded to a substance containing phosphoric acid . This category of organic molecules includes Fc receptors, Ulks, Calcineurins, K chips, and urocortins....

found in fresh milk. It has a very wide range of uses from being a filler for human foods, such as in ice cream

Ice cream

Ice cream is a frozen dessert usually made from dairy products, such as milk and cream, and often combined with fruits or other ingredients and flavours. Most varieties contain sugar, although some are made with other sweeteners...

, to the manufacture of products such as fabric, adhesive

Adhesive

An adhesive, or glue, is a mixture in a liquid or semi-liquid state that adheres or bonds items together. Adhesives may come from either natural or synthetic sources. The types of materials that can be bonded are vast but they are especially useful for bonding thin materials...

s, and plastic

Plastic

A plastic material is any of a wide range of synthetic or semi-synthetic organic solids used in the manufacture of industrial products. Plastics are typically polymers of high molecular mass, and may contain other substances to improve performance and/or reduce production costs...

s.

Cheese

CheeseCheese

Cheese is a generic term for a diverse group of milk-based food products. Cheese is produced throughout the world in wide-ranging flavors, textures, and forms....

is another product made from milk. Whole milk is reacted to form curds that can be compressed, processed and stored to form cheese. In countries where milk is legally allowed to be processed without pasteurisation a wide range of cheeses can be made using the bacteria naturally in the milk. In most other countries, the range of cheeses is smaller and the use of artificial cheese curing is greater. Whey is also the byproduct of this process. Some people that are lactose intolerant can eat certain types of cheese.

Whey

In earlier times whey was considered to be a waste product and it was, mostly, fed to pigs as a convenient means of disposal. Beginning about 1950, and mostly since about 1980, lactoseLactose

Lactose is a disaccharide sugar that is found most notably in milk and is formed from galactose and glucose. Lactose makes up around 2~8% of milk , although the amount varies among species and individuals. It is extracted from sweet or sour whey. The name comes from or , the Latin word for milk,...

and many other products, mainly food additives, are made from both casein and cheese whey.

Yogurt

YoghurtYoghurt

Yoghurt, yogurt or yogourt is a dairy product produced by bacterial fermentation of milk. The bacteria used to make yoghurt are known as "yoghurt cultures"...

(or yogurt) making is a process similar to cheese making, only the process is arrested before the curd becomes very hard.

Milk powders

Milk is also processed by various drying processes into powders. Whole milk, skim milk, buttermilk, and whey products are dried into a powder form and used for human and animal consumption. The main difference between production of powders for human or for animal consumption is in the protection of the process and the product from contamination. Some people drink milk reconstituted from powdered milk, because milk is about 88% water and it is much cheaper to transport the dried product.Other milk products

KumisKumis

Kumis, also spelled kumiss or koumiss in English is a fermented dairy product traditionally made from mare's milk. The drink remains important to the peoples of the Central Asian steppes, of Turkic and Mongol origin: Bashkirs, Kazakhs, Kyrgyz, Yakuts, Mongols and Kalmyks...

is produced commercially in Central Asia

Central Asia

Central Asia is a core region of the Asian continent from the Caspian Sea in the west, China in the east, Afghanistan in the south, and Russia in the north...

. Although it is traditionally made from mare

Horse

The horse is one of two extant subspecies of Equus ferus, or the wild horse. It is a single-hooved mammal belonging to the taxonomic family Equidae. The horse has evolved over the past 45 to 55 million years from a small multi-toed creature into the large, single-toed animal of today...

's milk, modern industrial variants may use cow's milk instead.

Transport of milk

Historically, the milking and the processing took place in the same place: on a dairy farm. Later, cream was separated from the milk by machine, on the farm, and the cream was transported to a factoryFactory

A factory or manufacturing plant is an industrial building where laborers manufacture goods or supervise machines processing one product into another. Most modern factories have large warehouses or warehouse-like facilities that contain heavy equipment used for assembly line production...

for buttermaking. The skim milk was fed to pig

Pig

A pig is any of the animals in the genus Sus, within the Suidae family of even-toed ungulates. Pigs include the domestic pig, its ancestor the wild boar, and several other wild relatives...

s. This allowed for the high cost of transport (taking the smallest volume high-value product), primitive trucks and the poor quality of roads. Only farms close to factories could afford to take whole milk, which was essential for cheesemaking in industrial quantities, to them. The development of refrigeration

Refrigeration

Refrigeration is a process in which work is done to move heat from one location to another. This work is traditionally done by mechanical work, but can also be done by magnetism, laser or other means...

and better road transport, in the late 1950s, has meant that most farmers milk their cows and only temporarily store the milk in large refrigerated bulk tank

Bulk tank

In dairy farming a bulk milk cooling tank is a large storage tank for cooling and holding milk at a cold temperature until it can be picked up by a milk hauler....

s, from where it is later transported by truck to central processing facilities.

Milking machines

Milking machines work in a way that is different from hand milking or calf suckling. Continuous vacuum is applied inside the soft liner to massage milk from the teat by creating a pressure difference across the teat canal (or opening at the end of the teat). Vacuum also helps keep the machine attached to the cow. The vacuum applied to the teat causes congestion of teat tissues (accumulation of blood and other fluids). Atmospheric air is admitted into the pulsation chamber about once per second (the pulsation rate) to allow the liner to collapse around the end of teat and relieve congestion in the teat tissue. The ratio of the time that the liner is open (milking phase) and closed (rest phase) is called the pulsation ratio.

The four streams of milk from the teatcups are usually combined in the claw and transported to the milkline, or the collection bucket (usually sized to the output of one cow) in a single milk hose. Milk is then transported (manually in buckets) or with a combination of airflow and mechanical pump

Pump

A pump is a device used to move fluids, such as liquids, gases or slurries.A pump displaces a volume by physical or mechanical action. Pumps fall into three major groups: direct lift, displacement, and gravity pumps...

to a central storage vat

Vat

Vat or VAT may refer to:* A type of container such as a barrel, storage tank, or tub, often constructed of welded sheet stainless steel, and used for holding, storing, and processing liquids such as milk, wine, and beer...

or bulk tank

Bulk tank

In dairy farming a bulk milk cooling tank is a large storage tank for cooling and holding milk at a cold temperature until it can be picked up by a milk hauler....

. Milk is refrigerated on the farm in most countries either by passing through a heat-exchanger or in the bulk tank, or both.

In the photo above is a bucket milking system with the stainless steel bucket visible on the far side of the cow. The two rigid stainless steel teatcup shells applied to the front two quarters of the udder are visible. The top of the flexible liner is visible at the top of the shells as are the short milk tubes and short pulsation tubes extending from the bottom of the shells to the claw. The bottom of the claw is transparent to allow observation of milk flow. When milking is completed the vacuum to the milking unit is shut off and the teatcups are removed.

Milking machines keep the milk enclosed and safe from external contamination. The interior 'milk contact' surfaces of the machine are kept clean by a manual or automated washing procedures implemented after milking is completed. Milk contact surfaces must comply with regulations requiring food-grade materials (typically stainless steel

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

and special plastics and rubber compounds) and are easily cleaned.

Most milking machines are powered by electricity

Electrical power industry

The electric power industry provides the production and delivery of electric energy, often known as power, or electricity, in sufficient quantities to areas that need electricity through a grid connection. The grid distributes electrical energy to customers...

but, in case of electrical failure, there can be an alternative means of motive power, often an internal combustion engine

Internal combustion engine

The internal combustion engine is an engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber. In an internal combustion engine, the expansion of the high-temperature and high -pressure gases produced by combustion apply direct force to some component of the engine...

, for the vacuum and milk pumps. Raghav Gowda from Karnataka

Karnataka

Karnataka , the land of the Kannadigas, is a state in South West India. It was created on 1 November 1956, with the passing of the States Reorganisation Act and this day is annually celebrated as Karnataka Rajyotsava...

, India has developed a low cost environment friendly milking machine which uses a 2-piston reciprocating pump operated manually for creating vacuum. Milk cows cannot tolerate delays in scheduled milking without serious milk production reductions.

Milking shed layouts

Bail-style sheds—This type of milking facility was the first development, after open-paddock milking, for many farmers. The building was a long, narrow, lean-to shed that was open along one long side. The cows were held in a yard at the open side and when they were about to be milked they were positioned in one of the bails (stalls). Usually the cows were restrained in the bail with a breech chain and a rope to restrain the outer back leg. The cow could not move about excessively and the milker could expect not to be kicked or trampled while sitting on a (three-legged) stool and milking into a bucket. When each cow was finished she backed out into the yard again. The UK bail, developed largely by Rex Patterson, was a six standing mobile shed with steps that the cow mounted, so the herdsman didn't have to bend so low. The milking equipment was much as today, a vacuum from a pump, pulsators, a claw-piece with pipes leading to the four shells and liners that stimulate and suck the milk from the teat. The milk went into churns, via a cooler.

As herd sizes increased a door was set into the front of each bail so that when the milking was done for any cow the milker could, after undoing the leg-rope and with a remote link, open the door and allow her to exit to the pasture. The door was closed, the next cow walked into the bail and was secured. When milking machines were introduced bails were set in pairs so that a cow was being milked in one paired bail while the other could be prepared for milking. When one was finished the machine's cups are swapped to the other cow. This is the same as for Swingover Milking Parlours as described below except that the cups are loaded on the udder from the side. As herd numbers increased it was easier to double-up the cup-sets and milk both cows simultaneously than to increase the number of bails. About 50 cows an hour can be milked in a shed with 8 bales by one person. Using the same teat cups for successive cows has the danger of transmitting infection, mastitis, from one cow to another. Some farmers have devised their own ways to disinfect the clusters between cows.

Herringbone Milking Parlours—

In herringbone milking sheds, or parlours, cows enter, in single file, and line up almost perpendicular to the central aisle of the milking parlour on both sides of a central pit in which the milker works (you can visualise a fishbone with the ribs representing the cows and the spine being the milker's working area; the cows face outward). After washing the udder and teats the cups of the milking machine are applied to the cows, from the rear of their hind legs, on both sides of the working area. Large herringbone sheds can milk up to 600 cows efficiently with two people.

Swingover Milking Parlours—

Swingover parlours are the same as herringbone parlours except they have only one set of milking cups to be shared between the two rows of cows, as one side is being milked the cows on the other side are moved out and replaced with unmilked ones. The advantage of this system is that it is less costly to equip, however it operates at slightly better than half-speed and one would not normally try to milk more than about 100 cows with one person.

Rotary milking sheds consist of a turntable with about 12 to 100 individual stalls for cows around the outer edge. A "good" rotary will be operated with 24–32 (~48–50+) stalls by one (two) milkers. The turntable is turned by an electric-motor drive at a rate that one turn is the time for a cow to be milked completely. As an empty stall passes the entrance a cow steps on, facing the centre, and rotates with the turntable. The next cow moves into the next vacant stall and so on. The operator, or milker, cleans the teats, attaches the cups and does any other feeding or whatever husbanding operations that are necessary. Cows are milked as the platform rotates. The milker, or an automatic device, removes the milking machine cups and the cow backs out and leaves at an exit just before the entrance. The rotary system is capable of milking very large herds—over a thousand cows.

Automatic Milking sheds—

Automatic milking

Automatic milking

Automatic milking is the milking of dairy animals, especially of dairy cattle, without human labour. Automatic milking systems , also called voluntary milking systems , were developed in the late 20th century. They are commercially available since the early 1990s...

or 'robotic milking' sheds can be seen in Australia

Australia

Australia , officially the Commonwealth of Australia, is a country in the Southern Hemisphere comprising the mainland of the Australian continent, the island of Tasmania, and numerous smaller islands in the Indian and Pacific Oceans. It is the world's sixth-largest country by total area...

, New Zealand and many European countries. Current automatic milking sheds use the voluntary milking (VM) method. These allow the cows to voluntarily present themselves for milking at any time of the day or night, although repeat visits may be limited by the farmer through computer software. A robot

Robot

A robot is a mechanical or virtual intelligent agent that can perform tasks automatically or with guidance, typically by remote control. In practice a robot is usually an electro-mechanical machine that is guided by computer and electronic programming. Robots can be autonomous, semi-autonomous or...

arm is used to clean teats and apply milking equipment, while automated gates direct cow traffic, eliminating the need for the farmer to be present during the process. The entire process is computer controlled.

Supplementary accessories in sheds—

Farmers soon realised that a milking shed was a good place to feed cows supplementary foods that overcame local dietary deficiencies or added to the cows' wellbeing and production. Each bail might have a box into which such feed is delivered as the cow arrives so that she is eating while being milked. A computer can read the eartag of each beast to ration the correct individual supplement. A close alternative is to use 'out-of-parlour-feeders', stalls that respond to a transponder around the cow's neck that is programmed to provide each cow with a supplementary feed, the quantity dependent on her production, stage in lactation, and the benefits of the main ration

The holding yard at the entrance of the shed is important as a means of keeping cows moving into the shed. Most yards have a powered gate that ensures that the cows are kept close to the shed.

Water

Water

Water is a chemical substance with the chemical formula H2O. A water molecule contains one oxygen and two hydrogen atoms connected by covalent bonds. Water is a liquid at ambient conditions, but it often co-exists on Earth with its solid state, ice, and gaseous state . Water also exists in a...

is a vital commodity on a dairy farm: cows drink about 20 gallons (80 litres) a day, sheds need water to cool and clean them. Pumps and reservoirs are common at milking facilities. Water can be warmed by heat transfer with milk.

Temporary milk storage

Milk coming from the cow is transported to a nearby storage vessel by the airflow leaking around the cups on the cow or by a special "air inlet" (5-10 l/min free air) in the claw. From there it is pumped by a mechanical pump and cooled by a heat exchangerHeat exchanger

A heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact...

. The milk is then stored in a large vat, or bulk tank

Bulk tank

In dairy farming a bulk milk cooling tank is a large storage tank for cooling and holding milk at a cold temperature until it can be picked up by a milk hauler....

, which is usually refrigerated until collection for processing.

Processing facilities

Topics:- PasteurizationPasteurizationPasteurization is a process of heating a food, usually liquid, to a specific temperature for a definite length of time, and then cooling it immediately. This process slows microbial growth in food...

, homogenizationHomogenization (chemistry)Homogenization or homogenisation is any of several processes used to make a chemical mixture the same throughout.-Definition:Homogenization is intensive blending of mutually related substances or groups of mutually related substances to form a constant of different insoluble phases to obtain a... - CreamCreamCream is a dairy product that is composed of the higher-butterfat layer skimmed from the top of milk before homogenization. In un-homogenized milk, over time, the lighter fat rises to the top. In the industrial production of cream this process is accelerated by using centrifuges called "separators"...

extraction - CheeseCheeseCheese is a generic term for a diverse group of milk-based food products. Cheese is produced throughout the world in wide-ranging flavors, textures, and forms....

making - ButterButterButter is a dairy product made by churning fresh or fermented cream or milk. It is generally used as a spread and a condiment, as well as in cooking applications, such as baking, sauce making, and pan frying...

making - CaseinCaseinCasein is the name for a family of related phosphoprotein proteins . These proteins are commonly found in mammalian milk, making up 80% of the proteins in cow milk and between 60% and 65% of the proteins in human milk....

making - Yogurt processing

Waste disposal

Irrigation

Irrigation may be defined as the science of artificial application of water to the land or soil. It is used to assist in the growing of agricultural crops, maintenance of landscapes, and revegetation of disturbed soils in dry areas and during periods of inadequate rainfall...

and fertilizer

Fertilizer

Fertilizer is any organic or inorganic material of natural or synthetic origin that is added to a soil to supply one or more plant nutrients essential to the growth of plants. A recent assessment found that about 40 to 60% of crop yields are attributable to commercial fertilizer use...

.

Surplus animals are slaughtered for processed meat

Meat

Meat is animal flesh that is used as food. Most often, this means the skeletal muscle and associated fat and other tissues, but it may also describe other edible tissues such as organs and offal...

and other rendered

Rendering (industrial)

Rendering is a process that converts waste animal tissue into stable, value-added materials. Rendering can refer to any processing of animal byproducts into more useful materials, or more narrowly to the rendering of whole animal fatty tissue into purified fats like lard or tallow...

products.

In the associated milk processing factories, most of the waste is washing water that is treated, usually by composting, and returned to waterways. This is much different from half a century ago, when the main products were butter, cheese and casein, and the rest of the milk had to be disposed of as waste (sometimes as animal feed).

In areas where cows are housed all year round, the waste problem is difficult because of the amount of feed that is brought in and the amount of bedding material that also has to be removed and composted. The size of the problem can be understood by standing downwind of the barns where such dairying goes on.

In many cases, modern farms have very large quantities of milk to be transported to a factory for processing. If anything goes wrong with the milking, transport or processing facilities it can be a major disaster trying to dispose of enormous quantities of milk. If a road tanker

Tank truck

A tank truck or road tanker is a motor vehicle designed to carry liquefied loads, dry bulk cargo or gases on roads. The largest such vehicles are similar to railroad tank cars which are also designed to carry liquefied loads...

overturns on a road, the rescue crew is looking at accommodating the spill of 5 to 10 thousand gallons of milk (20 to 45 thousand litres) without allowing any into the waterways. A derailed rail tanker-train

Tank car

A tank car is a type of railroad rolling stock designed to transport liquid and gaseous commodities.-Timeline:...

may involve 10 times that amount. Without refrigeration, milk is a fragile commodity, and it is very damaging to the environment in its raw state due to its high biochemical oxygen demand

Biochemical oxygen demand

Biochemical oxygen demand or B.O.D. is the amount of dissolved oxygen needed by aerobic biological organisms in a body of water to break down organic material present in a given water sample at certain temperature over a specific time period. The term also refers to a chemical procedure for...

. A widespread electrical power blackout

Power outage

A power outage is a short- or long-term loss of the electric power to an area.There are many causes of power failures in an electricity network...

is another disaster for the dairy industry, because both milking and processing facilities are affected. For this, farms may often use mobile generators. Such a situation occurred during the power outage caused by the 2010 Canterbury Earthquake

2010 Canterbury earthquake

The 2010 Canterbury earthquake was a 7.1 magnitude earthquake, which struck the South Island of New Zealand at 4:35 am on local time ....

.

In dairy-intensive areas, various methods have been proposed for disposing of large quantities of milk. These directives include feeding milk to livestock, spray irrigation or designating a sacrifice area. Large application rates of milk onto land, or disposing in a hole, is problematic as the residue from the decomposing milk will block the soil pores and thereby reduce the water infiltration rate through the soil profile. As recovery of this effect can take time, any land based application needs to be well managed and considered.

Associated diseases

- LeptospirosisLeptospirosisLeptospirosis is caused by infection with bacteria of the genus Leptospira, and affects humans as well as other mammals, birds, amphibians, and reptiles.The...

is one of the most common debilitating diseases of milkers, made somewhat worse since the introduction of herringbone sheds, because of unavoidable direct contact with bovine urine - CowpoxCowpoxCowpox is a skin disease caused by a virus known as the Cowpox virus. The pox is related to the vaccinia virus and got its name from the distribution of the disease when dairymaids touched the udders of infected cows. The ailment manifests itself in the form of red blisters and is transmitted by...

is one of the helpful diseases; it is barely harmful to humans and tends to inoculate them against other poxPoxA pox is a type of disease, often caused by an animal virus, characterised by pockmarks. The term may be used to refer to disease.Pox, as a disease, may refer to:*Poxviruses...

es such as small pox. - TuberculosisTuberculosisTuberculosis, MTB, or TB is a common, and in many cases lethal, infectious disease caused by various strains of mycobacteria, usually Mycobacterium tuberculosis. Tuberculosis usually attacks the lungs but can also affect other parts of the body...

(TB) is able to be transmitted from cattle mainly via milk products that are unpasteurisedPasteurizationPasteurization is a process of heating a food, usually liquid, to a specific temperature for a definite length of time, and then cooling it immediately. This process slows microbial growth in food...

. TB has been eradicated from many countries by testing for the disease and culling suspected animals. - BrucellosisBrucellosisBrucellosis, also called Bang's disease, Crimean fever, Gibraltar fever, Malta fever, Maltese fever, Mediterranean fever, rock fever, or undulant fever, is a highly contagious zoonosis caused by ingestion of unsterilized milk or meat from infected animals or close contact with their secretions...

is a bacterial disease transmitted to humans by dairy products and direct animal contact. Brucellosis has been eradicated from certain countries by testing for the disease and culling suspected animals - Listeria is a bacterial disease associated with unpasteurisedPasteurizationPasteurization is a process of heating a food, usually liquid, to a specific temperature for a definite length of time, and then cooling it immediately. This process slows microbial growth in food...

milk, and can affect some cheeses made in traditional ways. Careful observance of the traditional cheesemaking methods achieves reasonable protection for the consumer. - Johne's DiseaseJohne's diseaseParatuberculosis or Johne's disease is a contagious, chronic and sometimes fatal infection that primarily affects the small intestine of ruminants. It is caused by the bacterium Mycobacterium avium subspecies paratuberculosis...

is a contagious, chronic and sometimes fatal infection in ruminants caused by a bacterium named Mycobacterium avium subspecies paratuberculosisMycobacterium avium subspecies paratuberculosisMycobacterium avium subspecies paratuberculosis is an obligate pathogenic bacterium in the genus Mycobacterium. It is often abbreviated M. paratuberculosis or M. avium ssp. paratuberculosis. It is the causative agent of Johne's disease, which affects ruminants such as cattle, and also perhaps...

(M. paratuberculosis). The bacteria are present in retail milk, and are believed by some researchers to be the primary cause of Crohn's diseaseCrohn's diseaseCrohn's disease, also known as regional enteritis, is a type of inflammatory bowel disease that may affect any part of the gastrointestinal tract from mouth to anus, causing a wide variety of symptoms...

in humans. This disease is not known to infect animals in Australia and New Zealand.

External links

- Raising Dairy Calves

- Dairy Council of California

- National Dairy Council

- University of Guelph Dairy Science and Technology Education Series -- Online technical information about dairy products.

- Dairy Science and Food Technology: Starters, Probiotics, Cheese and Antimicrobial Systems

- Dairy Market review

- Dairy and the US Congress collection, Center for Digital Initiatives, University of Vermont Library