Stress corrosion cracking

Encyclopedia

Stress corrosion cracking (SCC) is the unexpected sudden failure of normally ductile metals subjected to a tensile stress in a corrosive

environment, especially at elevated temperature in the case of metals. SCC is highly chemically specific in that certain alloys are likely to undergo SCC only when exposed to a small number of chemical environments. The chemical environment that causes SCC for a given alloy is often one which is only mildly corrosive to the metal otherwise. Hence, metal parts with severe SCC can appear bright and shiny, while being filled with microscopic cracks. This factor makes it common for SCC to go undetected prior to failure. SCC often progresses rapidly, and is more common among alloys than pure metals. The specific environment is of crucial importance, and only very small concentrations of certain highly active chemicals are needed to produce catastrophic cracking, often leading to devastating and unexpected failure.

The stresses can be the result of the crevice loads due to stress concentration

, or can be caused by the type of assembly or residual stress

es from fabrication (e.g. cold working); the residual stresses can be relieved by annealing

.

stainless steel

s and aluminium

alloy

s crack in the presence of chloride

s, mild steel

cracks in the presence of alkali (boiler cracking) and nitrate

s, copper

alloys crack in ammonia

cal solutions (season cracking

). This limits the usefulness of austenitic stainless steel for containing water with higher than few ppm content of chlorides at temperatures above 50 °C. Worse still, high-tensile structural steels crack in an unexpectedly brittle manner in a whole variety of aqueous environments, especially containing chlorides. With the possible exception of the latter, which is a special example of hydrogen cracking, all the others display the phenomenon of subcritical crack

growth, i.e. small surface flaws propagate (usually smoothly) under conditions where fracture mechanics

predicts that failure should not occur. That is, in the presence of a corrodent, cracks develop and propagate well below KIc. In fact, the subcritical value of the stress intensity, designated as KIscc, may be less than 1% of KIc, as the following table shows:

is sensitive to attack by alkalis, but not by acids. On the other hand, polyesters are readily degraded by acids, and SCC is a likely failure

mechanism. Polymers are also susceptible to environmental stress cracking

where attacking agents do not necessarily degrade the materials chemically.

Nylon

is sensitive to degradation by acids, a process known as hydrolysis

, and nylon mouldings will crack when attacked by strong acids.

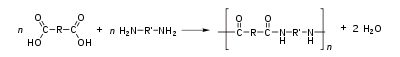

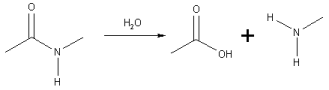

For example, the fracture surface of a fuel connector showed the progressive growth of the crack from acid attack (Ch) to the final cusp (C) of polymer. In this case the failure was caused by hydrolysis

For example, the fracture surface of a fuel connector showed the progressive growth of the crack from acid attack (Ch) to the final cusp (C) of polymer. In this case the failure was caused by hydrolysis

of the polymer by contact with sulfuric acid

leaking from a car battery

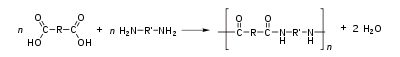

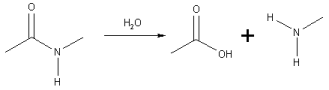

. The degradation reaction is the reverse of the synthesis reaction of the polymer:

Cracks can be formed in many different elastomers by ozone

Cracks can be formed in many different elastomers by ozone

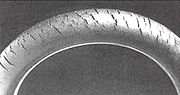

attack, another form of SCC in polymers. Tiny traces of the gas in the air will attack double bonds in rubber chains, with Natural rubber, Styrene-butadiene

rubber and NBR being most sensitive to degradation. Ozone cracks form in products under tension, but the critical strain is very small. The cracks are always oriented at right angles to the strain axis, so will form around the circumference in a rubber tube bent over. Such cracks are very dangerous when they occur in fuel pipes because the cracks will grow from the outside exposed surfaces into the bore of the pipe, so fuel leakage and fire may follow. The problem of ozone cracking

can be prevented by adding anti-ozonants to the rubber before vulcanization

. Ozone cracks were commonly seen in automobile tire

sidewalls, but are now seen rarely thanks to the use of these additives. On the other hand, the problem does recur in unprotected products such as rubber tubing and seals.

released as the crack propagates. That is,

The crack initiates at KIscc and thereafter propagates at a rate governed by the slowest process, which most of the time is the rate at which corrosive ions can diffuse to the crack tip. As the crack advances so K rises (because crack length appears in the calculation of stress intensity). Finally it reaches KIc , whereupon fast fracture ensues and the component fails. One of the practical difficulties with SCC is its unexpected nature. Stainless steel

s, for example, are employed because under most conditions they are "passive", i.e. effectively inert. Very often one finds a single crack has propagated while the rest of the metal surface stays apparently unaffected. The crack propagates perpendicular to the applied stress.

SCC caused the catastrophic collapse of the Silver Bridge

SCC caused the catastrophic collapse of the Silver Bridge

in December 1967, when an eyebar suspension bridge across the Ohio river at Point Pleasant

, West Virginia

, suddenly failed. The main chain joint failed and the whole structure fell into the river, killing 46 people in vehicles on the bridge at the time. Rust in the eyebar joint had caused a stress corrosion crack, which went critical as a result of high bridge loading and low temperature. The failure was exacerbated by a high level of residual stress

in the eyebar. The disaster led to a nationwide reappraisal of bridges.

Suspended ceilings in indoor swimming pools are safety-relevant components. As was demonstrated by the collapses of the ceiling of the Uster

(Switzerland

) indoor swimming pool

(1985) and again at Steenwijk

(Netherlands

, 2001), attention must be paid to selecting suitable materials and inspecting the state of such components. The reason for the failures was stress corrosion cracking of metal fastening components made of stainless steel

. The active chemical was chlorine

added to the water as a disinfectant.

A classic example of SCC is season cracking

of brass cartridge cases, a problem experienced by the British army in India

in the early 19th century. It was initiated by ammonia

from dung and horse manure decomposing at the higher temperatures of the spring and summer. There was substantial residual stress

in the cartridge shells as a result of cold forming. The problem was solved by annealing

the shells to ameliorate the stress.

Corrosion

Corrosion is the disintegration of an engineered material into its constituent atoms due to chemical reactions with its surroundings. In the most common use of the word, this means electrochemical oxidation of metals in reaction with an oxidant such as oxygen...

environment, especially at elevated temperature in the case of metals. SCC is highly chemically specific in that certain alloys are likely to undergo SCC only when exposed to a small number of chemical environments. The chemical environment that causes SCC for a given alloy is often one which is only mildly corrosive to the metal otherwise. Hence, metal parts with severe SCC can appear bright and shiny, while being filled with microscopic cracks. This factor makes it common for SCC to go undetected prior to failure. SCC often progresses rapidly, and is more common among alloys than pure metals. The specific environment is of crucial importance, and only very small concentrations of certain highly active chemicals are needed to produce catastrophic cracking, often leading to devastating and unexpected failure.

The stresses can be the result of the crevice loads due to stress concentration

Stress concentration

A stress concentration is a location in an object where stress is concentrated. An object is strongest when force is evenly distributed over its area, so a reduction in area, e.g. caused by a crack, results in a localized increase in stress...

, or can be caused by the type of assembly or residual stress

Residual stress

Residual stresses are stresses that remain after the original cause of the stresses has been removed. They remain along a cross section of the component, even without the external cause. Residual stresses occur for a variety of reasons, including inelastic deformations and heat treatment...

es from fabrication (e.g. cold working); the residual stresses can be relieved by annealing

Annealing (metallurgy)

Annealing, in metallurgy and materials science, is a heat treatment wherein a material is altered, causing changes in its properties such as strength and hardness. It is a process that produces conditions by heating to above the recrystallization temperature, maintaining a suitable temperature, and...

.

Metals attacked

Certain austeniticAustenite

Austenite, also known as gamma phase iron, is a metallic non-magnetic allotrope of iron or a solid solution of iron, with an alloying element. In plain-carbon steel, austenite exists above the critical eutectoid temperature of ; other alloys of steel have different eutectoid temperatures...

stainless steel

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

s and aluminium

Aluminium

Aluminium or aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances....

alloy

Alloy

An alloy is a mixture or metallic solid solution composed of two or more elements. Complete solid solution alloys give single solid phase microstructure, while partial solutions give two or more phases that may or may not be homogeneous in distribution, depending on thermal history...

s crack in the presence of chloride

Chloride

The chloride ion is formed when the element chlorine, a halogen, picks up one electron to form an anion Cl−. The salts of hydrochloric acid HCl contain chloride ions and can also be called chlorides. The chloride ion, and its salts such as sodium chloride, are very soluble in water...

s, mild steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

cracks in the presence of alkali (boiler cracking) and nitrate

Nitrate

The nitrate ion is a polyatomic ion with the molecular formula NO and a molecular mass of 62.0049 g/mol. It is the conjugate base of nitric acid, consisting of one central nitrogen atom surrounded by three identically-bonded oxygen atoms in a trigonal planar arrangement. The nitrate ion carries a...

s, copper

Copper

Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish...

alloys crack in ammonia

Ammonia

Ammonia is a compound of nitrogen and hydrogen with the formula . It is a colourless gas with a characteristic pungent odour. Ammonia contributes significantly to the nutritional needs of terrestrial organisms by serving as a precursor to food and fertilizers. Ammonia, either directly or...

cal solutions (season cracking

Season cracking

Season cracking is a form of stress-corrosion cracking of brass cartridge cases originally reported from British forces in India. During the monsoon season, military activity was temporarily reduced, and ammunition was stored in stables until the dry weather returned. Many brass cartridges were...

). This limits the usefulness of austenitic stainless steel for containing water with higher than few ppm content of chlorides at temperatures above 50 °C. Worse still, high-tensile structural steels crack in an unexpectedly brittle manner in a whole variety of aqueous environments, especially containing chlorides. With the possible exception of the latter, which is a special example of hydrogen cracking, all the others display the phenomenon of subcritical crack

Structural failure

Structural failure refers to loss of the load-carrying capacity of a component or member within a structure or of the structure itself. Structural failure is initiated when the material is stressed to its strength limit, thus causing fracture or excessive deformations...

growth, i.e. small surface flaws propagate (usually smoothly) under conditions where fracture mechanics

Fracture mechanics

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics to characterize the material's resistance to fracture.In...

predicts that failure should not occur. That is, in the presence of a corrodent, cracks develop and propagate well below KIc. In fact, the subcritical value of the stress intensity, designated as KIscc, may be less than 1% of KIc, as the following table shows:

| Alloy | KIc MN/m3/2 |

SCC environment | KIscc MN/m3/2 |

|---|---|---|---|

| 13Cr steel | 60 | 3% NaCl | 12 |

| 18Cr-8Ni | 200 | 42% MgCl2 | 10 |

| Cu-30Zn | 200 | NH4OH, pH7 | 1 |

| Al-3Mg-7Zn | 25 | Aqueous halides | 5 |

| Ti-6Al-1V | 60 | 0.6M KCl | 20 |

Polymers attacked

A similar process occurs in polymers, when products are exposed to aggressive chemicals such as acids and alkalis. As with metals, attack is confined to specific polymers and particular chemicals. Thus polycarbonatePolycarbonate

PolycarbonatePhysical PropertiesDensity 1.20–1.22 g/cm3Abbe number 34.0Refractive index 1.584–1.586FlammabilityV0-V2Limiting oxygen index25–27%Water absorption – Equilibrium0.16–0.35%Water absorption – over 24 hours0.1%...

is sensitive to attack by alkalis, but not by acids. On the other hand, polyesters are readily degraded by acids, and SCC is a likely failure

Failure

Failure refers to the state or condition of not meeting a desirable or intended objective, and may be viewed as the opposite of success. Product failure ranges from failure to sell the product to fracture of the product, in the worst cases leading to personal injury, the province of forensic...

mechanism. Polymers are also susceptible to environmental stress cracking

Environmental stress cracking

Environmental Stress Cracking is one of the most common causes of unexpected brittle failure of thermoplastic polymers known at present. Environmental stress cracking may account for around 15-30% of all plastic component failures in service.ESC and polymer resistance to ESC have been studied...

where attacking agents do not necessarily degrade the materials chemically.

Nylon

Nylon

Nylon is a generic designation for a family of synthetic polymers known generically as polyamides, first produced on February 28, 1935, by Wallace Carothers at DuPont's research facility at the DuPont Experimental Station...

is sensitive to degradation by acids, a process known as hydrolysis

Hydrolysis

Hydrolysis is a chemical reaction during which molecules of water are split into hydrogen cations and hydroxide anions in the process of a chemical mechanism. It is the type of reaction that is used to break down certain polymers, especially those made by condensation polymerization...

, and nylon mouldings will crack when attacked by strong acids.

Hydrolysis

Hydrolysis is a chemical reaction during which molecules of water are split into hydrogen cations and hydroxide anions in the process of a chemical mechanism. It is the type of reaction that is used to break down certain polymers, especially those made by condensation polymerization...

of the polymer by contact with sulfuric acid

Sulfuric acid

Sulfuric acid is a strong mineral acid with the molecular formula . Its historical name is oil of vitriol. Pure sulfuric acid is a highly corrosive, colorless, viscous liquid. The salts of sulfuric acid are called sulfates...

leaking from a car battery

Car battery

An automotive battery is a type of rechargeable battery that supplies electric energy to an automobile. Usually this refers to an SLI battery to power the starter motor, the lights, and the ignition system of a vehicle’s engine...

. The degradation reaction is the reverse of the synthesis reaction of the polymer:

Ozone

Ozone , or trioxygen, is a triatomic molecule, consisting of three oxygen atoms. It is an allotrope of oxygen that is much less stable than the diatomic allotrope...

attack, another form of SCC in polymers. Tiny traces of the gas in the air will attack double bonds in rubber chains, with Natural rubber, Styrene-butadiene

Styrene-butadiene

Styrene-Butadiene or Styrene-Butadiene-Rubber is a synthetic rubber copolymer consisting of styrene and butadiene. It has good abrasion resistance and good aging stability when protected by additives, and is widely used in car tires, where it may be blended with natural rubber...

rubber and NBR being most sensitive to degradation. Ozone cracks form in products under tension, but the critical strain is very small. The cracks are always oriented at right angles to the strain axis, so will form around the circumference in a rubber tube bent over. Such cracks are very dangerous when they occur in fuel pipes because the cracks will grow from the outside exposed surfaces into the bore of the pipe, so fuel leakage and fire may follow. The problem of ozone cracking

Ozone cracking

Cracks can be formed in many different elastomers by ozone attack, and the characteristic form of attack of vulnerable rubbers is known as ozone cracking...

can be prevented by adding anti-ozonants to the rubber before vulcanization

Vulcanization

Vulcanization or vulcanisation is a chemical process for converting rubber or related polymers into more durable materials via the addition of sulfur or other equivalent "curatives." These additives modify the polymer by forming crosslinks between individual polymer chains. Vulcanized material is...

. Ozone cracks were commonly seen in automobile tire

Tire

A tire or tyre is a ring-shaped covering that fits around a wheel rim to protect it and enable better vehicle performance by providing a flexible cushion that absorbs shock while keeping the wheel in close contact with the ground...

sidewalls, but are now seen rarely thanks to the use of these additives. On the other hand, the problem does recur in unprotected products such as rubber tubing and seals.

Crack growth

The subcritical nature of propagation may be attributed to the chemical energyChemical energy

Chemical energy is the potential of a chemical substance to undergo a transformation through a chemical reaction or, to transform other chemical substances...

released as the crack propagates. That is,

- elastic energy released + chemical energy = surface energy + deformation energy

The crack initiates at KIscc and thereafter propagates at a rate governed by the slowest process, which most of the time is the rate at which corrosive ions can diffuse to the crack tip. As the crack advances so K rises (because crack length appears in the calculation of stress intensity). Finally it reaches KIc , whereupon fast fracture ensues and the component fails. One of the practical difficulties with SCC is its unexpected nature. Stainless steel

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

s, for example, are employed because under most conditions they are "passive", i.e. effectively inert. Very often one finds a single crack has propagated while the rest of the metal surface stays apparently unaffected. The crack propagates perpendicular to the applied stress.

Prevention

SCC is the result of a combination of three factors – a susceptible material, exposure to a corrosive environment, and tensile stresses above a threshold. If you eliminate any one of these factors SCC initiation becomes impossible. The conventional approach to controlling the problem has been to develop new alloys that are more resistant to SCC. This is a costly proposition and can require a massive time investment to achieve only marginal success.Examples

Silver Bridge

The Silver Bridge collapsed in 1967, killing 46 people. The terms Silver Bridge or Silverbridge may also refer to:* Silver Memorial Bridge, the replacement for the above bridge, opened in 1969....

in December 1967, when an eyebar suspension bridge across the Ohio river at Point Pleasant

Point Pleasant, West Virginia

Point Pleasant is a city in Mason County, West Virginia, United States, at the confluence of the Ohio and Kanawha rivers. The population was 4,637 at the 2000 census...

, West Virginia

West Virginia

West Virginia is a state in the Appalachian and Southeastern regions of the United States, bordered by Virginia to the southeast, Kentucky to the southwest, Ohio to the northwest, Pennsylvania to the northeast and Maryland to the east...

, suddenly failed. The main chain joint failed and the whole structure fell into the river, killing 46 people in vehicles on the bridge at the time. Rust in the eyebar joint had caused a stress corrosion crack, which went critical as a result of high bridge loading and low temperature. The failure was exacerbated by a high level of residual stress

Residual stress

Residual stresses are stresses that remain after the original cause of the stresses has been removed. They remain along a cross section of the component, even without the external cause. Residual stresses occur for a variety of reasons, including inelastic deformations and heat treatment...

in the eyebar. The disaster led to a nationwide reappraisal of bridges.

Suspended ceilings in indoor swimming pools are safety-relevant components. As was demonstrated by the collapses of the ceiling of the Uster

Uster

Uster is a city and capital of the district Uster in the Swiss Canton of Zürich.It is the third largest city in the Canton of Zürich, with over 30,000 inhabitants, and is one of the twenty largest cities in Switzerland...

(Switzerland

Switzerland

Switzerland name of one of the Swiss cantons. ; ; ; or ), in its full name the Swiss Confederation , is a federal republic consisting of 26 cantons, with Bern as the seat of the federal authorities. The country is situated in Western Europe,Or Central Europe depending on the definition....

) indoor swimming pool

Swimming pool

A swimming pool, swimming bath, wading pool, or simply a pool, is a container filled with water intended for swimming or water-based recreation. There are many standard sizes; the largest is the Olympic-size swimming pool...

(1985) and again at Steenwijk

Steenwijk

Steenwijk is a city in the Dutch province of Overijssel. It is located in the municipality of Steenwijkerland. It is the largest town of the municipality.Steenwijk received city rights in 1327...

(Netherlands

Netherlands

The Netherlands is a constituent country of the Kingdom of the Netherlands, located mainly in North-West Europe and with several islands in the Caribbean. Mainland Netherlands borders the North Sea to the north and west, Belgium to the south, and Germany to the east, and shares maritime borders...

, 2001), attention must be paid to selecting suitable materials and inspecting the state of such components. The reason for the failures was stress corrosion cracking of metal fastening components made of stainless steel

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

. The active chemical was chlorine

Chlorine

Chlorine is the chemical element with atomic number 17 and symbol Cl. It is the second lightest halogen, found in the periodic table in group 17. The element forms diatomic molecules under standard conditions, called dichlorine...

added to the water as a disinfectant.

A classic example of SCC is season cracking

Season cracking

Season cracking is a form of stress-corrosion cracking of brass cartridge cases originally reported from British forces in India. During the monsoon season, military activity was temporarily reduced, and ammunition was stored in stables until the dry weather returned. Many brass cartridges were...

of brass cartridge cases, a problem experienced by the British army in India

India

India , officially the Republic of India , is a country in South Asia. It is the seventh-largest country by geographical area, the second-most populous country with over 1.2 billion people, and the most populous democracy in the world...

in the early 19th century. It was initiated by ammonia

Ammonia

Ammonia is a compound of nitrogen and hydrogen with the formula . It is a colourless gas with a characteristic pungent odour. Ammonia contributes significantly to the nutritional needs of terrestrial organisms by serving as a precursor to food and fertilizers. Ammonia, either directly or...

from dung and horse manure decomposing at the higher temperatures of the spring and summer. There was substantial residual stress

Residual stress

Residual stresses are stresses that remain after the original cause of the stresses has been removed. They remain along a cross section of the component, even without the external cause. Residual stresses occur for a variety of reasons, including inelastic deformations and heat treatment...

in the cartridge shells as a result of cold forming. The problem was solved by annealing

Annealing (metallurgy)

Annealing, in metallurgy and materials science, is a heat treatment wherein a material is altered, causing changes in its properties such as strength and hardness. It is a process that produces conditions by heating to above the recrystallization temperature, maintaining a suitable temperature, and...

the shells to ameliorate the stress.

See also

- Forensic chemistryForensic chemistryForensic chemistry is the application of chemistry to law enforcement or the failure of products or processes. Many different analytical methods may be used to reveal what chemical changes occurred during an incident, and so help reconstruct the sequence of events...

- Forensic engineeringForensic engineeringForensic engineering is the investigation of materials, products, structures or components that fail or do not operate or function as intended, causing personal injury or damage to property. The consequences of failure are dealt with by the law of product liability. The field also deals with...

- Forensic materials engineeringForensic materials engineeringA branch of Forensic engineering, the subject focuses on the material evidence from crime or accident scenes, seeking defects in those materials which might explain why an accident occurred, or the source of a specific material to identify a criminal...

- Forensic polymer engineeringForensic polymer engineeringThe study of failure in polymeric products is called forensic polymer engineering. The topic includes the fracture of plastic products, or any other reason why such a product fails in service, or fails to meet its specification...

- Fracture mechanicsFracture mechanicsFracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics to characterize the material's resistance to fracture.In...

- Environmental stress crackingEnvironmental stress crackingEnvironmental Stress Cracking is one of the most common causes of unexpected brittle failure of thermoplastic polymers known at present. Environmental stress cracking may account for around 15-30% of all plastic component failures in service.ESC and polymer resistance to ESC have been studied...

- Environmental stress fractureEnvironmental stress fractureIn materials science, environmental stress fracture or environment assisted fracture is the generic name given to premature failure under the influence of tensile stresses and harmful environments of materials such as metals and alloys, composites, plastics and ceramics.Metals and alloys exhibit...

- Ozone crackingOzone crackingCracks can be formed in many different elastomers by ozone attack, and the characteristic form of attack of vulnerable rubbers is known as ozone cracking...

- Polymer degradationPolymer degradationPolymer degradation is a change in the properties—tensile strength, colour, shape, etc.—of a polymer or polymer-based product under the influence of one or more environmental factors such as heat, light or chemicals such as acids, alkalis and some salts...

- Season crackingSeason crackingSeason cracking is a form of stress-corrosion cracking of brass cartridge cases originally reported from British forces in India. During the monsoon season, military activity was temporarily reduced, and ammunition was stored in stables until the dry weather returned. Many brass cartridges were...