CANDU reactor

Encyclopedia

Heavy water

Heavy water is water highly enriched in the hydrogen isotope deuterium; e.g., heavy water used in CANDU reactors is 99.75% enriched by hydrogen atom-fraction...

) moderator

Neutron moderator

In nuclear engineering, a neutron moderator is a medium that reduces the speed of fast neutrons, thereby turning them into thermal neutrons capable of sustaining a nuclear chain reaction involving uranium-235....

and its use of (originally, natural

Natural uranium

Natural uranium refers to refined uranium with the same isotopic ratio as found in nature. It contains 0.7 % uranium-235, 99.3 % uranium-238, and a trace of uranium-234 by weight. In terms of the amount of radioactivity, approximately 2.2 % comes from uranium-235, 48.6 % uranium-238, and 49.2 %...

) uranium

Uranium

Uranium is a silvery-white metallic chemical element in the actinide series of the periodic table, with atomic number 92. It is assigned the chemical symbol U. A uranium atom has 92 protons and 92 electrons, of which 6 are valence electrons...

fuel. CANDU reactors were first developed in the late 1950s and 1960s by a partnership between Atomic Energy of Canada Limited

Atomic Energy of Canada Limited

Atomic Energy of Canada Limited or AECL is a Canadian federal Crown corporation and Canada's largest nuclear science and technology laboratory...

(AECL), the Hydro-Electric Power Commission of Ontario (now Ontario Power Generation

Ontario Power Generation

Ontario Power Generation is a public company wholly owned by the Government of Ontario. OPG is responsible for approximately 70% of the electricity generation in the Province of Ontario, Canada. Sources of electricity include nuclear, hydroelectric, solar, wind, and fossil fuel...

), Canadian General Electric

General Electric

General Electric Company , or GE, is an American multinational conglomerate corporation incorporated in Schenectady, New York and headquartered in Fairfield, Connecticut, United States...

(now GE Canada), and other companies.

All power reactors built in Canada

Canada

Canada is a North American country consisting of ten provinces and three territories. Located in the northern part of the continent, it extends from the Atlantic Ocean in the east to the Pacific Ocean in the west, and northward into the Arctic Ocean...

are of the CANDU type. The reactor is also marketed abroad and there are CANDU-type units operating in India

India

India , officially the Republic of India , is a country in South Asia. It is the seventh-largest country by geographical area, the second-most populous country with over 1.2 billion people, and the most populous democracy in the world...

, Pakistan

Pakistan

Pakistan , officially the Islamic Republic of Pakistan is a sovereign state in South Asia. It has a coastline along the Arabian Sea and the Gulf of Oman in the south and is bordered by Afghanistan and Iran in the west, India in the east and China in the far northeast. In the north, Tajikistan...

, Argentina

Argentina

Argentina , officially the Argentine Republic , is the second largest country in South America by land area, after Brazil. It is constituted as a federation of 23 provinces and an autonomous city, Buenos Aires...

, South Korea

South Korea

The Republic of Korea , , is a sovereign state in East Asia, located on the southern portion of the Korean Peninsula. It is neighbored by the People's Republic of China to the west, Japan to the east, North Korea to the north, and the East China Sea and Republic of China to the south...

, Romania

Romania

Romania is a country located at the crossroads of Central and Southeastern Europe, on the Lower Danube, within and outside the Carpathian arch, bordering on the Black Sea...

and China

China

Chinese civilization may refer to:* China for more general discussion of the country.* Chinese culture* Greater China, the transnational community of ethnic Chinese.* History of China* Sinosphere, the area historically affected by Chinese culture...

. In October 2011, the Canadian Federal Government licensed the CANDU design to Candu Energy

Candu Energy Inc.

Candu Energy Inc. is a Canadian wholly owned subsidiary of Montreal-based SNC-Lavalin Inc., specializing in the design and supply of nuclear reactors, as well as nuclear reactor products and services. Candu Energy Inc...

(a wholly owned subsidiary of SNC-Lavalin

SNC-Lavalin

SNC-Lavalin Group Inc. is a large Canadian engineering firm. It is one of the ten largest engineering firms in the world and is based in Montreal, Quebec. It formed in 1991 from the merger of SNC and the failing Lavalin, another Quebec based engineering firm....

), which also acquired the former reactor development and marketing division of AECL at that time.

Basic design and operation

Steam turbine

A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. Its modern manifestation was invented by Sir Charles Parsons in 1884....

, normally located in a separate "power hall". A typical coal

Coal

Coal is a combustible black or brownish-black sedimentary rock usually occurring in rock strata in layers or veins called coal beds or coal seams. The harder forms, such as anthracite coal, can be regarded as metamorphic rock because of later exposure to elevated temperature and pressure...

-fired plant burns coal and air and produces mostly carbon dioxide

Carbon dioxide

Carbon dioxide is a naturally occurring chemical compound composed of two oxygen atoms covalently bonded to a single carbon atom...

and fly ash

Fly ash

Fly ash is one of the residues generated in combustion, and comprises the fine particles that rise with the flue gases. Ash which does not rise is termed bottom ash. In an industrial context, fly ash usually refers to ash produced during combustion of coal...

, the CANDU burns nuclear fuel in-situ; when the fuel is "burned up" it is removed from the reactor and stored.

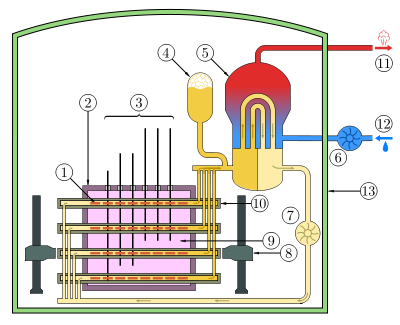

The CANDU reactor is similar to most light water reactor

Light water reactor

The light water reactor is a type of thermal reactor that uses normal water as its coolant and neutron moderator. Thermal reactors are the most common type of nuclear reactor, and light water reactors are the most common type of thermal reactor...

s in design. Fission

Nuclear fission

In nuclear physics and nuclear chemistry, nuclear fission is a nuclear reaction in which the nucleus of an atom splits into smaller parts , often producing free neutrons and photons , and releasing a tremendous amount of energy...

reactions in the reactor core heat pressurized heavy water in a primary cooling loop. A heat exchanger

Heat exchanger

A heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact...

, also known as a steam generator

Steam generator

A steam generator is a device used to boil water to create steam. It may refer to:*Boiler , a closed vessel in which water is heated under pressure...

, transfers the heat to a light-water secondary cooling loop, which powers a steam turbine

Turbine

A turbine is a rotary engine that extracts energy from a fluid flow and converts it into useful work.The simplest turbines have one moving part, a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades, or the blades react to the flow, so that they move and...

with an electrical generator

Electrical generator

In electricity generation, an electric generator is a device that converts mechanical energy to electrical energy. A generator forces electric charge to flow through an external electrical circuit. It is analogous to a water pump, which causes water to flow...

attached to it. The exhaust steam from the turbines is then condensed and returned as feedwater to the steam generator, often using cooling water from a nearby source, such as a lake, river, or ocean. Newer CANDU plants, such as the Darlington Nuclear Generating Station

Darlington Nuclear Generating Station

Darlington Nuclear Generating Station is a Canadian nuclear power station located on the north shore of Lake Ontario in Clarington, Ontario. The facility derives its name from the Township of Darlington, the former name of the municipality in which it is located.The Darlington station is a large...

near Toronto

Toronto

Toronto is the provincial capital of Ontario and the largest city in Canada. It is located in Southern Ontario on the northwestern shore of Lake Ontario. A relatively modern city, Toronto's history dates back to the late-18th century, when its land was first purchased by the British monarchy from...

, Ontario

Ontario

Ontario is a province of Canada, located in east-central Canada. It is Canada's most populous province and second largest in total area. It is home to the nation's most populous city, Toronto, and the nation's capital, Ottawa....

, use a diffuser to spread the warm condensor outlet water over a larger volume and limit the effects on the environment. A cooling tower

Cooling tower

Cooling towers are heat removal devices used to transfer process waste heat to the atmosphere. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet-bulb air temperature or in the case of closed circuit dry cooling towers rely...

can be used, but it reduces efficiency.

In a light water reactor

Light water reactor

The light water reactor is a type of thermal reactor that uses normal water as its coolant and neutron moderator. Thermal reactors are the most common type of nuclear reactor, and light water reactors are the most common type of thermal reactor...

(LWR), the entire reactor core is a single large pressure vessel containing the light water, which acts as moderator and coolant, and the fuel arranged in a series of long bundles running the length of the core. At the time of its design, Canada lacked the heavy industry to cast and machine the pressure vessel

Pressure vessel

A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.The pressure differential is dangerous and many fatal accidents have occurred in the history of their development and operation. Consequently, their design,...

s. In CANDU the pressure (and the fuel bundles) is contained in much smaller (10 cm diameter), easier to fabricate tubes. Each bundle is a cylinder assembled from alloy tubes containing ceramic pellets of fuel. In older designs the assembly had 28 or 37 half-meter-long fuel tubes with 12 such assemblies lying end to end in a pressure tube. The newer CANFLEX

CANFLEX

CANFLEX; the name is derived from its function: CANDU FLEXible fuelling, is an advanced fuel bundle design developed by Atomic Energy of Canada Ltd. , along with the Korean Atomic Energy Research Institute for use in CANDU design nuclear reactors...

bundle has 43 tubes, with two pellet sizes (so the power rating can be increased without melting the hottest pellets). It is about 10 cm (four inches) in diameter, 0.5 m (20 inches) long and weighs about 20 kg (44 lb) and replaces the 37-tube bundle. To allow the neutron

Neutron

The neutron is a subatomic hadron particle which has the symbol or , no net electric charge and a mass slightly larger than that of a proton. With the exception of hydrogen, nuclei of atoms consist of protons and neutrons, which are therefore collectively referred to as nucleons. The number of...

s to flow freely between the bundles, the tubes and bundles are made of neutron-transparent zircaloy

Zircaloy

Zirconium alloys are solid solutions of zirconium or other metals, a common subgroup having the trade mark Zircaloy. Zirconium has very low absorption cross-section of thermal neutrons, high hardness, ductility and corrosion resistance...

(zirconium

Zirconium

Zirconium is a chemical element with the symbol Zr and atomic number 40. The name of zirconium is taken from the mineral zircon. Its atomic mass is 91.224. It is a lustrous, grey-white, strong transition metal that resembles titanium...

+ 2.5% wt niobium

Niobium

Niobium or columbium , is a chemical element with the symbol Nb and atomic number 41. It's a soft, grey, ductile transition metal, which is often found in the pyrochlore mineral, the main commercial source for niobium, and columbite...

).

The zircaloy tubes are surrounded by a much larger low-pressure tank known as a calandria

Calandria

A calandria is the reactor core of the CANDU reactor. The calandria contains heavy water, a moderator used to moderate neutrons to achieve nuclear fission....

, which contains the majority of the moderator. To keep the hot coolant from boiling the moderator, a so-called calandria tube surrounds each pressure tube, with insulating CO2

Carbon dioxide

Carbon dioxide is a naturally occurring chemical compound composed of two oxygen atoms covalently bonded to a single carbon atom...

gas in between. Also slowing down neutrons releases energy, so a cooling system dissipates the heat. The moderator is actually a large heat sink

Heat sink

A heat sink is a term for a component or assembly that transfers heat generated within a solid material to a fluid medium, such as air or a liquid. Examples of heat sinks are the heat exchangers used in refrigeration and air conditioning systems and the radiator in a car...

that acts as an additional safety

Nuclear safety

Nuclear safety covers the actions taken to prevent nuclear and radiation accidents or to limit their consequences. This covers nuclear power plants as well as all other nuclear facilities, the transportation of nuclear materials, and the use and storage of nuclear materials for medical, power,...

feature. CANDU's fuel channels in a low-pressure calandria design makes it easier to refuel: a pressure-vessel reactor must be shut down, the pressure dropped, the lid removed, and a sizeable fraction of the fuel, e.g. one-third, replaced all at once. In CANDU individual channels can be refuelled without taking the reactor off-line, improving the capacity factor

Capacity factor

The net capacity factor or load factor of a power plant is the ratio of the actual output of a power plant over a period of time and its potential output if it had operated at full nameplate capacity the entire time...

. One fueling machine inserts new fuel into one end of the channel while the other receives discharged fuel from the opposite end. One significant operational advantage of on-line refuelling is that failed or leaking fuel bundles can be removed from the core once it has been located thus reducing the radiation fields in the primary systems.

Purpose of using heavy water

Isotope

Isotopes are variants of atoms of a particular chemical element, which have differing numbers of neutrons. Atoms of a particular element by definition must contain the same number of protons but may have a distinct number of neutrons which differs from atom to atom, without changing the designation...

s, mostly uranium-238

Uranium-238

Uranium-238 is the most common isotope of uranium found in nature. It is not fissile, but is a fertile material: it can capture a slow neutron and after two beta decays become fissile plutonium-239...

and 0.72% (by weight) of fissile uranium-235

Uranium-235

- References :* .* DOE Fundamentals handbook: Nuclear Physics and Reactor theory , .* A piece of U-235 the size of a grain of rice can produce energy equal to that contained in three tons of coal or fourteen barrels of oil. -External links:* * * one of the earliest articles on U-235 for the...

. A nuclear reactor aims to sustain a steady rate of fission reactions over time, a state known as "criticality

Critical mass

A critical mass is the smallest amount of fissile material needed for a sustained nuclear chain reaction. The critical mass of a fissionable material depends upon its nuclear properties A critical mass is the smallest amount of fissile material needed for a sustained nuclear chain reaction. The...

", where the neutrons released by fission cause an equal number of fission reactions in other fissile atoms

Fissile

In nuclear engineering, a fissile material is one that is capable of sustaining a chain reaction of nuclear fission. By definition, fissile materials can sustain a chain reaction with neutrons of any energy. The predominant neutron energy may be typified by either slow neutrons or fast neutrons...

. The neutrons released by these reactions are fairly energetic and aren't easily captured, they must be slowed down ("moderated") as much as possible, ideally to the same energy as the atoms themselves ("thermal neutrons"). During the moderating process it helps to separate the neutrons and uranium, since 238U has a large affinity for intermediate-energy neutrons ("resonance" absorption), but can only be easily fissioned by the few energetic neutrons above ~1.5-2 MeV

MEV

MeV and meV are multiples and submultiples of the electron volt unit referring to 1,000,000 eV and 0.001 eV, respectively.Mev or MEV may refer to:In entertainment:* Musica Elettronica Viva, an Italian musical group...

. Since the fuel contains mostly 238U, most reactor designs are based on thin fuel rods separated by spaces filled with the moderator, allowing the neutrons time to travel in the moderator before encountering the fuel again. Even with this design, the buildup of fission product

Fission product

Nuclear fission products are the atomic fragments left after a large atomic nucleus fissions. Typically, a large nucleus like that of uranium fissions by splitting into two smaller nuclei, along with a few neutrons and a large release of energy in the form of heat , gamma rays and neutrinos. The...

s that are even more neutron-absorbing than 238U eventually quenches the reaction and requires the reactor to be refuelled.

Light water makes an excellent moderator - the light hydrogen

Hydrogen

Hydrogen is the chemical element with atomic number 1. It is represented by the symbol H. With an average atomic weight of , hydrogen is the lightest and most abundant chemical element, constituting roughly 75% of the Universe's chemical elemental mass. Stars in the main sequence are mainly...

atoms are very close in mass to a neutron and can absorb a lot of energy in a single collision (like a collision of two billiard balls). However, light hydrogen is also fairly effective at absorbing neutrons, and there will be too few left over to react with the small amount of 235U in natural uranium, preventing criticality. In order to allow criticality, the fuel must be "enriched

Enriched uranium

Enriched uranium is a kind of uranium in which the percent composition of uranium-235 has been increased through the process of isotope separation. Natural uranium is 99.284% 238U isotope, with 235U only constituting about 0.711% of its weight...

", increasing the amount of 235U to an acceptable level. In light water reactor

Light water reactor

The light water reactor is a type of thermal reactor that uses normal water as its coolant and neutron moderator. Thermal reactors are the most common type of nuclear reactor, and light water reactors are the most common type of thermal reactor...

s, the fuel is typically enriched to between 2% and 5% 235U (the leftover fraction with less 235U is called depleted uranium

Depleted uranium

Depleted uranium is uranium with a lower content of the fissile isotope U-235 than natural uranium . Uses of DU take advantage of its very high density of 19.1 g/cm3...

). Enrichment facilities are expensive to build and operate. They're also a proliferation

Nuclear proliferation

Nuclear proliferation is a term now used to describe the spread of nuclear weapons, fissile material, and weapons-applicable nuclear technology and information, to nations which are not recognized as "Nuclear Weapon States" by the Treaty on the Nonproliferation of Nuclear Weapons, also known as the...

concern as they can be used to enrich the 235U much further, up to weapons-grade

Weapons-grade

A weapons-grade substance is one that is pure enough to be used to make a weapon or has properties that make it suitable for weapons use. Weapons-grade plutonium and uranium are the most common examples, but it may also be used to refer to chemical and biological weapons...

material (90% or more 235U). However, this can be remedied if the fuel is supplied and reprocessed by an internationally approved

International Atomic Energy Agency

The International Atomic Energy Agency is an international organization that seeks to promote the peaceful use of nuclear energy, and to inhibit its use for any military purpose, including nuclear weapons. The IAEA was established as an autonomous organization on 29 July 1957...

supplier.

The main advantage of heavy water

Heavy water

Heavy water is water highly enriched in the hydrogen isotope deuterium; e.g., heavy water used in CANDU reactors is 99.75% enriched by hydrogen atom-fraction...

moderator

Moderator

Moderator often refers to the chairman of a meeting. Specifically, it may refer to:-Government:*Moderator , elected official who presides over the Town Meeting form of government-Internet:...

over light water is reduced absorption of the neutrons that sustain the chain reaction, allowing a lower concentration of active atoms (to the point of using unenriched natural uranium fuel). Deuterium

Deuterium

Deuterium, also called heavy hydrogen, is one of two stable isotopes of hydrogen. It has a natural abundance in Earth's oceans of about one atom in of hydrogen . Deuterium accounts for approximately 0.0156% of all naturally occurring hydrogen in Earth's oceans, while the most common isotope ...

("heavy hydrogen") already has the extra neutron that light hydrogen would absorb, reducing the capture rate. However, deuterium is twice the mass of light hydrogen or of a single neutron; this mismatch means more collisions are needed to moderate the neutrons, which in turn requires a larger distance between the fuel rods. This increases the size of the reactor core, as well as the leakage of neutrons from the reactor. It is also the practical reason for the calandria design, otherwise a very large pressure vessel would be needed. The lower 235U density in natural uranium also generally implies that less of the fuel will be consumed before the fission rate drops too low to sustain criticality, because the percentage of 235U compared to fission products is already lower. However, in CANDU most of the moderator is at lower temperatures than in other designs, reducing the spread of speeds and the overall speed of the moderator particles. This means most of the neutrons are at a lower energy and more likely to cause fission, so CANDU not only "burns" natural uranium, but it does so more effectively as well. Overall, CANDU reactors use 30–40% less mined uranium than light-water reactors per unit of electricity produced. This is a major advantage to the heavy water design; it not only requires less fuel, but as the fuel does not have to be enriched, it is much less expensive as well.

A further unique feature of heavy-water moderation is the greater stability of the chain reaction

Chain reaction

A chain reaction is a sequence of reactions where a reactive product or by-product causes additional reactions to take place. In a chain reaction, positive feedback leads to a self-amplifying chain of events....

. This is due to the relatively low binding energy of the deuterium nucleus (2.2 MeV), leading to some energetic neutrons and especially gamma rays

Photodisintegration

Photodisintegration is a physical process in which an extremely high energy gamma ray interacts with an atomic nucleus and causes it to enter an excited state, which immediately decays by emitting a subatomic particle. A single proton or neutron is effectively knocked out of the nucleus by the...

breaking the nuclei apart and producing extra neutrons. Both gammas produced directly by fission and by the decay of fission fragments have enough energy, and the half-lives of the fission fragments range from seconds to hours or even years. As all neutrons are taken into account when performing any action, the presence of photoneutrons delays the response of the reactor and gives the operators extra time in case of an emergency. Since gamma ray

Gamma ray

Gamma radiation, also known as gamma rays or hyphenated as gamma-rays and denoted as γ, is electromagnetic radiation of high frequency . Gamma rays are usually naturally produced on Earth by decay of high energy states in atomic nuclei...

s travel for meters through water, an increased rate of chain reaction in one part of the reactor will produce a response from the rest of the reactor, allowing various negative feedbacks to stabilize the reaction.

Canada developed the heavy water moderated design in the post-World War II

World War II

World War II, or the Second World War , was a global conflict lasting from 1939 to 1945, involving most of the world's nations—including all of the great powers—eventually forming two opposing military alliances: the Allies and the Axis...

era in order to explore nuclear energy in an era when they lacked access to enrichment facilities. War-era enrichment systems were extremely expensive to build and operate, whereas the heavy water solution allowed the use of natural uranium in the experimental ZEEP

ZEEP

The ZEEP reactor was a nuclear reactor built at the Chalk River Laboratories near Chalk River, Ontario, Canada . ZEEP first went critical at 3:45 PM, September 5, 1945...

reactor. A much less expensive enrichment system was developed, but the United States classified work on the cheaper gas centrifuge process. The CANDU was therefore designed to use natural uranium.

Safety features

The CANDU includes a number of active and passive safety features in its design. Some of these are a side-effect of the physical layout of the system.CANDU designs have a positive void coefficient

Void coefficient

In nuclear engineering, the void coefficient is a number that can be used to estimate how much the reactivity of a nuclear reactor changes as voids form in the reactor moderator or coolant...

as well as a small power coefficient, normally considered bad in reactor design. This implies that steam generated in the coolant will increase the reaction rate, which in turn would generate more steam. This is one of the many reasons for the cooler mass of moderator in the calandria, as even a serious steam incident in the core would not have a major impact on the overall moderation cycle. Only if the moderator itself starts to boil would there be any significant effect, and the large thermal mass ensures this will occur slowly. The deliberately "sluggish" response of the fission process in CANDU allows controllers more time to diagnose and deal with problems.

The fuel channels can only maintain criticality if they are mechanically sound. If the temperature of the fuel bundles increases to the point where they are mechanically unstable, their horizontal layout means they will bend under gravity, shifting the layout of the bundles and reducing the efficiency of the reactions. Because the original fuel arrangement is optimum for a chain reaction and the natural uranium fuel has little excess reactivity, any significant deformation will stop the inter-fuel pellet fission reaction. This will not stop heat production from fission product decay, which would continue to supply a considerable heat output. If this process further weakens the fuel bundles, they will eventually bend far enough to touch the calandria tube, allowing heat to be efficiently transferred into the moderator tank. The moderator vessel has a considerable thermal capability on its own, and is normally kept relatively cool.

Heat generated by fission products would initially be at about 7% of full reactor power, which requires significant cooling. The CANDU designs have several emergency cooling systems, as well as having limited self-pumping capability through thermal means (the steam generator is well above the reactor). Even in the event of a catastrophic accident and core meltdown, it is important to remember that the fuel is not critical in light water. This means that cooling the core with water from nearby sources will not add to the reactivity of the fuel mass.

Normally the rate of fission is controlled by light-water compartments called liquid zone controllers, which absorb excess neutrons, and by adjuster rods which can be raised or lowered in the core to control the neutron flux. These are used for normal operation, allowing the controllers to adjust reactivity across the fuel mass as different portions would normal burn at different rates depending on their position. The adjuster rods can also be used to slow or stop criticality. Because these rods are inserted into the low-pressure calandria, not the high-pressure fuel tubes, they would not be "ejected" by steam, a design issue for many pressurized-water reactors.

There are two independent, fast-acting safety shutdown systems as well. Shutoff rods are held above the reactor by electromagnets, and drop under gravity into the core to quickly end criticality. This system works even in the event of a complete power failure, as the electromagnets only hold the rods out of the reactor when power is available. A secondary system injects a high-pressure gadolinium nitrate

Gadolinium nitrate

Gadolinium nitrate is an inorganic compound of gadolinium. It is used as a water-soluble neutron poison in nuclear reactors. Gadolinium nitrate, like all nitrates, is an oxidizing agent.-Use:...

neutron absorber solution into the calandria.

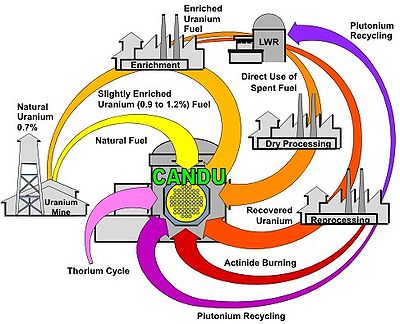

Fuel cycles

CANDU can also breed fuel

Thorium fuel cycle

The thorium fuel cycle is a nuclear fuel cycle that uses the naturally abundant isotope of thorium, , as the fertile material. In the reactor, is transmuted into the fissile artificial uranium isotope which is the nuclear fuel. Unlike natural uranium, natural thorium contains only trace amounts...

from the more abundant thorium

Thorium

Thorium is a natural radioactive chemical element with the symbol Th and atomic number 90. It was discovered in 1828 and named after Thor, the Norse god of thunder....

. This is being investigated

Thorium fuel cycle

The thorium fuel cycle is a nuclear fuel cycle that uses the naturally abundant isotope of thorium, , as the fertile material. In the reactor, is transmuted into the fissile artificial uranium isotope which is the nuclear fuel. Unlike natural uranium, natural thorium contains only trace amounts...

by India to take advantage of its natural thorium reserves.

Even better than LWRs, CANDU can burn a mix of uranium and plutonium oxides (MOX fuel

MOX fuel

Mixed oxide fuel, commonly referred to as MOX fuel, is nuclear fuel that contains more than one oxide of fissile material. MOX fuel contains plutonium blended with natural uranium, reprocessed uranium, or depleted uranium. MOX fuel is an alternative to the low-enriched uranium fuel used in the...

), the plutonium either from dismantled nuclear weapon

Nuclear weapon

A nuclear weapon is an explosive device that derives its destructive force from nuclear reactions, either fission or a combination of fission and fusion. Both reactions release vast quantities of energy from relatively small amounts of matter. The first fission bomb test released the same amount...

s or reprocessed reactor fuel. The mix of isotopes in reprocessed plutonium is not attractive for weapons, but can be used as fuel (instead of being simply nuclear waste), while burning weapons-grade plutonium eliminates a proliferation hazard. If the aim is explicitly to burn plutonium or other actinide

Actinide

The actinide or actinoid series encompasses the 15 metallic chemical elements with atomic numbers from 89 to 103, actinium through lawrencium.The actinide series derives its name from the group 3 element actinium...

s from spent fuel, then special inert-matrix fuels are proposed to do this more efficiently than MOX. Since they contain no uranium, these fuels do not breed any extra plutonium.

Economics

The neutron economy of heavy water moderation and precise control of on-line refueling allow CANDU to use a great range of fuels other than enriched uranium, e.g., natural uranium, reprocessed uranium, thoriumThorium

Thorium is a natural radioactive chemical element with the symbol Th and atomic number 90. It was discovered in 1828 and named after Thor, the Norse god of thunder....

, plutonium

Plutonium

Plutonium is a transuranic radioactive chemical element with the chemical symbol Pu and atomic number 94. It is an actinide metal of silvery-gray appearance that tarnishes when exposed to air, forming a dull coating when oxidized. The element normally exhibits six allotropes and four oxidation...

, and used LWR fuel. Given the expense of enrichment, this can make fuel much cheaper. There is however an initial investment into the tonnes of 99.75% pure heavy water to fill the core and heat transfer system. In the case of the Darlington plant, costs releases as part of a freedom of information act request put the cost of the heavy water at $1.528 billion, while capital costs on the plant were $5.117 billion. This means the cost of the heavy water is 23% of the capital costs of the plant.

Since heavy water is less efficient at slowing neutrons, CANDU needs a larger moderator to fuel ratio and a larger core for the same power output. Although a calandria-based core is cheaper to build, its size increases the cost for standard features like the containment building

Containment building

A containment building, in its most common usage, is a steel or reinforced concrete structure enclosing a nuclear reactor. It is designed, in any emergency, to contain the escape of radiation to a maximum pressure in the range of 60 to 200 psi...

. Generally nuclear plant construction and operations are ~65% of overall lifetime cost; for CANDU costs are dominated by construction even more. Fueling CANDU is cheaper than other reactors, costing only ~10% of the total, so the overall price per kWh electricity is comparable .The next generation Advanced CANDU Reactor

Advanced CANDU Reactor

The Advanced CANDU Reactor is a Generation III+ nuclear reactor design and is a further development of existing CANDU reactors designed by Atomic Energy of Canada Limited. The ACR is a light-water-cooled reactor that incorporates features of both Pressurised Heavy Water Reactors and Advanced...

(ACR) mitigates these disadvantages by having light water coolant and using a more compact core with less moderator.

When first introduced, CANDUs offered much better capacity factor

Capacity factor

The net capacity factor or load factor of a power plant is the ratio of the actual output of a power plant over a period of time and its potential output if it had operated at full nameplate capacity the entire time...

(ratio of power generated to what would be generated by running at full power, 100% of the time) than LWRs of a similar generation. The light-water designs spent, on average, about half the time being refueled or maintained. However, since the 1980s dramatic improvements in LWR outage management have narrowed the gap, with several units achieving capacity factors ~90% and higher, with an overall fleet performance of 92% in 2010. The latest-generation CANDU 6 reactors have a 88-90% CF, but overall performance is dominated by the older Canadian units with CFs on the order of 80%. Refurbished units have demonstrated poor performance to date, on the order of 65%.

Some CANDU plants suffered from cost overruns during construction, mainly from external factors. For instance, a number of imposed construction delays led to roughly a doubling of the cost of the Darlington Nuclear Generating Station near Toronto, Ontario. Technical problems and redesigns added about another billion to the resulting $14.4 billion price. In contrast, more recently two CANDU 6 reactors at Qinshan in China were completed on-schedule and on-budget, an achievement attributed to tight control over scope and schedule.

Nuclear nonproliferation

In terms of safeguards against nuclear weapons proliferationNuclear proliferation

Nuclear proliferation is a term now used to describe the spread of nuclear weapons, fissile material, and weapons-applicable nuclear technology and information, to nations which are not recognized as "Nuclear Weapon States" by the Treaty on the Nonproliferation of Nuclear Weapons, also known as the...

, CANDUs meet a similar level of international certification as other reactors. There is a common misconception that plutonium for India's first nuclear detonation, Operation Smiling Buddha in 1974, was produced in a CANDU design. In fact, it was produced in the unsafeguarded Canada-supplied CIRUS reactor

CIRUS reactor

CIRUS is a research reactor at the Bhabha Atomic Research Center in Trombay near Mumbai, India. CIRUS was supplied by Canada in 1954, but uses heavy water supplied by the United States. It is the second oldest reactor in India. It is modeled on the Canadian Chalk River National Research...

whose design is based on the NRX

NRX

NRX was a heavy water moderated, light water cooled, nuclear research reactor at the Canadian Chalk River Laboratories, which came into operation in 1947 at a design power rating of 10 MW , increasing to 42 MW by 1954...

, a Canadian research reactor. In addition to its two CANDU reactors, India has some unsafeguarded pressurised heavy water reactors (PHWRs) based on the CANDU design, and two safeguarded light-water reactors supplied by the US. Plutonium has been extracted from the spent fuel from all of these reactors; however India mainly relies on an Indian designed and built military reactor called Dhruva

Dhruva reactor

The Dhruva reactor is India's largest nuclear research reactor. Located in the Mumbai suburb of Trombay at the Bhabha Atomic Research Centre , it is India's primary generator of weapons-grade plutonium-bearing spent fuel for its nuclear weapons program. Originally named the R-5, this pool-type...

. The design is believed to be derived from the CIRUS reactor, with the Dhruva being scaled-up for more efficient plutonium production. It is this reactor which is thought to have produced the plutonium for India's more recent (1998) Operation Shakti nuclear tests.

Although heavy water is relatively immune to neutron capture, a small amount of the deuterium turns into tritium

Tritium

Tritium is a radioactive isotope of hydrogen. The nucleus of tritium contains one proton and two neutrons, whereas the nucleus of protium contains one proton and no neutrons...

in this way. Tritium+deuterium mix undergoes nuclear fusion

Nuclear fusion

Nuclear fusion is the process by which two or more atomic nuclei join together, or "fuse", to form a single heavier nucleus. This is usually accompanied by the release or absorption of large quantities of energy...

more easily than any other substance. Tritium can be used in both the "fusion boost" of a boosted fission weapon

Boosted fission weapon

A boosted fission weapon usually refers to a type of nuclear bomb that uses a small amount of fusion fuel to increase the rate, and thus yield, of a fission reaction. The neutrons released by the fusion reactions add to the neutrons released in the fission, as well as inducing the fission reactions...

and the main fusion process of an H-bomb. However, in an H-bomb, it's usually created in situ by neutron irradiation of lithium-6.

Tritium is extracted from some CANDU plants in Canada, mainly to improve safety in case of heavy-water leakage. The gas is stockpiled and used in a variety of commercial products, notably "powerless" lighting systems and medical devices. In 1985 what was then Ontario Hydro sparked controversy in Ontario due to its plans to sell tritium to the U.S. The plan, by law, involved sales to non-military applications only, but some speculated that the exports could have freed American tritium for the U.S. nuclear weapons program. Future demands appear to outstrip production, in particular the demands of future generations of experimental fusion reactors like ITER

ITER

ITER is an international nuclear fusion research and engineering project, which is currently building the world's largest and most advanced experimental tokamak nuclear fusion reactor at Cadarache in the south of France...

. Currently between 1.5 and 2.1 kg of tritium are recovered yearly at the Darlington separation facility, of which a minor fraction is sold.

The 1998 Operation Shakti test series in India included one bomb of about 45 kT yield that India has publicly claimed was a hydrogen bomb. An offhand comment in the BARC

BARC

Barc or BARC may refer to:Institutions* Beltsville Agricultural Research Center* Bhabha Atomic Research Centre, an Indian nuclear research facility* Bradford Amateur Rowing Club* British Automobile Racing ClubVessels and vehicles* Barque...

publication Heavy Water — Properties, Production and Analysis appears to suggest that the tritium was extracted from the heavy water in the CANDU and PHWR reactors in commercial operation. Janes Intelligence Review quotes the Chairman of the Indian Atomic Energy Commission as admitting to the tritium extraction plant, but refusing to comment on its use. However India is also capable of creating tritium more efficiently by irradiation of lithium-6 in reactors.

Tritium emissions

TritiumTritium

Tritium is a radioactive isotope of hydrogen. The nucleus of tritium contains one proton and two neutrons, whereas the nucleus of protium contains one proton and no neutrons...

is a radioactive form of hydrogen

Hydrogen

Hydrogen is the chemical element with atomic number 1. It is represented by the symbol H. With an average atomic weight of , hydrogen is the lightest and most abundant chemical element, constituting roughly 75% of the Universe's chemical elemental mass. Stars in the main sequence are mainly...

(H-3), with a half-life

Half-life

Half-life, abbreviated t½, is the period of time it takes for the amount of a substance undergoing decay to decrease by half. The name was originally used to describe a characteristic of unstable atoms , but it may apply to any quantity which follows a set-rate decay.The original term, dating to...

of 12.3 years. It is found in small amounts in nature (about 4 kg globally), created by cosmic ray

Cosmic ray

Cosmic rays are energetic charged subatomic particles, originating from outer space. They may produce secondary particles that penetrate the Earth's atmosphere and surface. The term ray is historical as cosmic rays were thought to be electromagnetic radiation...

interactions in the upper atmosphere. Tritium is considered a weak radionuclide

Radionuclide

A radionuclide is an atom with an unstable nucleus, which is a nucleus characterized by excess energy available to be imparted either to a newly created radiation particle within the nucleus or to an atomic electron. The radionuclide, in this process, undergoes radioactive decay, and emits gamma...

because of its low-energy radioactive emissions (beta particle

Beta particle

Beta particles are high-energy, high-speed electrons or positrons emitted by certain types of radioactive nuclei such as potassium-40. The beta particles emitted are a form of ionizing radiation also known as beta rays. The production of beta particles is termed beta decay...

energy 0 -19 keV). The beta particles do not travel very far in air and do not penetrate skin, so the main hazard is intake into the body (inhalation, ingestion, or absorption).

Tritium is generated in the fuel of all reactors; however, CANDU reactors generate tritium also in their coolant and moderator, due to neutron capture

Neutron capture

Neutron capture is a kind of nuclear reaction in which an atomic nucleus collides with one or more neutrons and they merge to form a heavier nucleus. Since neutrons have no electric charge they can enter a nucleus more easily than positively charged protons, which are repelled...

in heavy hydrogen. Some of this tritium escapes into containment and is generally recovered; however a small percentage (about 1%) escapes containment and is considered a routine radioactive emission (also higher than from an LWR of comparable size). Operating a CANDU plant therefore includes monitoring tritium in the surrounding environment (and publishing the results).

In some CANDU reactors the tritium is periodically extracted. Typical emissions from CANDU plants in Canada are less than 1% of the national regulatory limit, which is based on International Commission on Radiological Protection

International Commission on Radiological Protection

The International Commission on Radiological Protection is an advisory body providing recommendations and guidance on radiation protection; It was founded in 1928 by the International Society of Radiology and was then called the ‘International X-ray and Radium Protection Committee’...

(ICRP) guidelines (for example, the maximum permitted drinking water concentration for tritium in Canada, 7000 Bq/L, corresponds to 1/10 of the ICRP's dose limit for members of the public). Tritium emissions from other CANDU plants are similarly low.

In general there is significant public controversy about radioactive emissions from nuclear power plants, and for CANDU plants one of the main concerns is tritium. In 2007 Greenpeace

Greenpeace

Greenpeace is a non-governmental environmental organization with offices in over forty countries and with an international coordinating body in Amsterdam, The Netherlands...

published a critique of tritium emissions from Canadian nuclear power plants by Dr. Ian Fairlie. This report was criticized by Dr. Richard Osborne.

Evolving designs

The CANDU development effort has gone through four major stages over time. The first systems were experimental and prototype machines of limited power. These were replaced by a second generation of machines of 500 to 600 MWe (the CANDU6), a series of larger machines of 900 MWe, and finally developing into the CANDU9 and current ACR-1000 effort.Early efforts

The first heavy water moderated design in Canada was the ZEEPZEEP

The ZEEP reactor was a nuclear reactor built at the Chalk River Laboratories near Chalk River, Ontario, Canada . ZEEP first went critical at 3:45 PM, September 5, 1945...

, which started operation just after the end of World War II

World War II

World War II, or the Second World War , was a global conflict lasting from 1939 to 1945, involving most of the world's nations—including all of the great powers—eventually forming two opposing military alliances: the Allies and the Axis...

. ZEEP was joined by several other experimental machines, including the NRX and NRU. These efforts led to the first CANDU-type reactor, the Nuclear Power Demonstration

Nuclear Power Demonstration

Nuclear Power Demonstration was the first Canadian nuclear power reactor, and the prototype for the CANDU reactor design. Built by Canadian General Electric , in partnership with Atomic Energy of Canada Limited and Ontario Hydro , it consisted of a single 22 MWe pressurized heavy water reactor ...

(NPD), in Rolphton, Ontario. It was intended as a proof-of-concept and rated for only 22 MWe

MWE

MWE may refer to:*Manufacturer's Weight Empty*McDermott Will & Emery*Midwest Express, an airline*Merowe Airport - IATA code*Multiword expressionMWe may refer to:*Megawatt electrical...

, a very low power for a commercial power reactor. NPD produced the first nuclear-generated electricity in Canada, and ran successfully from 1962 to 1987.

The second CANDU was the Douglas Point

Douglas Point

The Douglas Point Nuclear Generating Station was Canada’s first full-scale nuclear power plant and the second CANDU Pressurised Heavy Water Reactor....

reactor, a more powerful version rated at roughly 200 MWe

MWE

MWE may refer to:*Manufacturer's Weight Empty*McDermott Will & Emery*Midwest Express, an airline*Merowe Airport - IATA code*Multiword expressionMWe may refer to:*Megawatt electrical...

and located near Kincardine

Kincardine, Ontario

The Municipality of Kincardine is located on the shores of Lake Huron in the County of Bruce in the province of Ontario, Canada. It has a population of 12,000, and covers an area of 580 square kilometres...

, Ontario. It went into service in 1968, and ran until 1984. Uniquely among CANDU stations, Douglas Point had an oil-filled window with a view of the east reactor face, even when the reactor was operating. Douglas Point was originally planned to be a two-unit station, but the second unit was cancelled because of the success of the larger 515 MWe units at Pickering

Pickering Nuclear Generating Station

Pickering Nuclear Generating Station is a Canadian nuclear power station located on the north shore of Lake Ontario in Pickering, Ontario. The facility derives its name from the City of Pickering in which it is located....

.

Gentilly-1

Gentilly Nuclear Generating Station

Gentilly Nuclear Generating Station is a Canadian nuclear power station located near Bécancour, Quebec. The facility derives its name from the Gentilly suburb of the city of Bécancour, in which it is located...

, in Bécancour, Quebec

Bécancour, Quebec

Bécancour is a town in the Centre-du-Québec region of Québec, Canada; it is the seat of the Bécancour Regional County Municipality. It is located on the south shore of the Saint Lawrence River at the confluence of the Bécancour River, opposite Trois-Rivières.Wôlinak, an Abenaki Indian reserve, is...

near Trois-Rivières

Trois-Rivières

Trois-Rivières means three rivers in French and may refer to:in Canada*Trois-Rivières, the largest city in the Mauricie region of Quebec, Canada*Circuit Trois-Rivières, a racetrack in Trois-Rivières, Quebec...

, Quebec

Quebec

Quebec or is a province in east-central Canada. It is the only Canadian province with a predominantly French-speaking population and the only one whose sole official language is French at the provincial level....

, was also an experimental version of CANDU, using a boiling light-water coolant and vertical pressure tubes, but was not considered successful and closed after seven years of fitful operation.. Gentilly-2, a CANDU-6 reactor, has been operating since 1983. It is owned and operated by Hydro-Québec

Hydro-Québec

Hydro-Québec is a government-owned public utility established in 1944 by the Government of Quebec. Based in Montreal, the company is in charge of the generation, transmission and distribution of electricity across Quebec....

.

In parallel with the classic CANDU design, experimental variants were being developed. WR-1

WR-1

The WR-1 reactor was a research reactor located at AECL's Whiteshell Laboratories, located near Pinawa, Manitoba.The 60 MWt WR-1 was designed and built by Canadian General Electric, and first achieved criticality in 1965. The reactor was built at a cost of $14.5 Million CDN . The original purpose...

, located at the AECL

Atomic Energy of Canada Limited

Atomic Energy of Canada Limited or AECL is a Canadian federal Crown corporation and Canada's largest nuclear science and technology laboratory...

's Whiteshell Laboratories

Whiteshell Laboratories

The Whiteshell Nuclear Research Establishment, now Whiteshell Laboratories, was established by the Government of Canada in 1963 as an AECL research laboratory in Pinawa, Manitoba...

in Pinawa, Manitoba

Pinawa, Manitoba

Pinawa is a small Canadian community of about 1500 residents located in southeastern Manitoba, 110 kilometres north-east of Winnipeg. The town is situated on the Canadian Shield within the western boundary of Whiteshell Provincial Park, which lies near the Manitoba-Ontario provincial boundary...

, used vertical pressure tubes and organic oil

Petroleum

Petroleum or crude oil is a naturally occurring, flammable liquid consisting of a complex mixture of hydrocarbons of various molecular weights and other liquid organic compounds, that are found in geologic formations beneath the Earth's surface. Petroleum is recovered mostly through oil drilling...

as the primary coolant. The oil used has a higher boiling point than water, allowing the reactor to operate at higher temperatures and lower pressures than a conventional reactor. WR-1 operated successfully for many years, and promised a significantly higher efficiency than water-cooled versions.

600 MWe designs

The successes at NPD and Douglas Point led to the decision to construct the first multi-unit station in Pickering, Ontario. Pickering A, consisting of Units 1 to 4, went into service in 1971. Pickering B with units 5 to 8 came online in 1983, giving a full-station capacity of 4,120 MWe. The station is very close to the city of TorontoToronto

Toronto is the provincial capital of Ontario and the largest city in Canada. It is located in Southern Ontario on the northwestern shore of Lake Ontario. A relatively modern city, Toronto's history dates back to the late-18th century, when its land was first purchased by the British monarchy from...

, in order to reduce transmission

Electric power transmission

Electric-power transmission is the bulk transfer of electrical energy, from generating power plants to Electrical substations located near demand centers...

costs.

A series of improvements to the basic Pickering design led to the CANDU 6 design, which first went into operation in the early 1980s. CANDU 6 was essentially a version of the Pickering power plant that was re-designed to be able to be built in single-reactor units. CANDU 6 was used in several installations outside Ontario, including the Gentilly-2

Gentilly Nuclear Generating Station

Gentilly Nuclear Generating Station is a Canadian nuclear power station located near Bécancour, Quebec. The facility derives its name from the Gentilly suburb of the city of Bécancour, in which it is located...

in Quebec, and Point Lepreau Nuclear Generating Station

Point Lepreau Nuclear Generating Station

Point Lepreau Nuclear Generating Station is a Canadian nuclear power station located 2 km northeast of Point Lepreau, New Brunswick. The facility was constructed between 1975-1983 by NB Power, the provincially-owned public utility....

in New Brunswick. CANDU 6 forms the majority of foreign CANDU systems, including the designs exported to Argentina, Romania, China and South Korea. Only India operates a CANDU system that is not based on the CANDU 6 design.

900 MWe designs

The economics of nuclear power plants generally scale well with size. However, this improvement at larger sizes is offset by the sudden appearance of large quantities of power on the grid, which leads to a lowering of electricity prices through supply and demand effects. Predictions in the late 1960s suggested that growth in electricity demand would overwhelm these downward pricing pressures, leading most designers to introduce plants in the 1000 MWe range.Pickering A was quickly followed by such an upscaling effort for the Bruce Nuclear Generating Station

Bruce Nuclear Generating Station

Bruce Nuclear Generating Station is a Canadian nuclear power station located on the eastern shore of Lake Huron, in the communities of Inverhuron and Tiverton, Ontario. It occupies 932 ha of land. The facility derives its name from Bruce County in which it is located, in the former Bruce Township...

, constructed in stages between 1970 and 1987. It is the largest nuclear facility in North America, and second largest in the world (after Kashiwazaki-Kariwa

Kashiwazaki-Kariwa Nuclear Power Plant

The is a large, modern nuclear power plant on a 4.2-square-kilometer site including land in the towns of Kashiwazaki and Kariwa in Niigata Prefecture, Japan on the coast of the Sea of Japan, from where it gets cooling water...

in Japan), with eight reactors

Nuclear reactor

A nuclear reactor is a device to initiate and control a sustained nuclear chain reaction. Most commonly they are used for generating electricity and for the propulsion of ships. Usually heat from nuclear fission is passed to a working fluid , which runs through turbines that power either ship's...

at around 800 MWe each, in total 6,232 MW (net) and 7,276 MW (gross). Another, smaller, upscaling led to the Darlington Nuclear Generating Station

Darlington Nuclear Generating Station

Darlington Nuclear Generating Station is a Canadian nuclear power station located on the north shore of Lake Ontario in Clarington, Ontario. The facility derives its name from the Township of Darlington, the former name of the municipality in which it is located.The Darlington station is a large...

design, similar to the Bruce plant, but delivering about 880 WMe per reactor.

As was the case for the development of the Pickering design into the CANDU 6, the Bruce design was also developed into the similar CANDU 9. Like the CANDU 6, the CANDU 9 is essentially a re-packaging of the Bruce design so it can be built as a single-reactor unit. However, no CANDU 9 reactors have been built.

Generation III+ designs

Through the 1980s and 90s the nuclear power market suffered a major crash, with few new plants being constructed in North America or Europe. Design work continued throughout, however, and a number of new design concepts were introduced that dramatically improved safety, capital costs, economics and overall performance. These Generation III+Generation III reactor

A generation III reactor is a development of any of the generation II nuclear reactor designs incorporating evolutionary improvements in design developed during the lifetime of the generation II reactor designs...

and Generation IV

Generation IV reactor

Generation IV reactors are a set of theoretical nuclear reactor designs currently being researched. Most of these designs are generally not expected to be available for commercial construction before 2030...

machines became a topic of considerable interest in the early 2000s as it appeared a nuclear renaissance

Nuclear renaissance

Since about 2001 the term nuclear renaissance has been used to refer to a possible nuclear power industry revival, driven by rising fossil fuel prices and new concerns about meeting greenhouse gas emission limits. At the same time, various barriers to a nuclear renaissance have been identified...

was underway and large numbers of new reactors would be built over the next decade.

AECL had been working on a design known as the ACR-700, using elements of the latest versions of the CANDU 6 and CANDU 9, with a design power of 700 MWe. During the nuclear renaissance, the upscaling seen in the earlier years re-expressed itself, and the ACR-700 was developed into the 1200 MWe ACR-1000. ACR-1000 is the next-generation (officially, "Generation III+") CANDU technology which makes some significant modifications to the existing CANDU design.

The main change, and the most radical among the CANDU generations, is the use of pressurized light water as the coolant. This significantly reduces the cost of implementing the primary cooling loop, which no longer has to be filled with expensive heavy water. The ACR-1000 uses about 1/3rd the heavy water needed in earlier generation designs. It also eliminates tritium production in the coolant loop, the major source of tritium leaks in operational CANDU designs. The redesign also allows for a slightly negative void reactivity

Void coefficient

In nuclear engineering, the void coefficient is a number that can be used to estimate how much the reactivity of a nuclear reactor changes as voids form in the reactor moderator or coolant...

, a major design goal of all GenIII+ machines.

However, the design also requires the use of slightly enriched uranium, enriched by about 1 or 2%. The main reason for this is to increase the burn-up ratio, allowing bundles to remain in the reactor longer, so that only a third as much used fuel is produced. This also has effects on operational costs and timetables, as the refuelling frequency is reduced. As is the case with earlier CANDU designs, the ACR-1000 also offers online refuelling.

Outside of the reactor, the ACR-1000 has a number of design changes that are expected to dramatically lower capital and operational costs. Primary among these changes is the design lifetime of 60 years, which dramatically lowers the price of the electricity generated over the lifetime of the plant. The design also has an expected capacity factor of 90%. Higher pressure steam generators and turbines improve efficiency downstream of the reactor.

Many of the operational design changes were also applied to the existing CANDU 6 to produce the Enhanced CANDU 6. Also known as CANDU 6e or EC 6, this was an evolutionary upgrade of the CANDU 6 design with a gross output of 740 MWe per unit. The reactors are designed with a lifetime of over fifty years, with a mid-life program to replace some of the key components e.g. the fuel channels. The projected average annual capacity factor

Capacity factor

The net capacity factor or load factor of a power plant is the ratio of the actual output of a power plant over a period of time and its potential output if it had operated at full nameplate capacity the entire time...

is more than ninety percent. Improvements to construction techniques (including modular, open-top assembly) decrease construction costs. The CANDU 6e is designed to operate at power settings as low as 50%, allowing them to adjust to load demand much better than the previous designs.

In Ontario

By most measures, the CANDU is "the Ontario reactor". The system was developed almost entirely in Ontario, and only two experimental designs were built outside the province. Of the 29 commercial CANDU reactors built, 17 of these are in Ontario. Of the 17, a number of reactors have been removed from service. Two new CANDU reactors have been proposed for Darlington with Canadian government help with financing.In Canada

AECL has heavily marketed CANDU within Canada, but has found a limited reception. To date, only two non-experimental reactors have been built in other provinces, one each in Quebec and New Brunswick. Most other provinces have concentrated on hydro or coal-fired plants.Interest has been expressed in Western Canada

Western Canada

Western Canada, also referred to as the Western provinces and commonly as the West, is a region of Canada that includes the four provinces west of the province of Ontario.- Provinces :...

, where CANDU reactors are being considered as heat and electricity sources for the energy-intensive oil sands

Tar sands

Bituminous sands, colloquially known as oil sands or tar sands, are a type of unconventional petroleum deposit. The sands contain naturally occurring mixtures of sand, clay, water, and a dense and extremely viscous form of petroleum technically referred to as bitumen...

extraction process, which currently uses natural gas

Natural gas

Natural gas is a naturally occurring gas mixture consisting primarily of methane, typically with 0–20% higher hydrocarbons . It is found associated with other hydrocarbon fuel, in coal beds, as methane clathrates, and is an important fuel source and a major feedstock for fertilizers.Most natural...

. Energy Alberta Corporation

Energy Alberta Corporation

Energy Alberta Corporation was created in 2005 to provide nuclear power to the energy-intensive development of the oil sands resources in northern Alberta. The company was founded by Hank Swartout, CEO of Precision Drilling Corporation, and Wayne Henuset, co-owner of Willow Park Wines and Spirits...

announced August 27, 2007 that they had applied for a licence to build a new nuclear plant at Lac Cardinal (30 km west of the town of Peace River, Alberta

Peace River, Alberta

Peace River is a town in northwestern Alberta, Canada, situated along the banks of the Peace River, at its confluence with the Smoky River, the Heart River and Pat's Creek. It is located northwest of Edmonton, and northeast of Grande Prairie, along Highway 2. The Peace River townsite is nearly ...

), two ACR-1000 reactors going online in 2017 producing 2.2 gigawatt (electric). However, a 2007 parliamentary review suggested placing the development efforts on hold. The company was later purchased by Bruce Power, who proposed expanding the plant to four units of a total 4.4 gigwatts. However, these plans were upset and Bruce later withdrew its application for the Lac Cardinal, proposing instead a new site about 60 km away.

Foreign sales

During the 1970s the international nuclear sales market was extremely competitive, with many national nuclear companies being supported by their governments foreign embassy machineries. Canada, a relatively new player on the international market, had numerous disadvantages in these efforts. However, the CANDU was deliberately designed to reduce the need for very large machined parts, making it suitable for construction by countries without a major industrial base. Sales efforts have had their most success in countries that could not locally build designs from other firms.In the late 1970s, AECL noted that each reactor sale would employ 3,600 Canadians and result in $300 million in balance-of-payments income. However, these sales efforts were aimed primarily at countries being run by dictatorships or similar, a fact that led to serious concerns in parliament. These efforts also led to a scandal when it was discovered millions of dollars had been given to foreign sales agents, with little or no record of who they were, or what they did to earn the money. This led to an Royal Canadian Mounted Police

Royal Canadian Mounted Police

The Royal Canadian Mounted Police , literally ‘Royal Gendarmerie of Canada’; colloquially known as The Mounties, and internally as ‘The Force’) is the national police force of Canada, and one of the most recognized of its kind in the world. It is unique in the world as a national, federal,...

investigation after questions were raised about sales efforts in Argentina, and new regulations on full disclosure of fees for future sales.

CANDU's first success was the sale of early CANDU designs to India. In 1963 an agreement was signed for export of a 200 MWe power reactor based on the Douglas Point reactor. The success of the deal led to the 1966 sale of a second reactor of the same design. The first reactor, then known as RAPP-1 for "Rajasthan Atomic Power Project", began operation in 1972. However, a serious problem with cracking of the reactor's end shield led to the reactor being shut down for long periods, and the reactor was finally downrated to 100 MW. Construction of the RAPP-2 reactor was still underway when India detonated its first atomic bomb in 1974, leading to Canada ending nuclear dealings with the country. Part of the sales agreement was a technology transfer process. When Canada withdrew from development, India continued construction of CANDU-like plants across the country.

In Pakistan the Karachi Nuclear Power Plant with a gross capacity of 137MWe was built between 1966-1971.

In 1972, AECL submitted a design based on the Pickering plant to Argentina's Comision Nacional de Energia Atomica process, in partnership with the Italian company Italimpianti. High inflation during construction led to massive losses, and efforts to re-negotiate the deal were interrupted by the March 1976 coup led by General Videla. The Embalse plant began commercial operation in January 1984. There have been ongoing negotiations to open more CANDU 6 reactors in the country, including a 2007 deal between Canada, China and Argentina, but to date no firm plans have been announced.

A licensing agreement with Romania was signed in 1977, selling the CANDU 6 design for $5 million per reactor for the first four reactors, and then $2 million each for the next twelve. In addition, Canadian companies would supply a varying amount of equipment for the reactors, about $100 million of the first reactor's $800 million price tag, and then falling over time. In 1980 Nicolae Ceausescu

Nicolae Ceausescu

Nicolae Ceaușescu was a Romanian Communist politician. He was General Secretary of the Romanian Communist Party from 1965 to 1989, and as such was the country's second and last Communist leader...

asked for a modification to provide goods instead of cash, in exchange the amount of Canadian content was increased and a second reactor would be built with Canadian help. Economic troubles in the country worsened throughout the construction phase. The first reactor only came online in April 1996, a decade after its December 1985 predicted startup. Further loans were arranged for completion of the second reactor, which went online in November 2007.

In January 1975 a deal was announced for a single CANDU 6 reactor to be built in South Korea, now known as the Wolsong-1 Power Reactor. Construction started in 1977 and commercial operation began in April 1983. In December 1990 a further deal was announced for three additional units at the same site, which began operation in the period 1997-1999. However, South Korea also negotiated development and technology transfer deals with Westinghouse for their advanced System-80 reactor design, and all future development is based on locally built versions of this reactor.

Turkey

Turkey

Turkey , known officially as the Republic of Turkey , is a Eurasian country located in Western Asia and in East Thrace in Southeastern Europe...

has repeatedly shown interest in the CANDU reactor, but currently plans to build reactors of a different type. There have been anti-nuclear protests in the past, e.g. in April 2006 plans to build a nuclear reactor on the Ince peninsula caused a large anti-nuclear demonstration in the Turkish city of Sinop

Sinop, Turkey

Sinop is a city with a population of 36,734 on İnce Burun , by its Cape Sinop which is situated on the most northern edge of the Turkish side of Black Sea coast, in the ancient region of Paphlagonia, in modern-day northern Turkey, historically known as Sinope...

. Despite opposition, Turkey aims to have five nuclear power plants by 2030.

A full list of countries and sales efforts for CANDU and related AECL designs can be here.

Future sales

In 2007 AECL submitted the ACR-1000 design to the British Generic Design Assessment process to evaluate reactors for a new British nuclear power station program. However in 2008 AECL withdrew the design, stating it "is focusing its marketing and licensing resources for the advanced Candu reactor on the immediate needs of the Canadian domestic marketplace."As of 2010, the only active sales effort is the ACR-1000 for Ontario's Darlington plant. At one time considered a "sure thing", the price was considered too high and plans to expand Darlington were dropped. However, these plans appear to be ongoing again, although AECL's bid has been interrupted by ongoing efforts to sell the reactor design division.

Economic performance

The cost of electricity from any power plant can be calculated by roughly the same selection of factors. These include capital costs for construction and/or the payments on loans made to secure that capital, the cost of fuel on a per-watt-hour basis, and fixed and variable maintenance fees. In the case of nuclear power, one normally includes two additional costs, the cost of permanent waste disposal, and the cost of decommissioning the plant when its useful lifetime is over. Generally, the capital costs dominate the price of nuclear power, as the amount of power produced is so large that it overwhelms the cost of fuel and maintenance. The World Nuclear Association calculates that the cost of fuel, including all processing, accounts for only 0.77 cents/kWh.Information on economic performance on CANDU is somewhat lopsided; the majority of reactors are in Ontario, which is also the "most public" among the major CANDU operators, so their performance dominates the available information. Based on Ontario's record, the economic performance of the CANDU system is quite poor. Although much attention has been focussed on the problems with the Darlington plant, in fact, every single CANDU design in Ontario went over budget by at least 25%, and average over 150% higher than estimated. Darlington was the worst offender, at 350% over budget, but this project was stopped in-progress thereby incurring additional interest charges during a period of high interest rates, which is a special situation that was not expected to repeat itself.

In the 1980s, the pressure tubes in the Pickering A reactors were replaced ahead of design life due to unexpected deterioration caused by hydrogen embrittlement. Extensive inspection and maintenance has avoided this problem in later reactors.

All the Pickering A and Bruce A reactors were shut down in 1999 in order to focus on restoring operational performance in the later generations at Pickering, Bruce and Darlington. Before restarting the Pickering A reactors, OPG undertook a limited refurbishment program. The original cost and time estimates based on inadequate project scope development were greatly below the actual time and cost and it was determined that Pickering Units 2 and 3 would not be restarted for commercial reasons. Despite this refurbishment, the reactors have not performed well since the restart.

These overruns were repeated at Bruce, with Units 3 and 4 running 90% over budget. Similar overruns were experienced at Point Lepreau, and the planned refurbishment of the Gentilly 2 plant has been delayed until the fall of 2012, and currently there are serious plans to simply shut it down instead.

Based on the projected capital costs, and the low cost of fuel and in-service maintenance, in 1994 power from CANDU was predicted to be well under 5 cents/kWh. In 1998, Ontario Hydro

Ontario Hydro

Ontario Hydro was the official name from 1974 of the Hydro-Electric Power Commission of Ontario which was established in 1906 by the provincial Power Commission Act to build transmission lines to supply municipal utilities with electricity generated by private companies already operating at Niagara...

calculated that the cost of generation from CANDU was 7.7 cents/kWh, whereas hydropower was only 1.1 cents, and their coal-fired plants were 4.3 cents. As Hydro received a regulated price averaging 6.3 cents/kWh for power in this period, the revenues from the other forms of generation were being used to fund the operating losses of the nuclear plants. The debt left over from the nuclear construction could not be included in the rate base until the reactors were declared in service, thereby exacerbating the total capital cost of construction with unpaid interest, at that time around $15 billion, and another $3.5 billion in debts throughout the system was held by a separate entity and repaid through a standing charge on electricity bills.

In 1999, Ontario Hydro was broken up and its generation facilities re-formed into Ontario Power Generation

Ontario Power Generation

Ontario Power Generation is a public company wholly owned by the Government of Ontario. OPG is responsible for approximately 70% of the electricity generation in the Province of Ontario, Canada. Sources of electricity include nuclear, hydroelectric, solar, wind, and fossil fuel...

(OPG). In order to make the successor companies more attractive for private investors, $19.4 billion in "stranded debt" was placed in the control of the Ontario Electricity Financial Corporation. This debt is slowly paid down through a variety of sources, including a 0.7 cent/kWh tariff on all power, all income taxes paid by all operating companies, and all dividends paid by the OPG and Hydro One

Hydro One

Hydro One Incorporated delivers electricity across the Canadian province of Ontario. It is a Corporation established under the Business Corporations Act with a single shareholder, the Government of Ontario....

. Even with these sources of income, the amount of debt has grown on several occasions, and in 2010 stood at almost $15 billion. This is in spite of total payments on the order of $19 billion, ostensibly enough to have paid off the debt entirely if interest repayment requirements are ignored.

Darlington is currently in the process of considering a major re-build of several units, as it too is reaching its design mid-life time. The budget is currently estimated to be between $8.5 and $14 billion, and produce power at 6 to 8 cents/kWh. However, this prediction is based on three assumptions that appear to have never been met in operation: that the rebuild will be completed on-budget, that the system will operate at an average capacity utilization

Capacity utilization

Capacity utilization is a concept in economics and managerial accounting which refers to the extent to which an enterprise or a nation actually uses its installed productive capacity...