Laser engraving

Encyclopedia

Laser

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of photons. The term "laser" originated as an acronym for Light Amplification by Stimulated Emission of Radiation...

s to engrave

Engraving

Engraving is the practice of incising a design on to a hard, usually flat surface, by cutting grooves into it. The result may be a decorated object in itself, as when silver, gold, steel, or glass are engraved, or may provide an intaglio printing plate, of copper or another metal, for printing...

or mark an object. The technique does not involve the use of inks, nor does it involve tool bit

Tool bit

The term tool bit generally refers to a non-rotary cutting tool used in metal lathes, shapers, and planers. Such cutters are also often referred to by the set-phrase name of single-point cutting tool. The cutting edge is ground to suit a particular machining operation and may be resharpened or...

s which contact the engraving surface and wear out. These properties distinguish laser engraving from alternative engraving or marking technologies where bit heads have to be replaced regularly or inks have to be used.

The impact of laser engraving has been more pronounced for specially-designed "laserable" materials. These include laser-sensitive polymer

Polymer

A polymer is a large molecule composed of repeating structural units. These subunits are typically connected by covalent chemical bonds...

s and novel metal alloys.

The term laser marking is also used as a generic term covering a broad spectrum of surfacing techniques including printing, hot-branding and laser bonding

Laser bonding

Laser bonding is a marking technique that uses lasers and other forms of radiant energy to bond an additive marking substance to a wide range of substrates....

. The machines for laser engraving and laser marking are the same, so that the two terms are usually interchangeable.

Laser engraving machines

Pencil

A pencil is a writing implement or art medium usually constructed of a narrow, solid pigment core inside a protective casing. The case prevents the core from breaking, and also from marking the user’s hand during use....

- the beam emitted from it allows the controller to trace patterns onto the surface. The controller (usually a computer) controls the direction, intensity, speed of movement, and spread of the laser beam aimed at the surface. The surface is picked to match what the laser can act on.

There are three main genres of engraving machines: The most common is the X-Y table where, usually, the workpiece (surface) is stationary and the laser optics move around in X and Y directions, directing the laser beam to draw vectors. Sometimes the laser is stationary and the workpiece moves. Sometimes the workpiece moves in the Y axis and the laser in the X axis. A second genre is for cylindrical workpieces (or flat workpieces mounted around a cylinder) where the laser effectively traverses a fine helix and on/off laser pulsing produces the desired image on a raster

Raster graphics

In computer graphics, a raster graphics image, or bitmap, is a data structure representing a generally rectangular grid of pixels, or points of color, viewable via a monitor, paper, or other display medium...

basis. In the third method, both the laser and workpiece are stationary and galvo

Galvanometer

A galvanometer is a type of ammeter: an instrument for detecting and measuring electric current. It is an analog electromechanical transducer that produces a rotary deflection of some type of pointer in response to electric current flowing through its coil in a magnetic field. .Galvanometers were...

mirrors move the laser beam over the workpiece surface. Laser engravers using this technology can work in either raster

Raster graphics

In computer graphics, a raster graphics image, or bitmap, is a data structure representing a generally rectangular grid of pixels, or points of color, viewable via a monitor, paper, or other display medium...

or vector mode.

The point where the laser (the terms "laser" and "laser beam" may be used interchangeably) touches the surface should be on the focal plane of the laser's optical system, and is usually synonymous with its focal point

Focus (optics)

In geometrical optics, a focus, also called an image point, is the point where light rays originating from a point on the object converge. Although the focus is conceptually a point, physically the focus has a spatial extent, called the blur circle. This non-ideal focusing may be caused by...

. This point is typically small, perhaps less than a fraction of a millimeter (depending on the optical wavelength). Only the area inside this focal point is significantly affected when the laser beam passes over the surface. The energy delivered by the laser changes the surface of the material under the focal point. It may heat up the surface and subsequently vaporize the material, or perhaps the material may fracture

Fracture

A fracture is the separation of an object or material into two, or more, pieces under the action of stress.The word fracture is often applied to bones of living creatures , or to crystals or crystalline materials, such as gemstones or metal...

(known as "glass" or "glass up") and flake off the surface. This is how material is removed from the surface to create an engraving.

If the surface material is vaporized during laser engraving, ventilation through the use of blowers or a vacuum

Vacuum

In everyday usage, vacuum is a volume of space that is essentially empty of matter, such that its gaseous pressure is much less than atmospheric pressure. The word comes from the Latin term for "empty". A perfect vacuum would be one with no particles in it at all, which is impossible to achieve in...

pump are almost always required to remove the noxious fumes and smoke arising from this process, and for removal of debris on the surface to allow the laser to continue engraving.

A laser can remove material very efficiently because the laser beam can be designed to deliver energy to the surface in a manner which converts a high percentage of the light energy into heat. The beam is highly focused and collimated - in most non-reflective materials like wood

Wood

Wood is a hard, fibrous tissue found in many trees. It has been used for hundreds of thousands of years for both fuel and as a construction material. It is an organic material, a natural composite of cellulose fibers embedded in a matrix of lignin which resists compression...

, plastic

Plastic

A plastic material is any of a wide range of synthetic or semi-synthetic organic solids used in the manufacture of industrial products. Plastics are typically polymers of high molecular mass, and may contain other substances to improve performance and/or reduce production costs...

s and enamel

Vitreous enamel

Vitreous enamel, also porcelain enamel in U.S. English, is a material made by fusing powdered glass to a substrate by firing, usually between 750 and 850 °C...

surfaces, the conversion of light energy to heat is more than {x%} efficient. However, because of this efficiency, the equipment used in laser engraving may heat up rather quickly. Elaborate cooling systems are required for the laser. Alternatively, the laser beam may be pulse

Pulse

In medicine, one's pulse represents the tactile arterial palpation of the heartbeat by trained fingertips. The pulse may be palpated in any place that allows an artery to be compressed against a bone, such as at the neck , at the wrist , behind the knee , on the inside of the elbow , and near the...

d to decrease the amount of excessive heating.

Different patterns can be engraved by programming the controller to traverse a particular path for the laser beam over time. The trace of the laser beam is carefully regulated to achieve a consistent removal depth of material. For example, criss-crossed paths are avoided to ensure that each etched surface is exposed to the laser only once, so the same amount of material is removed. The speed at which the beam moves across the material is also considered in creating engraving patterns. Changing the intensity and spread of the beam allows more flexibility in the design. For example, by changing the proportion of time (known as "duty-cycle") the laser is turned on during each pulse, the power delivered to the engraving surface can be controlled appropriately for the material.

Since the position of the laser is known exactly by the controller, it is not necessary to add barriers to the surface to prevent the laser from deviating from the prescribed engraving pattern. As a result, no resistive mask is needed in laser engraving. This is primarily why this technique is different from older engraving methods.

A good example of where laser engraving technology has been adopted into the industry norm is the production line

Production line

A production line is a set of sequential operations established in a factory whereby materials are put through a refining process to produce an end-product that is suitable for onward consumption; or components are assembled to make a finished article....

. In this particular setup, the laser beam is directed towards a rotating or vibrating mirror. The mirror moves in a manner which may trace out numbers and letters onto the surface being marked. This is particularly useful for printing dates, expiry codes, and lot numbering of products traveling along a production line. Laser engraving has allowed materials made of plastic and glass to be marked "on the move". The location where the marking takes place is called a "marking laser station", an entity often found in packaging and bottling plants. Older, slower technologies such as hot stamping

Hot stamping

Hot stamping is a dry printing method in which a heated die and foil are used to apply graphics to a surface. This is one method of security printing.- Process:Hot stamping is a straightforward process:# A die is mounted and heated,...

and pad printing

Pad printing

Pad printing is a printing process that can transfer a 2-D image onto a 3-D object. This is accomplished using an indirect offset printing process that involves an image being transferred from the cliché via a silicone pad onto a substrate...

have largely been phased out and replaced with laser engraving.

Lens (optics)

A lens is an optical device with perfect or approximate axial symmetry which transmits and refracts light, converging or diverging the beam. A simple lens consists of a single optical element...

at the engraving surface, allowing very precise and intricate patterns to be traced out.

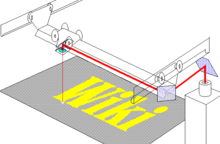

A typical setup of a laser table involves the fixed laser emitting light parallel

Parallel (geometry)

Parallelism is a term in geometry and in everyday life that refers to a property in Euclidean space of two or more lines or planes, or a combination of these. The assumed existence and properties of parallel lines are the basis of Euclid's parallel postulate. Two lines in a plane that do not...

to one axis of the table aimed at a mirror mounted on the end of an adjustable rail. The beam reflects off the mirror angle

Angle

In geometry, an angle is the figure formed by two rays sharing a common endpoint, called the vertex of the angle.Angles are usually presumed to be in a Euclidean plane with the circle taken for standard with regard to direction. In fact, an angle is frequently viewed as a measure of an circular arc...

d at 45 degree

Degree (angle)

A degree , usually denoted by ° , is a measurement of plane angle, representing 1⁄360 of a full rotation; one degree is equivalent to π/180 radians...

s so that the laser travels a path exactly along the length of the rail. This beam is then reflected by another mirror mounted to a movable trolley

Cart

A cart is a vehicle designed for transport, using two wheels and normally pulled by one or a pair of draught animals. A handcart is pulled or pushed by one or more people...

which directs the beam perpendicular

Perpendicular

In geometry, two lines or planes are considered perpendicular to each other if they form congruent adjacent angles . The term may be used as a noun or adjective...

to the original axis. In this scheme, two degrees of freedom

Degrees of freedom (physics and chemistry)

A degree of freedom is an independent physical parameter, often called a dimension, in the formal description of the state of a physical system...

(one vertical, and one horizontal) for etching can be represented.

In other laser engraving devices such as flat table or drum engraving, the laser beam is controlled to direct most of its energy a fixed penetration depth into the material to be engraved. In this manner, only a particular depth of material is removed when the engraving takes place. A simple machined stick or angle-iron can be used as a tool to help trained technologists adjust the engraver to achieve the required focusing. This setup is preferred for surfaces which do not vary in height appreciably.

For surfaces that vary in height, more elaborate focusing mechanisms have been developed. Some are known as dynamic auto focus system

System

System is a set of interacting or interdependent components forming an integrated whole....

s. They adjust the lasing parameters in real time to adapt to the changes to the material as it is being etched. Typically, the height and depth of the surface is monitored with devices tracking changes to ultrasound

Ultrasound

Ultrasound is cyclic sound pressure with a frequency greater than the upper limit of human hearing. Ultrasound is thus not separated from "normal" sound based on differences in physical properties, only the fact that humans cannot hear it. Although this limit varies from person to person, it is...

, infrared

Infrared

Infrared light is electromagnetic radiation with a wavelength longer than that of visible light, measured from the nominal edge of visible red light at 0.74 micrometres , and extending conventionally to 300 µm...

, or visible light aimed at the engraving surface. These devices, known as pilot beams or pilot lasers (if a laser is used) help guide the adjustments made to the lens of the laser in determining the optimal spot to focus on the surface and remove material effectively.

"X-Y" laser engraving machines may operate in vector and raster

Raster graphics

In computer graphics, a raster graphics image, or bitmap, is a data structure representing a generally rectangular grid of pixels, or points of color, viewable via a monitor, paper, or other display medium...

mode.

Vector engraving follows the line and curve of the pattern to be engraved, much like a pen-based plotter

Plotter

A plotter is a computer printing device for printing vector graphics. In the past, plotters were widely used in applications such as computer-aided design, though they have generally been replaced with wide-format conventional printers...

draws by constructing line segments from a description of the outlines of a pattern. Much early engraving of signs and plaques (laser or otherwise) used pre-stored font

Font

In typography, a font is traditionally defined as a quantity of sorts composing a complete character set of a single size and style of a particular typeface...

outlines so that letters, numbers or even logos could be scaled to size and reproduced with exactly defined strokes. Unfortunately, "fill

Fill

Fill may refer to:*Fill dirt, soil added to an area.*Fill , a short segment of instrumental music.*In textiles, the filling yarn is the same as weft, the yarn which is shuttled back and forth across the warp to create a woven fabric....

" areas were problem

Problem

A problem is an obstacle, impediment, difficulty or challenge, or any situation that invites resolution; the resolution of which is recognized as a solution or contribution toward a known purpose or goal...

atic, as cross-hatching patterns and dot-fills sometimes exhibited moiré effects or uber-patterns caused by the imprecise calculation of dot spacings. Moreover, rotations of a font or dynamic scaling often were beyond the capabilities of the font-rendering device. The introduction of the PostScript

PostScript

PostScript is a dynamically typed concatenative programming language created by John Warnock and Charles Geschke in 1982. It is best known for its use as a page description language in the electronic and desktop publishing areas. Adobe PostScript 3 is also the worldwide printing and imaging...

page-description language now allows much greater flexibility—now virtually anything that can be described in vectors by PostScript-enabled software like CorelDRAW

CorelDRAW

CorelDRAW is a vector graphics editor developed and marketed by Corel Corporation of Ottawa, Canada. It is also the name of Corel's Graphics Suite...

or Adobe Illustrator

Adobe Illustrator

Adobe Illustrator is a vector graphics editor developed and marketed by Adobe Systems. Illustrator is similar in scope, intended market, and functionality to its competitors, CorelDraw, Xara Designer Pro and Macromedia FreeHand....

can be outlined, filled with suitable patterns, and laser-engraved.

Raster engraving traces the laser across the surface in a back-and-forth slowly-advancing linear

Linear

In mathematics, a linear map or function f is a function which satisfies the following two properties:* Additivity : f = f + f...

pattern that will remind one of the printhead on an inkjet

Inkjet printer

An inkjet printer is a type of computer printer that creates a digital image by propelling droplets of ink onto paper. Inkjet printers are the most commonly used type of printer and range from small inexpensive consumer models to very large professional machines that can cost up to thousands of...

or similar printer. The pattern is usually optimized by the controller/computer so that areas to either side of the pattern which aren't to be engraved are ignored and the trace across the material is thus shortened for better efficiency

Material efficiency

Material efficiency is a description or metric which expresses the degree in which usage of raw materials, construction projects or physical processes are used or carried out in a manner which consumes, incorporates, or wastes less of a given material compared to previous measures...

. The amount of advance of each line is normally less than the actual dot-size of the laser; the engraved lines overlap just slightly to create a continuity of engravure. As is true of all rasterized devices, curves and diagonals can sometimes suffer if the length or position of the raster lines varies even slightly in relation to the adjacent raster scan; therefore exact positioning and repeatability are critically important to the design of the machine. The advantage of rasterizing is the near effortless "fill" it produces. Most images to be engraved are bold letters or have large continuously-engraved areas, and these are well-rasterized. Photos are rasterized (as in printing), with dots larger than that of the laser's spot, and these also are best engraved as a raster image. Almost any page-layout software can be used to feed a raster driver for an X-Y or drum laser engraver. While traditional sign and plaque engraving tended to favor the solid strokes of vectors out of necessity, modern shops tend to run their laser engravers mostly in raster mode, reserving vector for a traditional outline "look" or for speedily marking out lines or "hatch

Hatch

Hatch may refer to:* Hatching, also called "cross-hatching", an artistic technique used to create tonal or shading effects using closely spaced parallel lines* Hatching, the emergence of a young animal from an egg...

es" where a plate is to be cut.

Natural materials

Directly "burning" images on woodWood

Wood is a hard, fibrous tissue found in many trees. It has been used for hundreds of thousands of years for both fuel and as a construction material. It is an organic material, a natural composite of cellulose fibers embedded in a matrix of lignin which resists compression...

were some of the first uses of engraving lasers. The laser power required here is often less than 10 watt

Watt

The watt is a derived unit of power in the International System of Units , named after the Scottish engineer James Watt . The unit, defined as one joule per second, measures the rate of energy conversion.-Definition:...

s depending on the laser being used as most are different. Hardwood

Hardwood

Hardwood is wood from angiosperm trees . It may also be used for those trees themselves: these are usually broad-leaved; in temperate and boreal latitudes they are mostly deciduous, but in tropics and subtropics mostly evergreen.Hardwood contrasts with softwood...

s like walnut, oak, mahogany and maple produce good results. Softwood

Softwood

The term softwood is used to describe wood from trees that are known as gymnosperms.Conifers are an example. It may also be used to describe trees, which tend to be evergreen, notable exceptions being bald cypress and the larches....

s can be judiciously engraved but tend to vaporize at less-consistent depths. Burning a softwood with a fan blowing on it requires lowest power, quickest speed of cut, and enough airflow to extinguish what is trying meanwhile to ignite. Hard papers and fiberboard work well; linty papers and newsprint are like softwoods. Fur is not engraveable; finished leathers though can be laser-engraved with a look very similar to hot-branding. Certain latex

Latex

Latex is the stable dispersion of polymer microparticles in an aqueous medium. Latexes may be natural or synthetic.Latex as found in nature is a milky fluid found in 10% of all flowering plants . It is a complex emulsion consisting of proteins, alkaloids, starches, sugars, oils, tannins, resins,...

rubber compounds can be laser engraved; for example these can be used to fabricate

Fabrication (metal)

Fabrication as an industrial term refers to building metal structures by cutting, bending, and assembling. The cutting part of fabrication is via sawing, shearing, or chiseling ; torching with handheld torches ; and via CNC cutters...

inking-stamps.

Paper masking tape

Masking tape

Masking tape is a type of pressure sensitive tape made of a thin and easy-to-tear paper, and an easily released pressure sensitive adhesive. It is available in a variety of widths. It is used mainly in painting, to mask off areas that should not be painted...

is sometimes used as a pre-engraving overcoat on finished and resin

Resin

Resin in the most specific use of the term is a hydrocarbon secretion of many plants, particularly coniferous trees. Resins are valued for their chemical properties and associated uses, such as the production of varnishes, adhesives, and food glazing agents; as an important source of raw materials...

y woods so that cleanup is a matter of picking the tape off and out of the unengraved areas, which is easier than removing the sticky and smoky surround "halos" (and requires no varnish

Varnish

Varnish is a transparent, hard, protective finish or film primarily used in wood finishing but also for other materials. Varnish is traditionally a combination of a drying oil, a resin, and a thinner or solvent. Varnish finishes are usually glossy but may be designed to produce satin or semi-gloss...

-removing chemicals).

Plastics

Standard cast acrylic plastic, acrylic plastic sheet, and other cast resins generally laser very well. A commonly engraved award is a cast acrylic shape designed to be lasered from the back side. Styrene (as in compact disc cases) and many of the thermoformingThermoforming

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product...

plastics will tend to melt

Melt (manufacturing)

Melt is the term used to describe the working material in the steelmaking process, in making glass, and when forming thermoplastics. For thermoplastics, the term specifically refers to the plastic in its forming temperature, which can vary depending on how it is being used. For steelmaking, it...

around the edge of the engraving spot. The result is usually "soft" and has no "etch" contrast. The surface may actually deform or "ripple" at the lip areas. In some applications this is acceptable; for example date markings on 2-litre soda bottles do not need to be sharp.

For signage and faceplates, etc., special laser-engraving plastics were developed. These incorporate silicate

Silicate

A silicate is a compound containing a silicon bearing anion. The great majority of silicates are oxides, but hexafluorosilicate and other anions are also included. This article focuses mainly on the Si-O anions. Silicates comprise the majority of the earth's crust, as well as the other...

or other materials which conduct excess heat away from the material before it can deform. Outer laminate

Laminate

A laminate is a material that can be constructed by uniting two or more layers of material together. The process of creating a laminate is lamination, which in common parlance refers to the placing of something between layers of plastic and gluing them with heat and/or pressure, usually with an...

s of this material vaporize easily to expose different colored material below.

Other plastics may be successfully engraved, but orderly experimentation on a sample piece is recommended. Bakelite is said to be easily laser-engraved; some hard engineering plastics work well. Expanded plastics, foam

Foam

-Definition:A foam is a substance that is formed by trapping gas in a liquid or solid in a divided form, i.e. by forming gas regions inside liquid regions, leading to different kinds of dispersed media...

s and vinyl

Vinyl

A vinyl compound is any organic compound that contains a vinyl group ,which are derivatives of ethene, CH2=CH2, with one hydrogen atom replaced with some other group...

s however are generally candidates for routing rather than laser engraving. Urethane

Polyurethane

A polyurethane is any polymer composed of a chain of organic units joined by carbamate links. Polyurethane polymers are formed through step-growth polymerization, by reacting a monomer with another monomer in the presence of a catalyst.Polyurethanes are...

and silicone

Silicone

Silicones are inert, synthetic compounds with a variety of forms and uses. Typically heat-resistant and rubber-like, they are used in sealants, adhesives, lubricants, medical applications , cookware, and insulation....

plastics usually don't work well—unless it is a formulation filled with cellulose

Cellulose

Cellulose is an organic compound with the formula , a polysaccharide consisting of a linear chain of several hundred to over ten thousand β linked D-glucose units....

, stone or some other stable insulator

Thermal insulation

Thermal insulation is the reduction of the effects of the various processes of heat transfer between objects in thermal contact or in range of radiative influence. Heat transfer is the transfer of thermal energy between objects of differing temperature...

material.

Many light switchplates from companies such as Leviton

Leviton

Leviton Manufacturing Company, Inc., is the largest privately held manufacturer of electrical wiring equipment in North America. It produces electrical products: light sockets, receptacles , dimmers and other lighting control systems, wire, power cables, power cords, wall and ceiling occupancy...

or Lutron

Lutron

Lutron Electronics Company, Inc. is a privately held corporation that designs, manufactures, and sells lighting control systems and a variety of other related products...

can be laser engraved. Again, experimentation may be necessary to develop the correct laser settings to result in engraving the surface rather than melting it. Often the laser engraving is followed by paint filling the engraved surface to produce more contrast between the engraved surface and the surrounding surface.

Metals

The best traditional engraving materials started out to be the worst laser-engravable materials. This problem has now been solved using lasers at shorter wavelengths than the traditional 10,640 nm wavelength CO2 laser. Using Yb: Fiber Lasers, Nd:YVO4 or Nd:YAG lasers at 1,064 nm wavelength, or its harmonics at 532 and 355 nm, metals can now easily be engraved using commercial systems.Coated metals

However, the same conduction that works against the spot vaporization of metal is an asset if the objective is to vaporize some other coating away from the metal. Laser engraving metal plates are manufactured with a finely-polished metal, coated with an enamel paintEnamel paint

Enamel paint is paint that air dries to a hard, usually glossy, finish, used for coating surfaces that are outdoors or otherwise subject to hard wear or variations in temperature; it should not be confused with decorated objects in "painted enamel", where vitreous enamel is applied with brushes and...

made to be "burned off". At levels of 10-30 watts, excellent engravings are made as the enamel is removed quite cleanly. Much laser engraving is sold as exposed brass or silver

Silver

Silver is a metallic chemical element with the chemical symbol Ag and atomic number 47. A soft, white, lustrous transition metal, it has the highest electrical conductivity of any element and the highest thermal conductivity of any metal...

-coated steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

lettering on a black or dark-enamelled background. A wide variety of finishes are now available, including screen-printed marble

Marbling

Marbling may refer to:*The quality of a surface that has streaks of color, like marble. For example:**Marbleizing, also called faux marbling, the art of painting walls or furniture to look like real marble....

effects on the enamel. Spray coatings can be obtained for the specific use of laser engraving metals, these sprays apply a coating that is visible to the laser light which fuses the coating to the substrate where the laser passed over. Typically, these sprays can also be used to engrave other optically invisible or reflective substances such as glass and are available in a variety of colours.http://www.thermark.com/content/view/16/86/

Stone and glass

StoneRock (geology)

In geology, rock or stone is a naturally occurring solid aggregate of minerals and/or mineraloids.The Earth's outer solid layer, the lithosphere, is made of rock. In general rocks are of three types, namely, igneous, sedimentary, and metamorphic...

and glass

Glass

Glass is an amorphous solid material. Glasses are typically brittle and optically transparent.The most familiar type of glass, used for centuries in windows and drinking vessels, is soda-lime glass, composed of about 75% silica plus Na2O, CaO, and several minor additives...

do not turn gaseous very easily. As expected, this makes them generally a better candidate for other means of engraving, most notably sandblasting or cutting using diamonds and water

Water jet cutter

A water jet cutter, also known as a waterjet, is a tool capable of slicing into metal or other materials using a jet of water at high velocity and pressure, or a mixture of water and an abrasive substance. The process is essentially the same as water erosion found in nature but greatly accelerated...

. But when a laser hits glass or stone, something else interesting happens: it fractures. Pore

Porosity

Porosity or void fraction is a measure of the void spaces in a material, and is a fraction of the volume of voids over the total volume, between 0–1, or as a percentage between 0–100%...

s in the surface expose natural grain

GRAIN

GRAIN is a small international non-profit organisation that works to support small farmers and social movements in their struggles for community-controlled and biodiversity-based food systems. Our support takes the form of independent research and analysis, networking at local, regional and...

s and crystalline "stubs" which, when heated very quickly, can separate a microscopic sized "chip" from the surface because the hot piece is expanding relative to its surroundings. So lasers are indeed used to engrave on glass, and if the power, speed and focus are just right, excellent results can be achieved . One should avoid large "fill" areas in glass engraving because the results across an expanse tend to be uneven; the glass ablation simply cannot be depended on for visual consistency, which may be a disadvantage or an advantage depending on the circumstances and the desired effect.

Jewelry

The demand for personalized jewelry has made jewelers more aware of the benefits of the laser engraving process.Jewelers found that by using a laser, they could tackle an engraving task with greater precision

Accuracy and precision

In the fields of science, engineering, industry and statistics, the accuracy of a measurement system is the degree of closeness of measurements of a quantity to that quantity's actual value. The precision of a measurement system, also called reproducibility or repeatability, is the degree to which...

. In fact, jewelers discovered that laser engraving allowed for more precision than other types of engraving. At the same time, jewelers discovered that laser applied engravings had a number of other desirable features.

At one time jewelers who attempted to do laser engraving did need to use large pieces of equipment. Now the devices that perform laser engraving come in desktop

Desktop

Desktop refers to the surface of a desk.The term has been adopted as an adjective to distinguish office appliances which can be fitted on top of a desk, from larger equipment covering its own area on the floor....

units. Some entrepreneurs have placed such units in mall kiosks. That has made laser engraving jewelry much more accessible. The makers of machines for laser engraving jewelry have developed some very specialized equipment. They have designed machines that can engrave the inside of a ring

Ring (finger)

A finger ring is a circular band worn as a type of ornamental jewelry around a finger; it is the most common current meaning of the word ring. Other types of metal bands worn as ornaments are also called rings, such as arm rings and neck rings....

. They have also created machines that have the ability to engrave the back of a watch

Watch

A watch is a small timepiece, typically worn either on the wrist or attached on a chain and carried in a pocket, with wristwatches being the most common type of watch used today. They evolved in the 17th century from spring powered clocks, which appeared in the 15th century. The first watches were...

.

A laser can cut into both flat and curved surfaces. Jewelry contains both flat and curved surfaces. That points-up the reason why jewelers have welcomed all the adaptations for the creation of laser engraved jewelry.

Fine Art

Laser engraving can also be used to create works of fine art. Generally this involves engraving into planar surfaces, to reveal lower levels of the surface or to create grooves and striations which can be filled with inks, glazes, or other materials. Some laser engravers have rotary attachments which can engrave around an object. Artists may digitize drawings, scan or create images on a computer, and engrave the image onto any of the materials cited in this article.Direct laser engraving of flexographic plates and cylinders

Direct laser engraving of flexographic printing cylinders and plates has been an established process since the 1970s. This first began with the use of a carbon dioxide laser used to selectively ablate or evaporate a variety of rubber plate and sleeve materials to produce a print ready surface without the use of photography or chemicals. With this process there is no integral ablation mask as with direct photopolymer laser imaging (see below). Instead a high-power carbon dioxide laserCarbon dioxide laser

The carbon dioxide laser was one of the earliest gas lasers to be developed , and is still one of the most useful. Carbon dioxide lasers are the highest-power continuous wave lasers that are currently available...

head burns away, or ablates, unwanted material. The aim is to form sharp, relief images with steep first relief and contoured shoulder supported edges to give a high standard of process color reproduction. A short water wash and dry cycle follows, which is a lot less involved than in the post-processing stages for direct laser imaging or conventional flexo platemaking using photopolymer plates. After engraving, the photopolymer is exposed through the imaged black layer and washed out in the traditional photopolymer process requiring photography and chemicals. See below.

Before the year 2000 lasers only produced lower quality in rubber-like materials. In these rubber-like materials, which had a rough structure, higher quality was impossible. Since the year 2000 fiber laser

Fiber laser

A fiber laser or fibre laser is a laser in which the active gain medium is an optical fiber doped with rare-earth elements such as erbium, ytterbium, neodymium, dysprosium, praseodymium, and thulium. They are related to doped fiber amplifiers, which provide light amplification without lasing...

s have been introduced to give a much increased engraving quality direct into black polymeric materials. Also at the Drupa 2004 the direct engraving of polymer plates was introduced. This had also an effect on the rubber-developers who, in order to stay competitive, developed new high quality rubber-like materials. The development of suitable polymeric compounds has also allowed the engraving quality achievable with the fibre lasers to be realised in print. Since then direct laser engraving of flexo-printingforms is seen by many as the modern way to make printing-forms for it is the first real digital way.

As a competitive process, more recently laser system have been introduced to selectively engrave the thin opaque black layer of a specially produced photopolymer plate or sleeve.

Direct photopolymer laser imaging

closely related is the direct imaging of a digital flexo plates or sleeves 'in-the-round' on a fast-rotating drum, or cylinder. This is carried out on a platesetter integrated within a digital prepress workflow, that also supports digital proofing. Again, this is a filmless process, which removes one of the variables in obtaining the fine and sharp dots for screened affects, including process color printing.With this process the electronically-generated image is scanned at speed to a photopolymer plate material that carries a thin black mask layer on the surface. The infrared laser-imaging head, which runs parallel to the drum axis, ablates the integral mask to reveal the uncured polymer underneath. A main ultraviolet exposure follows to form the image through the mask. The remaining black layer absorbs the ultraviolet radiation, which polymer

Polymer

A polymer is a large molecule composed of repeating structural units. These subunits are typically connected by covalent chemical bonds...

izes the underlying photopolymer where the black layer has been removed. The exposed digital plate still needs to be processed like a conventional flexo plate. That is, using solvent-based washout with the necessary waste recovery techniques, although some water-washable digital plates are in development. This technology has been used since 1995 and is only now becoming more widely used around the world as more affordable equipment becomes available. Trade sources say there are around 650 digital platesetters installed in label, packaging and trade platemaking houses.

Laser engraving of anilox rolls

Prior to 1980 aniloxAnilox

In printing, anilox is a method used to provide a measured amount of ink to a flexo printing plate.An anilox roll is a hard cylinder, usually constructed of a steel or aluminum core which is coated by an industrial ceramic whose surface contains millions of very fine dimples, known as cells...

rolls were produced by a variety of mechanical processes. These metal anilox rolls were sometimes sprayed with ceramic to prolong their life in the flexographic printing press. During the 1980s laser engraving systems were produced which used a carbon dioxide laser

Carbon dioxide laser

The carbon dioxide laser was one of the earliest gas lasers to be developed , and is still one of the most useful. Carbon dioxide lasers are the highest-power continuous wave lasers that are currently available...

to engrave the required cell pattern directly into the polished ceramic surface. Since then Q-switched YAG lasers were used for a period as they provided a more focusable laser beam as well as increased pulsing frequencies capable of engraving the finer cell configuration demanded by the ever evolving flexographic printing process. Since approximately the year 2000 the direct anilox laser engraving process has been dominated by the use of fibre lasers which provide the high powers of the carbondioxide lasers together with the finely focusable beam of the YAG lasers. Optical systems providing the rapid switching of multiple beams have allowed the fibre laser system to be dominant in this market. This technology has become known as Multi-Beam-Anilox or MBA.

Sub-surface laser engraving (SSLE)

Sub-surface laser engraving is the process of engraving an image below the surface of a solid material, usually glass, with an optical clarity to minimize distortion of the laser.Since its inception in the late 1990s, SSLE has become more cost effective with a number of different sized machines ranging from small (~US$35,000–60,000) to large production sized tables (>US$250,000). Although these machines are becoming more available, it is estimated that only a few hundred are in operation worldwide. Many machines require very expensive cooling, maintenance and calibration for proper use. The more popular SSLE engraving machines use the Diode Pumped Solid State or DPSS laser process. The laser diode

Laser diode

The laser diode is a laser where the active medium is a semiconductor similar to that found in a light-emitting diode. The most common type of laser diode is formed from a p-n junction and powered by injected electric current...

, the primary component which excites a pulsed solid state laser, can easily cost one third of the machine itself and functions for a limited number of hours, but a good quality diode can last for thousands of hours, equating to years of use.

In the past five years, use of SSLE has become more cost effective to produce 3D images in souvenir 'crystal' or promotional items with only a few designers concentrating on designs incorporating large or monolithic sized crystal. A number of companies offer custom made souvenirs by taking 3D pictures or photos and engraving them into the crystal. Quality of the designs and images varies greatly between vendors in the promotional and personal services sector (photo engravers) – the mass producing curio vendors have the habit of reducing resolution of the points and lowering output to maximize their laser diode's lifespan.