Poppet valve

Encyclopedia

Valve

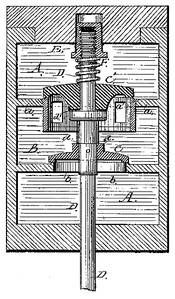

A valve is a device that regulates, directs or controls the flow of a fluid by opening, closing, or partially obstructing various passageways. Valves are technically pipe fittings, but are usually discussed as a separate category...

consisting of a hole, usually round or oval, and a tapered plug, usually a disk shape on the end of a shaft also called a valve stem. The shaft guides the plug portion by sliding through a valve guide

Valve guide

In most types of reciprocating engines, a valve guide is provided for each poppet valve in the cylinder head. Along with the valve spring, it serves to positively locate the valve so that it may make proper contact with the valve seat. A valve guide is a tube-shaped piece of metal, pressed into the...

. In most applications a pressure differential helps to seal the valve and in some applications also open it.

Presta

Presta valve

The Presta valve is a valve commonly found in high pressure road style and many mountain bicycle inner tubes. It comprises an outer valve stem and an inner valve body...

and Schrader valve

Schrader valve

The Schrader valve is a brand of pneumatic tire valve used on virtually every motor vehicle in the world today. The Schrader company, for which it was named, was founded in 1844 by August Schrader...

s used on pneumatic tire

Tire

A tire or tyre is a ring-shaped covering that fits around a wheel rim to protect it and enable better vehicle performance by providing a flexible cushion that absorbs shock while keeping the wheel in close contact with the ground...

s are examples of poppet valves. The Presta valve has no spring and relies on a pressure differential for opening and closing while being inflated.

Etymology

The word poppetPoppet

The word poppet is an older spelling of puppet, from the Middle English popet, meaning a small child or doll. In British Dialect it continues to hold this meaning. Poppet is also a chiefly English term of endearment.-Folk magic:...

shares etymology

Etymology

Etymology is the study of the history of words, their origins, and how their form and meaning have changed over time.For languages with a long written history, etymologists make use of texts in these languages and texts about the languages to gather knowledge about how words were used during...

with "puppet

Puppet

A puppet is an inanimate object or representational figure animated or manipulated by an entertainer, who is called a puppeteer. It is used in puppetry, a play or a presentation that is a very ancient form of theatre....

": it is from the Middle English

Middle English

Middle English is the stage in the history of the English language during the High and Late Middle Ages, or roughly during the four centuries between the late 11th and the late 15th century....

popet ("youth" or "doll"), from Middle French

Middle French

Middle French is a historical division of the French language that covers the period from 1340 to 1611. It is a period of transition during which:...

poupette, which is a diminutive

Diminutive

In language structure, a diminutive, or diminutive form , is a formation of a word used to convey a slight degree of the root meaning, smallness of the object or quality named, encapsulation, intimacy, or endearment...

of poupe. The use of the word poppet to describe a valve comes from the same word applied to marionette

Marionette

A marionette is a puppet controlled from above using wires or strings depending on regional variations. A marionette's puppeteer is called a manipulator. Marionettes are operated with the puppeteer hidden or revealed to an audience by using a vertical or horizontal control bar in different forms...

s, which – like the poppet valve – move bodily in response to remote motion transmitted linearly. In the past, "puppet valve" was a synonym for poppet valve; however, this usage of "puppet" is now obsolete.

Operation

The operating principle of poppet valves is described in the online article "How Poppet Valves Work". In most cases it is beneficial to have a "balanced poppet" in a direct-acting valve. Less force is needed to move the poppet because all forces on the poppet are nullified by equal and opposite forces. The solenoid coil has to counteract only the spring force.Applications

Poppet valves are used in many industrial processes, from controlling the flow of milkMilk

Milk is a white liquid produced by the mammary glands of mammals. It is the primary source of nutrition for young mammals before they are able to digest other types of food. Early-lactation milk contains colostrum, which carries the mother's antibodies to the baby and can reduce the risk of many...

to isolating sterile air in the semiconductor industry. However, they are most well known for their use in internal combustion and steam engines, as described below.

Internal combustion engine

Poppet valves are used in most piston engines to open and close the intake and exhaust portsCylinder head porting

Cylinder head porting refers to the process of modifying the intake and exhaust ports of an internal combustion engine to improve the quality and quantity of the air flow. Cylinder heads, as manufactured, are usually suboptimal due to design and manufacturing constraints...

in the cylinder head

Cylinder head

In an internal combustion engine, the cylinder head sits above the cylinders on top of the cylinder block. It closes in the top of the cylinder, forming the combustion chamber. This joint is sealed by a head gasket...

. The valve is usually a flat disk of metal with a long rod known as the valve stem attached to one side.

The stem is used to push down on the valve and open it, with a spring generally used to return it to the closed position when the stem is not being depressed. At high revolutions per minute

Revolutions per minute

Revolutions per minute is a measure of the frequency of a rotation. It annotates the number of full rotations completed in one minute around a fixed axis...

(RPM), the inertia

Inertia

Inertia is the resistance of any physical object to a change in its state of motion or rest, or the tendency of an object to resist any change in its motion. It is proportional to an object's mass. The principle of inertia is one of the fundamental principles of classical physics which are used to...

of the spring makes it too slow to return the valve to its seat between cycles, leading to 'valve float

Valve float

Valve float is an adverse condition which occurs when the poppet valves on an internal combustion engine valvetrain do not remain in contact with the camshaft lobe during the valve closure phase of the cam lobe profile...

'. In this situation desmodromic valve

Desmodromic valve

A desmodromic valve is a reciprocating engine valve that is positively closed by a cam and leverage system, rather than by a more conventional spring...

s are used which, being closed by a positive mechanical action instead of by a spring, are able to cycle at the high speeds required in, for instance, motorcycle

Motorcycle

A motorcycle is a single-track, two-wheeled motor vehicle. Motorcycles vary considerably depending on the task for which they are designed, such as long distance travel, navigating congested urban traffic, cruising, sport and racing, or off-road conditions.Motorcycles are one of the most...

and auto racing

Auto racing

Auto racing is a motorsport involving the racing of cars for competition. It is one of the world's most watched televised sports.-The beginning of racing:...

engines .

The engine normally operates the valves by pushing on the stems with cam

Cam

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion or vice-versa. It is often a part of a rotating wheel or shaft that strikes a lever at one or more points on its circular path...

s and cam follower

Tappet

A tappet is the noise made by a worn cam follower, however the term is widely used to represent the cam follower itself. In mechanical engineering it is a projection which imparts a linear motion to some other component within an assembly...

s. The shape and position of the cam determines the valve lift and when and how quickly (or slowly) the valve is opened. The cams are normally placed on a fixed camshaft

Camshaft

A camshaft is a shaft to which a cam is fastened or of which a cam forms an integral part.-History:An early cam was built into Hellenistic water-driven automata from the 3rd century BC. The camshaft was later described in Iraq by Al-Jazari in 1206. He employed it as part of his automata,...

which is then geared to the crankshaft

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

, running at half crankshaft speed in a four-stroke engine. On high-performance engines, the camshaft is movable and the cams have a varying height, so by axially moving the camshaft in relation with the engine RPM, also the valve lift varies. See variable valve timing

Variable valve timing

In internal combustion engines, variable valve timing , also known as Variable valve actuation , is a generalized term used to describe any mechanism or method that can alter the shape or timing of a valve lift event within an internal combustion engine...

.

For certain applications the valve stem and disk are made of different steel alloy

Alloy

An alloy is a mixture or metallic solid solution composed of two or more elements. Complete solid solution alloys give single solid phase microstructure, while partial solutions give two or more phases that may or may not be homogeneous in distribution, depending on thermal history...

s, or the valve stems may be hollow and filled with sodium

Sodium

Sodium is a chemical element with the symbol Na and atomic number 11. It is a soft, silvery-white, highly reactive metal and is a member of the alkali metals; its only stable isotope is 23Na. It is an abundant element that exists in numerous minerals, most commonly as sodium chloride...

to improve heat

Heat

In physics and thermodynamics, heat is energy transferred from one body, region, or thermodynamic system to another due to thermal contact or thermal radiation when the systems are at different temperatures. It is often described as one of the fundamental processes of energy transfer between...

transport and transfer. Although better heat conductors, aluminum cylinder heads require steel valve seat

Valve seat

The valve seat in an internal combustion gasoline or diesel engine is the surface against which an intake or an exhaust valve rests during the portion of the engine operating cycle when that valve is closed...

inserts, while cast-iron

Cast iron

Cast iron is derived from pig iron, and while it usually refers to gray iron, it also identifies a large group of ferrous alloys which solidify with a eutectic. The color of a fractured surface can be used to identify an alloy. White cast iron is named after its white surface when fractured, due...

cylinder heads often used integral valve seats in the past. Because the valve stem extends into lubrication in the cam chamber, it must be sealed against blow-by to prevent cylinder gases from escaping into the crankcase

Crankcase

In an internal combustion engine of the reciprocating type, the crankcase is the housing for the crankshaft. The enclosure forms the largest cavity in the engine and is located below the cylinder, which in a multicylinder engine are usually integrated into one or several cylinder blocks...

, even though the stem to valve clearance is very small, typically 0.04-0.06 mm. A rubber lip-type seal ensures that excessive amounts of oil are not drawn in from the crankcase on the induction stroke and that exhaust gas does not enter the crankcase on the exhaust stroke. Worn valve guides or defective oil seals are characterised by a puff of blue smoke from the exhaust when pressing back down on the accelerator pedal after allowing the engine to over-run, such as when changing gears.

Valve position

In very early engine designs the valves were 'upside down' in the block, parallel to the cylinderCylinder (engine)

A cylinder is the central working part of a reciprocating engine or pump, the space in which a piston travels. Multiple cylinders are commonly arranged side by side in a bank, or engine block, which is typically cast from aluminum or cast iron before receiving precision machine work...

s - the so called L-head engine because of the shape of the cylinder and combustion chamber

Combustion chamber

A combustion chamber is the part of an engine in which fuel is burned.-Internal combustion engine:The hot gases produced by the combustion occupy a far greater volume than the original fuel, thus creating an increase in pressure within the limited volume of the chamber...

, also called 'flathead engine

Flathead engine

A flathead engine is an internal combustion engine with valves placed in the engine block beside the piston, instead of in the cylinder head, as in an overhead valve engine...

' as the top of the cylinder head

Cylinder head

In an internal combustion engine, the cylinder head sits above the cylinders on top of the cylinder block. It closes in the top of the cylinder, forming the combustion chamber. This joint is sealed by a head gasket...

is flat. Although this design makes for simplified and cheap construction, it has two major drawbacks; the tortuous path followed by the intake charge limits air flow

Cylinder head porting

Cylinder head porting refers to the process of modifying the intake and exhaust ports of an internal combustion engine to improve the quality and quantity of the air flow. Cylinder heads, as manufactured, are usually suboptimal due to design and manufacturing constraints...

and effectively prevents speeds greater than 2,000–2,500 RPM, and the travels of the exhaust through the block can cause overheating under sustained heavy load. This design evolved into 'Intake Over Exhaust

IOE engine

The intake/inlet over exhaust engine, also known as F-head and pocket valve, is a valvetrain configuration used in early four-stroke internal combustion engines...

', IOE or F-head, where the intake valve was in the head and the exhaust valve was in the block; later both valves moved to the head.

In most such designs the camshaft remained relatively near the crankshaft, and the valves were operated through pushrods and rocker arm

Rocker arm

Generally referred to within the internal combustion engine of automotive, marine, motorcycle and reciprocating aviation engines, the rocker arm is a reciprocating lever that conveys radial movement from the cam lobe into linear movement at the poppet valve to open it...

s. This led to significant energy losses in the engine, but was simpler, especially in a V engine

V engine

A V engine, or Vee engine is a common configuration for an internal combustion engine. The cylinders and pistons are aligned, in two separate planes or 'banks', so that they appear to be in a "V" when viewed along the axis of the crankshaft...

where one camshaft can actuate the valves for both cylinder bank

Cylinder bank

Internal combustion piston engines are usually arranged so that the cylinders are in lines parallel to the crankshaft. Where they are in a single line, this is referred to as an inline or straight engine....

s; for this reason, pushrod engine designs persisted longer in these configurations than others.

More modern designs have the camshaft on top of the cylinder head, pushing directly on the valve stem (again through cam followers, also known as tappet

Tappet

A tappet is the noise made by a worn cam follower, however the term is widely used to represent the cam follower itself. In mechanical engineering it is a projection which imparts a linear motion to some other component within an assembly...

s), a system known as overhead camshaft; if there is just one camshaft, this is a single overhead cam or SOHC engine. Often there are two camshafts, one for the intake and one for exhaust valves, creating the dual overhead cam, or DOHC. The camshaft is driven by the crankshaft

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

- through gears, a chain or a timing belt

Timing belt

A timing belt, or cam belt , is a part of an internal combustion engine that controls the timing of the engine's valves. Some engines, such as the flat-4 Volkswagen air-cooled engine, and the straight-6 Toyota F engine use timing gears...

.

Valve wear

In the early days of engine building, the poppet valve was a major problem. MetallurgyMetallurgy

Metallurgy is a domain of materials science that studies the physical and chemical behavior of metallic elements, their intermetallic compounds, and their mixtures, which are called alloys. It is also the technology of metals: the way in which science is applied to their practical use...

was not what it is today, and the rapid opening and closing of the valves against the cylinder heads led to rapid wear. They would need to be re-ground every two years or so, in an expensive and time-consuming process known as a valve job

Valve job

A valve job is an operation which is performed on any four stroke cycle, internal combustion engine, the purpose of which is to clean up the mating surfaces of the poppet valves that control the intake and exhaust of the air/fuel mixture that powers the motion of the pistons.In the earliest...

. Adding tetra-ethyl lead

Tetra-ethyl lead

Tetraethyllead , abbreviated TEL, is an organolead compound with the formula 4Pb. An inexpensive additive, its addition to gasoline from the 1920's allowed octane ratings and thus engine compression to be boosted significantly, increasing power and fuel economy...

to the petrol reduced this problem to some degree, as the lead would coat the valve seats, in effect lubricating the metal. Valve seats made of improved alloys such as stellite

Stellite

Stellite alloy is a range of cobalt-chromium alloys designed for wear resistance. It may also contain tungsten or molybdenum and a small but important amount of carbon...

have generally made this problem disappear completely and made leaded fuel unnecessary.

Steam engine

Double beat valve

The double-beat valve, drop valve or equilibrium valve is a type of poppet valve arranged to allow it to be opened against a high pressure with a minimum of force....

, in which two valve plugs ride on a common stem, with the pressure on one plug largely balancing the pressure on the other. In these valves, the force needed to open the valve is determined by the pressure and the difference between the areas of the two valve openings.

Poppet valves have been used on steam locomotive

Steam locomotive

A steam locomotive is a railway locomotive that produces its power through a steam engine. These locomotives are fueled by burning some combustible material, usually coal, wood or oil, to produce steam in a boiler, which drives the steam engine...

s, often in conjunction with Lentz

Hugo Lentz

Hugo Lentz was an Austrian mechanical engineer, born in South Africa. He was the inventor of many award winning improvements to the steam engine....

or Caprotti

Caprotti valve gear

The Caprotti valve gear is a type of steam engine valve gear invented in the early 1920's by Italian architect and engineer Arturo Caprotti. It uses camshafts and poppet valves rather than the piston valves used in other valve gear...

valve gear

Valve gear

The valve gear of a steam engine is the mechanism that operates the inlet and exhaust valves to admit steam into the cylinder and allow exhaust steam to escape, respectively, at the correct points in the cycle...

. British examples include:

- LNER Class B12

- LNER Class D49LNER Class D49The London and North Eastern Railway D49 Class is a class of 4-4-0 steam locomotives designed by Nigel Gresley. They were named after fox hunts and shires.One, 246/62712 Morayshire has been preserved on the Bo'ness and Kinneil Railway....

- LNER Class P2LNER Class P2The London and North Eastern Railway Class P2 was a class of 2-8-2 steam locomotives designed by Sir Nigel Gresley for working heavy express trains over the harsh Edinburgh to Aberdeen Line...

- LMS Stanier Class 5 4-6-0LMS Stanier Class 5 4-6-0The London Midland and Scottish Railway's Class 5 4-6-0, almost universally known as the Black Five, is a class of steam locomotive. It was introduced by William Stanier in 1934 and 842 were built between then and 1951...

- BR standard class 5BR standard class 5The British Railways Standard Class 5MT 4-6-0 was one of the standard classes of steam locomotives built by British Railways in the 1950s. 172 were built, essentially being a development of the LMS Stanier Class 5 4-6-0 .- Background :...

- BR standard class 8 71000 Duke of Gloucester.

Sentinel Waggon Works

Sentinel Waggon Works

Sentinel Waggon Works Ltd was a British company based in Shrewsbury, Shropshire that made steam-powered lorries, railway locomotives, and later, diesel engined lorries and locomotives.-Alley & MacLellan, Sentinel Works, Jessie Street Glasgow:...

used poppet valves in their steam wagons and steam locomotives. Reversing was achieved by a simple sliding camshaft

Camshaft

A camshaft is a shaft to which a cam is fastened or of which a cam forms an integral part.-History:An early cam was built into Hellenistic water-driven automata from the 3rd century BC. The camshaft was later described in Iraq by Al-Jazari in 1206. He employed it as part of his automata,...

system.

The poppet valve was also used on the American Pennsylvania Railroad

Pennsylvania Railroad

The Pennsylvania Railroad was an American Class I railroad, founded in 1846. Commonly referred to as the "Pennsy", the PRR was headquartered in Philadelphia, Pennsylvania....

's T1

PRR T1

The Pennsylvania Railroad's 52 T1 class duplex-drive 4-4-4-4 steam locomotives, introduced in 1942 and 1946 , were their last-built steam locomotives and their most controversial. They were ambitious, technologically sophisticated, powerful, fast, and uniquely streamlined by Raymond Loewy...

duplex locomotive

Duplex locomotive

A duplex locomotive is a steam locomotive that divides the driving force on its wheels by using two pairs of cylinders rigidly mounted to a single locomotive frame; it is not an articulated locomotive...

s, although the valves commonly failed due to the fact that the locomotives were commonly operated in excess of 160 kilometre per hour, and the valves were not meant for the stresses of such speeds.

See also

- Corliss steam engineCorliss Steam EngineA Corliss steam engine is a steam engine, fitted with rotary valves and with variable valve timing patented in 1849, invented by and named after the American engineer George Henry Corliss in Providence, Rhode Island....

- D slide valveD slide valveThe slide valve is a rectilinear valve used to control the admission of steam into, and emission of exhaust from, the cylinder of a steam engine.-Use:...

- Piston valvePiston valveA piston valve is a device used to control the motion of a fluid along a tube or pipe by means of the linear motion of a piston within a chamber or cylinder.Examples of piston valves are:...

- Pressure relief valve

- Reed valveReed valveReed valves are a type of check valve which restrict the flow of fluids to a single direction, opening and closing under changing pressure on each face...

- Relief valveRelief valveThe relief valve is a type of valve used to control or limit the pressure in a system or vessel which can build up by a process upset, instrument or equipment failure, or fire....

- Rotary valveRotary valveA rotary valve is a type of valve in which the rotation of a passage or passages in a transverse plug regulates the flow of liquid or gas through the attached pipes. The common stopcock is the simplest form of rotary valve...

- Sleeve valveSleeve valveThe sleeve valve is a type of valve mechanism for piston engines, distinct from the usual poppet valve. Sleeve-valve engines saw use in a number of pre-World War II luxury cars and in USA in the Willys-Knight car and light truck...

- Safety valveSafety valveA safety valve is a valve mechanism for the automatic release of a substance from a boiler, pressure vessel, or other system when the pressure or temperature exceeds preset limits....