Forensic polymer engineering

Encyclopedia

The study of failure in polymer

ic products is called forensic polymer engineering. The topic includes the fracture

of plastic products, or any other reason why such a product fails in service, or fails to meet its specification. The subject focuses on the material evidence from crime or accident scenes, seeking defects in those materials that might explain why an accident occurred, or the source of a specific material to identify a criminal. Many analytical methods used for polymer identification may be used in investigations, the exact set being determined by the nature of the polymer in question, be it thermoset, thermoplastic

, elastomeric or composite

in nature.

One aspect is the analysis of trace evidence

such as skid mark

s on exposed surfaces, where contact between dissimilar materials leaves material traces of one left on the other. Provided the traces can be analyzed successfully, then an accident or crime can often be reconstructed.

Thermoplastic

Thermoplastic

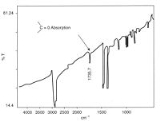

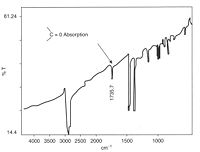

s can be analysed using infra-red spectroscopy, ultraviolet–visible spectroscopy, nuclear magnetic resonance spectroscopy and the environmental scanning electron microscope. Failed samples can either be dissolved in a suitable solvent and examined directly (UV, IR and NMR spectroscopy) or be a thin film cast from solvent or cut using microtomy from the solid product. Infra-red spectrosocpy is especially useful for assessing oxidation of polymers, such as the polymer degradation

caused by faulty injection moulding

. The spectrum shows the characteristic carbonyl group produced by oxidation of polypropylene

, which made the product brittle

. It was a critical part of a crutch, and when it failed, the user fell and injured herself very seriously. The spectrum was obtained from a thin film cast from a solution of a sample of the plastic taken from the failed forearm crutch

.

Microtomy is preferable since there are no complications from solvent absorption, and the integrity of the sample is partly preserved. Thermosets, composites

and elastomers can often be examined using only microtomy owing to the insoluble nature of these materials.

, an especially useful method for all broken components using macrophotography and optical microscopy. Although polymers usually possess quite different properties to metals, ceramic

s and glass

es, they are just as susceptible to failure from mechanical overload

, fatigue

and stress corrosion cracking

if products are poorly designed or manufactured.

Scanning electron microscopy or ESEM

is especially useful for examining fracture surfaces and can also provide elemental analysis of viewed parts of the sample being investigated. It is effectively a technique of microanalysis

and valuable for examination of trace evidence

. On the other hand, colour rendition is absent in ESEM

, and there is no information provided about the way in which those elements are bonded to one another. Specimens will be exposed to a partial vacuum, so any volatiles may be removed, and surfaces may be contaminated by substances used to attach the sample to the mount.

. Polymer degradation

leads to sample embrittlement, and fracture under low applied loads.

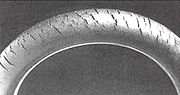

Polymer

Polymer

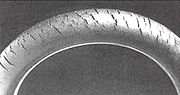

s for example, can be attacked by aggressive chemicals, and if under load, then cracks will grow by the mechanism of stress corrosion cracking

. Perhaps the oldest known example is the ozone cracking

of rubbers, where traces of ozone in the atmosphere attack double bonds in the chains of the materials. Elastomers with double bonds in their chains include natural rubber, nitrile rubber

and styrene-butadiene

rubber. They are all highly susceptible to ozone attack, and can cause problems like vehicle fires (from rubber fuel lines) and tyre

blow-outs. Nowadays, anti-ozonants are widely added to these polymers, so the incidence of cracking has dropped. However, not all safety-critical rubber products are protected, and, since only ppb

of ozone will start attack, failures are still occurring.

Another highly reactive gas is chlorine

Another highly reactive gas is chlorine

, which will attack susceptible polymers such as acetal resin and polybutylene

pipework. There have been many examples of such pipes and acetal fittings failing in properties in the USA as a result of chlorine-induced cracking. Essentially the gas attacks sensitive parts of the chain molecules (especially secondary , tertiary or allylic carbon atoms), oxidising the chains and ultimately causing chain cleavage. The root cause is traces of chlorine in the water supply, added for its anti-bacterial action, attack occurring even at parts per million traces of the dissolved gas. The chlorine attacks weak parts of a product, and, in the case of an acetal resin junction in a water supply system, it is the thread roots that were attacked first, causing a brittle crack to grow. The discoloration on the fracture surface was caused by deposition of carbonates from the hard water

supply, so the joint had been in a critical state for many months.

in the presence of water, often a reaction catalysed by acid

or alkali

. Nylon

for example, will degrade and crack rapidly if exposed to strong acids, a phenomenon well known to ladies who accidentally spill acid onto their tights. The broken fuel pipe caused a serious accident when diesel fuel poured out from a van onto the road. A following car skidded and the driver was seriously injured when she collided with an oncoming lorry. Scanning electron microscopy or SEM showed that the nylon

The broken fuel pipe caused a serious accident when diesel fuel poured out from a van onto the road. A following car skidded and the driver was seriously injured when she collided with an oncoming lorry. Scanning electron microscopy or SEM showed that the nylon

connector had fractured by stress corrosion cracking

due to a small leak of battery acid. Nylon is susceptible to hydrolysis

in contact with sulfuric acid

, and only a small leak of acid would have sufficed to start a brittle crack in the injection moulded connector by a mechanism known as stress corrosion cracking

, or SCC. The crack took about 7 days to grow across the diameter of the tube, hence the van driver should have seen the leak well before the crack grew to a critical size. He did not, therefore resulting in the accident. The fracture surface showed a mainly brittle surface with striations indicating progressive growth of the crack across the diameter of the pipe. Once the crack had penetrated the inner bore, fuel started leaking onto the road. Diesel is especially hazardous on road surfaces because it forms a thin oily film that cannot be seen easily by drivers. It is akin to black ice

The crack took about 7 days to grow across the diameter of the tube, hence the van driver should have seen the leak well before the crack grew to a critical size. He did not, therefore resulting in the accident. The fracture surface showed a mainly brittle surface with striations indicating progressive growth of the crack across the diameter of the pipe. Once the crack had penetrated the inner bore, fuel started leaking onto the road. Diesel is especially hazardous on road surfaces because it forms a thin oily film that cannot be seen easily by drivers. It is akin to black ice

in lubricity, so skids are common when diesel leaks occur. The insurers of the van driver admitted liability and the injured driver was compensated.

Polycarbonate

is susceptible to alkali hydrolysis, the reaction simply depolymerising the material. Polyesters are prone to degrade when treated with strong acids, and in all these cases, care must be taken to dry the raw materials for processing at high temperatures to prevent the problem occurring.

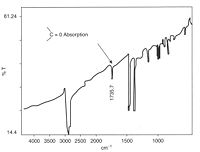

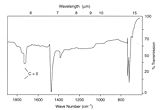

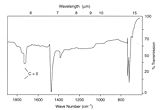

Many polymers are also attacked by UV radiation at vulnerable points in their chain structures. Thus polypropylene

Many polymers are also attacked by UV radiation at vulnerable points in their chain structures. Thus polypropylene

suffers severe cracking in sunlight

unless anti-oxidants are added. The point of attack occurs at the tertiary carbon atom present in every repeat unit, causing oxidation and finally chain breakage. Polyethylene

is also susceptible to UV degradation, especially those variants that are branched polymers such as LDPE. The branch points are tertiary carbon atoms, so polymer degradation

starts there and results in chain cleavage, and embrittlement. In the example shown at left, carbonyl groups were easily detected by IR spectroscopy from a cast thin film. The product was a road cone that had cracked in service, and many similar cones also failed because an anti-UV additive had not been used.

Polymer

A polymer is a large molecule composed of repeating structural units. These subunits are typically connected by covalent chemical bonds...

ic products is called forensic polymer engineering. The topic includes the fracture

Fracture

A fracture is the separation of an object or material into two, or more, pieces under the action of stress.The word fracture is often applied to bones of living creatures , or to crystals or crystalline materials, such as gemstones or metal...

of plastic products, or any other reason why such a product fails in service, or fails to meet its specification. The subject focuses on the material evidence from crime or accident scenes, seeking defects in those materials that might explain why an accident occurred, or the source of a specific material to identify a criminal. Many analytical methods used for polymer identification may be used in investigations, the exact set being determined by the nature of the polymer in question, be it thermoset, thermoplastic

Thermoplastic

Thermoplastic, also known as a thermosoftening plastic, is a polymer that turns to a liquid when heated and freezes to a very glassy state when cooled sufficiently...

, elastomeric or composite

Composite material

Composite materials, often shortened to composites or called composition materials, are engineered or naturally occurring materials made from two or more constituent materials with significantly different physical or chemical properties which remain separate and distinct at the macroscopic or...

in nature.

One aspect is the analysis of trace evidence

Trace evidence

Trace evidence is evidence that occurs when different objects contact one another. Such materials are often transferred by heat induced by contact friction....

such as skid mark

Skid mark

A skid mark is the mark a tire makes when a vehicle wheel stops rolling and slides or spins on the surface of the road. More generally, any solid which moves against another can cause visible marks, and is an important aspect of trace evidence analysis in forensic science and forensic engineering...

s on exposed surfaces, where contact between dissimilar materials leaves material traces of one left on the other. Provided the traces can be analyzed successfully, then an accident or crime can often be reconstructed.

Methods of analysis

Thermoplastic

Thermoplastic, also known as a thermosoftening plastic, is a polymer that turns to a liquid when heated and freezes to a very glassy state when cooled sufficiently...

s can be analysed using infra-red spectroscopy, ultraviolet–visible spectroscopy, nuclear magnetic resonance spectroscopy and the environmental scanning electron microscope. Failed samples can either be dissolved in a suitable solvent and examined directly (UV, IR and NMR spectroscopy) or be a thin film cast from solvent or cut using microtomy from the solid product. Infra-red spectrosocpy is especially useful for assessing oxidation of polymers, such as the polymer degradation

Polymer degradation

Polymer degradation is a change in the properties—tensile strength, colour, shape, etc.—of a polymer or polymer-based product under the influence of one or more environmental factors such as heat, light or chemicals such as acids, alkalis and some salts...

caused by faulty injection moulding

Injection moulding

Injection molding is a manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials. Material is fed into a heated barrel, mixed, and forced into a mold cavity where it cools and hardens to the configuration of the cavity...

. The spectrum shows the characteristic carbonyl group produced by oxidation of polypropylene

Polypropylene

Polypropylene , also known as polypropene, is a thermoplastic polymer used in a wide variety of applications including packaging, textiles , stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes...

, which made the product brittle

Brittle

A material is brittle if, when subjected to stress, it breaks without significant deformation . Brittle materials absorb relatively little energy prior to fracture, even those of high strength. Breaking is often accompanied by a snapping sound. Brittle materials include most ceramics and glasses ...

. It was a critical part of a crutch, and when it failed, the user fell and injured herself very seriously. The spectrum was obtained from a thin film cast from a solution of a sample of the plastic taken from the failed forearm crutch

Crutch

Crutches are mobility aids used to counter a mobility impairment or an injury that limits walking ability.- Types :There are several different types of crutches:...

.

Microtomy is preferable since there are no complications from solvent absorption, and the integrity of the sample is partly preserved. Thermosets, composites

Composite material

Composite materials, often shortened to composites or called composition materials, are engineered or naturally occurring materials made from two or more constituent materials with significantly different physical or chemical properties which remain separate and distinct at the macroscopic or...

and elastomers can often be examined using only microtomy owing to the insoluble nature of these materials.

Fracture

Fractured products can be examined using fractographyFractography

Fractography is the study of fracture surfaces of materials. Fractographic methods are routinely used to determine the cause of failure in engineering structures, especially in product failure and the practice of forensic engineering or failure analysis...

, an especially useful method for all broken components using macrophotography and optical microscopy. Although polymers usually possess quite different properties to metals, ceramic

Ceramic

A ceramic is an inorganic, nonmetallic solid prepared by the action of heat and subsequent cooling. Ceramic materials may have a crystalline or partly crystalline structure, or may be amorphous...

s and glass

Glass

Glass is an amorphous solid material. Glasses are typically brittle and optically transparent.The most familiar type of glass, used for centuries in windows and drinking vessels, is soda-lime glass, composed of about 75% silica plus Na2O, CaO, and several minor additives...

es, they are just as susceptible to failure from mechanical overload

Mechanical overload

The failure or fracture of a product or component in a single event is known as mechanical overload. It is a common failure mode, and may be contrasted with fatigue, creep, rupture, or stress relaxation. The terms are used in forensic engineering and structural engineering when analysing product...

, fatigue

Fatigue (material)

'In materials science, fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. The nominal maximum stress values are less than the ultimate tensile stress limit, and may be below the yield stress limit of the material.Fatigue occurs...

and stress corrosion cracking

Stress corrosion cracking

Stress corrosion cracking is the unexpected sudden failure of normally ductile metals subjected to a tensile stress in a corrosive environment, especially at elevated temperature in the case of metals. SCC is highly chemically specific in that certain alloys are likely to undergo SCC only when...

if products are poorly designed or manufactured.

Scanning electron microscopy or ESEM

ESEM

The environmental scanning electron microscope or ESEM is a scanning electron microscope that allows for the option of collecting electron micrographs of specimens that are "wet," uncoated, or both by allowing for a gaseous environment in the specimen chamber...

is especially useful for examining fracture surfaces and can also provide elemental analysis of viewed parts of the sample being investigated. It is effectively a technique of microanalysis

Microanalysis

Microanalysis is the chemical identification and quantitative analysis of very small amounts of chemical substances or very small surfaces of material...

and valuable for examination of trace evidence

Trace evidence

Trace evidence is evidence that occurs when different objects contact one another. Such materials are often transferred by heat induced by contact friction....

. On the other hand, colour rendition is absent in ESEM

ESEM

The environmental scanning electron microscope or ESEM is a scanning electron microscope that allows for the option of collecting electron micrographs of specimens that are "wet," uncoated, or both by allowing for a gaseous environment in the specimen chamber...

, and there is no information provided about the way in which those elements are bonded to one another. Specimens will be exposed to a partial vacuum, so any volatiles may be removed, and surfaces may be contaminated by substances used to attach the sample to the mount.

Examples

Many polymers are attacked by specific chemicals in the environment, and serious problems can arise, including road accidents and personal injuryPersonal injury

Personal injury is a legal term for an injury to the body, mind or emotions, as opposed to an injury to property. The term is most commonly used to refer to a type of tort lawsuit alleging that the plaintiff's injury has been caused by the negligence of another, but also arises in defamation...

. Polymer degradation

Polymer degradation

Polymer degradation is a change in the properties—tensile strength, colour, shape, etc.—of a polymer or polymer-based product under the influence of one or more environmental factors such as heat, light or chemicals such as acids, alkalis and some salts...

leads to sample embrittlement, and fracture under low applied loads.

Ozone cracking

Polymer

A polymer is a large molecule composed of repeating structural units. These subunits are typically connected by covalent chemical bonds...

s for example, can be attacked by aggressive chemicals, and if under load, then cracks will grow by the mechanism of stress corrosion cracking

Stress corrosion cracking

Stress corrosion cracking is the unexpected sudden failure of normally ductile metals subjected to a tensile stress in a corrosive environment, especially at elevated temperature in the case of metals. SCC is highly chemically specific in that certain alloys are likely to undergo SCC only when...

. Perhaps the oldest known example is the ozone cracking

Ozone cracking

Cracks can be formed in many different elastomers by ozone attack, and the characteristic form of attack of vulnerable rubbers is known as ozone cracking...

of rubbers, where traces of ozone in the atmosphere attack double bonds in the chains of the materials. Elastomers with double bonds in their chains include natural rubber, nitrile rubber

Nitrile rubber

Nitrile rubber, also known as Buna-N, Perbunan, or NBR, is a synthetic rubber copolymer of acrylonitrile and butadiene. Trade names include Nipol, Krynac and Europrene....

and styrene-butadiene

Styrene-butadiene

Styrene-Butadiene or Styrene-Butadiene-Rubber is a synthetic rubber copolymer consisting of styrene and butadiene. It has good abrasion resistance and good aging stability when protected by additives, and is widely used in car tires, where it may be blended with natural rubber...

rubber. They are all highly susceptible to ozone attack, and can cause problems like vehicle fires (from rubber fuel lines) and tyre

Tire

A tire or tyre is a ring-shaped covering that fits around a wheel rim to protect it and enable better vehicle performance by providing a flexible cushion that absorbs shock while keeping the wheel in close contact with the ground...

blow-outs. Nowadays, anti-ozonants are widely added to these polymers, so the incidence of cracking has dropped. However, not all safety-critical rubber products are protected, and, since only ppb

PPB

PPB can stand for:* Party political broadcast, a type of political programming in the United Kingdom* parts-per-billion, a unit of concentration* Portland Police Bureau, a police agency for the city of Portland...

of ozone will start attack, failures are still occurring.

Chlorine-induced cracking

Chlorine

Chlorine is the chemical element with atomic number 17 and symbol Cl. It is the second lightest halogen, found in the periodic table in group 17. The element forms diatomic molecules under standard conditions, called dichlorine...

, which will attack susceptible polymers such as acetal resin and polybutylene

Polybutylene

Polybutylene is a polyolefin or saturated polymer with the chemical formula n. It should not be confused with polybutene, a low molecular weight oligomer with a different repeat unit....

pipework. There have been many examples of such pipes and acetal fittings failing in properties in the USA as a result of chlorine-induced cracking. Essentially the gas attacks sensitive parts of the chain molecules (especially secondary , tertiary or allylic carbon atoms), oxidising the chains and ultimately causing chain cleavage. The root cause is traces of chlorine in the water supply, added for its anti-bacterial action, attack occurring even at parts per million traces of the dissolved gas. The chlorine attacks weak parts of a product, and, in the case of an acetal resin junction in a water supply system, it is the thread roots that were attacked first, causing a brittle crack to grow. The discoloration on the fracture surface was caused by deposition of carbonates from the hard water

Hard water

Hard water is water that has high mineral content . Hard water has high concentrations of Ca2+ and Mg2+ ions. Hard water is generally not harmful to one's health but can pose serious problems in industrial settings, where water hardness is monitored to avoid costly breakdowns in boilers, cooling...

supply, so the joint had been in a critical state for many months.

Hydrolysis

Most step-growth polymers can suffer hydrolysisHydrolysis

Hydrolysis is a chemical reaction during which molecules of water are split into hydrogen cations and hydroxide anions in the process of a chemical mechanism. It is the type of reaction that is used to break down certain polymers, especially those made by condensation polymerization...

in the presence of water, often a reaction catalysed by acid

Acid

An acid is a substance which reacts with a base. Commonly, acids can be identified as tasting sour, reacting with metals such as calcium, and bases like sodium carbonate. Aqueous acids have a pH of less than 7, where an acid of lower pH is typically stronger, and turn blue litmus paper red...

or alkali

Alkali

In chemistry, an alkali is a basic, ionic salt of an alkali metal or alkaline earth metal element. Some authors also define an alkali as a base that dissolves in water. A solution of a soluble base has a pH greater than 7. The adjective alkaline is commonly used in English as a synonym for base,...

. Nylon

Nylon

Nylon is a generic designation for a family of synthetic polymers known generically as polyamides, first produced on February 28, 1935, by Wallace Carothers at DuPont's research facility at the DuPont Experimental Station...

for example, will degrade and crack rapidly if exposed to strong acids, a phenomenon well known to ladies who accidentally spill acid onto their tights.

Nylon

Nylon is a generic designation for a family of synthetic polymers known generically as polyamides, first produced on February 28, 1935, by Wallace Carothers at DuPont's research facility at the DuPont Experimental Station...

connector had fractured by stress corrosion cracking

Stress corrosion cracking

Stress corrosion cracking is the unexpected sudden failure of normally ductile metals subjected to a tensile stress in a corrosive environment, especially at elevated temperature in the case of metals. SCC is highly chemically specific in that certain alloys are likely to undergo SCC only when...

due to a small leak of battery acid. Nylon is susceptible to hydrolysis

Hydrolysis

Hydrolysis is a chemical reaction during which molecules of water are split into hydrogen cations and hydroxide anions in the process of a chemical mechanism. It is the type of reaction that is used to break down certain polymers, especially those made by condensation polymerization...

in contact with sulfuric acid

Sulfuric acid

Sulfuric acid is a strong mineral acid with the molecular formula . Its historical name is oil of vitriol. Pure sulfuric acid is a highly corrosive, colorless, viscous liquid. The salts of sulfuric acid are called sulfates...

, and only a small leak of acid would have sufficed to start a brittle crack in the injection moulded connector by a mechanism known as stress corrosion cracking

Stress corrosion cracking

Stress corrosion cracking is the unexpected sudden failure of normally ductile metals subjected to a tensile stress in a corrosive environment, especially at elevated temperature in the case of metals. SCC is highly chemically specific in that certain alloys are likely to undergo SCC only when...

, or SCC.

Black ice

Black ice, sometimes called glare ice or clear ice, refers to a thin coating of glazed ice on a surface.While not truly black, it is virtually transparent, allowing black asphalt/macadam roadways to be seen through it, hence the term "black ice"...

in lubricity, so skids are common when diesel leaks occur. The insurers of the van driver admitted liability and the injured driver was compensated.

Polycarbonate

Polycarbonate

PolycarbonatePhysical PropertiesDensity 1.20–1.22 g/cm3Abbe number 34.0Refractive index 1.584–1.586FlammabilityV0-V2Limiting oxygen index25–27%Water absorption – Equilibrium0.16–0.35%Water absorption – over 24 hours0.1%...

is susceptible to alkali hydrolysis, the reaction simply depolymerising the material. Polyesters are prone to degrade when treated with strong acids, and in all these cases, care must be taken to dry the raw materials for processing at high temperatures to prevent the problem occurring.

UV degradation

Polypropylene

Polypropylene , also known as polypropene, is a thermoplastic polymer used in a wide variety of applications including packaging, textiles , stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes...

suffers severe cracking in sunlight

Sunlight

Sunlight, in the broad sense, is the total frequency spectrum of electromagnetic radiation given off by the Sun. On Earth, sunlight is filtered through the Earth's atmosphere, and solar radiation is obvious as daylight when the Sun is above the horizon.When the direct solar radiation is not blocked...

unless anti-oxidants are added. The point of attack occurs at the tertiary carbon atom present in every repeat unit, causing oxidation and finally chain breakage. Polyethylene

Polyethylene

Polyethylene or polythene is the most widely used plastic, with an annual production of approximately 80 million metric tons...

is also susceptible to UV degradation, especially those variants that are branched polymers such as LDPE. The branch points are tertiary carbon atoms, so polymer degradation

Polymer degradation

Polymer degradation is a change in the properties—tensile strength, colour, shape, etc.—of a polymer or polymer-based product under the influence of one or more environmental factors such as heat, light or chemicals such as acids, alkalis and some salts...

starts there and results in chain cleavage, and embrittlement. In the example shown at left, carbonyl groups were easily detected by IR spectroscopy from a cast thin film. The product was a road cone that had cracked in service, and many similar cones also failed because an anti-UV additive had not been used.

See also

- Applied spectroscopyApplied spectroscopyApplied spectroscopy is the application of various spectroscopic methods for detection and identification of different elements/compounds in solving problems in the fields of forensics, medicine, oil industry, atmospheric chemistry, pharmacology, etc....

- Catastrophic failureCatastrophic failureA catastrophic failure is a sudden and total failure of some system from which recovery is impossible. Catastrophic failures often lead to cascading systems failure....

- Circumstantial evidenceCircumstantial evidenceCircumstantial evidence is evidence in which an inference is required to connect it to a conclusion of fact, like a fingerprint at the scene of a crime...

- Environmental stress crackingEnvironmental stress crackingEnvironmental Stress Cracking is one of the most common causes of unexpected brittle failure of thermoplastic polymers known at present. Environmental stress cracking may account for around 15-30% of all plastic component failures in service.ESC and polymer resistance to ESC have been studied...

- Forensic chemistryForensic chemistryForensic chemistry is the application of chemistry to law enforcement or the failure of products or processes. Many different analytical methods may be used to reveal what chemical changes occurred during an incident, and so help reconstruct the sequence of events...

- Forensic electrical engineeringForensic electrical engineeringForensic electrical engineering is a branch of forensic engineering, and is concerned with investigating electrical failures and accidents in a legal context. Many forensic electrical engineering investigations apply to fires suspected to be caused by electrical failures...

- Forensic evidence

- Forensic photographyForensic photographyForensic photography, sometimes referred to as forensic imaging or crime scene photography, is the art of producing an accurate reproduction of a crime scene or an accident scene using photography for the benefit of a court or to aid in an investigation. It is part of the process of evidence...

- Forensic engineeringForensic engineeringForensic engineering is the investigation of materials, products, structures or components that fail or do not operate or function as intended, causing personal injury or damage to property. The consequences of failure are dealt with by the law of product liability. The field also deals with...

- Forensic materials engineeringForensic materials engineeringA branch of Forensic engineering, the subject focuses on the material evidence from crime or accident scenes, seeking defects in those materials which might explain why an accident occurred, or the source of a specific material to identify a criminal...

- Forensic science

- FractographyFractographyFractography is the study of fracture surfaces of materials. Fractographic methods are routinely used to determine the cause of failure in engineering structures, especially in product failure and the practice of forensic engineering or failure analysis...

- Ozone crackingOzone crackingCracks can be formed in many different elastomers by ozone attack, and the characteristic form of attack of vulnerable rubbers is known as ozone cracking...

- Polymer degradationPolymer degradationPolymer degradation is a change in the properties—tensile strength, colour, shape, etc.—of a polymer or polymer-based product under the influence of one or more environmental factors such as heat, light or chemicals such as acids, alkalis and some salts...

- Skid markSkid markA skid mark is the mark a tire makes when a vehicle wheel stops rolling and slides or spins on the surface of the road. More generally, any solid which moves against another can cause visible marks, and is an important aspect of trace evidence analysis in forensic science and forensic engineering...

- Stress corrosion crackingStress corrosion crackingStress corrosion cracking is the unexpected sudden failure of normally ductile metals subjected to a tensile stress in a corrosive environment, especially at elevated temperature in the case of metals. SCC is highly chemically specific in that certain alloys are likely to undergo SCC only when...

- Trace evidenceTrace evidenceTrace evidence is evidence that occurs when different objects contact one another. Such materials are often transferred by heat induced by contact friction....

- UV degradationUV degradationMany natural and synthetic polymers are attacked by ultra-violet radiation and products made using these materials may crack or disintegrate . The problem is known as UV degradation, and is a common problem in products exposed to sunlight...