Gasification

Encyclopedia

Gasification is a process that converts organic

or fossil

based carbonaceous

materials into carbon monoxide

, hydrogen

, carbon dioxide

and methane

. This is achieved by reacting the material at high temperatures (>700°C), without combustion, with a controlled amount of oxygen

and/or steam

. The resulting gas mixture is called syngas

(from synthesis gas or synthetic gas) or producer gas

and is itself a fuel. The power derived from gasification of biomass and combustion of the resultant gas is considered to be a source of renewable energy

; the gasification of fossil fuel derived materials such as plastic is not considered to be renewable energy.

The advantage of gasification is that using the syngas is potentially more efficient than direct combustion of the original fuel because it can be combusted at higher temperatures or even in fuel cell

s, so that the thermodynamic upper limit to the efficiency defined by Carnot's rule

is higher or not applicable. Syngas may be burned directly in gas engines, used to produce methanol

and hydrogen, or converted via the Fischer-Tropsch process

into synthetic fuel

. Gasification can also begin with material which would otherwise have been disposed of such as biodegradable waste. In addition, the high-temperature process refines out corrosive ash elements such as chloride

and potassium

, allowing clean gas production from otherwise problematic fuels. Gasification of fossil fuels is currently widely used on industrial scales to generate electricity

.

The process of producing energy using the gasification method has been in use for more than 180 years. During that time coal

The process of producing energy using the gasification method has been in use for more than 180 years. During that time coal

and peat

were used to power these plants. Initially developed to produce town gas for lighting & cooking in 1800s, this was replaced by electricity and natural gas

, it was also used in blast furnaces but the bigger role was played in the production of synthetic

chemicals where it has been in use since the 1920s.

During both world wars especially the Second World War the need of gasification produced fuel reemerged due to the shortage of petroleum. Wood gas generator

s, called Gasogene or Gazogène, were used to power motor vehicles in Europe

. By 1945 there were trucks, buses and agricultural machines that were powered by gasification. It is estimated that there were close to 9,000,000 vehicles running on producer gas all over the world.

In essence, a limited amount of oxygen or air is introduced into the reactor to allow some of the organic material to be "burned" to produce carbon monoxide and energy, which drives a second reaction that converts further organic material to hydrogen and additional carbon dioxide. Further reactions occur when the formed carbon monoxide and residual water

from the organic material react to form methane and excess carbon dioxide. This third reaction occurs more abundantly in reactors that increase the residence time of the reactive gases and organic materials, as well as heat and pressure. Catalysts are used in more sophisticated reactors to improve reaction rates, thus moving the system closer to the reaction equilibrium for a fixed residence time

.

, entrained flow and plasma.

. The slagging gasifiers have a lower ratio of steam to carbon, achieving temperatures higher than the ash fusion temperature. The nature of the gasifier means that the fuel must have high mechanical strength and must ideally be non-caking so that it will form a permeable bed, although recent developments have reduced these restrictions to some extent. The throughput for this type of gasifier is relatively low. Thermal efficiency is high as the gas exit temperatures are relatively low. However, this means that tar and methane production is significant at typical operation temperatures, so product gas must be extensively cleaned before use. The tar can be recycled to the reactor.

In the gasification of fine, undensified biomass such as rice hulls, it is necessary to force air into the reactor by means of a fan. This creates very high gasification temperatures, at times as high as 1000 C. Above the gasification zone, a bed of fine, hot char is formed, and as the gas is forced through this bed, most complex hydrocarbons are broken down into simple components of hydrogen and carbon monoxide.

in oxygen and steam or air. The ash is removed dry or as heavy agglomerates that defluidize. The temperatures are relatively low in dry ash gasifiers, so the fuel must be highly reactive; low-grade coals are particularly suitable. The agglomerating gasifiers have slightly higher temperatures, and are suitable for higher rank coals. Fuel throughput is higher than for the fixed bed, but not as high as for the entrained flow gasifier. The conversion efficiency can be rather low due to elutriation

of carbonaceous material. Recycle or subsequent combustion of solids can be used to increase conversion. Fluidized bed gasifiers are most useful for fuels that form highly corrosive ash that would damage the walls of slagging gasifiers. Biomass fuels generally contain high levels of corrosive ash.

s and because the coal particles are well separated from one another.

The high temperatures and pressures also mean that a higher throughput can be achieved, however thermal efficiency is somewhat lower as the gas must be cooled before it can be cleaned with existing technology. The high temperatures also mean that tar and methane are not present in the product gas; however the oxygen requirement is higher than for the other types of gasifiers. All entrained flow gasifiers remove the major part of the ash as a slag as the operating temperature is well above the ash fusion temperature.

A smaller fraction of the ash is produced either as a very fine dry fly ash or as a black colored fly ash slurry. Some fuels, in particular certain types of biomasses, can form slag that is corrosive for ceramic inner walls that serve to protect the gasifier outer wall. However some entrained flow type of gasifiers do not possess a ceramic inner wall but have an inner water or steam cooled wall covered with partially solidified slag. These types of gasifiers do not suffer from corrosive slags.

Some fuels have ashes with very high ash fusion temperatures. In this case mostly limestone is mixed with the fuel prior to gasification. Addition of a little limestone will usually suffice for the lowering the fusion temperatures. The fuel particles must be much smaller than for other types of gasifiers. This means the fuel must be pulverized, which requires somewhat more energy than for the other types of gasifiers. By far the most energy consumption related to entrained flow gasification is not the milling of the fuel but the production of oxygen used for the gasification.

A wide variety of feedstocks can be gasified, with wood pellets and chips, waste wood, plastics and aluminium, Municipal Solid Waste

(MSW), Refuse-derived fuel

(RDF), agricultural and industrial wastes, sewage sludge, switch grass, discarded seed corn, corn stover and other crop residues all being used.

Chemrec

has developed a process for gasification of black liquor

.

Waste gasification has several advantages over incineration:

Waste gasification has several advantages over incineration:

A major challenge for waste gasification technologies is to reach an acceptable (positive) gross electric efficiency. The high efficiency of converting syngas to electric power is counteracted by significant power consumption in the waste preprocessing, the consumption of large amounts of pure oxygen (which is often used as gasification agent), and gas cleaning. Another challenge becoming apparent when implementing the processes in real life is to obtain long service intervals in the plants, so that it is not necessary to close down the plant every few months for cleaning the reactor.

Several waste gasification processes have been proposed, but few have yet been built and tested, and only a handful have been implemented as plants processing real waste, and most of the time in combination with fossil fuels.

One plant (in Chiba

, Japan

using the Thermoselect process) has been processing industrial waste since year 2000, but has not yet documented positive net energy production from the process.

In the USA, gasification of waste is expanding across the country. Ze-gen

is operating a waste gasification demonstration facility in New Bedford, Massachusetts

. The facility was designed to demonstrate gasification of specific non-MSW waste streams using liquid metal gasification. In addition, construction of a biomass gasification plant was approved in DeKalb County, Georgia on June 14, 2011 and in Green Bay Wisconsin a deal was made with the Oneida Nation and the city of Green Bay to build a gasification power plant which will supply electricity to over 4,000 homes.

Also in the USA, plasma is being used to gasify municipal solid waste, hazardous waste and biomedical waste at the Hurlburt Field Florida Special Operations Command Air Force base. PyroGenesis Canada Inc. is the technology provider.

Syngas can also be used for further processing to liquid fuels or chemicals.

), with the possibility of producing methane and hydrogen for fuel cells. IGCC is also a more efficient method of CO2 capture as compared to conventional technologies. IGCC demonstration plants have been operating since the early 1970s and some of the plants constructed in the 1990s are now entering commercial service.

s can be operated on dual fuel mode using producer gas. Diesel substitution of over 80% at high loads and 70-80% under normal load variations can easily be achieved. Spark ignition engines and SOFC fuel cells can operate on 100% gasification gas. Mechanical energy from the engines may be used for e.g. driving water pumps for irrigation or for coupling with an alternator for electrical power generation.

While small scale gasifiers have existed for well over 100 years, there have been few sources to obtain a ready to use machine. Small scale devices are typically DIY projects. However, currently in the United States

, several companies offer gasifiers to operate small engines. In 2009 21stCenturyMotorworks claimed to have developed gasification technology in a prototype pickup truck that could use any biomass materials for fuel, the vehicle was displayed at multiple events including the 2009 Boston Greenfest.

In principle, gasification can proceed from just about any organic material, including biomass and plastic waste. The resulting syngas can be combusted. Alternatively, if the syngas is clean enough, it may be used for power production in gas engines, gas turbines or even fuel cells, or converted efficiently to dimethyl ether

In principle, gasification can proceed from just about any organic material, including biomass and plastic waste. The resulting syngas can be combusted. Alternatively, if the syngas is clean enough, it may be used for power production in gas engines, gas turbines or even fuel cells, or converted efficiently to dimethyl ether

(DME) by methanol dehydration, methane via the Sabatier reaction

, or diesel-like synthetic fuel via the Fischer-Tropsch process. In many gasification processes most of the inorganic components of the input material, such as metals and minerals, are retained in the ash. In some gasification processes (slagging gasification) this ash has the form of a glassy solid with low leaching

properties, but the net power production in slagging gasification is low (sometimes negative) and costs are higher.

Regardless of the final fuel form, gasification itself and subsequent processing neither directly emits nor traps greenhouse gases such as carbon dioxide. Power consumption in the gasification and syngas conversion processes may be significant though, and may indirectly cause CO2 emissions; in slagging and plasma gasification, the electricity consumption may even exceed any power production from the syngas.

Combustion of syngas or derived fuels emits exactly the same amount of carbon dioxide as would have been emitted from direct combustion of the initial fuel. Biomass gasification and combustion could play a significant role in a renewable energy economy, because biomass production removes the same amount of CO2 from the atmosphere as is emitted from gasification and combustion. While other biofuel technologies such as biogas and biodiesel

are carbon neutral

, gasification in principle may run on a wider variety of input materials and can be used to produce a wider variety of output fuels.

There are at present a few industrial scale biomass gasification plants. Since 2008 in Svenljunga, Sweden

, a biomass gasification plant generates up to 14 MWth, supplying industries and citizens of Svenljunga with process steam and district heating

, respectively. The gasifier uses biomass fuels such as CCA

or creosote

impregnated waste wood and other kinds of recycled wood to produces syngas that is combusted on site. In 2011 a similar gasifier, using the same kinds of fuels, is being installed at Munkfors Energy's CHP

plant. The CHP plant will generate 2 MWe (electricity) and 8 MWth (district heating

).

Examples of demonstration projects include:

Biomass

Biomass, as a renewable energy source, is biological material from living, or recently living organisms. As an energy source, biomass can either be used directly, or converted into other energy products such as biofuel....

or fossil

Fossil fuel

Fossil fuels are fuels formed by natural processes such as anaerobic decomposition of buried dead organisms. The age of the organisms and their resulting fossil fuels is typically millions of years, and sometimes exceeds 650 million years...

based carbonaceous

Carbonaceous

Carbonaceous is the defining attribute of a substance rich in carbon. Particularly, carbonaceous hydrocarbons are very unsaturated, high-molecular-weight hydrocarbons, having an elevated carbon:hydrogen ratio....

materials into carbon monoxide

Carbon monoxide

Carbon monoxide , also called carbonous oxide, is a colorless, odorless, and tasteless gas that is slightly lighter than air. It is highly toxic to humans and animals in higher quantities, although it is also produced in normal animal metabolism in low quantities, and is thought to have some normal...

, hydrogen

Hydrogen

Hydrogen is the chemical element with atomic number 1. It is represented by the symbol H. With an average atomic weight of , hydrogen is the lightest and most abundant chemical element, constituting roughly 75% of the Universe's chemical elemental mass. Stars in the main sequence are mainly...

, carbon dioxide

Carbon dioxide

Carbon dioxide is a naturally occurring chemical compound composed of two oxygen atoms covalently bonded to a single carbon atom...

and methane

Methane

Methane is a chemical compound with the chemical formula . It is the simplest alkane, the principal component of natural gas, and probably the most abundant organic compound on earth. The relative abundance of methane makes it an attractive fuel...

. This is achieved by reacting the material at high temperatures (>700°C), without combustion, with a controlled amount of oxygen

Oxygen

Oxygen is the element with atomic number 8 and represented by the symbol O. Its name derives from the Greek roots ὀξύς and -γενής , because at the time of naming, it was mistakenly thought that all acids required oxygen in their composition...

and/or steam

Steam

Steam is the technical term for water vapor, the gaseous phase of water, which is formed when water boils. In common language it is often used to refer to the visible mist of water droplets formed as this water vapor condenses in the presence of cooler air...

. The resulting gas mixture is called syngas

Syngas

Syngas is the name given to a gas mixture that contains varying amounts of carbon monoxide and hydrogen. Examples of production methods include steam reforming of natural gas or liquid hydrocarbons to produce hydrogen, the gasification of coal, biomass, and in some types of waste-to-energy...

(from synthesis gas or synthetic gas) or producer gas

Producer gas

-USA:Producer Gas is a generic term referring to:* Wood gas: produced in a gasifier to power cars with ordinary internal combustion engines.* Town gas: manufactured gas, originally produced from coal, for sale to consumers and municipalities....

and is itself a fuel. The power derived from gasification of biomass and combustion of the resultant gas is considered to be a source of renewable energy

Renewable energy

Renewable energy is energy which comes from natural resources such as sunlight, wind, rain, tides, and geothermal heat, which are renewable . About 16% of global final energy consumption comes from renewables, with 10% coming from traditional biomass, which is mainly used for heating, and 3.4% from...

; the gasification of fossil fuel derived materials such as plastic is not considered to be renewable energy.

The advantage of gasification is that using the syngas is potentially more efficient than direct combustion of the original fuel because it can be combusted at higher temperatures or even in fuel cell

Fuel cell

A fuel cell is a device that converts the chemical energy from a fuel into electricity through a chemical reaction with oxygen or another oxidizing agent. Hydrogen is the most common fuel, but hydrocarbons such as natural gas and alcohols like methanol are sometimes used...

s, so that the thermodynamic upper limit to the efficiency defined by Carnot's rule

Carnot's rule

Carnot's theorem, developed in 1824, also called Carnot's rule is a principle that specifies limits on the maximum efficiency any heat engine can obtain, which thus solely depends on the difference between the hot and cold temperature reservoirs....

is higher or not applicable. Syngas may be burned directly in gas engines, used to produce methanol

Methanol

Methanol, also known as methyl alcohol, wood alcohol, wood naphtha or wood spirits, is a chemical with the formula CH3OH . It is the simplest alcohol, and is a light, volatile, colorless, flammable liquid with a distinctive odor very similar to, but slightly sweeter than, ethanol...

and hydrogen, or converted via the Fischer-Tropsch process

Fischer-Tropsch process

The Fischer–Tropsch process is a set of chemical reactions that convert a mixture of carbon monoxide and hydrogen into liquid hydrocarbons. The process, a key component of gas to liquids technology, produces a petroleum substitute, typically from coal, natural gas, or biomass for use as synthetic...

into synthetic fuel

Synthetic fuel

Synthetic fuel or synfuel is a liquid fuel obtained from coal, natural gas, oil shale, or biomass. It may also refer to fuels derived from other solids such as plastics or rubber waste. It may also refer to gaseous fuels produced in a similar way...

. Gasification can also begin with material which would otherwise have been disposed of such as biodegradable waste. In addition, the high-temperature process refines out corrosive ash elements such as chloride

Chloride

The chloride ion is formed when the element chlorine, a halogen, picks up one electron to form an anion Cl−. The salts of hydrochloric acid HCl contain chloride ions and can also be called chlorides. The chloride ion, and its salts such as sodium chloride, are very soluble in water...

and potassium

Potassium

Potassium is the chemical element with the symbol K and atomic number 19. Elemental potassium is a soft silvery-white alkali metal that oxidizes rapidly in air and is very reactive with water, generating sufficient heat to ignite the hydrogen emitted in the reaction.Potassium and sodium are...

, allowing clean gas production from otherwise problematic fuels. Gasification of fossil fuels is currently widely used on industrial scales to generate electricity

Electricity

Electricity is a general term encompassing a variety of phenomena resulting from the presence and flow of electric charge. These include many easily recognizable phenomena, such as lightning, static electricity, and the flow of electrical current in an electrical wire...

.

History

Coal

Coal is a combustible black or brownish-black sedimentary rock usually occurring in rock strata in layers or veins called coal beds or coal seams. The harder forms, such as anthracite coal, can be regarded as metamorphic rock because of later exposure to elevated temperature and pressure...

and peat

Peat

Peat is an accumulation of partially decayed vegetation matter or histosol. Peat forms in wetland bogs, moors, muskegs, pocosins, mires, and peat swamp forests. Peat is harvested as an important source of fuel in certain parts of the world...

were used to power these plants. Initially developed to produce town gas for lighting & cooking in 1800s, this was replaced by electricity and natural gas

Natural gas

Natural gas is a naturally occurring gas mixture consisting primarily of methane, typically with 0–20% higher hydrocarbons . It is found associated with other hydrocarbon fuel, in coal beds, as methane clathrates, and is an important fuel source and a major feedstock for fertilizers.Most natural...

, it was also used in blast furnaces but the bigger role was played in the production of synthetic

Chemical synthesis

In chemistry, chemical synthesis is purposeful execution of chemical reactions to get a product, or several products. This happens by physical and chemical manipulations usually involving one or more reactions...

chemicals where it has been in use since the 1920s.

During both world wars especially the Second World War the need of gasification produced fuel reemerged due to the shortage of petroleum. Wood gas generator

Wood gas generator

A wood gas generator is a gasification unit which converts timber or charcoal into wood gas, a syngas consisting of atmospheric nitrogen, carbon monoxide, hydrogen, traces of methane, and other gases, which - after cooling and filtering - can then be used to power an internal combustion engine or...

s, called Gasogene or Gazogène, were used to power motor vehicles in Europe

Europe

Europe is, by convention, one of the world's seven continents. Comprising the westernmost peninsula of Eurasia, Europe is generally 'divided' from Asia to its east by the watershed divides of the Ural and Caucasus Mountains, the Ural River, the Caspian and Black Seas, and the waterways connecting...

. By 1945 there were trucks, buses and agricultural machines that were powered by gasification. It is estimated that there were close to 9,000,000 vehicles running on producer gas all over the world.

Chemistry

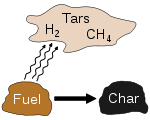

In a gasifier, the carbonaceous material undergoes several different processes:

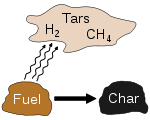

- The dehydrationDehydrationIn physiology and medicine, dehydration is defined as the excessive loss of body fluid. It is literally the removal of water from an object; however, in physiological terms, it entails a deficiency of fluid within an organism...

or drying process occurs at around 100°C. Typically the resulting steam is mixed into the gas flow and may be involved with subsequent chemical reactions, notably the water-gas reaction if the temperature is sufficiently high enough (see step #5). - The pyrolysisPyrolysisPyrolysis is a thermochemical decomposition of organic material at elevated temperatures without the participation of oxygen. It involves the simultaneous change of chemical composition and physical phase, and is irreversible...

(or devolatilization) process occurs at around 200-300°C. Volatiles are released and charCharringCharring is a chemical process of incomplete combustion of certain solids when subjected to high heat. The resulting residue matter is called Char. By the action of heat, charring removes hydrogen and oxygen from the solid, so that the remaining char is composed primarily of carbon...

is produced, resulting in up to 70% weight loss for coal. The process is dependent on the properties of the carbonaceous material and determines the structure and composition of the char, which will then undergo gasification reactions. - The combustionCombustionCombustion or burning is the sequence of exothermic chemical reactions between a fuel and an oxidant accompanied by the production of heat and conversion of chemical species. The release of heat can result in the production of light in the form of either glowing or a flame...

process occurs as the volatile products and some of the char reacts with oxygen to primarily form carbon dioxide and small amounts of carbon monoxide, which provides heat for the subsequent gasification reactions. Letting C represent a carbon-containing organic compoundOrganic compoundAn organic compound is any member of a large class of gaseous, liquid, or solid chemical compounds whose molecules contain carbon. For historical reasons discussed below, a few types of carbon-containing compounds such as carbides, carbonates, simple oxides of carbon, and cyanides, as well as the...

, the basic reaction here is

- The gasification process occurs as the char reacts with carbon and steam to produce carbon monoxide and hydrogen, via the reaction

- In addition, the reversibleReversible reactionA reversible reaction is a chemical reaction that results in an equilibrium mixture of reactants and products. For a reaction involving two reactants and two products this can be expressed symbolically as...

gas phase water gas shift reactionWater gas shift reactionThe water-gas shift reaction is a chemical reaction in which carbon monoxide reacts with water vapor to form carbon dioxide and hydrogen:The water-gas shift reaction is an important industrial reaction. It is often used in conjunction with steam reforming of methane or other hydrocarbons, which is...

reaches equilibriumChemical equilibriumIn a chemical reaction, chemical equilibrium is the state in which the concentrations of the reactants and products have not yet changed with time. It occurs only in reversible reactions, and not in irreversible reactions. Usually, this state results when the forward reaction proceeds at the same...

very fast at the temperatures in a gasifier. This balances the concentrations of carbon monoxide, steam, carbon dioxide and hydrogen.

In essence, a limited amount of oxygen or air is introduced into the reactor to allow some of the organic material to be "burned" to produce carbon monoxide and energy, which drives a second reaction that converts further organic material to hydrogen and additional carbon dioxide. Further reactions occur when the formed carbon monoxide and residual water

Water

Water is a chemical substance with the chemical formula H2O. A water molecule contains one oxygen and two hydrogen atoms connected by covalent bonds. Water is a liquid at ambient conditions, but it often co-exists on Earth with its solid state, ice, and gaseous state . Water also exists in a...

from the organic material react to form methane and excess carbon dioxide. This third reaction occurs more abundantly in reactors that increase the residence time of the reactive gases and organic materials, as well as heat and pressure. Catalysts are used in more sophisticated reactors to improve reaction rates, thus moving the system closer to the reaction equilibrium for a fixed residence time

Residence time

Residence time is the average amount of time that a particle spends in a particular system. This measurement varies directly with the amount of substance that is present in the system....

.

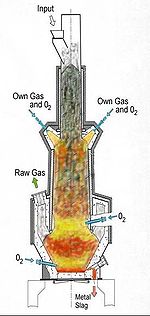

Gasification processes

Several types of gasifier are currently available for commercial use: counter-current fixed bed, co-current fixed bed, fluidized bedFluidized bed

A fluidized bed is formed when a quantity of a solid particulate substance is placed under appropriate conditions to cause the solid/fluid mixture to behave as a fluid. This is usually achieved by the introduction of pressurized fluid through the particulate medium...

, entrained flow and plasma.

Counter-current fixed bed ("up draft") gasifier

A fixed bed of carbonaceous fuel (e.g. coal or biomass) through which the "gasification agent" (steam, oxygen and/or air) flows in counter-current configuration. The ash is either removed dry or as a slagSlag

Slag is a partially vitreous by-product of smelting ore to separate the metal fraction from the unwanted fraction. It can usually be considered to be a mixture of metal oxides and silicon dioxide. However, slags can contain metal sulfides and metal atoms in the elemental form...

. The slagging gasifiers have a lower ratio of steam to carbon, achieving temperatures higher than the ash fusion temperature. The nature of the gasifier means that the fuel must have high mechanical strength and must ideally be non-caking so that it will form a permeable bed, although recent developments have reduced these restrictions to some extent. The throughput for this type of gasifier is relatively low. Thermal efficiency is high as the gas exit temperatures are relatively low. However, this means that tar and methane production is significant at typical operation temperatures, so product gas must be extensively cleaned before use. The tar can be recycled to the reactor.

In the gasification of fine, undensified biomass such as rice hulls, it is necessary to force air into the reactor by means of a fan. This creates very high gasification temperatures, at times as high as 1000 C. Above the gasification zone, a bed of fine, hot char is formed, and as the gas is forced through this bed, most complex hydrocarbons are broken down into simple components of hydrogen and carbon monoxide.

Co-current fixed bed ("down draft") gasifier

Similar to the counter-current type, but the gasification agent gas flows in co-current configuration with the fuel (downwards, hence the name "down draft gasifier"). Heat needs to be added to the upper part of the bed, either by combusting small amounts of the fuel or from external heat sources. The produced gas leaves the gasifier at a high temperature, and most of this heat is often transferred to the gasification agent added in the top of the bed, resulting in an energy efficiency on level with the counter-current type. Since all tars must pass through a hot bed of char in this configuration, tar levels are much lower than the counter-current type.Fluidized bed reactor

The fuel is fluidizedFluidization

Fluidization is a process similar to liquefaction whereby a granular material is converted from a static solid-like state to a dynamic fluid-like state...

in oxygen and steam or air. The ash is removed dry or as heavy agglomerates that defluidize. The temperatures are relatively low in dry ash gasifiers, so the fuel must be highly reactive; low-grade coals are particularly suitable. The agglomerating gasifiers have slightly higher temperatures, and are suitable for higher rank coals. Fuel throughput is higher than for the fixed bed, but not as high as for the entrained flow gasifier. The conversion efficiency can be rather low due to elutriation

Elutriation

Elutriation, also known as air classification, is a process for separating lighter particles from heavier ones using a vertically-directed stream of gas or liquid . This method is predominately used for particles with size...

of carbonaceous material. Recycle or subsequent combustion of solids can be used to increase conversion. Fluidized bed gasifiers are most useful for fuels that form highly corrosive ash that would damage the walls of slagging gasifiers. Biomass fuels generally contain high levels of corrosive ash.

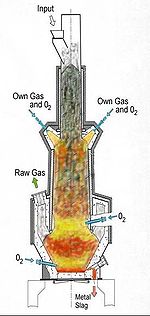

Entrained flow gasifier

A dry pulverized solid, an atomized liquid fuel or a fuel slurry is gasified with oxygen (much less frequent: air) in co-current flow. The gasification reactions take place in a dense cloud of very fine particles. Most coals are suitable for this type of gasifier because of the high operating temperatureOperating temperature

An operating temperature is the temperature at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the device function and application context, and ranges from the minimum operating temperature to the...

s and because the coal particles are well separated from one another.

The high temperatures and pressures also mean that a higher throughput can be achieved, however thermal efficiency is somewhat lower as the gas must be cooled before it can be cleaned with existing technology. The high temperatures also mean that tar and methane are not present in the product gas; however the oxygen requirement is higher than for the other types of gasifiers. All entrained flow gasifiers remove the major part of the ash as a slag as the operating temperature is well above the ash fusion temperature.

A smaller fraction of the ash is produced either as a very fine dry fly ash or as a black colored fly ash slurry. Some fuels, in particular certain types of biomasses, can form slag that is corrosive for ceramic inner walls that serve to protect the gasifier outer wall. However some entrained flow type of gasifiers do not possess a ceramic inner wall but have an inner water or steam cooled wall covered with partially solidified slag. These types of gasifiers do not suffer from corrosive slags.

Some fuels have ashes with very high ash fusion temperatures. In this case mostly limestone is mixed with the fuel prior to gasification. Addition of a little limestone will usually suffice for the lowering the fusion temperatures. The fuel particles must be much smaller than for other types of gasifiers. This means the fuel must be pulverized, which requires somewhat more energy than for the other types of gasifiers. By far the most energy consumption related to entrained flow gasification is not the milling of the fuel but the production of oxygen used for the gasification.

Plasma gasifier

In a plasma gasifier a high-voltage current is fed to a torch, creating a high-temperature arc. The inorganic residue is retrieved as a glass-like substance.Feedstock

There are a large number of different feedstock types for use in a gasifier, each with different characteristics, including size, shape, bulk density, moisture content, energy content, chemical composition, ash fusion characteristics, and homogeneity of all these properties.A wide variety of feedstocks can be gasified, with wood pellets and chips, waste wood, plastics and aluminium, Municipal Solid Waste

Municipal solid waste

Municipal solid waste , commonly known as trash or garbage , refuse or rubbish is a waste type consisting of everyday items we consume and discard. It predominantly includes food wastes, yard wastes, containers and product packaging, and other miscellaneous inorganic wastes from residential,...

(MSW), Refuse-derived fuel

Refuse-derived fuel

Refuse-derived fuel or solid recovered fuel/ specified recovered fuel is a fuel produced by shredding and dehydrating solid waste with a Waste converter technology. RDF consists largely of combustible components of municipal waste such as plastics and biodegradable waste...

(RDF), agricultural and industrial wastes, sewage sludge, switch grass, discarded seed corn, corn stover and other crop residues all being used.

Chemrec

Chemrec

Chemrec is a Stockholm, Sweden corporation that develops technology for entrained flow gasification of black liquor and certain types brown liquor for production of biofuels from the resulting syngas....

has developed a process for gasification of black liquor

Black liquor

Black liquor is the spent cooking liquor from the kraft process when digesting pulpwood into paper pulp removing lignin, hemicelluloses and other extractives from the wood to free the cellulose fibers....

.

Waste disposal

- The necessary extensive flue gas cleaning may be performed on the syngas instead of the much larger volume of flue gasFlue gasFlue gas is the gas exiting to the atmosphere via a flue, which is a pipe or channel for conveying exhaust gases from a fireplace, oven, furnace, boiler or steam generator. Quite often, the flue gas refers to the combustion exhaust gas produced at power plants...

after combustion. - Electric powerElectric powerElectric power is the rate at which electric energy is transferred by an electric circuit. The SI unit of power is the watt.-Circuits:Electric power, like mechanical power, is represented by the letter P in electrical equations...

may be generated in enginesInternal combustion engineThe internal combustion engine is an engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber. In an internal combustion engine, the expansion of the high-temperature and high -pressure gases produced by combustion apply direct force to some component of the engine...

and gas turbineGas turbineA gas turbine, also called a combustion turbine, is a type of internal combustion engine. It has an upstream rotating compressor coupled to a downstream turbine, and a combustion chamber in-between....

s, which are much cheaper and more efficient than the steam cycleRankine cycleThe Rankine cycle is a cycle that converts heat into work. The heat is supplied externally to a closed loop, which usually uses water. This cycle generates about 90% of all electric power used throughout the world, including virtually all solar thermal, biomass, coal and nuclear power plants. It is...

used in incineration. Even fuel cells may potentially be used, but these have rather severe requirements regarding the purity of the gas. - Chemical processing of the syngas may produce other synthetic fuels instead of electricity.

- Some gasification processes treat ash containing heavy metals at very high temperatures so that it is released in a glassy and chemically stable form.

A major challenge for waste gasification technologies is to reach an acceptable (positive) gross electric efficiency. The high efficiency of converting syngas to electric power is counteracted by significant power consumption in the waste preprocessing, the consumption of large amounts of pure oxygen (which is often used as gasification agent), and gas cleaning. Another challenge becoming apparent when implementing the processes in real life is to obtain long service intervals in the plants, so that it is not necessary to close down the plant every few months for cleaning the reactor.

Several waste gasification processes have been proposed, but few have yet been built and tested, and only a handful have been implemented as plants processing real waste, and most of the time in combination with fossil fuels.

One plant (in Chiba

Chiba, Chiba

is the capital city of Chiba Prefecture, Japan. It is located approximately 40 km east of the center of Tokyo on Tokyo Bay. Chiba City became a government designated city in 1992. Its population as of 2008 is approximately 960,000....

, Japan

Japan

Japan is an island nation in East Asia. Located in the Pacific Ocean, it lies to the east of the Sea of Japan, China, North Korea, South Korea and Russia, stretching from the Sea of Okhotsk in the north to the East China Sea and Taiwan in the south...

using the Thermoselect process) has been processing industrial waste since year 2000, but has not yet documented positive net energy production from the process.

In the USA, gasification of waste is expanding across the country. Ze-gen

Ze-gen

Ze-gen, Inc. is a renewable energy company developing advanced gasification technology to convert waste into synthesis gas. Founded in 2004, Ze-gen is a venture-backed company based in Boston, Massachusetts....

is operating a waste gasification demonstration facility in New Bedford, Massachusetts

New Bedford, Massachusetts

New Bedford is a city in Bristol County, Massachusetts, United States, located south of Boston, southeast of Providence, Rhode Island, and about east of Fall River. As of the 2010 census, the city had a total population of 95,072, making it the sixth-largest city in Massachusetts...

. The facility was designed to demonstrate gasification of specific non-MSW waste streams using liquid metal gasification. In addition, construction of a biomass gasification plant was approved in DeKalb County, Georgia on June 14, 2011 and in Green Bay Wisconsin a deal was made with the Oneida Nation and the city of Green Bay to build a gasification power plant which will supply electricity to over 4,000 homes.

Also in the USA, plasma is being used to gasify municipal solid waste, hazardous waste and biomedical waste at the Hurlburt Field Florida Special Operations Command Air Force base. PyroGenesis Canada Inc. is the technology provider.

Current applications

Syngas can be used for heat production and for generation of mechanical and electrical power. Like other gaseous fuels, producer gas gives greater control over power levels when compared to solid fuels, leading to more efficient and cleaner operation.Syngas can also be used for further processing to liquid fuels or chemicals.

Heat

Gasifiers offer a flexible option for thermal applications, as they can be retrofitted into existing gas fueled devices such as ovens, furnaces, boilers, etc., where syngas may replace fossil fuels. Heating values of syngas are generally around 4-10 MJ/m3.Electricity

Industrial-scale gasification is currently mostly used to produce electricity from fossil fuels such as coal, where the syngas is burned in a gas turbine. Gasification is also used industrially in the production of electricity, ammonia and liquid fuels (oil) using Integrated Gasification Combined Cycles (IGCCIntegrated Gasification Combined Cycle

An integrated gasification combined cycle is a technology that turns coal into gas—synthesis gas . It then removes impurities from the coal gas before it is combusted and attempts to turn any pollutants into re-usable byproducts. This results in lower emissions of sulfur dioxide, particulates, and...

), with the possibility of producing methane and hydrogen for fuel cells. IGCC is also a more efficient method of CO2 capture as compared to conventional technologies. IGCC demonstration plants have been operating since the early 1970s and some of the plants constructed in the 1990s are now entering commercial service.

Combined heat and power

In small business and building applications, where the wood source is sustainable, 250-1000 kWe and new zero carbon biomass gasification plants have been installed in Europe that produce tar free syngas from wood and burn it in reciprocating engines connected to a generator with heat recovery. This type of plant is often referred to as a wood biomass CHP unit but is a plant with seven different processes: biomass processing, fuel delivery, gasification, gas cleaning, waste disposal, electricity generation and heat recovery.Transport fuel

Diesel engineDiesel engine

A diesel engine is an internal combustion engine that uses the heat of compression to initiate ignition to burn the fuel, which is injected into the combustion chamber...

s can be operated on dual fuel mode using producer gas. Diesel substitution of over 80% at high loads and 70-80% under normal load variations can easily be achieved. Spark ignition engines and SOFC fuel cells can operate on 100% gasification gas. Mechanical energy from the engines may be used for e.g. driving water pumps for irrigation or for coupling with an alternator for electrical power generation.

While small scale gasifiers have existed for well over 100 years, there have been few sources to obtain a ready to use machine. Small scale devices are typically DIY projects. However, currently in the United States

United States

The United States of America is a federal constitutional republic comprising fifty states and a federal district...

, several companies offer gasifiers to operate small engines. In 2009 21stCenturyMotorworks claimed to have developed gasification technology in a prototype pickup truck that could use any biomass materials for fuel, the vehicle was displayed at multiple events including the 2009 Boston Greenfest.

Renewable energy and fuels

Dimethyl ether

Dimethyl ether , also known as methoxymethane, is the organic compound with the formula . The simplest ether, it is a colourless gas that is a useful precursor to other organic compounds and an aerosol propellant. When combusted, DME produces minimal soot and CO, though HC and NOx formation is...

(DME) by methanol dehydration, methane via the Sabatier reaction

Sabatier reaction

The Sabatier reaction or Sabatier process involves the reaction of hydrogen with carbon dioxide at elevated temperatures and pressures in the presence of a nickel catalyst to produce methane and water. Optionally ruthenium on alumina makes a more efficient catalyst...

, or diesel-like synthetic fuel via the Fischer-Tropsch process. In many gasification processes most of the inorganic components of the input material, such as metals and minerals, are retained in the ash. In some gasification processes (slagging gasification) this ash has the form of a glassy solid with low leaching

Leaching (chemical science)

Leaching is the process of extracting minerals from a solid by dissolving them in a liquid, either in nature or through an industrial process. In the chemical processing industry, leaching has a variety of commercial applications, including separation of metal from ore using acid, and sugar from...

properties, but the net power production in slagging gasification is low (sometimes negative) and costs are higher.

Regardless of the final fuel form, gasification itself and subsequent processing neither directly emits nor traps greenhouse gases such as carbon dioxide. Power consumption in the gasification and syngas conversion processes may be significant though, and may indirectly cause CO2 emissions; in slagging and plasma gasification, the electricity consumption may even exceed any power production from the syngas.

Combustion of syngas or derived fuels emits exactly the same amount of carbon dioxide as would have been emitted from direct combustion of the initial fuel. Biomass gasification and combustion could play a significant role in a renewable energy economy, because biomass production removes the same amount of CO2 from the atmosphere as is emitted from gasification and combustion. While other biofuel technologies such as biogas and biodiesel

Biodiesel

Biodiesel refers to a vegetable oil- or animal fat-based diesel fuel consisting of long-chain alkyl esters. Biodiesel is typically made by chemically reacting lipids with an alcohol....

are carbon neutral

Carbon neutral

Carbon neutrality, or having a net zero carbon footprint, refers to achieving net zero carbon emissions by balancing a measured amount of carbon released with an equivalent amount sequestered or offset, or buying enough carbon credits to make up the difference...

, gasification in principle may run on a wider variety of input materials and can be used to produce a wider variety of output fuels.

There are at present a few industrial scale biomass gasification plants. Since 2008 in Svenljunga, Sweden

Sweden

Sweden , officially the Kingdom of Sweden , is a Nordic country on the Scandinavian Peninsula in Northern Europe. Sweden borders with Norway and Finland and is connected to Denmark by a bridge-tunnel across the Öresund....

, a biomass gasification plant generates up to 14 MWth, supplying industries and citizens of Svenljunga with process steam and district heating

District heating

District heating is a system for distributing heat generated in a centralized location for residential and commercial heating requirements such as space heating and water heating...

, respectively. The gasifier uses biomass fuels such as CCA

Chromated copper arsenate

Chromated copper arsenate is a wood preservative used for timber treatment since the mid-1930s. It is a mix of chromium, copper and arsenic formulated as oxides or salts. It preserves the wood from decay fungi, wood attacking insects, including termites, and marine borers...

or creosote

Creosote

Creosote is the portion of chemical products obtained by the distillation of a tar that remains heavier than water, notably useful for its anti-septic and preservative properties...

impregnated waste wood and other kinds of recycled wood to produces syngas that is combusted on site. In 2011 a similar gasifier, using the same kinds of fuels, is being installed at Munkfors Energy's CHP

Cogeneration

Cogeneration is the use of a heat engine or a power station to simultaneously generate both electricity and useful heat....

plant. The CHP plant will generate 2 MWe (electricity) and 8 MWth (district heating

District heating

District heating is a system for distributing heat generated in a centralized location for residential and commercial heating requirements such as space heating and water heating...

).

Examples of demonstration projects include:

- Those of the Renewable Energy Network Austria, including a plant using dual fluidized bed gasification that has supplied the town of GüssingGüssingGüssing is a town in Burgenland, Austria. It is located at , with a population of 3,811 , and is the administrative center of the Güssing district.The Güssing Castle, built in 1157, is the oldest castle in Burgenland and a regional landmark....

with 2 MW of electricity, produced utilising GE Jenbacher reciprocating gas engineGas engineA gas engine means an engine running on a gas, such as coal gas, producer gas biogas, landfill gas, or natural gas. In the UK, the term is unambiguous...

s and 4 MW of heat, generated from wood chips, since 2003. - Chemrec's pilot plant in PiteåPiteåPiteå is a locality and the seat of Piteå Municipality in Norrbotten County, Sweden. The town has 22,650 inhabitants out of a municipal total of 41,000 in 2008.- Geography :...

that has produced 3 MW of clean syngas since 2006, generated from entrained flow gasification of black liquor. - The US Air Force Transportable Plasma Waste to Energy System (TPWES) facility at Hurlburt Field, Florida.

See also

- Coal gasificationCoal gasificationCoal gasification is the process of producing coal gas, a type of syngas–a mixture of carbon monoxide , hydrogen , carbon dioxide and water vapour –from coal...

- Fluidized bed combustionFluidized bed combustionFluidized bed combustion is a combustion technology used in power plants. Fluidized beds suspend solid fuels on upward-blowing jets of air during the combustion process. The result is a turbulent mixing of gas and solids. The tumbling action, much like a bubbling fluid, provides more effective...

- History of manufactured gasHistory of manufactured gasThe history of manufactured gas, important for lighting, heating, and cooking purposes throughout most of the nineteenth century and the first half of the 20th century, began with the development of analytical and pneumatic chemistry in the eighteenth century...

- Isle of Wight gasification facilityIsle of Wight gasification facilityThe Isle of Wight gasification facility is a municipal waste treatment plant in southern England. It entered the commissioning phase in autumn 2008...

- List of solid waste treatment technologies

- Plasma arc waste disposalPlasma arc waste disposalPlasma arc gasification or Plasma Gasification Process abbreviated PGP is a waste treatment technology that uses electrical energy and the high temperatures created by an electric arc gasifier. This arc breaks down waste primarily into elemental gas and solid waste , in a device called a plasma...

- Renewable natural gasRenewable natural gasRenewable natural gas, also known as sustainable natural gas, is a biogas which has been upgraded to a quality similar to fossil natural gas. A biogas is a gas methane obtained from biomass. By upgrading the quality to that of natural gas, it becomes possible to distribute the gas to customers via...

- Water gasWater gasWater gas is a synthesis gas, containing carbon monoxide and hydrogen. It is a useful product but requires careful handling because of the risk of carbon monoxide poisoning. The gas is made by passing steam over a red-hot hydrocarbon fuel such as coke:...