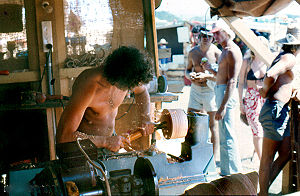

Woodturning

Encyclopedia

Woodworking

Woodworking is the process of building, making or carving something using wood.-History:Along with stone, mud, and animal parts, wood was one of the first materials worked by early humans. Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood...

that is used to create wooden objects on a lathe (see: also antique wooden polelathe

Polelathe

A pole lathe is a wood-turning lathe that uses a long pole as a return spring for a treadle. Pressing the treadle with your foot pulls on a cord that is wrapped around the piece of wood or billet being turned. The other end of the cord reaches up to the end of a long springy pole. As the action is...

). Woodturning differs from most other forms of woodworking in that the wood

Wood

Wood is a hard, fibrous tissue found in many trees. It has been used for hundreds of thousands of years for both fuel and as a construction material. It is an organic material, a natural composite of cellulose fibers embedded in a matrix of lignin which resists compression...

is moving while a stationary tool is used to cut and shape it. Many intricate shapes and designs can be made by turning wood.

There are two distinct methods of turning wood: spindle turning

Spindle turning

Spindle turning, or turning between centers, is a woodturning method referring to a piece of wood on a wood lathe that is being turned on its center axis.-Method:...

and faceplate turning. In spindle turning, the wood is fixed between 2 points. The spur center digs in to the wood and is powered by a motor

Electric motor

An electric motor converts electrical energy into mechanical energy.Most electric motors operate through the interaction of magnetic fields and current-carrying conductors to generate force...

. The other, a hard center or a live center may be a point or set of points in the tailstock. In face plate turning, the wood is secured with screws to a faceplate or in a chuck or jig. the tail stock and a center may also be used for added support on large pieces with a faceplate. Most bowls, platters and many vessels are face plate turned, while, Pens, furniture legs, spindles, and some vessels are spindle turned. The method used may differ depending on the shape of the blank and the technique of the turner, and both methods may be used on the same piece.

When wood is cut in such a way that the fiber being cut is not supported by the fiber below it, it tends to separate and tear. This "tearout" exhibits a rough, highly damaged looking surface texture and greatly reduces the value of any product exhibiting it. The direction of cut is different in spindle turning and faceplate turning because cutting in the wrong direction can cause tearout. Spindle turning cuts are made from high points toward the axis on the outside of the piece, and from the axis toward the outside when hollowing. When faceplate turning, the opposite applies.

History

Ancient Egypt

Ancient Egypt was an ancient civilization of Northeastern Africa, concentrated along the lower reaches of the Nile River in what is now the modern country of Egypt. Egyptian civilization coalesced around 3150 BC with the political unification of Upper and Lower Egypt under the first pharaoh...

first developed a two-person lathe. One person would turn the wood with a rope while the other used a sharp tool to cut shapes in the wood. The Romans

Ancient Rome

Ancient Rome was a thriving civilization that grew on the Italian Peninsula as early as the 8th century BC. Located along the Mediterranean Sea and centered on the city of Rome, it expanded to one of the largest empires in the ancient world....

improved the Egyptian design with the addition of a turning bow. Early bow lathes were also developed and used in Germany, France and Britain. In the Middle Ages

Middle Ages

The Middle Ages is a periodization of European history from the 5th century to the 15th century. The Middle Ages follows the fall of the Western Roman Empire in 476 and precedes the Early Modern Era. It is the middle period of a three-period division of Western history: Classic, Medieval and Modern...

a pedal replaced hand-operated turning, freeing both the craftsman's hands to hold the woodturning tools. The pedal was usually connected to a pole, often a straight-grained sapling. The system today is called the "spring pole" lathe (see Polelathe

Polelathe

A pole lathe is a wood-turning lathe that uses a long pole as a return spring for a treadle. Pressing the treadle with your foot pulls on a cord that is wrapped around the piece of wood or billet being turned. The other end of the cord reaches up to the end of a long springy pole. As the action is...

). Spring pole lathes were in common use into the early 20th Century. A two-person lathe, called a "great lathe", allowed a piece to turn continuously (like today's power lathes). A master would cut the wood while an apprentice turned the crank.

The term "bodger" stems from pole lathe turners who used to make the chair legs and spindles. A bodger would typically purchase all the trees on a plot of land, set up camp on the plot, and then fell the trees and turn the wood. The spindles and legs that were produced were sold in bulk, for pence per dozen. The bodger's job was considered unfinished because he only made component parts. The term now describes a person who leaves a job unfinished, or does it badly.

During the industrial revolution

Industrial Revolution

The Industrial Revolution was a period from the 18th to the 19th century where major changes in agriculture, manufacturing, mining, transportation, and technology had a profound effect on the social, economic and cultural conditions of the times...

the lathe was motorized, allowing turned items to be created in less time. The motor also produced a greater rotational speed for the wood, making it easier to quickly produce high quality work. Today most commercial woodturning is done by computer

Computer

A computer is a programmable machine designed to sequentially and automatically carry out a sequence of arithmetic or logical operations. The particular sequence of operations can be changed readily, allowing the computer to solve more than one kind of problem...

-operated machinery allowing for mass-production that can be created with precision and without the cost of employing craftsmen. Despite this, there is still a demand for hand-turned products

Product (business)

In general, the product is defined as a "thing produced by labor or effort" or the "result of an act or a process", and stems from the verb produce, from the Latin prōdūce ' lead or bring forth'. Since 1575, the word "product" has referred to anything produced...

. Woodturning is also a hobby

Hobby

A hobby is a regular activity or interest that is undertaken for pleasure, typically done during one's leisure time.- Etymology :A hobby horse is a wooden or wickerwork toy made to be ridden just like a real horse...

enjoyed by many people.

Modern professional woodturners are typically either "production" turners producing large quantities of functional pieces, or artistic turners producing smaller numbers of pieces, often enhanced after turning by carving, piercing, coloring, applying pyrography

Pyrography

Pyrography is the art of decorating wood or other materials with burn marks resulting from the controlled application of a heated object such as a poker. It is also known as pokerwork or wood burning....

, gilding

Gilding

The term gilding covers a number of decorative techniques for applying fine gold leaf or powder to solid surfaces such as wood, stone, or metal to give a thin coating of gold. A gilded object is described as "gilt"...

, or a number of other techniques to produce objects for the art market.

Common woodturned items

- Furniture parts - spindleSpindle (furniture)A Spindle, in furniture, is an cylindrically symmetric shaft, usually made of wood. A spindle is usually made of a single piece of wood and typically has decoration fashioned by hand or with a lathe...

s, table legs, stretcherStretcher (furniture)A stretcher is a horizontal support element of a table, chair or other item of furniture; this structure is normally made of exposed wood and ties vertical elements of the piece together. There are numerous styles of the stretcher including circumferential, double and spindle design. This term is...

s, finialFinialThe finial is an architectural device, typically carved in stone and employed decoratively to emphasize the apex of a gable or any of various distinctive ornaments at the top, end, or corner of a building or structure. Smaller finials can be used as a decorative ornament on the ends of curtain rods...

s, or other furniture parts - Bowls - vessels with a large opening on top

- PlattersPlatter (dishware)A platter is a large type of dishware used for serving food. It is a tray on which food is displayed and served to people. It can have oval, round, rectangular, or square shape. It can be made of metal, ceramic, or plastic. Plain and ornate platters suitable for more formal settings or occasions...

and serving trays - PensPensPens may refer to:* plural of pen, Fountain pens - writing instruments* Pens * a nickname for the Pittsburgh PenguinsPENS may refer to:* Percutaneous Electrical Nerve Stimulation, commonly referred to as electroacupuncture...

, mechanical pencilMechanical pencilA mechanical pencil or a propelling pencil is a pencil with a replaceable and mechanically extendable solid pigment core called a lead . It is designed such that the lead can be extended as its point is worn away...

s, keyrings and other small items - Hollow forms - similar to bowls, except usually taller and with a small opening, when compared to the hollow interior

- Pepper & salt mills and candlestickCandlestickA candlestick, chamberstick, or candelabrum is a holder for one or more candles, used for illumination, rituals, or decorative purposes. The name 'candlestick' derives from the fact that it is usually tall and stick-shaped.Candlesticks are also called candle holders...

s - Chess pieceChess pieceChess pieces or chessmen are the pieces deployed on a chessboard to play the game of chess. The pieces vary in abilities, giving them different values in the game...

s (some cutting may be required after turning, depending on design) - Sculptural forms

- Spindle whorls

- Pool cuesCue stickA cue stick , is an item of sporting equipment essential to the games of pool, snooker and carom billiards. It is used to strike a ball, usually the...

- Tool handles, especially those for files and lathe tools

- Baseball batsBaseball batA baseball bat is a smooth wooden or metal club used in the game of baseball to hit the ball after the ball is thrown by the pitcher. It is no more than 2.75 inches in diameter at the thickest part and no more than 42 inches in length. It typically weighs no more than 33 ounces , but it...

- Woodwind musical instruments - e.g., clarinets, oboe, wood flutes, bagpipes

- LampsLampLamp is a light source, while LAMP is an acronym.-Lamps:Lamp may refer to one of the following:*Oil lamp, the original use of the term*Kerosene lamp, a lamp burning liquid petroleum...

Tools

Turning tools are generally made from three different types of steelSteel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

, Carbon steel, High speed steel

High speed steel

High speed steelMost copyeditors today would tend to choose to style the unit adjective high-speed with a hyphen, rendering the full term as high-speed steel, and this styling is not uncommon . However, it is true that in the metalworking industries the styling high speed steel is long-established...

(HSS), and more recently Powdered Metal

Powder metallurgy

Powder metallurgy is the process of blending fine powdered materials, pressing them into a desired shape , and then heating the compressed material in a controlled atmosphere to bond the material . The powder metallurgy process generally consists of four basic steps: powder manufacture, powder...

. Comparing the three types, high speed steel tools maintain their edge longer, requiring less frequent sharpening than carbon steel, but not as long as powdered metal tools. The harder the type of high speed steel used, the longer the edge will maintain sharpness. Powdered steel is even harder than HSS, but takes more effort to obtain an edge as sharp as HSS, just as HSS is harder to get as sharp as Carbon Steel. Unlike other edged woodworking tools

Woodworking

Woodworking is the process of building, making or carving something using wood.-History:Along with stone, mud, and animal parts, wood was one of the first materials worked by early humans. Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood...

, woodturning tools require more frequent sharpening, because the wood passes at a great speed. To maintain a clean cut, the sharpness of the tools edge must be maintained. The sharpening process requires either skill of the craftsman, or one of the many available sharpening jigs, which facilitate maintaining a specific bevel on the tool. High speed steel is not prone to blueing (overheating) whereas carbon steel blues easily, requiring frequent quenching to avoid losing temper (making the edge too soft.)

Types

- roughing gouge - a wide fluted gouge used to initially round a wooden spindle, and to roughly shape it. Generally not intended for cutting end grain due to the large cut it takes and the relatively weak tang connecting the blade to the handle. Unsafe for making bowls or any faceplate work.

- spindle gouge or detail gouge - a shallow fluted gouge used to create details on spindles, including beads (raised portions of the turning typically semi-circular in cross section) and coves (relieved portions of the turning).

- bowl gouge - a deep fluted gouge used to turn the outside and inside of bowls and vessels. Often has a thicker shaft and longer handle than a spindle gouge because it has to cut farther away from the handrest and deal with the forces of turning a large bowl.

- skew chisel - a wide, steeply pointed chiselChiselA chisel is a tool with a characteristically shaped cutting edge of blade on its end, for carving or cutting a hard material such as wood, stone, or metal. The handle and blade of some types of chisel are made of metal or wood with a sharp edge in it.In use, the chisel is forced into the material...

with the edge running at an angle to the length of the tool. Used to smooth flat spindles, cut beads, and add details. Skew chisels are only used on spindle work (never on faceplate work) and are honed after sharpening to create a razor edge. - parting tool - a pointed tool used to separate (part off) work from the lathe, and to create a straight edge separating large and small diameter sections - wide parting tools also called bedanBedanBedan is named as the deliverer of Israelites in 1 Samuel 12:11. He is not mentioned elsewhere as a judge of Israel. Bp. Patrick and others hypothesis the name to be a contraction of ben Dan by which they suppose Samson is meant, as the Targum reads...

s are used to create evenly sized spindle sections. - hollowing tool - many different types of tools used to cut out the deep sections of steep bowls, vases and hollow vessels. Often with very long handles, to maintain enough leverage when working in a deep vessel, far away from the handrest.

- scraper - a tool that scrapes the wood fibers instead of cutting - these are used to smooth off wooden items cut with other tools, and to shape items that are not possible or difficult to shape with gouges. A sharp scraper has a burr at the edge which cuts the wood, only a dull scraper actually scrapes.

- bowl saver - a tool used to core out the inside part of a bowl, allowing the waste piece to be used to create a smaller bowl, and to limit the amount of wood chips created when hollowing out a bowl.

- auger - a drill bitDrill bitDrill bits are cutting tools used to create cylindrical holes. Bits are held in a tool called a drill, which rotates them and provides torque and axial force to create the hole. Specialized bits are also available for non-cylindrical-shaped holes....

used to drill a hole partway or all the way through a wooden item. For cutting the hole for a lamp cord, or as the first step when hollowing out a bowl or vessel - chatter tool - a flexible scraper used to add decorative chatter marks to turned items

- wire - a simple wire, sometimes with handles attached at either side, for the purpose of burning lines into the piece with frictionFrictionFriction is the force resisting the relative motion of solid surfaces, fluid layers, and/or material elements sliding against each other. There are several types of friction:...

. - there are also several tool types for special purposes, as well as tools that are a combination design of the above tools, i.e. skew/chisel combinations, threadScrew threadA screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a straight thread and the latter called a tapered thread...

cutting tools, ring cutting tools, medium fluted gouges, etc.

Other techniques

- Eccentric turning - turning a single piece multiple times, upon different axes each time.

- Oval or elliptical turning - turning a piece using an accessory mounted to the headstock that changes the center of rotation of the piece in time with the rotation, so that a cutting tool held in a fixed position on the tool-rest cuts an oval rather than a round path on the workpiece

- Therming - mounting a carrier between centers, and then mounting the small workpiece(s) to the carrier, so that the axis of the headstock/tail-stock does not pass through any of the workpieces, and each workpiece gets cut only on one face. As noted in Wood-turning Methods by Mike Darlow, the etymology of the term "therming" comes via a corruption of the name of the Greek god HermesHermesHermes is the great messenger of the gods in Greek mythology and a guide to the Underworld. Hermes was born on Mount Kyllini in Arcadia. An Olympian god, he is also the patron of boundaries and of the travelers who cross them, of shepherds and cowherds, of the cunning of thieves, of orators and...

, who was often represented as a statue set atop a plinth with a construction characteristic of thermed work. - Segmented turningSegmented turningSegmented turning is turning on a lathe where the initial workpiece is composed of multiple glued-together parts. The process involves gluing up several pieces of wood to create patterns and visual effects in turned projects....

- a method of woodturning where the wood blank is constructed from many individual pieces of wood (segments) which are glued together before being turned. Many interesting patterns can be generated through the process of gluing and shaping on the lathe. - Green or wet turning - turning wood while its moisture content is above equilibrium. Often done when the wood is newly felled. May be turned to finished thickness, in which case the differential shrinkage of the wood will result in a finished piece that is not perfectly round. Alternatively, it may be "rough turned". Rough turning involves turning the piece only to its general shape, leaving enough thickness so that after turning it can be allowed to dry to equilibrium moisture content and distort. The advantage over first drying the wood then turning is that a rough turned piece dries faster, will probably distort instead of split as massive wood is wont to do, and that wet wood turns better, since it creates less dust. Rough turning is inexact science: turning wood too thick will lead to splits, turning wood too thin will lead to distortion that cannot be removed, because not enough thickness is left. Once dry, it is mounted on the lathe a second time and turned to its final form. Rough turning is typically used on most functional work and some artistic pieces.

- Natural edge work - pieces which include the outside of the tree trunk or limb as the edge of the piece. Typically artistic turnings, usually bowls or hollow vessels, and usually green turned to final dimension. May include the bark or not, but pieces with bark should not have any bark damaged or missing.

- Ornamental turning - also known as OT, a method in which the piece is mounted upon a rocking headstock, and a spinning tool is used to cut out exotic and decorative patterns. The device is called a rose engine lathe

Safety

When woodturning, it is important to wear certain personal protective equipment (PPEPPE

PPE may stand for:*Palmoplantar erythrodysesthesia syndrome*Park Place Entertainment, now part of Caesar's Entertainment*Personal protective equipment*Philosophy, Politics and Economics, an academic degree*Polyphenyl ether...

). Loose clothing should not be worn, all jewelry should be removed, and long hair should be tied back. Wood shavings generated during turning will also need to be periodically removed.

- Eye protection is a necessity when woodturning. There are several PPE available for eye protection such as safety gogglesGogglesGoggles or safety glasses are forms of protective eyewear that usually enclose or protect the area surrounding the eye in order to prevent particulates, water or chemicals from striking the eyes. They are used in chemistry laboratories and in woodworking. They are often used in snow sports as well,...

, glasses and visorVisorA visor is a surface that protects the eyes, such as shading them from the sun or other bright light or protecting them from objects....

s, some of which feature built-in respiratorRespiratorA respirator is a device designed to protect the wearer from inhaling harmful dusts, fumes, vapors, or gases. Respirators come in a wide range of types and sizes used by the military, private industry, and the public...

s. Although all of these are adequate, for the highest level of protection, a visor that protects the entire head from dust and debris should be worn. - Respiratory equipment and Dust collection systemDust collection systemA dust collection system is an air quality improvement system used in industrial, commercial, and home production shops to improve breathable air quality and safety by removing particulate matter from the air and environment. Dust collection systems work on the basic formula of CAPTURE, CONVEY and...

s are also important when woodturning or doing any type of woodworking that creates dust. This can range from a simple disposable dust mask, to a full face helmet with built in respirator. Most stand alone respiratory equipment will interfere with dust shields and visors, so devices that incorporate both are available. Many woods create dust that is actually a health hazard. For example, cocoboloCocoboloCocobolo is a tropical hardwood of the tree Dalbergia retusa from Central America.Only the heartwood is used: this is typically orange or reddish-brown in color, often with a figuring of darker irregular traces weaving through the wood. The sapwood is a creamy yellow, with a sharp boundary with...

(granadillo) dust is known to be toxic (toxic shock). Many people are sensitive to oils carried in walnutWalnutJuglans is a plant genus of the family Juglandaceae, the seeds of which are known as walnuts. They are deciduous trees, 10–40 meters tall , with pinnate leaves 200–900 millimetres long , with 5–25 leaflets; the shoots have chambered pith, a character shared with the wingnuts , but not the hickories...

, locust, and oakOakAn oak is a tree or shrub in the genus Quercus , of which about 600 species exist. "Oak" may also appear in the names of species in related genera, notably Lithocarpus...

sawdust. Long term exposure to fine wood dust has also been linked with an increased risk of developing cancer. - Ear protection Compared to other power tools, a lathe is a quiet machine. Ear protectionEarplugAn earplug is a device that is meant to be inserted in the ear canal to protect the wearer's ears from loud noises or the intrusion of water, foreign bodies, dust or excessive wind.-Protection from water:...

should be used if noiseIndustrial noiseIndustrial noise is usually considered mainly from the point of view of environmental health and safety, rather than nuisance, as sustained exposure can cause permanent hearing damage. Traditionally, occupational noise has been a hazard linked to heavy industries such as ship-building and...

is excessive, this may be due to motor (fan) noise from a shop dust collector, or the combination of wood and tool being used. - Hand/Skin protection Gloves should not be used with rotating equipment, since there's always a risk of getting tangled in the machine. Nevertheless, some woods provide splinters that not only puncture skin, but also cause festering sores and/or skin irritation. Polishes and finishes used in woodturning can also be harmful or irritant to skin, often containing organic solvents such as methanolMethanolMethanol, also known as methyl alcohol, wood alcohol, wood naphtha or wood spirits, is a chemical with the formula CH3OH . It is the simplest alcohol, and is a light, volatile, colorless, flammable liquid with a distinctive odor very similar to, but slightly sweeter than, ethanol...

, turpentineTurpentineTurpentine is a fluid obtained by the distillation of resin obtained from trees, mainly pine trees. It is composed of terpenes, mainly the monoterpenes alpha-pinene and beta-pinene...

and tolueneTolueneToluene, formerly known as toluol, is a clear, water-insoluble liquid with the typical smell of paint thinners. It is a mono-substituted benzene derivative, i.e., one in which a single hydrogen atom from the benzene molecule has been replaced by a univalent group, in this case CH3.It is an aromatic...

. This subject continues to be debated in the community. - Foot protection. Protective footwear, often leatherLeatherLeather is a durable and flexible material created via the tanning of putrescible animal rawhide and skin, primarily cattlehide. It can be produced through different manufacturing processes, ranging from cottage industry to heavy industry.-Forms:...

steel-toe bootsSteel-toe bootsA steel-toe boot is a durable boot or shoe that has a protective reinforcement in the toe which protects the foot from falling objects or compression, usually it is combined with a mid sole plate to protect against punctures from below.Although traditionally made of steel, the reinforcement can...

, is required for any type of shop activity.

Safe usage of a lathe also depends on the operator knowing proper techniques and being aware of the limitations of both the machine and the workpiece. For example, using a high spindle speed with an unbalanced workpiece may cause the lathe to vibrate dangerously. Spinning a large workpiece too fast may cause it to explode. Inappropriate use of tools such as gouges and skew chisels can cause a catch, where the tool bites suddenly and aggressively into the wood in an uncontrolled manner. This exerts very large forces on the workpiece, the tool, the lathe and the operator, often causing the workpiece to break apart or tear free from the lathe or pulling the tool out of the operator's hands and throwing it through the air.

External links

- The Irish Woodturners' Guild - IWG

- The Dublin 15 IWG Chapter - Craobh Cuig Deag

- The American Association of Woodturners

- Association of Woodturners of Great Britain

- The National Association of Woodworkers inc. New Zealand

- The British Woodturners Association (BWTA)

- - Information about Ornamental Turning and Gallery

- Ornamental Turners International

- Woodturning Online

- Woodturner's Resource

- Ornamental Turning