Fractography

Encyclopedia

Fractography is the study of fracture surfaces of materials. Fractographic methods are routinely used to determine the cause of failure in engineering structures, especially in product failure and the practice of forensic engineering

or failure analysis

. In material science research, fractography is used to develop and evaluate theoretical models of crack growth behavior.

One of the aims of fractographic examination is to determine the cause of failure by studying the characteristics of a fracture surface. Different types of crack growth (e.g. fatigue

, stress corrosion cracking

, hydrogen embrittlement

) produce characteristic features on the surface, which can be used to help identify the failure mode. The overall pattern of cracking can be more important than a single crack, however, especially in the case of brittle materials like ceramic

s and glass

es.

An important aim of fractography is to establish and examine the origin of cracking, as examination at the origin may reveal the cause of crack initiation. Initial fractographic examination is commonly carried out on a macro scale utilising low power optical microscopy and oblique lighting techniques to identify the extent of cracking, possible modes and likely origins. Optical microscopy or macrophotography are often enough to pinpoint the nature of the failure and the causes of crack initiation and growth if the loading pattern is known.

An important aim of fractography is to establish and examine the origin of cracking, as examination at the origin may reveal the cause of crack initiation. Initial fractographic examination is commonly carried out on a macro scale utilising low power optical microscopy and oblique lighting techniques to identify the extent of cracking, possible modes and likely origins. Optical microscopy or macrophotography are often enough to pinpoint the nature of the failure and the causes of crack initiation and growth if the loading pattern is known.

Common features that may cause crack initiation are inclusion

s, void

s or empty holes in the material, contamination

, and stress concentration

s. "Hachures", are the lines on fracture surfaces which show crack direction. The broken crankshaft shown at right failed from a surface defect near the bulb at lower centre, the single brittle crack growing up into the bulk material by small steps, a problem known as fatigue

. The crankshaft also shows hachures which point back to the origin of the fracture. Some modes of crack growth can leave characteristic marks on the surface that identify the mode of crack growth and origin on a macro scale e.g. beachmarks or striation

s on fatigue cracks. The areas of the product can also be very revealing, especially if there are traces of sub-critical cracks, or cracks which have not grown to completion. They can indicate that the material was faulty when loaded, or alternatively, that the sample was overloaded at the time of failure.

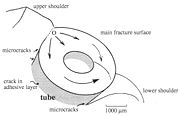

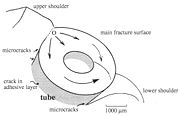

A Cusp (singularity)

A Cusp (singularity)

is formed where brittle cracks meet, as shown on the picture of a failed catheter (Cp). The cusp was formed by brittle failure of the catheter

on a breast implant in silicone rubber

. The origin of the cracks is at the shoulder at the left-hand side. Identifying such features will allow a fracture surface map to be made of the surface being studied. The implant failed because of overload, all the imposed loads being concentrated at the connection between the catheter and the bag holding salt solution. As a result, the patient reported loss of fluid from the implant, and it was extracted surgically and replaced.

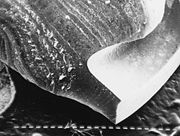

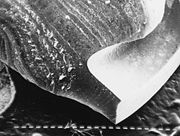

A schematic fracture surface map is a valuable result of visual or microscopic examination. It seeks to isolate and identify the features on the surface which show how the product failed. Such a map can be a valuable way of presenting information which shows clearly how a crack was initiated and grew with time. In the case of the failed breast implant, the crack path was very simple, but the cause more subtle. Further scanning electron microscopy showed numerous microcracks between the bag and the catheter, indicating that the adhesive bond between the two components had failed prematurely, perhaps through faulty manufacture. The material of construction of both bag and catheter, silicone rubber is a physically weak elastomer, and product design must allow for the low tear or shear strength

A schematic fracture surface map is a valuable result of visual or microscopic examination. It seeks to isolate and identify the features on the surface which show how the product failed. Such a map can be a valuable way of presenting information which shows clearly how a crack was initiated and grew with time. In the case of the failed breast implant, the crack path was very simple, but the cause more subtle. Further scanning electron microscopy showed numerous microcracks between the bag and the catheter, indicating that the adhesive bond between the two components had failed prematurely, perhaps through faulty manufacture. The material of construction of both bag and catheter, silicone rubber is a physically weak elastomer, and product design must allow for the low tear or shear strength

of the material.

or SEM. The resolution is much higher than the optical microscope, although samples are examined in a partial vacuum and colour is absent. Improved SEM's now allow examination at near atmospheric pressures, so allowing examination of sensitive materials such as those of biological origin.

The SEM is especially useful when combined with Energy dispersive X-ray spectroscopy or EDX, which can be performed in the microscope, so very small areas of the sample can be analysed for their elemental composition.

The fracture surface photograph shows a brittle fracture in a car brake seal. Crack growth can be seen from the fine lines or striations in the surface, indicative of fatigue

The fracture surface photograph shows a brittle fracture in a car brake seal. Crack growth can be seen from the fine lines or striations in the surface, indicative of fatigue

. The problem led to an accident when the crack suddenly grew to completion, hydraulic fluid was lost, the driver lost braking power, and the vehicle crashed. The crack grew from cuts at the edge of the seal, probably caused by sharp particles trapped in the brake cylinder.

, forensic materials engineering

and fracture mechanics

to understand the causes of failures and also to verify theoretical failure predictions with real life failures. It is of use in forensic science for analysing broken products which have been used as weapons, such as broken bottles for example. Thus a defendant might claim that a bottle was faulty and broke accidentally when it impacted a victim of an assault. Fractography could show the allegation to be false, and that considerable force was needed to smash the bottle before using the broken end as a weapon to deliberately attack the victim. Bullet

holes in glass windscreens or windows can also indicate the direction of impact and the energy of the projectile. In these cases, the overall pattern of cracking is vital to reconstructing the sequence of events, rather than the specific characteristics of a single crack. Fractography can determine whether a cause of train derailment was a faulty rail, or if a wing of a plane had fatigue cracks before a crash.

Forensic engineering

Forensic engineering is the investigation of materials, products, structures or components that fail or do not operate or function as intended, causing personal injury or damage to property. The consequences of failure are dealt with by the law of product liability. The field also deals with...

or failure analysis

Failure analysis

Failure analysis is the process of collecting and analyzing data to determine the cause of a failure. It is an important discipline in many branches of manufacturing industry, such as the electronics industry, where it is a vital tool used in the development of new products and for the improvement...

. In material science research, fractography is used to develop and evaluate theoretical models of crack growth behavior.

One of the aims of fractographic examination is to determine the cause of failure by studying the characteristics of a fracture surface. Different types of crack growth (e.g. fatigue

Fatigue (material)

'In materials science, fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. The nominal maximum stress values are less than the ultimate tensile stress limit, and may be below the yield stress limit of the material.Fatigue occurs...

, stress corrosion cracking

Stress corrosion cracking

Stress corrosion cracking is the unexpected sudden failure of normally ductile metals subjected to a tensile stress in a corrosive environment, especially at elevated temperature in the case of metals. SCC is highly chemically specific in that certain alloys are likely to undergo SCC only when...

, hydrogen embrittlement

Hydrogen embrittlement

Hydrogen embrittlement is the process by which various metals, most importantly high-strength steel, become brittle and fracture following exposure to hydrogen...

) produce characteristic features on the surface, which can be used to help identify the failure mode. The overall pattern of cracking can be more important than a single crack, however, especially in the case of brittle materials like ceramic

Ceramic

A ceramic is an inorganic, nonmetallic solid prepared by the action of heat and subsequent cooling. Ceramic materials may have a crystalline or partly crystalline structure, or may be amorphous...

s and glass

Glass

Glass is an amorphous solid material. Glasses are typically brittle and optically transparent.The most familiar type of glass, used for centuries in windows and drinking vessels, is soda-lime glass, composed of about 75% silica plus Na2O, CaO, and several minor additives...

es.

Methods

Common features that may cause crack initiation are inclusion

Inclusion

Inclusion may refer to:- Metallurgy :*Inclusion , a type of metal casting defect*Inclusions in Aluminium Alloys, solid particles in liquid aluminium alloy- Social inclusion of persons :...

s, void

Void

-In science and engineering:*Void , the empty spaces between galaxy filaments*Lack of matter, or vacuum*Void, in boiling heat transfer, formed where there is a departure from nucleate boiling, causing a critical heat flux...

s or empty holes in the material, contamination

Contamination

Contamination is the presence of a minor and unwanted constituent in material, physical body, natural environment, at a workplace, etc.-Specifics:"Contamination" also has more specific meanings in science:...

, and stress concentration

Stress concentration

A stress concentration is a location in an object where stress is concentrated. An object is strongest when force is evenly distributed over its area, so a reduction in area, e.g. caused by a crack, results in a localized increase in stress...

s. "Hachures", are the lines on fracture surfaces which show crack direction. The broken crankshaft shown at right failed from a surface defect near the bulb at lower centre, the single brittle crack growing up into the bulk material by small steps, a problem known as fatigue

Fatigue (material)

'In materials science, fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. The nominal maximum stress values are less than the ultimate tensile stress limit, and may be below the yield stress limit of the material.Fatigue occurs...

. The crankshaft also shows hachures which point back to the origin of the fracture. Some modes of crack growth can leave characteristic marks on the surface that identify the mode of crack growth and origin on a macro scale e.g. beachmarks or striation

Striation

Striations means a series of ridges, furrows or linear marks, and are used in several ways* Glacial striation* Striation , a striation as a result of a geological fault* In medicine, striated muscle...

s on fatigue cracks. The areas of the product can also be very revealing, especially if there are traces of sub-critical cracks, or cracks which have not grown to completion. They can indicate that the material was faulty when loaded, or alternatively, that the sample was overloaded at the time of failure.

Cusp (singularity)

In the mathematical theory of singularities a cusp is a type of singular point of a curve. Cusps are local singularities in that they are not formed by self intersection points of the curve....

is formed where brittle cracks meet, as shown on the picture of a failed catheter (Cp). The cusp was formed by brittle failure of the catheter

Catheter

In medicine, a catheter is a tube that can be inserted into a body cavity, duct, or vessel. Catheters thereby allow drainage, administration of fluids or gases, or access by surgical instruments. The process of inserting a catheter is catheterization...

on a breast implant in silicone rubber

Silicone rubber

Silicone rubber is an elastomer composed of silicone—itself a polymer—containing silicon together with carbon, hydrogen, and oxygen. Silicone rubbers are widely used in industry, and there are multiple formulations...

. The origin of the cracks is at the shoulder at the left-hand side. Identifying such features will allow a fracture surface map to be made of the surface being studied. The implant failed because of overload, all the imposed loads being concentrated at the connection between the catheter and the bag holding salt solution. As a result, the patient reported loss of fluid from the implant, and it was extracted surgically and replaced.

Fracture surface map

Shear strength

Shear strength in engineering is a term used to describe the strength of a material or component against the type of yield or structural failure where the material or component fails in shear. A shear load is a force that tends to produce a sliding failure on a material along a plane that is...

of the material.

Scanning electron microscopy

In many cases, fractography requires examination at a finer scale, which is usually carried out in a Scanning electron microscopeScanning electron microscope

A scanning electron microscope is a type of electron microscope that images a sample by scanning it with a high-energy beam of electrons in a raster scan pattern...

or SEM. The resolution is much higher than the optical microscope, although samples are examined in a partial vacuum and colour is absent. Improved SEM's now allow examination at near atmospheric pressures, so allowing examination of sensitive materials such as those of biological origin.

The SEM is especially useful when combined with Energy dispersive X-ray spectroscopy or EDX, which can be performed in the microscope, so very small areas of the sample can be analysed for their elemental composition.

Fatigue (material)

'In materials science, fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. The nominal maximum stress values are less than the ultimate tensile stress limit, and may be below the yield stress limit of the material.Fatigue occurs...

. The problem led to an accident when the crack suddenly grew to completion, hydraulic fluid was lost, the driver lost braking power, and the vehicle crashed. The crack grew from cuts at the edge of the seal, probably caused by sharp particles trapped in the brake cylinder.

Applications

Fractography is a widely used technique in forensic engineeringForensic engineering

Forensic engineering is the investigation of materials, products, structures or components that fail or do not operate or function as intended, causing personal injury or damage to property. The consequences of failure are dealt with by the law of product liability. The field also deals with...

, forensic materials engineering

Forensic materials engineering

A branch of Forensic engineering, the subject focuses on the material evidence from crime or accident scenes, seeking defects in those materials which might explain why an accident occurred, or the source of a specific material to identify a criminal...

and fracture mechanics

Fracture mechanics

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics to characterize the material's resistance to fracture.In...

to understand the causes of failures and also to verify theoretical failure predictions with real life failures. It is of use in forensic science for analysing broken products which have been used as weapons, such as broken bottles for example. Thus a defendant might claim that a bottle was faulty and broke accidentally when it impacted a victim of an assault. Fractography could show the allegation to be false, and that considerable force was needed to smash the bottle before using the broken end as a weapon to deliberately attack the victim. Bullet

Bullet

A bullet is a projectile propelled by a firearm, sling, or air gun. Bullets do not normally contain explosives, but damage the intended target by impact and penetration...

holes in glass windscreens or windows can also indicate the direction of impact and the energy of the projectile. In these cases, the overall pattern of cracking is vital to reconstructing the sequence of events, rather than the specific characteristics of a single crack. Fractography can determine whether a cause of train derailment was a faulty rail, or if a wing of a plane had fatigue cracks before a crash.

See also

- Conchoidal fractureConchoidal fractureConchoidal fracture describes the way that brittle materials break when they do not follow any natural planes of separation. Materials that break in this way include flint and other fine-grained minerals, as well as most amorphous solids, such as obsidian and other types of glass.Conchoidal...

- Fatigue (material)Fatigue (material)'In materials science, fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. The nominal maximum stress values are less than the ultimate tensile stress limit, and may be below the yield stress limit of the material.Fatigue occurs...

- Failure analysisFailure analysisFailure analysis is the process of collecting and analyzing data to determine the cause of a failure. It is an important discipline in many branches of manufacturing industry, such as the electronics industry, where it is a vital tool used in the development of new products and for the improvement...

- Forensic engineeringForensic engineeringForensic engineering is the investigation of materials, products, structures or components that fail or do not operate or function as intended, causing personal injury or damage to property. The consequences of failure are dealt with by the law of product liability. The field also deals with...

- Forensic materials engineeringForensic materials engineeringA branch of Forensic engineering, the subject focuses on the material evidence from crime or accident scenes, seeking defects in those materials which might explain why an accident occurred, or the source of a specific material to identify a criminal...

- FractureFractureA fracture is the separation of an object or material into two, or more, pieces under the action of stress.The word fracture is often applied to bones of living creatures , or to crystals or crystalline materials, such as gemstones or metal...

- Fracture mechanicsFracture mechanicsFracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics to characterize the material's resistance to fracture.In...

- Fracture toughnessFracture toughnessIn materials science, fracture toughness is a property which describes the ability of a material containing a crack to resist fracture, and is one of the most important properties of any material for virtually all design applications. The fracture toughness of a material is determined from the...

- Forensic polymer engineeringForensic polymer engineeringThe study of failure in polymeric products is called forensic polymer engineering. The topic includes the fracture of plastic products, or any other reason why such a product fails in service, or fails to meet its specification...

- Forensic science

- Structural engineeringStructural engineeringStructural engineering is a field of engineering dealing with the analysis and design of structures that support or resist loads. Structural engineering is usually considered a specialty within civil engineering, but it can also be studied in its own right....