Brewery

Encyclopedia

Beer

Beer is the world's most widely consumed andprobably oldest alcoholic beverage; it is the third most popular drink overall, after water and tea. It is produced by the brewing and fermentation of sugars, mainly derived from malted cereal grains, most commonly malted barley and malted wheat...

, though beer can be made at home, and has been for much of beer's history. A company which makes beer is called either a brewery or a brewing company.

The diversity of size in breweries is matched by the diversity of processes, degrees of automation

Automation

Automation is the use of control systems and information technologies to reduce the need for human work in the production of goods and services. In the scope of industrialization, automation is a step beyond mechanization...

, and kinds of beer produced in breweries. Typically a brewery is divided into distinct sections, with each section reserved for one part of the brewing

Brewing

Brewing is the production of beer through steeping a starch source in water and then fermenting with yeast. Brewing has taken place since around the 6th millennium BCE, and archeological evidence suggests that this technique was used in ancient Egypt...

process.

History

Weihenstephan

Weihenstephan is a part of Freising north of Munich, Germany.Weihenstephan is known for:* the site of one of the three campuses of the Technische Universität München , namely the one for life sciences* the Fachhochschule Weihenstephan...

brewery in the city of Freising

Freising

Freising is a town in Bavaria, Germany, and capital of the district Freising. Total population 48,500.The city is located north of Munich at the Isar river, near the Munich International Airport...

, Bavaria

Bavaria

Bavaria, formally the Free State of Bavaria is a state of Germany, located in the southeast of Germany. With an area of , it is the largest state by area, forming almost 20% of the total land area of Germany...

. It can trace its history back to 1040 AD (this is disputed by the nearby Weltenburg Abbey

Weltenburg Abbey

Weltenburg Abbey is a Benedictine monastery in Weltenburg in Kelheim on the Danube in Bavaria, Germany.-First foundation:...

brewery, who can trace back its beer-brewing tradition to at least 1050 AD, claiming the Weihenstephan document is at least controversial. The Zatec brewery in the Czech Republic claims it can prove that it paid a beer tax in 1004 AD).

The industrialization of the brewery

Beer, in some form, can be traced back almost 5000 years to MesopotamiaMesopotamia

Mesopotamia is a toponym for the area of the Tigris–Euphrates river system, largely corresponding to modern-day Iraq, northeastern Syria, southeastern Turkey and southwestern Iran.Widely considered to be the cradle of civilization, Bronze Age Mesopotamia included Sumer and the...

n writings describing daily rations of beer and bread to workers. Before the rise of production breweries, the production of beer took place at home and was the domain of women, as baking and brewing were seen as "women's work". Breweries, as production facilities reserved for making beer, did not emerge until monasteries

Monastery

Monastery denotes the building, or complex of buildings, that houses a room reserved for prayer as well as the domestic quarters and workplace of monastics, whether monks or nuns, and whether living in community or alone .Monasteries may vary greatly in size – a small dwelling accommodating only...

and other Christian

Christianity

Christianity is a monotheistic religion based on the life and teachings of Jesus as presented in canonical gospels and other New Testament writings...

institutions started producing beer not only for their own consumption, but also to use as payment. This industrialization of brewing shifted the responsibility of making beer to men.

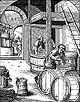

Early breweries were almost always built on multiple stories, with equipment on higher floors used earlier in the production process, so that gravity could assist with the transfer of product from one stage to the next. This layout often is preserved in breweries today, but mechanical pumps allow more flexibility in brewery design.

Early breweries typically used large copper vats in the brewhouse, and fermentation

Fermentation (food)

Fermentation in food processing typically is the conversion of carbohydrates to alcohols and carbon dioxide or organic acids using yeasts, bacteria, or a combination thereof, under anaerobic conditions. Fermentation in simple terms is the chemical conversion of sugars into ethanol...

and packaging took place in lined wooden containers. Such breweries were common until the Industrial Revolution

Industrial Revolution

The Industrial Revolution was a period from the 18th to the 19th century where major changes in agriculture, manufacturing, mining, transportation, and technology had a profound effect on the social, economic and cultural conditions of the times...

, when better materials became available, and scientific advances led to a better understanding of the brewing process. Today, almost all brewery equipment is made of stainless steel

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

.

Major technological advances

The steam engine

Steam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid.Steam engines are external combustion engines, where the working fluid is separate from the combustion products. Non-combustion heat sources such as solar power, nuclear power or geothermal energy may be...

, vastly improved in 1765 by James Watt, brought automatic stirring mechanisms and pumps into the brewery. It gave brewers the ability to mix liquids more reliably while heating, particularly the mash, to prevent scorching, and a quick way to transfer liquid from one container to another. Almost all breweries now use electric-powered stirring mechanisms and pumps. The steam engine also allowed the brewer to make greater quantities of beer, as human power was no longer a limiting factor in moving and stirring.

Carl von Linde

Carl von Linde

Professor Doctor Carl Paul Gottfried von Linde was a German engineer who developed refrigeration and gas separation technologies...

, along with others, is credited with developing the refrigeration

Refrigeration

Refrigeration is a process in which work is done to move heat from one location to another. This work is traditionally done by mechanical work, but can also be done by magnetism, laser or other means...

machine in 1871. Refrigeration allowed beer to be produced year-round, and always at the same temperature. Yeast

Yeast

Yeasts are eukaryotic micro-organisms classified in the kingdom Fungi, with 1,500 species currently described estimated to be only 1% of all fungal species. Most reproduce asexually by mitosis, and many do so by an asymmetric division process called budding...

is very sensitive to temperature, and if a beer was produced during summer, the yeast would impart unpleasant flavors onto the beer. Most brewers would produce enough beer during winter to last through the summer, and store it in underground cellars, or even caves, to protect it from summer's heat.

Most importantly, the discovery of microbes by Louis Pasteur

Louis Pasteur

Louis Pasteur was a French chemist and microbiologist born in Dole. He is remembered for his remarkable breakthroughs in the causes and preventions of diseases. His discoveries reduced mortality from puerperal fever, and he created the first vaccine for rabies and anthrax. His experiments...

was instrumental in the control of fermentation. The idea that yeast was a microorganism

Microorganism

A microorganism or microbe is a microscopic organism that comprises either a single cell , cell clusters, or no cell at all...

that worked on wort

Wort (brewing)

Wort, , is the liquid extracted from the mashing process during the brewing of beer or whisky. Wort contains the sugars that will be fermented by the brewing yeast to produce alcohol.- Production :...

to produce beer led to the isolation of a single yeast cell by Emil Christian Hansen

Emil Christian Hansen

Emil Christian Hansen was a Danish mycologist and fermentation physiologist.Born in Ribe, he financed his education by writing novels and he was awarded a gold medal in 1876 for an essay on fungi....

. Pure yeast cultures allow brewers to pick out yeasts for their fermentation characteristics, including flavor profiles and fermentation ability. Some breweries in Belgium, however, still rely on "spontaneous" fermentation for their beers (see lambic

Lambic

Lambic is a very distinctive type of beer brewed only in the Pajottenland region of Belgium and in Brussels itself at the Cantillon Brewery and museum...

).

The modern brewery

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

, although vessels often have a decorative copper

Copper

Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish...

cladding for a nostalgic look. Stainless steel has many favorable characteristics which make it a well-suited material for brewing equipment. It imparts no flavor in beer, it reacts with very few chemicals, which means almost any cleaning solution

Solution

In chemistry, a solution is a homogeneous mixture composed of only one phase. In such a mixture, a solute is dissolved in another substance, known as a solvent. The solvent does the dissolving.- Types of solutions :...

can be used on it (concentrated chlorine bleach

Bleach

Bleach refers to a number of chemicals that remove color, whiten, or disinfect, often via oxidation. Common chemical bleaches include household chlorine bleach , lye, oxygen bleach , and bleaching powder...

being a notable exception) and it is very sturdy. Sturdiness is important, as most tanks in the brewery have positive pressure applied to them as a matter of course, and it is not unusual that a vacuum will be formed incidentally during cleaning.

Heating in the brewhouse usually is achieved through pressurized steam, although direct-fire systems are not unusual in small breweries. Similarly, cooling in other areas of the brewery is typically done by cooling jackets on tanks, which allow the brewer to control precisely the temperature on each tank individually, although whole-room cooling is also common.

Today modern brewing plants perform myriad analyses on their beers for quality control purposes. Shipments of ingredients are analyzed to correct for variations. Samples are pulled at almost every step and tested for oxygen

Oxygen

Oxygen is the element with atomic number 8 and represented by the symbol O. Its name derives from the Greek roots ὀξύς and -γενής , because at the time of naming, it was mistakenly thought that all acids required oxygen in their composition...

content, unwanted microbial infections, and other beer-aging compounds. A representative sample of the finished product often is stored for months for comparison, when complaints are received.

Brewing process

Mashing is the process of mixing milled grain (typically malt

Malt

Malt is germinated cereal grains that have been dried in a process known as "malting". The grains are made to germinate by soaking in water, and are then halted from germinating further by drying with hot air...

ed grain) with water, and heating this mixture up with rests at certain temperatures to allow enzyme

Enzyme

Enzymes are proteins that catalyze chemical reactions. In enzymatic reactions, the molecules at the beginning of the process, called substrates, are converted into different molecules, called products. Almost all chemical reactions in a biological cell need enzymes in order to occur at rates...

s in the malt to break down the starch

Starch

Starch or amylum is a carbohydrate consisting of a large number of glucose units joined together by glycosidic bonds. This polysaccharide is produced by all green plants as an energy store...

in the grain into sugar

Sugar

Sugar is a class of edible crystalline carbohydrates, mainly sucrose, lactose, and fructose, characterized by a sweet flavor.Sucrose in its refined form primarily comes from sugar cane and sugar beet...

s, typically maltose

Maltose

Maltose , or malt sugar, is a disaccharide formed from two units of glucose joined with an αbond, formed from a condensation reaction. The isomer "isomaltose" has two glucose molecules linked through an α bond. Maltose is the second member of an important biochemical series of glucose chains....

.

Lautering

Lautering

Lautering is a process in brewing beer in which the mash is separated into the clear liquid wort and the residual grain. Lautering usually consists of 3 steps: mashout, recirculation, and sparging.-Mashout:...

is the separation of the extracts won during mashing from the spent grain to create wort

Wort (brewing)

Wort, , is the liquid extracted from the mashing process during the brewing of beer or whisky. Wort contains the sugars that will be fermented by the brewing yeast to produce alcohol.- Production :...

. It is achieved in either a lauter tun, a wide vessel with a false bottom, or a mash filter, a plate-and-frame filter designed for this kind of separation. Lautering has two stages: first wort run-off, during which the extract is separated in an undiluted state from the spent grains, and sparging, in which extract which remains with the grains is rinsed off with hot water.

Boiling the wort ensures its sterility, and thus prevents infections. During the boil, hops are added, which contribute their bitterness, aroma and flavor compounds to the beer. Along with the heat of the boil, they cause proteins in the wort to coagulate and the pH

PH

In chemistry, pH is a measure of the acidity or basicity of an aqueous solution. Pure water is said to be neutral, with a pH close to 7.0 at . Solutions with a pH less than 7 are said to be acidic and solutions with a pH greater than 7 are basic or alkaline...

of the wort to fall, and they inhibit the later growth of certain bacteria. Finally, the vapors produced during the boil volatilize off-flavors, including dimethyl sulfide

Dimethyl sulfide

Dimethyl sulfide or methylthiomethane is an organosulfur compound with the formula 2S. Dimethyl sulfide is a water-insoluble flammable liquid that boils at and has a characteristic disagreeable odor. It is a component of the smell produced from cooking of certain vegetables, notably maize,...

precursors.

The boil must be conducted so that it is even and intense. The boil lasts between 60 and 120 minutes, depending on its intensity, the hop addition schedule, and volume of wort the brewer

Brewer

Brewer may refer to:*Brewer, someone who makes beer by brewing*Brewer , a disambiguation page that lists people with the surname Brewer*Brewer, Maine, a city in southern Penobscot County, Maine, United States, near the city of Bangor...

expects to evaporate.

Fermenting

Fermentation, as a step in the brewing process, starts as soon as yeast is added to the cooled wort. This is also the point at which the product is first called beer. It is during this stage that fermentable sugars won from the maltMalt

Malt is germinated cereal grains that have been dried in a process known as "malting". The grains are made to germinate by soaking in water, and are then halted from germinating further by drying with hot air...

(maltose, maltotriose, glucose, fructose and sucrose) are metabolized into alcohol

Ethanol

Ethanol, also called ethyl alcohol, pure alcohol, grain alcohol, or drinking alcohol, is a volatile, flammable, colorless liquid. It is a psychoactive drug and one of the oldest recreational drugs. Best known as the type of alcohol found in alcoholic beverages, it is also used in thermometers, as a...

and carbon dioxide

Carbon dioxide

Carbon dioxide is a naturally occurring chemical compound composed of two oxygen atoms covalently bonded to a single carbon atom...

. Fermentation tanks come in all sorts of forms, from enormous cylindroconical vessels which can look like storage silo

Storage silo

A silo is a structure for storing bulk materials. Silos are used in agriculture to store grain or fermented feed known as silage. Silos are more commonly used for bulk storage of grain, coal, cement, carbon black, woodchips, food products and sawdust. Three types of silos are in widespread use...

s, to five gallon

Gallon

The gallon is a measure of volume. Historically it has had many different definitions, but there are three definitions in current use: the imperial gallon which is used in the United Kingdom and semi-officially within Canada, the United States liquid gallon and the lesser used United States dry...

glass carboy

Carboy

A carboy is a rigid container with a typical capacity of 5 to 15 gallons . Carboys are primarily used for transporting fluids, often water or chemicals.They are also used for in-home fermentation of beverages, often wine.-Brewing:...

s in a homebrewer's closet.

Most breweries today use cylindroconical vessels, or CCVs, which have a conical bottom and a cylindrical top. The cone's aperture

Aperture

In optics, an aperture is a hole or an opening through which light travels. More specifically, the aperture of an optical system is the opening that determines the cone angle of a bundle of rays that come to a focus in the image plane. The aperture determines how collimated the admitted rays are,...

is typically around 70°, an angle that will allow the yeast to flow smoothly out through the cone's apex at the end of fermentation, but is not so steep as to take up too much vertical space. CCVs can handle both fermenting and conditioning in the same tank. At the end of fermentation, the yeast and other solids which have fallen to the cone's apex can be simply flushed out through a port at the apex.

Open fermentation vessels are also used, often for show in brewpubs, and in Europe in wheat beer fermentation. These vessels have no tops, which makes harvesting top-fermenting yeasts very easy. The open tops of the vessels make the risk of infection greater, but with proper cleaning procedures and careful protocol about who enters fermentation chambers, the risk can be well controlled.

Fermentation tanks are typically made of stainless steel. If they are simple cylindrical tanks with beveled ends, they are arranged vertically, as opposed to conditioning tanks which are usually laid out horizontally.

A very few breweries still use wooden vats for fermentation but wood is difficult to keep clean and infection-free and must be repitched more or less yearly.

After high kraeusen, a bung device (German: Spundapparat) is often put on the tanks to allow the C

Carbon

Carbon is the chemical element with symbol C and atomic number 6. As a member of group 14 on the periodic table, it is nonmetallic and tetravalent—making four electrons available to form covalent chemical bonds...

O

Oxygen

Oxygen is the element with atomic number 8 and represented by the symbol O. Its name derives from the Greek roots ὀξύς and -γενής , because at the time of naming, it was mistakenly thought that all acids required oxygen in their composition...

2

Carbon dioxide

Carbon dioxide is a naturally occurring chemical compound composed of two oxygen atoms covalently bonded to a single carbon atom...

produced by the yeast to naturally carbonate the beer. This bung device can be set to a given pressure to match the type of beer being produced. The more pressure the bung holds back, the more carbonated the beer becomes.

Conditioning

When the sugars in the fermenting beer have been almost completely digested, the fermentation slows down and the yeast cells will naturally start to die off and begin to settle towards the bottom of the tank at an accelerated rate.At this stage, esp if the beer is cooled to around freezing, most of the remaining live yeast cells will quickly go into a dormant state and will also begin to settle out along with the heavier protein chains due simply to gravity and molecular dehydration.

If the fermentation tanks have cooling jackets on them, as opposed to the whole fermentation cellar being cooled, conditioning can take place in the same tank as fermentation. Otherwise separate tanks (in a separate cellar) must be employed.

On the other hand, oftentimes beers from the brewpubs will barely be conditioned if at all, what with an active yeast culture from a on-going batch simply being added to the next boil after chilling to 80 or so deg F being all that's really needed when the major objective happens to be to rapidly produce a fresh and highly palatable beer that can be easily duplicated in mass quantity.

Filtering

Not all beer will be actively filtered after the conditioning stage, as not all conditioning will even involve an actual temperature drop.

For instance, most home brewers and probably even a majority of craft breweries consider the natural gravitational settlement and coagulation of organic impurities which occurs during the (sometimes prolonged) conditioning stage to be entirely sufficient.

In localities where a tax assessment is collected by government pursuant to local laws, any additional filtration will typically be done using an active filtering system, the filtered product finally passing into a calibrated vessel for measurement just after any cold conditioning and prior to final packaging.

Filters come in many types. Many use pre-made filtration media such as sheets or candles, while others use a fine powder made of, for example, diatomaceous earth

Diatomaceous earth

Diatomaceous earth also known as diatomite or kieselgur/kieselguhr, is a naturally occurring, soft, siliceous sedimentary rock that is easily crumbled into a fine white to off-white powder. It has a particle size ranging from less than 1 micrometre to more than 1 millimetre, but typically 10 to...

, also called kieselguhr, which is introduced into the beer and recirculated past screens to form a filtration bed.

Filters range from rough filters that remove much of the yeast and any solids (e.g. hops, grain particles) left in the beer, to filters tight enough to strain color and body from the beer. Normally used filtration ratings are divided into rough, fine and sterile. Rough filtration leaves some cloudiness in the beer, but it is noticeably clearer than unfiltered beer. Fine filtration gives a glass of beer that you could read a newspaper through, with no noticeable cloudiness. Finally, as its name implies, sterile filtration is fine enough that almost all microorganisms in the beer are removed during the filtration process.

Filling

Filling (a.k.a. "packaging") is putting the beer into the containers in which it will leave the brewery. The containers are usually bottleBottle

A bottle is a rigid container with a neck that is narrower than the body and a "mouth". By contrast, a jar has a relatively large mouth or opening. Bottles are often made of glass, clay, plastic, aluminum or other impervious materials, and typically used to store liquids such as water, milk, soft...

s, cans

Beverage can

A beverage can is a tin can designed to hold a specific portion of a beverage. Beverage cans are made of tin-plated steel or aluminium.- History :...

, or keg

Keg

A keg is a small barrel.Traditionally, a wooden keg is made by a cooper used to transport items such as nails, gunpowder., and a variety of liquids....

s; sometimes bulk tanks are used for high-volume customers.

Brewing companies

Ringwood Brewery

Ringwood Brewery is a small brewery situated on the edge of the New Forest in Hampshire, England near the Dorset border. It produces mainly cask ales and some bottled beers.The emblem for the brewery is a boar....

, to massive multinational conglomerates, like SABMiller

SABMiller

SABMiller plc is a global brewing and bottling company headquartered in London, United Kingdom. It is the world's second-largest brewing company measured by revenues and is also a major bottler of Coca-Cola. Its brands include Grolsch, Miller Genuine Draft, Peroni Nastro Azzurro and Pilsner Urquell...

in London or Anheuser-Busch InBev

Anheuser-Busch InBev

Anheuser-Busch InBev N.V. is a Belgian-Brazilian publicly-traded company, based in Leuven, Belgium. It is the largest global brewer with nearly 25% global market share and one of the world's top five consumer products companies by EBITA....

, that produce hundreds of million

Million

One million or one thousand thousand, is the natural number following 999,999 and preceding 1,000,001. The word is derived from the early Italian millione , from mille, "thousand", plus the augmentative suffix -one.In scientific notation, it is written as or just 106...

s of barrels annually. The biggest brewer in the world is the Belgian company Anheuser-Busch InBev

Anheuser-Busch InBev

Anheuser-Busch InBev N.V. is a Belgian-Brazilian publicly-traded company, based in Leuven, Belgium. It is the largest global brewer with nearly 25% global market share and one of the world's top five consumer products companies by EBITA....

.

Some commonly used descriptions of breweries are:

- MicrobreweryMicrobreweryA microbrewery or craft brewer is a brewery which produces a limited amount of beer, and is associated by consumers with innovation and uniqueness....

–A late 20th century name for a small brewery. The term started to be replaced with craft brewer at the start of the 21st century. - Brewpub–A brewery whose beer is brewed primarily on the same site from which it is sold to the public, such as a pubPublic houseA public house, informally known as a pub, is a drinking establishment fundamental to the culture of Britain, Ireland, Australia and New Zealand. There are approximately 53,500 public houses in the United Kingdom. This number has been declining every year, so that nearly half of the smaller...

or restaurantRestaurantA restaurant is an establishment which prepares and serves food and drink to customers in return for money. Meals are generally served and eaten on premises, but many restaurants also offer take-out and food delivery services...

. If the amount of beer that a brewpub distributes off-site exceeds 75%, it may also be described as a craft or microbrewery. - Contract brewing company or contract brewery–A business that hires another brewery to produce its beer. The contract brewing company generally handles all of the beer's marketing, sales, and distribution, while leaving the brewing and packaging to the producer-brewery (which, confusingly, is also sometimes referred to as a contract brewer).

- Regional brewery–An established term for a brewery that supplies beer in a fixed geographical location.

- Craft brewer–A term that is replacing microbrewery. A craft brewery is a brewery which does not use adjuncts and/or is considered to make craft beer.

- Macrobrewery or Megabrewery–Terms for a large brewery, which sometimes carry a negative connotation.

- A brewmaster, or formerly braumeister, is a person who is in charge of the production of beer. The major breweries employ engineers with a ChemistryChemistryChemistry is the science of matter, especially its chemical reactions, but also its composition, structure and properties. Chemistry is concerned with atoms and their interactions with other atoms, and particularly with the properties of chemical bonds....

/BiotechnologyBiotechnologyBiotechnology is a field of applied biology that involves the use of living organisms and bioprocesses in engineering, technology, medicine and other fields requiring bioproducts. Biotechnology also utilizes these products for manufacturing purpose...

background. The title of Brewmaster is given to a person after 2½ years of extra study in the art of brewingBrewingBrewing is the production of beer through steeping a starch source in water and then fermenting with yeast. Brewing has taken place since around the 6th millennium BCE, and archeological evidence suggests that this technique was used in ancient Egypt...

thus earning a degree equivalent to a Master's degreeMaster's degreeA master's is an academic degree granted to individuals who have undergone study demonstrating a mastery or high-order overview of a specific field of study or area of professional practice...

.

There are organisations that assist the development of brewing, such as the Seibel Institute of Technology in the USA and the Institute of Brewing and Distilling

Institute of Brewing and Distilling

The Institute of Brewing and Distilling is an industry trade association for brewers and distillers, both in the United Kingdom and internationally...

in the UK.

See also

- BrewerianaBrewerianaBreweriana commonly refers to any article containing a brewery name or brand name, usually in connection to collecting them as a hobby. Examples include beer cans, bottles, openers, tin signs, coasters, beer trays, wooden cases and neon signs.- History :...

, the hobby of brewery advertising collecting - BrewingBrewingBrewing is the production of beer through steeping a starch source in water and then fermenting with yeast. Brewing has taken place since around the 6th millennium BCE, and archeological evidence suggests that this technique was used in ancient Egypt...

- HomebrewingHomebrewingHomebrewing is the brewing of beer, wine, sake, mead, cider, perry and other beverages through fermentation on a small scale as a hobby for personal consumption, free distribution at social gatherings, amateur brewing competitions or other non-commercial reasons...

- HopsHopsHops are the female flower clusters , of a hop species, Humulus lupulus. They are used primarily as a flavoring and stability agent in beer, to which they impart a bitter, tangy flavor, though hops are also used for various purposes in other beverages and herbal medicine...

- MaltMaltMalt is germinated cereal grains that have been dried in a process known as "malting". The grains are made to germinate by soaking in water, and are then halted from germinating further by drying with hot air...