Properties of concrete

Encyclopedia

Concrete

has relatively high compressive strength

, but significantly lower tensile strength

, and as such is usually reinforced with materials that are strong in tension (often steel). The elasticity of concrete is relatively constant at low stress levels but starts decreasing at higher stress levels as matrix cracking develops. Concrete has a very low coefficient of thermal expansion, and as it matures concrete shrinks. All concrete structures will crack to some extent, due to shrinkage and tension. Concrete which is subjected to long-duration forces is prone to creep

.

Tests can be made to ensure the properties of concrete correspond to specifications for the application.

The density of concrete varies, but is around 2,400 kg/m³ (150 pounds per cubic foot or 4,050 lb/yd³).

As a result, without compensating, concrete would almost always fail from tensile stresses – even when loaded in compression. The practical implication of this is that concrete elements subjected to tensile stresses must be reinforced with materials that are strong in tension.

Reinforced concrete

is the most common form of concrete. The reinforcement is often steel, rebar

(mesh, spiral, bars and other forms). Structural fibers

of various materials are available.

Concrete can also be prestressed

(reducing tensile stress) using internal steel cables (tendons), allowing for beams

or slabs with a longer span

than is practical with reinforced concrete alone. Inspection of concrete structures can be non-destructive if carried out with equipment such as a Schmidt hammer

, which is used to estimate concrete strength.

The ultimate strength of concrete is influenced by the water-cementitious ratio (w/cm), the design constituents, and the mixing, placement and curing methods employed. All things being equal, concrete with a lower water-cement (cementitious) ratio makes a stronger concrete than that with a higher ratio. The total quantity of cementitious materials (portland cement

, slag cement, pozzolan

s) can affect strength, water demand, shrinkage, abrasion resistance and density. All concrete will crack independent of whether or not it has sufficient compressive strength. In fact, high Portland cement content mixtures can actually crack more readily due to increased hydration rate. As concrete transforms from its plastic state, hydrating to a solid, the material undergoes shrinkage. Plastic shrinkage cracks can occur soon after placement but if the evaporation rate is high they often can actually occur during finishing operations, for example in hot weather or a breezy day.

In very high-strength concrete mixtures (greater than 70 MPa) the crushing strength of the aggregate can be a limiting factor

to the ultimate compressive strength. In lean concretes (with a high water-cement ratio) the crushing strength of the aggregates is not so significant.

The internal forces in common shapes of structure, such as arch

es, vaults

, columns and walls are predominantly compressive forces, with floors and pavements subjected to tensile forces. Compressive strength is widely used for specification requirement and quality control of concrete. The engineer knows his target tensile (flexural) requirements and will express these in terms of compressive strength.

Wired.com reported on April 13, 2007 that a team from the University of Tehran

, competing in a contest sponsored by the American Concrete Institute

, demonstrated several blocks of concretes with abnormally high compressive strengths between 340 and 410 MPa (49,312.8 and 59,465.5 psi) at 28 days. The blocks appeared to use an aggregate of steel

fibres and quartz

– a mineral with a compressive strength of 1100 MPa, much higher than typical high-strength aggregates such as granite

(100–140 MPa or 14,503.8–20,305.3 psi).

Reactive Powder Concrete, also known as Ultra-High Performance Concrete, can be even stronger, with strengths of up to 800 MPa (116,000 PSI). These are made by eliminating large aggregate completely, carefully controlling the size of the fine aggregates to ensure the best possible packing, and incorporating steel fibers (sometimes produced by grinding steel wool) into the matrix. Reactive Powder Concretes may also make use of silica fume as a fine aggregate. Commercial Reactive Powder Concretes are available in the 170–210 MPa (24,656.4–30,457.9 psi) strength range.

The American Concrete Institute

allows the modulus of elasticity to be calculated using the following equation: (psi

(psi

)

where weight of concrete (pounds per cubic foot) and where

weight of concrete (pounds per cubic foot) and where

compressive strength of concrete at 28 days (psi)

compressive strength of concrete at 28 days (psi)

This equation is completely empirical and is not based on theory. Note that the value of Ec found is in units of psi. For normalweight concrete (defined as concrete with a wc of 150 lb/ft3 and subtracting 5 lb/ft3 for steel) Ec is permitted to be taken as .

.

. The coefficient of thermal expansion of Portland cement concrete is 0.000008 to 0.000012 (per degree Celsius) (8 to 12 microstrains/°C)(8-12 1/MK).

As concrete matures it continues to shrink, due to the ongoing reaction taking place in the material, although the rate of shrinkage falls relatively quickly and keeps reducing over time (for all practical purposes concrete is usually considered to not shrink due to hydration any further after 30 years). The relative shrinkage and expansion of concrete and brickwork require careful accommodation when the two forms of construction interface.

Because concrete is continuously shrinking for years after it is initially placed, it is generally accepted that under thermal loading it will never expand to its originally placed volume.

Due to its low thermal conductivity

, a layer of concrete is frequently used for fireproofing of steel structures.

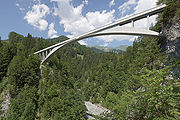

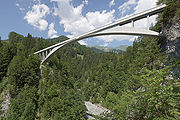

All concrete structures will crack to some extent. One of the early designers of reinforced concrete, Robert Maillart

All concrete structures will crack to some extent. One of the early designers of reinforced concrete, Robert Maillart

, employed reinforced concrete in a number of arched bridges. His first bridge was simple, using a large volume of concrete. He then realized that much of the concrete was very cracked, and could not be a part of the structure under compressive loads, yet the structure clearly worked. His later designs simply removed the cracked areas, leaving slender, beautiful concrete arches. The Salginatobel Bridge

is an example of this.

Concrete cracks due to tensile stress induced by shrinkage or stresses occurring during setting or use. Various means are used to overcome this. Fiber reinforced concrete

uses fine fibers distributed throughout the mix or larger metal or other reinforcement

elements to limit the size and extent of cracks. In many large structures joints or concealed saw-cuts are placed in the concrete as it sets to make the inevitable cracks occur where they can be managed and out of sight. Water tanks and highways are examples of structures requiring crack control.

Plastic-shrinkage cracks are immediately apparent, visible within 0 to 2 days of placement, while drying-shrinkage cracks develop over time. Autogenous shrinkage also occurs when the concrete is quite young and results from the volume reduction resulting from the chemical reaction of the Portland cement.

s where a transversely applied load will put one surface into compression and the opposite surface into tension due to induced bending

. The portion of the beam that is in tension may crack. The size and length of cracks is dependent on the magnitude of the bending moment and the design of the reinforcing in the beam at the point under consideration. Reinforced concrete beams are designed to crack in tension rather than in compression. This is achieved by providing reinforcing steel which yields before failure of the concrete in compression occurs and allowing remediation, repair, or if necessary, evacuation of an unsafe area.

. Short-duration forces (such as wind or earthquakes) do not cause creep. Creep can sometimes reduce the amount of cracking that occurs in a concrete structure or element, but it also must be controlled. The amount of primary and secondary reinforcing in concrete structures contributes to a reduction in the amount of shrinkage, creep and cracking.

Engineers usually specify the required compressive strength of concrete, which is normally given as the 28 day compressive strength in megapascals (MPa) or pounds per square inch (psi). Twenty eight days is a long wait to determine if desired strengths are going to be obtained, so three-day and seven-day strengths can be useful to predict the ultimate 28-day compressive strength of the concrete. A 25% strength gain between 7 and 28 days is often observed with 100% OPC (ordinary Portland cement) mixtures, and up to 40% strength gain can be realized with the inclusion of pozzolans and supplementary cementitious materials (SCMs) such as fly ash and/or slag cement. Strength gain depends on the type of mixture, its constituents, the use of standard curing, proper testing and care of cylinders in transport, etc. It is imperative to accurately test the fundamental properties of concrete in its fresh, plastic state.

Engineers usually specify the required compressive strength of concrete, which is normally given as the 28 day compressive strength in megapascals (MPa) or pounds per square inch (psi). Twenty eight days is a long wait to determine if desired strengths are going to be obtained, so three-day and seven-day strengths can be useful to predict the ultimate 28-day compressive strength of the concrete. A 25% strength gain between 7 and 28 days is often observed with 100% OPC (ordinary Portland cement) mixtures, and up to 40% strength gain can be realized with the inclusion of pozzolans and supplementary cementitious materials (SCMs) such as fly ash and/or slag cement. Strength gain depends on the type of mixture, its constituents, the use of standard curing, proper testing and care of cylinders in transport, etc. It is imperative to accurately test the fundamental properties of concrete in its fresh, plastic state.

Concrete is typically sampled while being placed, with testing protocols requiring that test samples be cured under laboratory conditions (standard cured). Additional samples may be field cured (non-standard) for the purpose of early 'stripping' strengths, that is, form removal, evaluation of curing, etc. but the standard cured cylinders comprise acceptance criteria. Concrete tests can measure the "plastic" (unhydrated) properties of concrete prior to, and during placement. As these properties affect the hardened compressive strength and durability of concrete (resistance to freeze-thaw), the properties of workability (slump/flow), temperature, density and age are monitored to ensure the production and placement of 'quality' concrete. Tests are performed per ASTM International

, European Committee for Standardization

or Canadian Standards Association

. As measurement of quality must represent the potential of concrete material delivered and placed, it is imperative that concrete technicians performing concrete tests are certified to do so according to these standards. Structural design, material design and properties are often specified in accordance with national/regional design codes such as American Concrete Institute

.

Compressive strength

tests are conducted using an instrumented hydraulic ram

to compress a standard cylindrical or cubic sample to failure. Tensile strength tests are conducted either by three-point bending of a prismatic beam specimen or by compression along the sides of a standard cylindrical specimen. These are not to be equated with nondestructive testing

using a rebound hammer

or probe systems which are hand-held indicators, for relative strength of the top few millimeters, of comparative concretes in the field.

Concrete

Concrete is a composite construction material, composed of cement and other cementitious materials such as fly ash and slag cement, aggregate , water and chemical admixtures.The word concrete comes from the Latin word...

has relatively high compressive strength

Compressive strength

Compressive strength is the capacity of a material or structure to withstand axially directed pushing forces. When the limit of compressive strength is reached, materials are crushed. Concrete can be made to have high compressive strength, e.g...

, but significantly lower tensile strength

Tensile strength

Ultimate tensile strength , often shortened to tensile strength or ultimate strength, is the maximum stress that a material can withstand while being stretched or pulled before necking, which is when the specimen's cross-section starts to significantly contract...

, and as such is usually reinforced with materials that are strong in tension (often steel). The elasticity of concrete is relatively constant at low stress levels but starts decreasing at higher stress levels as matrix cracking develops. Concrete has a very low coefficient of thermal expansion, and as it matures concrete shrinks. All concrete structures will crack to some extent, due to shrinkage and tension. Concrete which is subjected to long-duration forces is prone to creep

Creep (deformation)

In materials science, creep is the tendency of a solid material to slowly move or deform permanently under the influence of stresses. It occurs as a result of long term exposure to high levels of stress that are below the yield strength of the material....

.

Tests can be made to ensure the properties of concrete correspond to specifications for the application.

The density of concrete varies, but is around 2,400 kg/m³ (150 pounds per cubic foot or 4,050 lb/yd³).

As a result, without compensating, concrete would almost always fail from tensile stresses – even when loaded in compression. The practical implication of this is that concrete elements subjected to tensile stresses must be reinforced with materials that are strong in tension.

Reinforced concrete

Reinforced concrete

Reinforced concrete is concrete in which reinforcement bars , reinforcement grids, plates or fibers have been incorporated to strengthen the concrete in tension. It was invented by French gardener Joseph Monier in 1849 and patented in 1867. The term Ferro Concrete refers only to concrete that is...

is the most common form of concrete. The reinforcement is often steel, rebar

Rebar

A rebar , also known as reinforcing steel, reinforcement steel, rerod, or a deformed bar, is a common steel bar, and is commonly used as a tensioning device in reinforced concrete and reinforced masonry structures holding the concrete in compression...

(mesh, spiral, bars and other forms). Structural fibers

Fiber reinforced concrete

Fiber-reinforced concrete is concrete containing fibrous material which increases its structural integrity. It contains short discrete fibers that are uniformly distributed and randomly oriented. Fibers include steel fibers, glass fibers, synthetic fibers and natural fibers...

of various materials are available.

Concrete can also be prestressed

Prestressed concrete

Prestressed concrete is a method for overcoming concrete's natural weakness in tension. It can be used to produce beams, floors or bridges with a longer span than is practical with ordinary reinforced concrete...

(reducing tensile stress) using internal steel cables (tendons), allowing for beams

Beam (structure)

A beam is a horizontal structural element that is capable of withstanding load primarily by resisting bending. The bending force induced into the material of the beam as a result of the external loads, own weight, span and external reactions to these loads is called a bending moment.- Overview...

or slabs with a longer span

Span (architecture)

Span is the distance between two intermediate supports for a structure, e.g. a beam or a bridge.A span can be closed by a solid beam or of a rope...

than is practical with reinforced concrete alone. Inspection of concrete structures can be non-destructive if carried out with equipment such as a Schmidt hammer

Schmidt hammer

A Schmidt hammer, also known as a Swiss hammer or a rebound hammer, is a device to measure the elastic properties or strength of concrete or rock, mainly surface hardness and penetration resistance.It was invented by Ernst Schmidt, a Swiss engineer....

, which is used to estimate concrete strength.

The ultimate strength of concrete is influenced by the water-cementitious ratio (w/cm), the design constituents, and the mixing, placement and curing methods employed. All things being equal, concrete with a lower water-cement (cementitious) ratio makes a stronger concrete than that with a higher ratio. The total quantity of cementitious materials (portland cement

Portland cement

Portland cement is the most common type of cement in general use around the world because it is a basic ingredient of concrete, mortar, stucco and most non-specialty grout...

, slag cement, pozzolan

Pozzolan

A pozzolan is a material which, when combined with calcium hydroxide, exhibits cementitious properties. Pozzolans are commonly used as an addition to Portland cement concrete mixtures to increase the long-term strength and other material properties of Portland cement concrete, and in some cases...

s) can affect strength, water demand, shrinkage, abrasion resistance and density. All concrete will crack independent of whether or not it has sufficient compressive strength. In fact, high Portland cement content mixtures can actually crack more readily due to increased hydration rate. As concrete transforms from its plastic state, hydrating to a solid, the material undergoes shrinkage. Plastic shrinkage cracks can occur soon after placement but if the evaporation rate is high they often can actually occur during finishing operations, for example in hot weather or a breezy day.

In very high-strength concrete mixtures (greater than 70 MPa) the crushing strength of the aggregate can be a limiting factor

Limiting factor

A limiting factor or limiting resource is a factor that controls a process, such as organism growth or species population, size, or distribution. The availability of food, predation pressure, or availability of shelter are examples of factors that could be limiting for an organism...

to the ultimate compressive strength. In lean concretes (with a high water-cement ratio) the crushing strength of the aggregates is not so significant.

The internal forces in common shapes of structure, such as arch

Arch

An arch is a structure that spans a space and supports a load. Arches appeared as early as the 2nd millennium BC in Mesopotamian brick architecture and their systematic use started with the Ancient Romans who were the first to apply the technique to a wide range of structures.-Technical aspects:The...

es, vaults

Vault (architecture)

A Vault is an architectural term for an arched form used to provide a space with a ceiling or roof. The parts of a vault exert lateral thrust that require a counter resistance. When vaults are built underground, the ground gives all the resistance required...

, columns and walls are predominantly compressive forces, with floors and pavements subjected to tensile forces. Compressive strength is widely used for specification requirement and quality control of concrete. The engineer knows his target tensile (flexural) requirements and will express these in terms of compressive strength.

Wired.com reported on April 13, 2007 that a team from the University of Tehran

University of Tehran

The University of Tehran , also known as Tehran University and UT, is Iran's oldest university. Located in Tehran, the university is among the most prestigious in the country, and is consistently selected as the first choice of many applicants in the annual nationwide entrance exam for top Iranian...

, competing in a contest sponsored by the American Concrete Institute

American Concrete Institute

The American Concrete Institute is a non-profit technical society and standard developing organization . ACI was founded in 1904 and its headquarters are currently located in Farmington Hills, Michigan, USA.- ACI History :1904-1929:...

, demonstrated several blocks of concretes with abnormally high compressive strengths between 340 and 410 MPa (49,312.8 and 59,465.5 psi) at 28 days. The blocks appeared to use an aggregate of steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

fibres and quartz

Quartz

Quartz is the second-most-abundant mineral in the Earth's continental crust, after feldspar. It is made up of a continuous framework of SiO4 silicon–oxygen tetrahedra, with each oxygen being shared between two tetrahedra, giving an overall formula SiO2. There are many different varieties of quartz,...

– a mineral with a compressive strength of 1100 MPa, much higher than typical high-strength aggregates such as granite

Granite

Granite is a common and widely occurring type of intrusive, felsic, igneous rock. Granite usually has a medium- to coarse-grained texture. Occasionally some individual crystals are larger than the groundmass, in which case the texture is known as porphyritic. A granitic rock with a porphyritic...

(100–140 MPa or 14,503.8–20,305.3 psi).

Reactive Powder Concrete, also known as Ultra-High Performance Concrete, can be even stronger, with strengths of up to 800 MPa (116,000 PSI). These are made by eliminating large aggregate completely, carefully controlling the size of the fine aggregates to ensure the best possible packing, and incorporating steel fibers (sometimes produced by grinding steel wool) into the matrix. Reactive Powder Concretes may also make use of silica fume as a fine aggregate. Commercial Reactive Powder Concretes are available in the 170–210 MPa (24,656.4–30,457.9 psi) strength range.

Elasticity

The modulus of elasticity of concrete is a function of the modulus of elasticity of the aggregates and the cement matrix and their relative proportions. The modulus of elasticity of concrete is relatively constant at low stress levels but starts decreasing at higher stress levels as matrix cracking develops. The elastic modulus of the hardened paste may be in the order of 10-30 GPa and aggregates about 45 to 85 GPa. The concrete composite is then in the range of 30 to 50 GPa.The American Concrete Institute

American Concrete Institute

The American Concrete Institute is a non-profit technical society and standard developing organization . ACI was founded in 1904 and its headquarters are currently located in Farmington Hills, Michigan, USA.- ACI History :1904-1929:...

allows the modulus of elasticity to be calculated using the following equation:

(psi

(psiPounds per square inch

The pound per square inch or, more accurately, pound-force per square inch is a unit of pressure or of stress based on avoirdupois units...

)

where

weight of concrete (pounds per cubic foot) and where

weight of concrete (pounds per cubic foot) and where

compressive strength of concrete at 28 days (psi)

compressive strength of concrete at 28 days (psi)This equation is completely empirical and is not based on theory. Note that the value of Ec found is in units of psi. For normalweight concrete (defined as concrete with a wc of 150 lb/ft3 and subtracting 5 lb/ft3 for steel) Ec is permitted to be taken as

.

.Expansion and shrinkage

Concrete has a very low coefficient of thermal expansion. However, if no provision is made for expansion, very large forces can be created, causing cracks in parts of the structure not capable of withstanding the force or the repeated cycles of expansion and contractionThermal expansion

Thermal expansion is the tendency of matter to change in volume in response to a change in temperature.When a substance is heated, its particles begin moving more and thus usually maintain a greater average separation. Materials which contract with increasing temperature are rare; this effect is...

. The coefficient of thermal expansion of Portland cement concrete is 0.000008 to 0.000012 (per degree Celsius) (8 to 12 microstrains/°C)(8-12 1/MK).

As concrete matures it continues to shrink, due to the ongoing reaction taking place in the material, although the rate of shrinkage falls relatively quickly and keeps reducing over time (for all practical purposes concrete is usually considered to not shrink due to hydration any further after 30 years). The relative shrinkage and expansion of concrete and brickwork require careful accommodation when the two forms of construction interface.

Because concrete is continuously shrinking for years after it is initially placed, it is generally accepted that under thermal loading it will never expand to its originally placed volume.

Due to its low thermal conductivity

Thermal conductivity

In physics, thermal conductivity, k, is the property of a material's ability to conduct heat. It appears primarily in Fourier's Law for heat conduction....

, a layer of concrete is frequently used for fireproofing of steel structures.

Cracking

Robert Maillart

Robert Maillart was a Swiss civil engineer who revolutionized the use of structural reinforced concrete with such designs as the three-hinged arch and the deck-stiffened arch for bridges, and the beamless floor slab and mushroom ceiling for industrial buildings...

, employed reinforced concrete in a number of arched bridges. His first bridge was simple, using a large volume of concrete. He then realized that much of the concrete was very cracked, and could not be a part of the structure under compressive loads, yet the structure clearly worked. His later designs simply removed the cracked areas, leaving slender, beautiful concrete arches. The Salginatobel Bridge

Salginatobel Bridge

Salginatobel Bridge is a reinforced concrete arch bridge designed by renowned Swiss civil engineer Robert Maillart. It was constructed across an alpine valley in Schiers, Switzerland between 1929 and 1930...

is an example of this.

Concrete cracks due to tensile stress induced by shrinkage or stresses occurring during setting or use. Various means are used to overcome this. Fiber reinforced concrete

Fiber reinforced concrete

Fiber-reinforced concrete is concrete containing fibrous material which increases its structural integrity. It contains short discrete fibers that are uniformly distributed and randomly oriented. Fibers include steel fibers, glass fibers, synthetic fibers and natural fibers...

uses fine fibers distributed throughout the mix or larger metal or other reinforcement

Rebar

A rebar , also known as reinforcing steel, reinforcement steel, rerod, or a deformed bar, is a common steel bar, and is commonly used as a tensioning device in reinforced concrete and reinforced masonry structures holding the concrete in compression...

elements to limit the size and extent of cracks. In many large structures joints or concealed saw-cuts are placed in the concrete as it sets to make the inevitable cracks occur where they can be managed and out of sight. Water tanks and highways are examples of structures requiring crack control.

Shrinkage cracking

Shrinkage cracks occur when concrete members undergo restrained volumetric changes (shrinkage) as a result of either drying, autogenous shrinkage or thermal effects. Restraint is provided either externally (i.e. supports, walls, and other boundary conditions) or internally (differential drying shrinkage, reinforcement). Once the tensile strength of the concrete is exceeded, a crack will develop. The number and width of shrinkage cracks that develop are influenced by the amount of shrinkage that occurs, the amount of restraint present and the amount and spacing of reinforcement provided.These are minor indications and have no real structural impact on the concrete member.Plastic-shrinkage cracks are immediately apparent, visible within 0 to 2 days of placement, while drying-shrinkage cracks develop over time. Autogenous shrinkage also occurs when the concrete is quite young and results from the volume reduction resulting from the chemical reaction of the Portland cement.

Tension cracking

Concrete members may be put into tension by applied loads. This is most common in concrete beamBeam (structure)

A beam is a horizontal structural element that is capable of withstanding load primarily by resisting bending. The bending force induced into the material of the beam as a result of the external loads, own weight, span and external reactions to these loads is called a bending moment.- Overview...

s where a transversely applied load will put one surface into compression and the opposite surface into tension due to induced bending

Bending

In engineering mechanics, bending characterizes the behavior of a slender structural element subjected to an external load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, typically...

. The portion of the beam that is in tension may crack. The size and length of cracks is dependent on the magnitude of the bending moment and the design of the reinforcing in the beam at the point under consideration. Reinforced concrete beams are designed to crack in tension rather than in compression. This is achieved by providing reinforcing steel which yields before failure of the concrete in compression occurs and allowing remediation, repair, or if necessary, evacuation of an unsafe area.

Creep

Creep is the term used to describe the permanent movement or deformation of a material in order to relieve stresses within the material. Concrete which is subjected to long-duration forces is prone to creepCreep (deformation)

In materials science, creep is the tendency of a solid material to slowly move or deform permanently under the influence of stresses. It occurs as a result of long term exposure to high levels of stress that are below the yield strength of the material....

. Short-duration forces (such as wind or earthquakes) do not cause creep. Creep can sometimes reduce the amount of cracking that occurs in a concrete structure or element, but it also must be controlled. The amount of primary and secondary reinforcing in concrete structures contributes to a reduction in the amount of shrinkage, creep and cracking.

Concrete testing

Concrete is typically sampled while being placed, with testing protocols requiring that test samples be cured under laboratory conditions (standard cured). Additional samples may be field cured (non-standard) for the purpose of early 'stripping' strengths, that is, form removal, evaluation of curing, etc. but the standard cured cylinders comprise acceptance criteria. Concrete tests can measure the "plastic" (unhydrated) properties of concrete prior to, and during placement. As these properties affect the hardened compressive strength and durability of concrete (resistance to freeze-thaw), the properties of workability (slump/flow), temperature, density and age are monitored to ensure the production and placement of 'quality' concrete. Tests are performed per ASTM International

ASTM International

ASTM International, known until 2001 as the American Society for Testing and Materials , is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services...

, European Committee for Standardization

European Committee for Standardization

The European Committee for Standardization or Comité Européen de Normalisation , is a non-profit organisation whose mission is to foster the European economy in global trading, the welfare of European citizens and the environment by providing an efficient infrastructure to interested parties for...

or Canadian Standards Association

Canadian Standards Association

The Canadian Standards Association, also known as the CSA, is a not-for-profit Standards organization with the stated aim of developing standards for use in 57 different areas of specialisation...

. As measurement of quality must represent the potential of concrete material delivered and placed, it is imperative that concrete technicians performing concrete tests are certified to do so according to these standards. Structural design, material design and properties are often specified in accordance with national/regional design codes such as American Concrete Institute

American Concrete Institute

The American Concrete Institute is a non-profit technical society and standard developing organization . ACI was founded in 1904 and its headquarters are currently located in Farmington Hills, Michigan, USA.- ACI History :1904-1929:...

.

Compressive strength

Compressive strength

Compressive strength is the capacity of a material or structure to withstand axially directed pushing forces. When the limit of compressive strength is reached, materials are crushed. Concrete can be made to have high compressive strength, e.g...

tests are conducted using an instrumented hydraulic ram

Hydraulic ram

A hydraulic ram, or hydram, is a cyclic water pump powered by hydropower. It functions as a hydraulic transformer that takes in water at one "hydraulic head" and flow-rate, and outputs water at a higher hydraulic-head and lower flow-rate...

to compress a standard cylindrical or cubic sample to failure. Tensile strength tests are conducted either by three-point bending of a prismatic beam specimen or by compression along the sides of a standard cylindrical specimen. These are not to be equated with nondestructive testing

Nondestructive testing

Nondestructive testing or Non-destructive testing is a wide group of analysis techniques used in science and industry to evaluate the properties of a material, component or system without causing damage....

using a rebound hammer

Schmidt hammer

A Schmidt hammer, also known as a Swiss hammer or a rebound hammer, is a device to measure the elastic properties or strength of concrete or rock, mainly surface hardness and penetration resistance.It was invented by Ernst Schmidt, a Swiss engineer....

or probe systems which are hand-held indicators, for relative strength of the top few millimeters, of comparative concretes in the field.