Etching (microfabrication)

Encyclopedia

Microfabrication

Microfabrication is the term that describes processes of fabrication of miniature structures, of micrometre sizes and smaller. Historically the earliest microfabrication processes were used for integrated circuit fabrication, also known as "semiconductor manufacturing" or "semiconductor device...

to chemically remove layers from the surface of a wafer

Wafer (electronics)

A wafer is a thin slice of semiconductor material, such as a silicon crystal, used in the fabrication of integrated circuits and other microdevices...

during manufacturing. Etching is a critically important process module, and every wafer undergoes many etching steps before it is complete.

For many etch steps, part of the wafer is protected from the etchant by a "masking" material which resists etching. In some cases, the masking material is a photoresist

Photoresist

A photoresist is a light-sensitive material used in several industrial processes, such as photolithography and photoengraving to form a patterned coating on a surface.-Tone:Photoresists are classified into two groups: positive resists and negative resists....

which has been patterned using photolithography

Photolithography

Photolithography is a process used in microfabrication to selectively remove parts of a thin film or the bulk of a substrate. It uses light to transfer a geometric pattern from a photomask to a light-sensitive chemical "photoresist", or simply "resist," on the substrate...

. Other situations require a more durable mask, such as silicon nitride

Silicon nitride

Silicon nitride is a chemical compound of silicon and nitrogen. If powdered silicon is heated between 1300° and 1400°C in an atmosphere of nitrogen, trisilicon tetranitride, Si3N4, is formed. The silicon sample weight increases progressively due to the chemical combination of silicon and nitrogen...

.

Figures of merit

If the etch is intended to make a cavity in a material, the depth of the cavity may be controlled approximately using the etching time and the known etch rate. More often, though, etching must entirely remove the top layer of a multilayer structure, without damaging the underlying or masking layers. The etching system's ability to do this depends on the ratio of etch rates in the two materials (selectivity).Some etches undercut

Undercut (manufacturing)

In manufacturing, an undercut is a special type of recessed surface. In turning it refers to a recess in a diameter. In machining it refers to a recess in a corner. In molding it refers to a feature that cannot be molded using only a single pull mold...

the masking layer and form cavities with sloping sidewalls. The distance of undercutting is called bias. Etchants with large bias are called isotropic, because they erode the substrate equally in all directions. Modern processes greatly prefer anisotropic etches, because they produce sharp, well-controlled features.

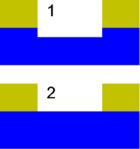

| Selectivity |  |

Yellow: layer to be removed; blue: layer to remain

|

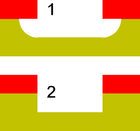

| Isotropy |  |

Red: masking layer; yellow: layer to be removed

|

Etching media and technology

The two fundamental types of etchants are liquidLiquid

Liquid is one of the three classical states of matter . Like a gas, a liquid is able to flow and take the shape of a container. Some liquids resist compression, while others can be compressed. Unlike a gas, a liquid does not disperse to fill every space of a container, and maintains a fairly...

-phase ("wet") and plasma

Plasma (physics)

In physics and chemistry, plasma is a state of matter similar to gas in which a certain portion of the particles are ionized. Heating a gas may ionize its molecules or atoms , thus turning it into a plasma, which contains charged particles: positive ions and negative electrons or ions...

-phase ("dry"). Each of these exists in several varieties.

Wet etching

The first etching processes used liquidLiquid

Liquid is one of the three classical states of matter . Like a gas, a liquid is able to flow and take the shape of a container. Some liquids resist compression, while others can be compressed. Unlike a gas, a liquid does not disperse to fill every space of a container, and maintains a fairly...

-phase ("wet") etchants. The wafer can be immersed in a bath of etchant, which must be agitated to achieve good process control. For instance, buffered hydrofluoric acid

Buffered oxide etch

Buffered oxide etch , also known as buffered HF or BHF, is a wet etchant used in microfabrication. Its primary use is in etching thin films of silicon dioxide or silicon nitride . It is a mixture of a buffering agent, such as ammonium fluoride , and hydrofluoric acid...

(BHF) is used commonly to etch silicon dioxide

Silicon dioxide

The chemical compound silicon dioxide, also known as silica , is an oxide of silicon with the chemical formula '. It has been known for its hardness since antiquity...

over a silicon

Silicon

Silicon is a chemical element with the symbol Si and atomic number 14. A tetravalent metalloid, it is less reactive than its chemical analog carbon, the nonmetal directly above it in the periodic table, but more reactive than germanium, the metalloid directly below it in the table...

substrate.

Different specialised etchants can be used to characterise the surface etched.

Wet etchants are usually isotropic, which leads to large bias when etching thick films. They also require the disposal of large amounts of toxic waste. For these reasons, they are seldom used in state-of-the-art processes. However, the photographic developer

Photographic developer

In the processing of photographic films, plates or papers, the photographic developer is a chemical that makes the latent image on the film or print visible. It does this by reducing the silver halides that have been exposed to light to elemental silver in the gelatine matrix...

used for photoresist

Photoresist

A photoresist is a light-sensitive material used in several industrial processes, such as photolithography and photoengraving to form a patterned coating on a surface.-Tone:Photoresists are classified into two groups: positive resists and negative resists....

resembles wet etching.

As an alternative to immersion, single wafer machines use the Bernoulli principle to employ a gas (usually, pure nitrogen

Nitrogen

Nitrogen is a chemical element that has the symbol N, atomic number of 7 and atomic mass 14.00674 u. Elemental nitrogen is a colorless, odorless, tasteless, and mostly inert diatomic gas at standard conditions, constituting 78.08% by volume of Earth's atmosphere...

) to cushion and protect one side of the wafer while etchant is applied to the other side. It can be done to either the front side or back side. The etch chemistry is dispensed on the top side when in the machine and the bottom side is not affected. This etch method is particularly effective just before "backend" processing (BEOL

BEOL

Back-end-of-line denotes the second portion of IC fabrication where the individual devices get interconnected with wiring on the wafer. BEOL generally begins when the first layer of metal is deposited on the wafer...

), where wafers are normally very much thinner after wafer backgrinding

Wafer backgrinding

Wafer backgrinding is a semiconductor device fabrication step during which wafer thickness is reduced to allow for stacking and high density packaging of integrated circuits ....

, and very sensitive to thermal or mechanical stress. Etching a thin layer of even a few micrometres will remove microcracks produced during backgrinding resulting in the wafer having dramatically increased strength and flexibility without breaking.

Anisotropic wet etching (Orientation dependent etching)

Some wet etchants etch crystalCrystal

A crystal or crystalline solid is a solid material whose constituent atoms, molecules, or ions are arranged in an orderly repeating pattern extending in all three spatial dimensions. The scientific study of crystals and crystal formation is known as crystallography...

line materials at very different rates depending upon which crystal face is exposed. In single-crystal materials (e.g. silicon wafers), this effect can allow very high anisotropy, as shown in the figure.

Several anisotropic wet etchants are available for silicon, all of them hot aqueous caustics. For instance, potassium hydroxide

Potassium hydroxide

Potassium hydroxide is an inorganic compound with the formula KOH, commonly called caustic potash.Along with sodium hydroxide , this colorless solid is a prototypical strong base. It has many industrial and niche applications. Most applications exploit its reactivity toward acids and its corrosive...

(KOH) displays an etch rate selectivity 400 times higher in <100> crystal directions than in <111> directions. EDP (an aqueous solution of ethylene diamine

Ethylene diamine

Ethylenediamine is the organic compound with the formula C2H42. This colorless liquid with an ammonia-like odor is a strongly basic amine. The liquid fumes upon contact with humid air...

and pyrocatechol

Pyrocatechol

Catechol, also known as pyrocatechol or 1,2-dihydroxybenzene, is an organic compound with the molecular formula C6H42. It is the ortho isomer of the three isomeric benzenediols. This colourless compound occurs naturally in trace amounts...

), displays a <100>/<111> selectivity of 17X, does not etch silicon dioxide as KOH does, and also displays high selectivity between lightly doped and heavily boron-doped (p-type) silicon. Use of these etchants on wafers that already contain CMOS

CMOS

Complementary metal–oxide–semiconductor is a technology for constructing integrated circuits. CMOS technology is used in microprocessors, microcontrollers, static RAM, and other digital logic circuits...

integrated circuit

Integrated circuit

An integrated circuit or monolithic integrated circuit is an electronic circuit manufactured by the patterned diffusion of trace elements into the surface of a thin substrate of semiconductor material...

s requires protecting the circuitry, for example using the Protek films recently introduced by Brewer Science. KOH may introduce mobile potassium

Potassium

Potassium is the chemical element with the symbol K and atomic number 19. Elemental potassium is a soft silvery-white alkali metal that oxidizes rapidly in air and is very reactive with water, generating sufficient heat to ignite the hydrogen emitted in the reaction.Potassium and sodium are...

ions into silicon dioxide

Silicon dioxide

The chemical compound silicon dioxide, also known as silica , is an oxide of silicon with the chemical formula '. It has been known for its hardness since antiquity...

, and EDP is highly corrosive

Corrosive

A corrosive substance is one that will destroy or irreversibly damage another surface or substance with which it comes into contact. The main hazards to people include damage to the eyes, the skin, and the tissue under the skin; inhalation or ingestion of a corrosive substance can damage the...

and carcinogenic, so care is required in their use. Tetramethylammonium hydroxide

Tetramethylammonium hydroxide

Tetramethylammonium hydroxide is a quaternary ammonium salt with the molecular formula 4NOH. It is used as an anisotropic etchant of silicon. It is also used as a basic solvent in the development of acidic photoresist in the photolithography process. Since it is a phase transfer catalyst, it is...

(TMAH) presents a safer alternative than EDP, with a 37X selectivity between <100> and <111> planes in silicon.

Etching a (100) silicon surface through a rectangular hole in a masking material, for example a hole in a layer of silicon nitride, creates a pit with flat sloping <111>-oriented sidewalls and a flat <100>-oriented bottom. The <111>-oriented sidewalls have an angle to the surface of the wafer of:

If the etching is continued "to completion", i.e. until the flat bottom disappears, the pit becomes a trench with a V-shaped cross section. If the original rectangle was a perfect square, the pit when etched to completion displays a pyramidal shape.

The undercut, δ, under an edge of the masking material is given by:

-

,

,

where Rxxx is the etch rate in the

Different etchants have different anisotropies. Below is a table of common anisotropic etchants for silicon:

| Etchant | Operating temp (°C) | R100 (μm/min) | S=R100/R111 | Mask materials |

|---|---|---|---|---|

| Ethylenediamine pyrocatechol Ethylenediamine pyrocatechol Ethylenediamine pyrocatechol , also known as ethylenediamine-pyrocatechol-water , is an anisotropic etchant solution for silicon. A typical formulation consists of ethylenediamine, pyrocatechol, pyrazine and water. It is carcinogenic and very corrosive... (EDP) |

110 | 0.47 | 17 | SiO2 Silicon dioxide The chemical compound silicon dioxide, also known as silica , is an oxide of silicon with the chemical formula '. It has been known for its hardness since antiquity... , Si3N4 Silicon nitride Silicon nitride is a chemical compound of silicon and nitrogen. If powdered silicon is heated between 1300° and 1400°C in an atmosphere of nitrogen, trisilicon tetranitride, Si3N4, is formed. The silicon sample weight increases progressively due to the chemical combination of silicon and nitrogen... , Au Gold Gold is a chemical element with the symbol Au and an atomic number of 79. Gold is a dense, soft, shiny, malleable and ductile metal. Pure gold has a bright yellow color and luster traditionally considered attractive, which it maintains without oxidizing in air or water. Chemically, gold is a... , Cr Chromium Chromium is a chemical element which has the symbol Cr and atomic number 24. It is the first element in Group 6. It is a steely-gray, lustrous, hard metal that takes a high polish and has a high melting point. It is also odorless, tasteless, and malleable... , Ag Silver Silver is a metallic chemical element with the chemical symbol Ag and atomic number 47. A soft, white, lustrous transition metal, it has the highest electrical conductivity of any element and the highest thermal conductivity of any metal... , Cu Copper Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish... |

| Potassium hydroxide Potassium hydroxide Potassium hydroxide is an inorganic compound with the formula KOH, commonly called caustic potash.Along with sodium hydroxide , this colorless solid is a prototypical strong base. It has many industrial and niche applications. Most applications exploit its reactivity toward acids and its corrosive... /Isopropyl alcohol Isopropyl alcohol Isopropyl alcohol is a common name for a chemical compound with the molecular formula C3H8O. It is a colorless, flammable chemical compound with a strong odor... (KOH/IPA) |

50 | 1.0 | 400 | Si3N4, SiO2 (etches at 2.8nm/min) |

| Tetramethylammonium hydroxide Tetramethylammonium hydroxide Tetramethylammonium hydroxide is a quaternary ammonium salt with the molecular formula 4NOH. It is used as an anisotropic etchant of silicon. It is also used as a basic solvent in the development of acidic photoresist in the photolithography process. Since it is a phase transfer catalyst, it is... (TMAH) |

80 | 0.6 | 37 | Si3N4, SiO2 |

Plasma etching

Modern VLSIVery-large-scale integration

Very-large-scale integration is the process of creating integrated circuits by combining thousands of transistors into a single chip. VLSI began in the 1970s when complex semiconductor and communication technologies were being developed. The microprocessor is a VLSI device.The first semiconductor...

processes avoid wet etching, and use plasma etching

Plasma etching

Plasma etching is a form of plasma processing used to fabricate integrated circuits. It involves a high-speed stream of glow discharge of an appropriate gas mixture being shot at a sample. The plasma source, known as etch species, can be either charged or neutral...

instead. Plasma etcher

Plasma etcher

A plasma etcher, or etching tool, is a tool used in the production of semiconductor devices. Plasma etcher produces a plasma from a process gas, typically oxygen or a fluorine bearing gas, using a high frequency electric field, typically 13.56 MHz. A silicon wafer is placed in the plasma etcher,...

s can operate in several modes by adjusting the parameters of the plasma. Ordinary plasma etching operates between 0.1 and 5 Torr

Torr

The torr is a non-SI unit of pressure with the ratio of 760 to 1 standard atmosphere, chosen to be roughly equal to the fluid pressure exerted by a millimetre of mercury, i.e., a pressure of 1 torr is approximately equal to 1 mmHg...

. (This unit of pressure, commonly used in vacuum engineering, equals approximately 133.3 pascal

Pascal (unit)

The pascal is the SI derived unit of pressure, internal pressure, stress, Young's modulus and tensile strength, named after the French mathematician, physicist, inventor, writer, and philosopher Blaise Pascal. It is a measure of force per unit area, defined as one newton per square metre...

s.) The plasma produces energetic free radicals, neutrally charge

Electric charge

Electric charge is a physical property of matter that causes it to experience a force when near other electrically charged matter. Electric charge comes in two types, called positive and negative. Two positively charged substances, or objects, experience a mutual repulsive force, as do two...

d, that react at the surface of the wafer. Since neutral particles attack the wafer from all angles, this process is isotropic.

Plasma etching can be isotropic, i.e., exhibiting a lateral undercut rate on a patterned surface approximately the same as its downward etch rate, or can be anisotropic, i.e., exhibiting a smaller lateral undercut rate than its downward etch rate. Such anisotropy is maximized in deep reactive ion etching

Deep reactive ion etching

Deep reactive-ion etching is a highly anisotropic etch process used to create deep penetration, steep-sided holes and trenches in wafers/substrates, typically with high aspect ratios...

. The use of the term anisotropy for plasma etching should not be conflated with the use of the same term when referring to orientation-dependent etching.

The source gas for the plasma usually contains small molecules rich in chlorine

Chlorine

Chlorine is the chemical element with atomic number 17 and symbol Cl. It is the second lightest halogen, found in the periodic table in group 17. The element forms diatomic molecules under standard conditions, called dichlorine...

or fluorine

Fluorine

Fluorine is the chemical element with atomic number 9, represented by the symbol F. It is the lightest element of the halogen column of the periodic table and has a single stable isotope, fluorine-19. At standard pressure and temperature, fluorine is a pale yellow gas composed of diatomic...

. For instance, carbon tetrachloride

Carbon tetrachloride

Carbon tetrachloride, also known by many other names is the organic compound with the formula CCl4. It was formerly widely used in fire extinguishers, as a precursor to refrigerants, and as a cleaning agent...

(CCl4) etches silicon and aluminium

Aluminium

Aluminium or aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances....

, and trifluoromethane etches silicon dioxide

Silicon dioxide

The chemical compound silicon dioxide, also known as silica , is an oxide of silicon with the chemical formula '. It has been known for its hardness since antiquity...

and silicon nitride

Silicon nitride

Silicon nitride is a chemical compound of silicon and nitrogen. If powdered silicon is heated between 1300° and 1400°C in an atmosphere of nitrogen, trisilicon tetranitride, Si3N4, is formed. The silicon sample weight increases progressively due to the chemical combination of silicon and nitrogen...

. A plasma containing oxygen

Oxygen

Oxygen is the element with atomic number 8 and represented by the symbol O. Its name derives from the Greek roots ὀξύς and -γενής , because at the time of naming, it was mistakenly thought that all acids required oxygen in their composition...

is used to oxidize ("ash

Plasma ashing

In semiconductor manufacturing plasma ashing is the process of removing the photoresist from an etched wafer. Using a plasma source, a monatomic reactive species is generated. Oxygen or fluorine are the most common reactive species...

") photoresist and facilitate its removal.

Ion milling, or sputter etching, uses lower pressures, often as low as 10-4 Torr (10 mPa). It bombards the wafer with energetic ions of noble gas

Noble gas

The noble gases are a group of chemical elements with very similar properties: under standard conditions, they are all odorless, colorless, monatomic gases, with very low chemical reactivity...

es, often Ar

Argon

Argon is a chemical element represented by the symbol Ar. Argon has atomic number 18 and is the third element in group 18 of the periodic table . Argon is the third most common gas in the Earth's atmosphere, at 0.93%, making it more common than carbon dioxide...

+, which knock atoms from the substrate by transferring momentum

Momentum

In classical mechanics, linear momentum or translational momentum is the product of the mass and velocity of an object...

. Because the etching is performed by ions, which approach the wafer approximately from one direction, this process is highly anisotropic. On the other hand, it tends to display poor selectivity. Reactive-ion etching (RIE) operates under conditions intermediate between sputter and plasma etching (between 10-3 and 10-1 Torr). Deep reactive-ion etching (DRIE) modifies the RIE technique to produce deep, narrow features.

Common etch processes used in microfabrication

| Material to be etched | Wet etchants | Plasma etchants |

|---|---|---|

| Aluminium Aluminium Aluminium or aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances.... (Al) |

80% phosphoric acid Phosphoric acid Phosphoric acid, also known as orthophosphoric acid or phosphoric acid, is a mineral acid having the chemical formula H3PO4. Orthophosphoric acid molecules can combine with themselves to form a variety of compounds which are also referred to as phosphoric acids, but in a more general way... (H3PO4) + 5% acetic acid Acetic acid Acetic acid is an organic compound with the chemical formula CH3CO2H . It is a colourless liquid that when undiluted is also called glacial acetic acid. Acetic acid is the main component of vinegar , and has a distinctive sour taste and pungent smell... + 5% nitric acid Nitric acid Nitric acid , also known as aqua fortis and spirit of nitre, is a highly corrosive and toxic strong acid.Colorless when pure, older samples tend to acquire a yellow cast due to the accumulation of oxides of nitrogen. If the solution contains more than 86% nitric acid, it is referred to as fuming... (HNO3) + 10% water (H2O) at 35–45 °C |

Cl2 Chlorine Chlorine is the chemical element with atomic number 17 and symbol Cl. It is the second lightest halogen, found in the periodic table in group 17. The element forms diatomic molecules under standard conditions, called dichlorine... , CCl4 Carbon tetrachloride Carbon tetrachloride, also known by many other names is the organic compound with the formula CCl4. It was formerly widely used in fire extinguishers, as a precursor to refrigerants, and as a cleaning agent... , SiCl4 Silicon tetrachloride Silicon tetrachloride is the inorganic compound with the formula SiCl4. It is a colourless volatile liquid that fumes in air. It is used to produce high purity silicon and silica for commercial applications.-Preparation:... , BCl3 Boron trichloride Boron trichloride is a chemical compound with the formula BCl3. This colorless gas is a valuable reagent in organic synthesis. It is also dangerously reactive.-Production and properties:Boron reacts with halogens to give the corresponding trihalides... |

| Indium tin oxide Indium tin oxide Indium tin oxide is a solid solution of indium oxide and tin oxide , typically 90% In2O3, 10% SnO2 by weight. It is transparent and colorless in thin layers while in bulk form it is yellowish to grey... [ITO] (In2O3:SnO2) |

Hydrochloric acid Hydrochloric acid Hydrochloric acid is a solution of hydrogen chloride in water, that is a highly corrosive, strong mineral acid with many industrial uses. It is found naturally in gastric acid.... (HCl) + nitric acid (HNO3) + water (H2O) (1:0.1:1) at 40 °C |

|

| Chromium Chromium Chromium is a chemical element which has the symbol Cr and atomic number 24. It is the first element in Group 6. It is a steely-gray, lustrous, hard metal that takes a high polish and has a high melting point. It is also odorless, tasteless, and malleable... (Cr) |

|

|

|

Gallium Arsenide (GaAs) |

|

Carbon tetrachloride Carbon tetrachloride, also known by many other names is the organic compound with the formula CCl4. It was formerly widely used in fire extinguishers, as a precursor to refrigerants, and as a cleaning agent... , SiCl4 Silicon tetrachloride Silicon tetrachloride is the inorganic compound with the formula SiCl4. It is a colourless volatile liquid that fumes in air. It is used to produce high purity silicon and silica for commercial applications.-Preparation:... , BCl3 Boron trichloride Boron trichloride is a chemical compound with the formula BCl3. This colorless gas is a valuable reagent in organic synthesis. It is also dangerously reactive.-Production and properties:Boron reacts with halogens to give the corresponding trihalides... , CCl2F2 Dichlorodifluoromethane Dichlorodifluoromethane , is a colorless gas, and usually sold under the brand name Freon-12, is a chlorofluorocarbon halomethane , used as a refrigerant and aerosol spray propellant. Complying with the Montreal Protocol, its manufacture was banned in the United States along with many other... |

| Gold Gold Gold is a chemical element with the symbol Au and an atomic number of 79. Gold is a dense, soft, shiny, malleable and ductile metal. Pure gold has a bright yellow color and luster traditionally considered attractive, which it maintains without oxidizing in air or water. Chemically, gold is a... (Au) |

Aqua regia Aqua regia Aqua regia or aqua regis is a highly corrosive mixture of acids, fuming yellow or red solution, also called nitro-hydrochloric acid. The mixture is formed by freshly mixing concentrated nitric acid and hydrochloric acid, usually in a volume ratio of 1:3, respectively... |

|

| Molybdenum Molybdenum Molybdenum , is a Group 6 chemical element with the symbol Mo and atomic number 42. The name is from Neo-Latin Molybdaenum, from Ancient Greek , meaning lead, itself proposed as a loanword from Anatolian Luvian and Lydian languages, since its ores were confused with lead ores... (Mo) |

CF4 Tetrafluoromethane Tetrafluoromethane, also known as carbon tetrafluoride, is the simplest fluorocarbon . It has a very high bond strength due to the nature of the carbon–fluorine bond. It can also be classified as a haloalkane or halomethane... |

|

| Organic residues and photoresist | Piranha etch: sulfuric acid Sulfuric acid Sulfuric acid is a strong mineral acid with the molecular formula . Its historical name is oil of vitriol. Pure sulfuric acid is a highly corrosive, colorless, viscous liquid. The salts of sulfuric acid are called sulfates... (H2SO4) + hydrogen peroxide Hydrogen peroxide Hydrogen peroxide is the simplest peroxide and an oxidizer. Hydrogen peroxide is a clear liquid, slightly more viscous than water. In dilute solution, it appears colorless. With its oxidizing properties, hydrogen peroxide is often used as a bleach or cleaning agent... (H2O2) |

O2 Oxygen Oxygen is the element with atomic number 8 and represented by the symbol O. Its name derives from the Greek roots ὀξύς and -γενής , because at the time of naming, it was mistakenly thought that all acids required oxygen in their composition... (ashing Plasma ashing In semiconductor manufacturing plasma ashing is the process of removing the photoresist from an etched wafer. Using a plasma source, a monatomic reactive species is generated. Oxygen or fluorine are the most common reactive species... ) |

| Platinum Platinum Platinum is a chemical element with the chemical symbol Pt and an atomic number of 78. Its name is derived from the Spanish term platina del Pinto, which is literally translated into "little silver of the Pinto River." It is a dense, malleable, ductile, precious, gray-white transition metal... (Pt) |

Aqua regia | |

| Silicon Silicon Silicon is a chemical element with the symbol Si and atomic number 14. A tetravalent metalloid, it is less reactive than its chemical analog carbon, the nonmetal directly above it in the periodic table, but more reactive than germanium, the metalloid directly below it in the table... (Si) |

Nitric acid (HNO3) + hydrofluoric acid Hydrofluoric acid Hydrofluoric acid is a solution of hydrogen fluoride in water. It is a valued source of fluorine and is the precursor to numerous pharmaceuticals such as fluoxetine and diverse materials such as PTFE .... (HF) |

Sulfur hexafluoride Sulfur hexafluoride is an inorganic, colorless, odorless, and non-flammable greenhouse gas. has an octahedral geometry, consisting of six fluorine atoms attached to a central sulfur atom. It is a hypervalent molecule. Typical for a nonpolar gas, it is poorly soluble in water but soluble in... , NF3 Nitrogen trifluoride Nitrogen trifluoride is the inorganic compound with the formula NF3. This nitrogen-fluorine compound is a colorless, toxic, odourless, nonflammable gas. It finds increasing use as an etchant in microelectronics.-Applications:... Dichlorodifluoromethane Dichlorodifluoromethane , is a colorless gas, and usually sold under the brand name Freon-12, is a chlorofluorocarbon halomethane , used as a refrigerant and aerosol spray propellant. Complying with the Montreal Protocol, its manufacture was banned in the United States along with many other... |

| Silicon dioxide Silicon dioxide The chemical compound silicon dioxide, also known as silica , is an oxide of silicon with the chemical formula '. It has been known for its hardness since antiquity... (SiO2) |

Buffered oxide etch Buffered oxide etch , also known as buffered HF or BHF, is a wet etchant used in microfabrication. Its primary use is in etching thin films of silicon dioxide or silicon nitride . It is a mixture of a buffering agent, such as ammonium fluoride , and hydrofluoric acid... [BOE]: ammonium fluoride Ammonium fluoride Ammonium fluoride is the inorganic compound with the formula NH4F. It crystallizes as small colourless prisms, having a sharp saline taste, and is exceedingly soluble in water.-Crystal structure:... (NH4F) and hydrofluoric acid Hydrofluoric acid Hydrofluoric acid is a solution of hydrogen fluoride in water. It is a valued source of fluorine and is the precursor to numerous pharmaceuticals such as fluoxetine and diverse materials such as PTFE .... (HF) |

CF4, SF6, NF3 |

| Silicon nitride Silicon nitride Silicon nitride is a chemical compound of silicon and nitrogen. If powdered silicon is heated between 1300° and 1400°C in an atmosphere of nitrogen, trisilicon tetranitride, Si3N4, is formed. The silicon sample weight increases progressively due to the chemical combination of silicon and nitrogen... (Si3N4) |

|

CF4, SF6, NF3 |

| Tantalum Tantalum Tantalum is a chemical element with the symbol Ta and atomic number 73. Previously known as tantalium, the name comes from Tantalus, a character in Greek mythology. Tantalum is a rare, hard, blue-gray, lustrous transition metal that is highly corrosion resistant. It is part of the refractory... (Ta) |

CF4 | |

| Titanium Titanium Titanium is a chemical element with the symbol Ti and atomic number 22. It has a low density and is a strong, lustrous, corrosion-resistant transition metal with a silver color.... (Ti) |

Hydrofluoric acid (HF) | BCl3 |

| Titanium nitride Titanium nitride Titanium nitride is an extremely hard ceramic material, often used as a coating on titanium alloys, steel, carbide, and aluminium components to improve the substrate's surface properties.... (TiN) |

|

|

| Tungsten Tungsten Tungsten , also known as wolfram , is a chemical element with the chemical symbol W and atomic number 74.A hard, rare metal under standard conditions when uncombined, tungsten is found naturally on Earth only in chemical compounds. It was identified as a new element in 1781, and first isolated as... (W) |

|

Tetrafluoromethane Tetrafluoromethane, also known as carbon tetrafluoride, is the simplest fluorocarbon . It has a very high bond strength due to the nature of the carbon–fluorine bond. It can also be classified as a haloalkane or halomethane... Sulfur hexafluoride Sulfur hexafluoride is an inorganic, colorless, odorless, and non-flammable greenhouse gas. has an octahedral geometry, consisting of six fluorine atoms attached to a central sulfur atom. It is a hypervalent molecule. Typical for a nonpolar gas, it is poorly soluble in water but soluble in... |