History of mints

Encyclopedia

Lydia

Lydia was an Iron Age kingdom of western Asia Minor located generally east of ancient Ionia in the modern Turkish provinces of Manisa and inland İzmir. Its population spoke an Anatolian language known as Lydian....

for coining gold, silver and electrum

Electrum

Electrum is a naturally occurring alloy of gold and silver, with trace amounts of copper and other metals. It has also been produced artificially. The ancient Greeks called it 'gold' or 'white gold', as opposed to 'refined gold'. Its color ranges from pale to bright yellow, depending on the...

. The Lydian innovation of manufacturing coins under the authority of the state spread to neighboring Greece

Greece

Greece , officially the Hellenic Republic , and historically Hellas or the Republic of Greece in English, is a country in southeastern Europe....

, and from there spread to other areas of the Mediterranean. At about the same time, coins and mints appeared independently in China

China

Chinese civilization may refer to:* China for more general discussion of the country.* Chinese culture* Greater China, the transnational community of ethnic Chinese.* History of China* Sinosphere, the area historically affected by Chinese culture...

and spread to Korea

Korea

Korea ) is an East Asian geographic region that is currently divided into two separate sovereign states — North Korea and South Korea. Located on the Korean Peninsula, Korea is bordered by the People's Republic of China to the northwest, Russia to the northeast, and is separated from Japan to the...

and Japan

Japan

Japan is an island nation in East Asia. Located in the Pacific Ocean, it lies to the east of the Sea of Japan, China, North Korea, South Korea and Russia, stretching from the Sea of Okhotsk in the north to the East China Sea and Taiwan in the south...

. The manufacture of coins in the Roman Empire

Roman Empire

The Roman Empire was the post-Republican period of the ancient Roman civilization, characterised by an autocratic form of government and large territorial holdings in Europe and around the Mediterranean....

, dating from about the 4th century BC, significantly influenced later development of coin minting in Europe.

The origin of the word "mint" is ascribed to the manufacture of silver coin at Rome in 269 BC at the temple of Juno Moneta

Moneta

In Roman mythology, Moneta was a title given to two separate goddesses: the goddess of memory and an epithet of Juno, called Juno Moneta...

. This goddess became the personification of money, and her name was applied both to money and to its place of manufacture. Metals were used for money at an early stage of civilization, and are well suited to the purpose, owing to their great intrinsic value and their durability, indestructibility, divisibility and rarity. The best metals for coinage are gold, silver, platinum, copper, tin, nickel, aluminum, zinc, iron, and their alloys; certain alloys of gold, silver, copper and nickel have the best combination of the required qualities.

From rings and ornaments to coins

The earliest metallic money did not consist of coins, but of unminted metal in the form of rings and other ornaments or of weapons, which were used for thousands of years by the EgyptianAncient Egypt

Ancient Egypt was an ancient civilization of Northeastern Africa, concentrated along the lower reaches of the Nile River in what is now the modern country of Egypt. Egyptian civilization coalesced around 3150 BC with the political unification of Upper and Lower Egypt under the first pharaoh...

, Chaldea

Chaldea

Chaldea or Chaldaea , from Greek , Chaldaia; Akkadian ; Hebrew כשדים, Kaśdim; Aramaic: ܟܐܠܕܘ, Kaldo) was a marshy land located in modern-day southern Iraq which came to briefly rule Babylon...

n and Assyria

Assyria

Assyria was a Semitic Akkadian kingdom, extant as a nation state from the mid–23rd century BC to 608 BC centred on the Upper Tigris river, in northern Mesopotamia , that came to rule regional empires a number of times through history. It was named for its original capital, the ancient city of Assur...

n empires.

Silver was coined in the island of Aegina soon afterwards. The art of coining was introduced by the Greeks into Italy and other countries bordering on the Mediterranean and into Persia and India. Subsequently the Romans laid the foundations of modern minting. Coining originated independently in China, and spread from China to Japan and Korea.

Early minting technology

Coins may be made by casting in mouldsMolding (process)

Molding or moulding is the process of manufacturing by shaping pliable raw material using a rigid frame or model called a pattern....

or by striking between engraved dies. The Romans cast their larger copper coins, in clay moulds carrying distinctive markings, not because they knew nothing of striking, but because it was not suitable for such large masses of metal. Casting is now used only by counterfeiters. The most ancient coins were cast in bulletshaped or conical moulds and marked on one side by means of a die which was struck with a hammer. The "blank" or unmarked piece of metal was placed on a small anvil

Anvil

An anvil is a basic tool, a block with a hard surface on which another object is struck. The inertia of the anvil allows the energy of the striking tool to be transferred to the work piece. In most cases the anvil is used as a forging tool...

(ambos), and the die was held in position with tongs

Tongs

Tongs are used for gripping and lifting tools, of which there are many forms adapted to their specific use. Some are merely large pincers or nippers, but the greatest number fall into three classes:...

. The reverse or lower side of the coin received a rectangular mark made by the sharp edges of the little anvil. Subsequently the anvil was marked in various ways, and decorated with letters and figures of beasts, and later still the ambos was replaced by a reverse die. The spherical blanks soon gave place to lenticular-shaped

Lens (geometry)

In geometry, a lens is a biconvex shape comprising two circular arcs, joined at their endpoints. If the arcs have equal radii, it is called a symmetric lens.A concave-convex shape is called a lune...

ones. The blank was made red-hot and struck between cold dies. One blow was usually insufficient, and the method was similar to that still used in striking medals in high relief, except that the blank is now allowed to cool before being struck. With the substitution of iron for bronze as the material for dies, about 300 AD, the practice of striking the blanks while they were hot was gradually discarded.

In the Middle Ages bars of metal were cast and hammered out on an anvil. Portions of the flattened sheets were then cut out with shears

Shears

Shears may mean:* trauma shears, scissors used by emergency medical personnel to quickly and safely cut clothing* kitchen shears, a kind of scissors* pinking shears, a kind of scissors* blade shears, typically used for shearing animals...

, struck between dies and again trimmed with shears. A similar method had been used in Egypt under the Ptolemies (c. 300 BC) but had been forgotten. Square pieces of metal were also cut from cast bars, converted into round disks by hammering and then struck between dies. In striking, the lower die was fixed into a block of wood, and the blank piece of metal laid upon it by hand. The upper die was then placed on the blank, and kept in position by means of a holder round which was placed a roll of lead

Lead

Lead is a main-group element in the carbon group with the symbol Pb and atomic number 82. Lead is a soft, malleable poor metal. It is also counted as one of the heavy metals. Metallic lead has a bluish-white color after being freshly cut, but it soon tarnishes to a dull grayish color when exposed...

to protect the hand of the operator while heavy blows were struck with a hammer. An early improvement was the introduction of a tool resembling a pair of tongs, the two dies being placed one at the extremity of each leg. This avoided the necessity of readjusting the dies between blows, and ensured greater accuracy in the impression.

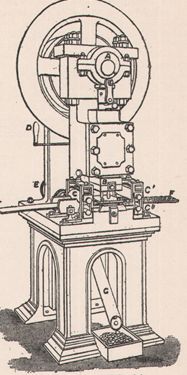

Minting technology in 16th and 17th century Europe

Machine press

A machine press, commonly shortened to press, is a machine tool that changes the shape of a workpiece.-Servomechanism:A servomechanism press, also known as a servo press or a electro press, is a press driven by an AC servo motor. The torque produced is converted to a linear force via a ball screw....

) intervened between the hand hammers and the screw press in many places. In Birmingham in particular this system became highly developed and was long in use. In 1553, the French engineer Aubin Olivier

Aubin Olivier

Aubin Olivier was a French engineer who introduced use of the screw press in minting coins. To reform French coinage, Henri II sent Olivier to investigate press technology being used by an Augsburg goldsmith. Olivier subsequently established the Royal Mill Mint on the Île de la Cité in...

introduced screw presses for striking coins, together with rolls for reducing the cast bars and machines for punching-out round disks from flattened sheets of metal. After being discarded in 1585, except for making medals, they were reintroduced by Jean Varin

Jean Varin

Jean Varin or Warin was French sculptor and engraver who made important innovations in the process of minting coins.Born in Liège, Varin moved to Paris in 1626. After demonstrating talent as an engraver, he obtained the support of Cardinal Richelieu and in 1647 was appointed head of the French mint...

in 1640 and the practice of hammering was forbidden in 1645. In England the new machinery was tried in London in 1561, but abandoned soon afterwards; it was finally adopted in 1662, although the old pieces continued in circulation until 1696. At first the rolls were driven by workmen by means of cranks, but later they were worked by horses, mules or water-power.

Minting technology advances in the industrial revolution

Steam-power was introduced to coin manufacture by Matthew Boulton and Watt in Birmingham in 1788, and was adopted by the Royal Mint, London, in 1810. Boulton and Watt's screw press, invented in 1788 and used at the Royal Mint until 1881, was worked by atmospheric pressure applied to a piston. The piston was in communication with a vacuum vessel from which the air had been pumped by steam power.Modern minting technology

See also

- Mint (coin)Mint (coin)A mint is an industrial facility which manufactures coins for currency.The history of mints correlates closely with the history of coins. One difference is that the history of the mint is usually closely tied to the political situation of an era...

- Soho MintSoho MintSoho Mint was created by Matthew Boulton in 1788 in his Soho Manufactory in Handsworth, West Midlands, England. A mint was erected at the manufactory containing eight machines, driven by steam engine, each capable of striking 70 to 84 coins per minute....

- Royal MintRoyal MintThe Royal Mint is the body permitted to manufacture, or mint, coins in the United Kingdom. The Mint originated over 1,100 years ago, but since 2009 it operates as Royal Mint Ltd, a company which has an exclusive contract with HM Treasury to supply all coinage for the UK...

- Coining (machining)Coining (machining)Coining is a form of precision stamping in which a workpiece is subjected to a sufficiently high stress to induce plastic flow on the surface of the material. A beneficial feature is that in some metals, the plastic flow reduces surface grain size, and work hardens the surface, while the material...

- Coin die

- Benvenuto CelliniBenvenuto CelliniBenvenuto Cellini was an Italian goldsmith, sculptor, painter, soldier and musician, who also wrote a famous autobiography. He was one of the most important artists of Mannerism.-Youth:...