Thermal power station

Encyclopedia

Steam

Steam is the technical term for water vapor, the gaseous phase of water, which is formed when water boils. In common language it is often used to refer to the visible mist of water droplets formed as this water vapor condenses in the presence of cooler air...

driven. Water is heated, turns into steam and spins a steam turbine

Steam turbine

A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. Its modern manifestation was invented by Sir Charles Parsons in 1884....

which drives an electrical generator

Electrical generator

In electricity generation, an electric generator is a device that converts mechanical energy to electrical energy. A generator forces electric charge to flow through an external electrical circuit. It is analogous to a water pump, which causes water to flow...

. After it passes through the turbine, the steam is condensed

Condensation

Condensation is the change of the physical state of matter from gaseous phase into liquid phase, and is the reverse of vaporization. When the transition happens from the gaseous phase into the solid phase directly, the change is called deposition....

in a condenser and recycled to where it was heated; this is known as a Rankine cycle

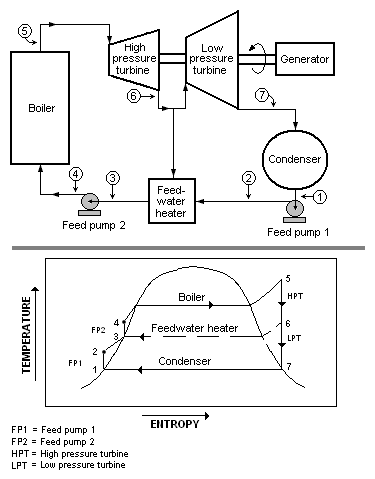

Rankine cycle

The Rankine cycle is a cycle that converts heat into work. The heat is supplied externally to a closed loop, which usually uses water. This cycle generates about 90% of all electric power used throughout the world, including virtually all solar thermal, biomass, coal and nuclear power plants. It is...

. The greatest variation in the design of thermal power stations is due to the different fuel sources. Some prefer to use the term energy center because such facilities convert forms of heat

Heat

In physics and thermodynamics, heat is energy transferred from one body, region, or thermodynamic system to another due to thermal contact or thermal radiation when the systems are at different temperatures. It is often described as one of the fundamental processes of energy transfer between...

energy

Energy

In physics, energy is an indirectly observed quantity. It is often understood as the ability a physical system has to do work on other physical systems...

into electricity. Some thermal power plants also deliver heat energy for industrial purposes, for district heating

District heating

District heating is a system for distributing heat generated in a centralized location for residential and commercial heating requirements such as space heating and water heating...

, or for desalination

Desalination

Desalination, desalinization, or desalinisation refers to any of several processes that remove some amount of salt and other minerals from saline water...

of water as well as delivering electrical power. A large part of human CO2 emissions comes from fossil fueled thermal power plants; efforts to reduce these outputs are various and widespread.

Introductory overview

Almost all coalCoal

Coal is a combustible black or brownish-black sedimentary rock usually occurring in rock strata in layers or veins called coal beds or coal seams. The harder forms, such as anthracite coal, can be regarded as metamorphic rock because of later exposure to elevated temperature and pressure...

, nuclear

Nuclear power

Nuclear power is the use of sustained nuclear fission to generate heat and electricity. Nuclear power plants provide about 6% of the world's energy and 13–14% of the world's electricity, with the U.S., France, and Japan together accounting for about 50% of nuclear generated electricity...

, geothermal

Geothermal power

Geothermal energy is thermal energy generated and stored in the Earth. Thermal energy is the energy that determines the temperature of matter. Earth's geothermal energy originates from the original formation of the planet and from radioactive decay of minerals...

, solar thermal electric, and waste incineration plants

Incineration

Incineration is a waste treatment process that involves the combustion of organic substances contained in waste materials. Incineration and other high temperature waste treatment systems are described as "thermal treatment". Incineration of waste materials converts the waste into ash, flue gas, and...

, as well as many natural gas power plants are thermal. Natural gas

Natural gas

Natural gas is a naturally occurring gas mixture consisting primarily of methane, typically with 0–20% higher hydrocarbons . It is found associated with other hydrocarbon fuel, in coal beds, as methane clathrates, and is an important fuel source and a major feedstock for fertilizers.Most natural...

is frequently combusted

Flue gas emissions from fossil fuel combustion

Flue-gas emissions from fossil-fuel combustion refers to the combustion product gas resulting from the much as 10 to 25 volume percent or more of the flue gas. This is closely followed in volume by water vapor created by the combustion of the hydrogen in the fuel with atmospheric oxygen...

in gas turbine

Gas turbine

A gas turbine, also called a combustion turbine, is a type of internal combustion engine. It has an upstream rotating compressor coupled to a downstream turbine, and a combustion chamber in-between....

s as well as boiler

Boiler

A boiler is a closed vessel in which water or other fluid is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications.-Materials:...

s. The waste heat

Waste heat

Waste heat sometimes called Secondary heat or Low-grade heat refers to heat produced by machines, electrical equipment and industrial processes for which no useful application is found. Energy is often produced by a heat engine, running on a source of high-temperature heat...

from a gas turbine can be used to raise steam, in a combined cycle

Combined cycle

In electric power generation a combined cycle is an assembly of heat engines that work in tandem off the same source of heat, converting it into mechanical energy, which in turn usually drives electrical generators...

plant that improves overall efficiency. Power plants burning coal, fuel oil

Fuel oil

Fuel oil is a fraction obtained from petroleum distillation, either as a distillate or a residue. Broadly speaking, fuel oil is any liquid petroleum product that is burned in a furnace or boiler for the generation of heat or used in an engine for the generation of power, except oils having a flash...

, or natural gas are often called fossil-fuel power plants. Some biomass

Biomass

Biomass, as a renewable energy source, is biological material from living, or recently living organisms. As an energy source, biomass can either be used directly, or converted into other energy products such as biofuel....

-fueled thermal power plants have appeared also. Non-nuclear thermal power plants, particularly fossil-fueled plants, which do not use co-generation are sometimes referred to as conventional power plants.

Commercial electric utility

Electric utility

An electric utility is a company that engages in the generation, transmission, and distribution of electricity for sale generally in a regulated market. The electrical utility industry is a major provider of energy in most countries. It is indispensable to factories, commercial establishments,...

power stations are usually constructed on a large scale and designed for continuous operation. Electric power plants typically use three-phase

Three-phase

In electrical engineering, three-phase electric power systems have at least three conductors carrying voltage waveforms that are radians offset in time...

electrical generator

Electrical generator

In electricity generation, an electric generator is a device that converts mechanical energy to electrical energy. A generator forces electric charge to flow through an external electrical circuit. It is analogous to a water pump, which causes water to flow...

s to produce alternating current (AC) electric power at a frequency of 50 Hz or 60 Hz

Hertz

The hertz is the SI unit of frequency defined as the number of cycles per second of a periodic phenomenon. One of its most common uses is the description of the sine wave, particularly those used in radio and audio applications....

. Large companies or institutions may have their own power plants to supply heating or electricity to their facilities, especially if steam is created anyway for other purposes. Steam-driven power plants have been used in various large ships, but are now usually used in large naval

Navy

A navy is the branch of a nation's armed forces principally designated for naval and amphibious warfare; namely, lake- or ocean-borne combat operations and related functions...

ships. Shipboard power plants usually directly couple the turbine to the ship's propellers through gearboxes. Power plants in such ships also provide steam to smaller turbines driving electric generators to supply electricity. Shipboard steam power plants can be either fossil fuel or nuclear. Nuclear marine propulsion

Nuclear marine propulsion

Nuclear marine propulsion is propulsion of a ship by a nuclear reactor. Naval nuclear propulsion is propulsion that specifically refers to naval warships...

is, with few exceptions, used only in naval vessels. There have been perhaps about a dozen turbo-electric

Turbo-electric

A turbo-electric transmission uses electric generators to convert the mechanical energy of a turbine into electric energy and electric motors to convert it back into mechanical energy to power the driveshafts....

ships in which a steam-driven turbine drives an electric generator which powers an electric motor

Electric motor

An electric motor converts electrical energy into mechanical energy.Most electric motors operate through the interaction of magnetic fields and current-carrying conductors to generate force...

for propulsion

Marine propulsion

Marine propulsion is the mechanism or system used to generate thrust to move a ship or boat across water. While paddles and sails are still used on some smaller boats, most modern ships are propelled by mechanical systems consisting a motor or engine turning a propeller, or less frequently, in jet...

.

combined heat and power (CH&P) plants, often called co-generation plants, produce both electric power and heat for process heat or space heating. Steam and hot water lose energy when piped over substantial distance, so carrying heat energy by steam or hot water is often only worthwhile within a local area, such as a ship, industrial plant, or district heating

District heating

District heating is a system for distributing heat generated in a centralized location for residential and commercial heating requirements such as space heating and water heating...

of nearby buildings.

History

Reciprocating steam engines have been used for mechanical power sources since the 18th Century, with notable improvements being made by James WattJames Watt

James Watt, FRS, FRSE was a Scottish inventor and mechanical engineer whose improvements to the Newcomen steam engine were fundamental to the changes brought by the Industrial Revolution in both his native Great Britain and the rest of the world.While working as an instrument maker at the...

. The very first commercial central electrical generating stations in the Pearl Street Station

Pearl Street Station

Pearl Street Station was the first central power plant in the United States. It was located at 255-257 Pearl Street in Manhattan on a site measuring 50 by 100 feet, just south of Fulton Street. It began with one direct current generator, and it started generating electricity on September 4, 1882,...

, New York and the Holborn Viaduct power station, London, in 1882, also used reciprocating steam engines. The development of the steam turbine

Steam turbine

A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. Its modern manifestation was invented by Sir Charles Parsons in 1884....

allowed larger and more efficient central generating stations to be built. By 1892 it was considered as an alternative to reciprocating engines Turbines offered higher speeds, more compact machinery, and stable speed regulation allowing for parallel synchronous operation of generators on a common bus. Turbines entirely replaced reciprocating engines in large central stations after about 1905. The largest reciprocating engine-generator sets ever built were completed in 1901 for the Manhattan Elevated Railway. Each of seventeen units weighed about 500 tons and was rated 6000 kilowatts; a contemporary turbine-set of similar rating would have weighed about 20% as much.

Efficiency

The energy efficiency of a conventional thermal power station, considered as salable energy as a percent of the heating value of the fuel consumed, is typically 33% to 48%. This efficiency is limited as all heat engines are governed by the laws of thermodynamics. The rest of the energy must leave the plant in the form of heat. This waste heatWaste heat

Waste heat sometimes called Secondary heat or Low-grade heat refers to heat produced by machines, electrical equipment and industrial processes for which no useful application is found. Energy is often produced by a heat engine, running on a source of high-temperature heat...

can go through a condenser and be disposed of with cooling water or in cooling tower

Cooling tower

Cooling towers are heat removal devices used to transfer process waste heat to the atmosphere. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet-bulb air temperature or in the case of closed circuit dry cooling towers rely...

s. If the waste heat is instead utilized for district heating

District heating

District heating is a system for distributing heat generated in a centralized location for residential and commercial heating requirements such as space heating and water heating...

, it is called co-generation. An important class of thermal power station are associated with desalination

Desalination

Desalination, desalinization, or desalinisation refers to any of several processes that remove some amount of salt and other minerals from saline water...

facilities; these are typically found in desert countries with large supplies of natural gas

Natural gas

Natural gas is a naturally occurring gas mixture consisting primarily of methane, typically with 0–20% higher hydrocarbons . It is found associated with other hydrocarbon fuel, in coal beds, as methane clathrates, and is an important fuel source and a major feedstock for fertilizers.Most natural...

and in these plants, freshwater production and electricity are equally important co-products.

Critical point (thermodynamics)

In physical chemistry, thermodynamics, chemistry and condensed matter physics, a critical point, also called a critical state, specifies the conditions at which a phase boundary ceases to exist...

for water

Water (data page)

This page provides supplementary data of the properties of water.Further comprehensive authoritative data can be found at the page on thermophysical properties of fluids.-Structure and properties:-Thermodynamic properties:-Liquid physical properties:...

of 705 °F (373.9 °C) and 3212 psi (22.06 MPa), there is no phase transition

Phase transition

A phase transition is the transformation of a thermodynamic system from one phase or state of matter to another.A phase of a thermodynamic system and the states of matter have uniform physical properties....

from water to steam, but only a gradual decrease in density

Density

The mass density or density of a material is defined as its mass per unit volume. The symbol most often used for density is ρ . In some cases , density is also defined as its weight per unit volume; although, this quantity is more properly called specific weight...

. Boiling

Boiling

Boiling is the rapid vaporization of a liquid, which occurs when a liquid is heated to its boiling point, the temperature at which the vapor pressure of the liquid is equal to the pressure exerted on the liquid by the surrounding environmental pressure. While below the boiling point a liquid...

does not occur and it is not possible to remove impurities via steam separation. In this case a super critical steam plant is required to utilize the increased thermodynamic efficiency by operating at higher temperatures. These plants, also called once-through plants because boiler water does not circulate multiple times, require additional water purification steps to ensure that any impurities picked up during the cycle will be removed. This purification takes the form of high pressure ion exchange units called condensate polisher

Condensate polisher

A condensate polisher is a device used to filter water condensed from steam as part of the steam cycle, for example in a conventional or nuclear power plant...

s between the steam condenser and the feed water heaters. Sub-critical fossil fuel power plants can achieve 36–40% efficiency. Super critical designs have efficiencies in the low to mid 40% range, with new "ultra critical" designs using pressures of 4400 psi (30.3 MPa) and dual stage reheat reaching about 48% efficiency.

Current nuclear power plant

Nuclear power plant

A nuclear power plant is a thermal power station in which the heat source is one or more nuclear reactors. As in a conventional thermal power station the heat is used to generate steam which drives a steam turbine connected to a generator which produces electricity.Nuclear power plants are usually...

s operate below the temperatures and pressures that coal-fired plants do. This limits their thermodynamic efficiency to 30–32%. Some advanced reactor designs being studied, such as the Very high temperature reactor

Very high temperature reactor

The Very High Temperature Reactor , or High Temperature Gas-cooled Reactor , is a Generation IV reactor concept that uses a graphite-moderated nuclear reactor with a once-through uranium fuel cycle. The VHTR is a type of High Temperature Reactor that can conceptually have an outlet temperature of...

, Advanced gas-cooled reactor

Advanced gas-cooled reactor

An advanced gas-cooled reactor is a type of nuclear reactor. These are the second generation of British gas-cooled reactors, using graphite as the neutron moderator and carbon dioxide as coolant...

and Super critical water reactor, would operate at temperatures and pressures similar to current coal plants, producing comparable thermodynamic efficiency.

Electricity cost

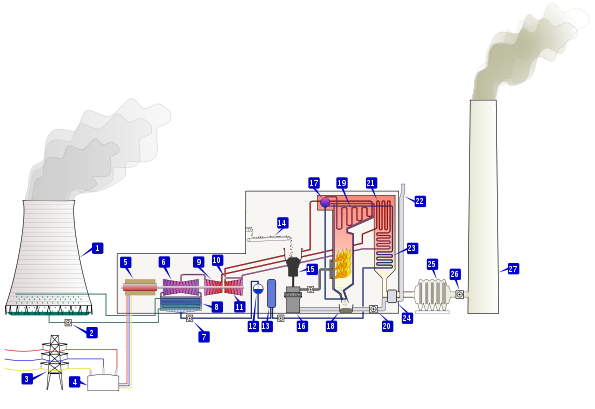

The direct cost of electric energy produced by a thermal power station is the result of cost of fuel, capital cost for the plant, operator labour, maintenance, and such factors as ash handling and disposal. Indirect, social or environmental costs such as the economic value of environmental impacts, or environmental and health effects of the complete fuel cycle and plant decommissioning, are not usually assigned to generation costs for thermal stations in utility practice, but may form part of an environmental impact assessment.Diagram of a typical coal-fired thermal power station

Boiler and steam cycle

In fossil-fueled power plants, steam generatorBoiler (steam generator)

A boiler or steam generator is a device used to create steam by applying heat energy to water. Although the definitions are somewhat flexible, it can be said that older steam generators were commonly termed boilers and worked at low to medium pressure but, at pressures above this, it is more...

refers to a furnace that burns the fossil fuel to boil water to generate steam.

In the nuclear plant

Nuclear power

Nuclear power is the use of sustained nuclear fission to generate heat and electricity. Nuclear power plants provide about 6% of the world's energy and 13–14% of the world's electricity, with the U.S., France, and Japan together accounting for about 50% of nuclear generated electricity...

field, steam generator

Steam generator (nuclear power)

Steam generators are heat exchangers used to convert water into steam from heat produced in a nuclear reactor core. They are used in pressurized water reactors between the primary and secondary coolant loops....

refers to a specific type of large heat exchanger

Heat exchanger

A heat exchanger is a piece of equipment built for efficient heat transfer from one medium to another. The media may be separated by a solid wall, so that they never mix, or they may be in direct contact...

used in a pressurized water reactor

Pressurized water reactor

Pressurized water reactors constitute a large majority of all western nuclear power plants and are one of three types of light water reactor , the other types being boiling water reactors and supercritical water reactors...

(PWR) to thermally connect the primary (reactor plant) and secondary (steam plant) systems, which generates steam. In a nuclear reactor called a boiling water reactor

Boiling water reactor

The boiling water reactor is a type of light water nuclear reactor used for the generation of electrical power. It is the second most common type of electricity-generating nuclear reactor after the pressurized water reactor , also a type of light water nuclear reactor...

(BWR), water is boiled to generate steam directly in the reactor itself and there are no units called steam generators.

In some industrial settings, there can also be steam-producing heat exchangers called heat recovery steam generators (HRSG) which utilize heat from some industrial process. The steam generating boiler has to produce steam at the high purity, pressure and temperature required for the steam turbine that drives the electrical generator.

Geothermal plants

Geothermal power

Geothermal energy is thermal energy generated and stored in the Earth. Thermal energy is the energy that determines the temperature of matter. Earth's geothermal energy originates from the original formation of the planet and from radioactive decay of minerals...

need no boiler since they use naturally occurring steam sources. Heat exchangers may be used where the geothermal steam is very corrosive or contains excessive suspended solids.

A fossil fuel steam generator includes an economizer

Economizer

Economizers , or economisers , are mechanical devices intended to reduce energy consumption, or to perform another useful function such as preheating a fluid. The term economizer is used for other purposes as well. Boiler, powerplant, and heating, ventilating, and air-conditioning uses are...

, a steam drum

Steam drum

A steam drum is a standard feature of a water-tube boiler. It is a reservoir of water/steam at the top end of the water tubes. The drum stores the steam generated in the water tubes and acts as a phase-separator for the steam/water mixture...

, and the furnace

Furnace

A furnace is a device used for heating. The name derives from Latin fornax, oven.In American English and Canadian English, the term furnace on its own is generally used to describe household heating systems based on a central furnace , and sometimes as a synonym for kiln, a device used in the...

with its steam generating tubes and superheater coils. Necessary safety valve

Safety valve

A safety valve is a valve mechanism for the automatic release of a substance from a boiler, pressure vessel, or other system when the pressure or temperature exceeds preset limits....

s are located at suitable points to avoid excessive boiler pressure. The air and flue gas

Flue gas

Flue gas is the gas exiting to the atmosphere via a flue, which is a pipe or channel for conveying exhaust gases from a fireplace, oven, furnace, boiler or steam generator. Quite often, the flue gas refers to the combustion exhaust gas produced at power plants...

path equipment include: forced draft (FD) fan

Centrifugal fan

A centrifugal fan is a mechanical device for moving air or other gases. It has a fan wheel composed of a number of fan blades, or ribs, mounted around a hub. As shown in Figure 1, the hub turns on a driveshaft that passes through the fan housing...

, Air Preheater

Air preheater

An air preheater is a general term to describe any device designed to heat air before another process with the primary objective of increasing the thermal efficiency of the process...

(AP), boiler furnace, induced draft (ID) fan, fly ash collectors (electrostatic precipitator

Electrostatic precipitator

An electrostatic precipitator , or electrostatic air cleaner is a particulate collection device that removes particles from a flowing gas using the force of an induced electrostatic charge...

or baghouse) and the flue gas stack

Flue gas stack

A flue-gas stack is a type of chimney, a vertical pipe, channel or similar structure through which combustion product gases called flue gases are exhausted to the outside air. Flue gases are produced when coal, oil, natural gas, wood or any other fuel is combusted in an industrial furnace, a power...

.

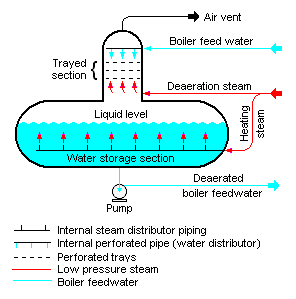

Feed water heating and deaeration

The feed water used in the steamSteam

Steam is the technical term for water vapor, the gaseous phase of water, which is formed when water boils. In common language it is often used to refer to the visible mist of water droplets formed as this water vapor condenses in the presence of cooler air...

boiler is a means of transferring heat energy from the burning fuel to the mechanical energy of the spinning steam turbine

Steam turbine

A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. Its modern manifestation was invented by Sir Charles Parsons in 1884....

. The total feed water consists of recirculated condensate water and purified makeup water. Because the metallic materials it contacts are subject to corrosion

Corrosion

Corrosion is the disintegration of an engineered material into its constituent atoms due to chemical reactions with its surroundings. In the most common use of the word, this means electrochemical oxidation of metals in reaction with an oxidant such as oxygen...

at high temperatures and pressures, the makeup water is highly purified before use. A system of water softeners and ion exchange

Ion exchange

Ion exchange is an exchange of ions between two electrolytes or between an electrolyte solution and a complex. In most cases the term is used to denote the processes of purification, separation, and decontamination of aqueous and other ion-containing solutions with solid polymeric or mineralic 'ion...

demineralizers produces water so pure that it coincidentally becomes an electrical insulator

Electrical insulation

thumb|250px|[[Coaxial Cable]] with dielectric insulator supporting a central coreThis article refers to electrical insulation. For insulation of heat, see Thermal insulation...

, with conductivity in the range of 0.3–1.0 microsiemens per centimeter. The makeup water in a 500 MWe plant amounts to perhaps 20 US gallons per minute (1.25 L/s) to offset the small losses from steam leaks in the system.

The feed water cycle begins with condensate water being pumped out of the condenser after traveling through the steam turbines. The condensate flow rate at full load in a 500 MW plant is about 6,000 US gallons per minute (400 L/s).

Deaerator

A deaerator is a device that is widely used for the removal of oxygen and other dissolved gases from the feedwater to steam-generating boilers. In particular, dissolved oxygen in boiler feedwaters will cause serious corrosion damage in steam systems by attaching to the walls of metal piping and...

that removes dissolved air from the water, further purifying and reducing its corrosiveness. The water may be dosed following this point with hydrazine

Hydrazine

Hydrazine is an inorganic compound with the formula N2H4. It is a colourless flammable liquid with an ammonia-like odor. Hydrazine is highly toxic and dangerously unstable unless handled in solution. Approximately 260,000 tons are manufactured annually...

, a chemical that removes the remaining oxygen

Oxygen

Oxygen is the element with atomic number 8 and represented by the symbol O. Its name derives from the Greek roots ὀξύς and -γενής , because at the time of naming, it was mistakenly thought that all acids required oxygen in their composition...

in the water to below 5 parts per billion (ppb). It is also dosed with pH

PH

In chemistry, pH is a measure of the acidity or basicity of an aqueous solution. Pure water is said to be neutral, with a pH close to 7.0 at . Solutions with a pH less than 7 are said to be acidic and solutions with a pH greater than 7 are basic or alkaline...

control agents such as ammonia

Ammonia

Ammonia is a compound of nitrogen and hydrogen with the formula . It is a colourless gas with a characteristic pungent odour. Ammonia contributes significantly to the nutritional needs of terrestrial organisms by serving as a precursor to food and fertilizers. Ammonia, either directly or...

or morpholine

Morpholine

Morpholine is an organic chemical compound having the chemical formula O2NH. This heterocycle, pictured at right, features both amine and ether functional groups. Because of the amine, morpholine is a base; its conjugate acid is called morpholinium...

to keep the residual acid

Acid

An acid is a substance which reacts with a base. Commonly, acids can be identified as tasting sour, reacting with metals such as calcium, and bases like sodium carbonate. Aqueous acids have a pH of less than 7, where an acid of lower pH is typically stronger, and turn blue litmus paper red...

ity low and thus non-corrosive.

Boiler operation

The boiler is a rectangular furnaceFurnace

A furnace is a device used for heating. The name derives from Latin fornax, oven.In American English and Canadian English, the term furnace on its own is generally used to describe household heating systems based on a central furnace , and sometimes as a synonym for kiln, a device used in the...

about 50 feet (15.2 m) on a side and 130 feet (39.6 m) tall. Its walls are made of a web of high pressure steel tubes about 2.3 inches (58.4 mm) in diameter.

Pulverized coal

Coal dust

Coal dust is a fine powdered form of coal, which is created by the crushing, grinding, or pulverizing of coal. Because of the brittle nature of coal, coal dust can be created during mining, transportation, or by mechanically handling coal.-Explosions:...

is air-blown into the furnace from fuel nozzles at the four corners and it rapidly burns, forming a large fireball at the center. The thermal radiation

Thermal radiation

Thermal radiation is electromagnetic radiation generated by the thermal motion of charged particles in matter. All matter with a temperature greater than absolute zero emits thermal radiation....

of the fireball heats the water that circulates through the boiler tubes near the boiler perimeter. The water circulation rate in the boiler is three to four times the throughput and is typically driven by pumps. As the water in the boiler

Boiler

A boiler is a closed vessel in which water or other fluid is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications.-Materials:...

circulates it absorbs heat and changes into steam at 700 °F (371.1 °C) and 3200 psi (2,249,054,366,727.8 mp). It is separated from the water inside a drum at the top of the furnace. The saturated steam is introduced into superheat

Superheat

Superheat is a live album by Dutch alternative rock band The Gathering, released on 25 January 2000 by Century Media. The album was recorded at Paradiso, Amsterdam, Netherlands on 16 April 1999, with the exception of "Rescue Me" & "Strange Machines", which were recorded at 013, Tilburg, Netherlands...

pendant tubes that hang in the hottest part of the combustion gases as they exit the furnace. Here the steam is superheated to 1000 °F (537.8 °C) to prepare it for the turbine.

Plants designed for lignite

Lignite

Lignite, often referred to as brown coal, or Rosebud coal by Northern Pacific Railroad,is a soft brown fuel with characteristics that put it somewhere between coal and peat...

(brown coal) are increasingly used in locations as varied as Germany

Germany

Germany , officially the Federal Republic of Germany , is a federal parliamentary republic in Europe. The country consists of 16 states while the capital and largest city is Berlin. Germany covers an area of 357,021 km2 and has a largely temperate seasonal climate...

, Victoria

Victoria (Australia)

Victoria is the second most populous state in Australia. Geographically the smallest mainland state, Victoria is bordered by New South Wales, South Australia, and Tasmania on Boundary Islet to the north, west and south respectively....

, and North Dakota

North Dakota

North Dakota is a state located in the Midwestern region of the United States of America, along the Canadian border. The state is bordered by Canada to the north, Minnesota to the east, South Dakota to the south and Montana to the west. North Dakota is the 19th-largest state by area in the U.S....

. Lignite is a much younger form of coal than black coal. It has a lower energy density than black coal and requires a much larger furnace for equivalent heat output. Such coals may contain up to 70% water and ash, yielding lower furnace temperatures and requiring larger induced-draft fans. The firing systems also differ from black coal and typically draw hot gas from the furnace-exit level and mix it with the incoming coal in fan-type mills that inject the pulverized coal and hot gas mixture into the boiler.

Plants that use gas turbines to heat the water for conversion into steam use boilers known as heat recovery steam generators (HRSG). The exhaust heat from the gas turbines is used to make superheated steam that is then used in a conventional water-steam generation cycle, as described in gas turbine combined-cycle plants section below.

Boiler furnace and steam drum

Once water inside the boilerBoiler

A boiler is a closed vessel in which water or other fluid is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications.-Materials:...

or steam generator

Steam generator

A steam generator is a device used to boil water to create steam. It may refer to:*Boiler , a closed vessel in which water is heated under pressure...

, the process of adding the latent heat of vaporization or enthalpy

Enthalpy

Enthalpy is a measure of the total energy of a thermodynamic system. It includes the internal energy, which is the energy required to create a system, and the amount of energy required to make room for it by displacing its environment and establishing its volume and pressure.Enthalpy is a...

is underway. The boiler transfers energy to the water by the chemical reaction of burning some type of fuel.

The water enters the boiler through a section in the convection pass called the economizer

Economizer

Economizers , or economisers , are mechanical devices intended to reduce energy consumption, or to perform another useful function such as preheating a fluid. The term economizer is used for other purposes as well. Boiler, powerplant, and heating, ventilating, and air-conditioning uses are...

. From the economizer it passes to the steam drum

Steam drum

A steam drum is a standard feature of a water-tube boiler. It is a reservoir of water/steam at the top end of the water tubes. The drum stores the steam generated in the water tubes and acts as a phase-separator for the steam/water mixture...

. Once the water enters the steam drum it goes down to the lower inlet water wall headers. From the inlet headers the water rises through the water walls and is eventually turned into steam due to the heat being generated by the burners located on the front and rear water walls (typically). As the water is turned into steam/vapor in the water walls, the steam/vapor once again enters the steam drum. The steam/vapor is passed through a series of steam and water separators and then dryers inside the steam drum. The steam separator

Steam separator

A Steam separator, sometimes referred to as a moisture separator, is a device for separating water droplets from steam. The simplest type of steam separator is the steam dome on a steam locomotive...

s and dryers remove water droplets from the steam and the cycle through the water walls is repeated. This process is known as natural circulation

Natural circulation

Natural circulation refers to the ability of a fluid in a system to circulate continuously, with gravity and changes in heat energy being the only driving force. This force is known as "thermal head" or "thermal driving head."...

.

The boiler furnace auxiliary equipment includes coal

Coal

Coal is a combustible black or brownish-black sedimentary rock usually occurring in rock strata in layers or veins called coal beds or coal seams. The harder forms, such as anthracite coal, can be regarded as metamorphic rock because of later exposure to elevated temperature and pressure...

feed nozzles and igniter guns, soot blower

Soot blower

A Sootblower is a system for removing the soot that is deposited on the furnace tubes of a boiler during combustion. Various types of soot blowers such as Wall Blowers, Long Retractable Blowers and Air Heater Blowers are used for the cleaning...

s, water lancing and observation ports (in the furnace walls) for observation of the furnace interior. Furnace explosion

Explosion

An explosion is a rapid increase in volume and release of energy in an extreme manner, usually with the generation of high temperatures and the release of gases. An explosion creates a shock wave. If the shock wave is a supersonic detonation, then the source of the blast is called a "high explosive"...

s due to any accumulation of combustible gases after a trip-out are avoided by flushing out such gases from the combustion zone before igniting the coal.

The steam drum (as well as the super heater coils and headers) have air vents and drains needed for initial start up. The steam drum has internal devices that removes moisture from the wet steam entering the drum from the steam generating tubes. The dry steam then flows into the super heater coils.

Superheater

Fossil fuel power plants can have a superheater and/or re-heater section in the steam generating furnace. In a fossil fuel plant, after the steam is conditioned by the drying equipment inside the steam drum, it is piped from the upper drum area into tubes inside an area of the furnace known as the superheater, which has an elaborate set up of tubing where the steam vapor picks up more energy from hot flue gases outside the tubing and its temperature is now superheated above the saturation temperature. The superheated steam is then piped through the main steam lines to the valves before the high pressure turbine.Nuclear-powered steam plants do not have such sections but produce steam at essentially saturated conditions. Experimental nuclear plants were equipped with fossil-fired super heaters in an attempt to improve overall plant operating cost.

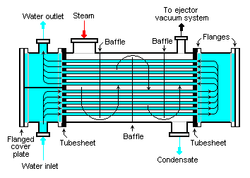

Steam condensing

The condenser condenses the steam from the exhaust of the turbine into liquid to allow it to be pumped. If the condenser can be made cooler, the pressure of the exhaust steam is reduced and efficiency of the cycleRankine cycle

The Rankine cycle is a cycle that converts heat into work. The heat is supplied externally to a closed loop, which usually uses water. This cycle generates about 90% of all electric power used throughout the world, including virtually all solar thermal, biomass, coal and nuclear power plants. It is...

increases.

Shell and tube heat exchanger

A shell and tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell with a...

in which cooling water is circulated through the tubes. The exhaust steam from the low pressure turbine enters the shell where it is cooled and converted to condensate (water) by flowing over the tubes as shown in the adjacent diagram. Such condensers use steam ejector

Injector

ʎ̩An injector, ejector, steam ejector, steam injector, eductor-jet pump or thermocompressor is a pump-like device that uses the Venturi effect of a converging-diverging nozzle to convert the pressure energy of a motive fluid to velocity energy which creates a low pressure zone that dɯaws in and...

s or rotary motor-driven exhausters for continuous removal of air and gases from the steam side to maintain vacuum

Vacuum

In everyday usage, vacuum is a volume of space that is essentially empty of matter, such that its gaseous pressure is much less than atmospheric pressure. The word comes from the Latin term for "empty". A perfect vacuum would be one with no particles in it at all, which is impossible to achieve in...

.

For best efficiency, the temperature in the condenser must be kept as low as practical in order to achieve the lowest possible pressure in the condensing steam. Since the condenser temperature can almost always be kept significantly below 100 °C where the vapor pressure

Vapor pressure

Vapor pressure or equilibrium vapor pressure is the pressure of a vapor in thermodynamic equilibrium with its condensed phases in a closed system. All liquids have a tendency to evaporate, and some solids can sublimate into a gaseous form...

of water is much less than atmospheric pressure, the condenser generally works under vacuum

Vacuum

In everyday usage, vacuum is a volume of space that is essentially empty of matter, such that its gaseous pressure is much less than atmospheric pressure. The word comes from the Latin term for "empty". A perfect vacuum would be one with no particles in it at all, which is impossible to achieve in...

. Thus leaks of non-condensible air into the closed loop must be prevented.

Typically the cooling water causes the steam to condense at a temperature of about 35 °C (95 °F) and that creates an absolute pressure in the condenser of about 2–7 kPa (0.590599428890352–2.1 inHg), i.e. a vacuum

Vacuum

In everyday usage, vacuum is a volume of space that is essentially empty of matter, such that its gaseous pressure is much less than atmospheric pressure. The word comes from the Latin term for "empty". A perfect vacuum would be one with no particles in it at all, which is impossible to achieve in...

of about -95 kPa relative to atmospheric pressure. The large decrease in volume that occurs when water vapor condenses to liquid creates the low vacuum that helps pull steam through and increase the efficiency of the turbines.

The limiting factor is the temperature of the cooling water and that, in turn, is limited by the prevailing average climatic conditions at the power plant's location (it may be possible to lower the temperature beyond the turbine limits during winter, causing excessive condensation in the turbine). Plants operating in hot climates may have to reduce output if their source of condenser cooling water becomes warmer; unfortunately this usually coincides with periods of high electrical demand for air conditioning

Air conditioning

An air conditioner is a home appliance, system, or mechanism designed to dehumidify and extract heat from an area. The cooling is done using a simple refrigeration cycle...

.

The condenser generally uses either circulating cooling water from a cooling tower

Cooling tower

Cooling towers are heat removal devices used to transfer process waste heat to the atmosphere. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet-bulb air temperature or in the case of closed circuit dry cooling towers rely...

to reject waste heat to the atmosphere, or once-through water from a river, lake or ocean.

Cooling tower

Cooling towers are heat removal devices used to transfer process waste heat to the atmosphere. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet-bulb air temperature or in the case of closed circuit dry cooling towers rely...

s (as seen in the image to the right) that reduce the temperature of the water by evaporation, by about 11 to 17 °C (20 to 30 °F)—expelling waste heat

Waste heat

Waste heat sometimes called Secondary heat or Low-grade heat refers to heat produced by machines, electrical equipment and industrial processes for which no useful application is found. Energy is often produced by a heat engine, running on a source of high-temperature heat...

to the atmosphere. The circulation flow rate of the cooling water in a 500 MW

MW

-Transportation:* Maintenance of way, railroad upkeep* Maya Island Air IATA airline designator-Games:* Mafia Wars, a game on Facebook* MechWarrior, a profession in the fictional universe of BattleTech...

unit is about 14.2 m³/s (500 ft³/s or 225,000 US gal/min) at full load.

The condenser tubes are made of brass

Brass

Brass is an alloy of copper and zinc; the proportions of zinc and copper can be varied to create a range of brasses with varying properties.In comparison, bronze is principally an alloy of copper and tin...

or stainless steel

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

to resist corrosion from either side. Nevertheless they may become internally fouled during operation by bacteria or algae in the cooling water or by mineral scaling, all of which inhibit heat transfer and reduce thermodynamic efficiency. Many plants include an automatic cleaning system that circulates sponge rubber balls through the tubes to scrub them clean without the need to take the system off-line.

The cooling water used to condense the steam in the condenser returns to its source without having been changed other than having been warmed. If the water returns to a local water body (rather than a circulating cooling tower), it is tempered with cool 'raw' water to prevent thermal shock when discharged into that body of water.

Another form of condensing system is the air-cooled condenser. The process is similar to that of a radiator

Radiator

Radiators are heat exchangers used to transfer thermal energy from one medium to another for the purpose of cooling and heating. The majority of radiators are constructed to function in automobiles, buildings, and electronics...

and fan. Exhaust heat from the low pressure section of a steam turbine runs through the condensing tubes, the tubes are usually finned and ambient air is pushed through the fins with the help of a large fan. The steam condenses to water to be reused in the water-steam cycle. Air-cooled condensers typically operate at a higher temperature than water-cooled versions. While saving water, the efficiency of the cycle is reduced (resulting in more carbon dioxide per megawatt of electricity).

From the bottom of the condenser, powerful condensate pump

Condensate pump

A condensate pump is a specific type of pump used to pump the condensate produced in an HVAC , refrigeration, condensing boiler furnace or steam system...

s recycle the condensed steam (water) back to the water/steam cycle.

Reheater

Power plant furnaces may have a reheater section containing tubes heated by hot flue gases outside the tubes. Exhaust steam from the high pressure turbine is passed through these heated tubes to collect more energy before driving the intermediate and then low pressure turbines.Air path

External fans are provided to give sufficient air for combustion. The forced draft fan takes air from the atmosphere and, first warming it in the air preheater for better combustion, injects it via the air nozzles on the furnace wall.The induced draft fan assists the FD fan by drawing out combustible gases from the furnace, maintaining a slightly negative pressure in the furnace to avoid backfiring through any opening.

Steam turbine generator

Turbine

A turbine is a rotary engine that extracts energy from a fluid flow and converts it into useful work.The simplest turbines have one moving part, a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades, or the blades react to the flow, so that they move and...

s interconnected to each other and a generator on a common shaft. There is a high pressure turbine at one end, followed by an intermediate pressure turbine, two low pressure turbines, and the generator. As steam moves through the system and loses pressure and thermal energy it expands in volume, requiring increasing diameter and longer blades at each succeeding stage to extract the remaining energy. The entire rotating mass may be over 200 metric tons and 100 feet (30.5 m) long. It is so heavy that it must be kept turning slowly even when shut down (at 3 rpm

Revolutions per minute

Revolutions per minute is a measure of the frequency of a rotation. It annotates the number of full rotations completed in one minute around a fixed axis...

) so that the shaft will not bow even slightly and become unbalanced. This is so important that it is one of only five functions of blackout emergency power batteries on site. Other functions are emergency lighting, communication

Communication

Communication is the activity of conveying meaningful information. Communication requires a sender, a message, and an intended recipient, although the receiver need not be present or aware of the sender's intent to communicate at the time of communication; thus communication can occur across vast...

, station alarms and turbogenerator lube oil.

Superheated steam from the boiler is delivered through 14–16 in (355.6–406.4 mm) diameter piping to the high pressure turbine where it falls in pressure to 600 psi (4.1 MPa) and to 600 °F (315.6 °C) in temperature through the stage. It exits via 24–26 in (609.6–660.4 mm) diameter cold reheat lines and passes back into the boiler where the steam is reheated in special reheat pendant tubes back to 1000 °F (537.8 °C). The hot reheat steam is conducted to the intermediate pressure turbine where it falls in both temperature

Temperature

Temperature is a physical property of matter that quantitatively expresses the common notions of hot and cold. Objects of low temperature are cold, while various degrees of higher temperatures are referred to as warm or hot...

and pressure

Pressure

Pressure is the force per unit area applied in a direction perpendicular to the surface of an object. Gauge pressure is the pressure relative to the local atmospheric or ambient pressure.- Definition :...

and exits directly to the long-bladed low pressure turbines and finally exits to the condenser.

The generator, 30 feet (9.1 m) long and 12 feet (3.7 m) in diameter, contains a stationary stator

Stator

The stator is the stationary part of a rotor system, found in an electric generator, electric motor and biological rotors.Depending on the configuration of a spinning electromotive device the stator may act as the field magnet, interacting with the armature to create motion, or it may act as the...

and a spinning rotor

Rotor (electric)

The rotor is the non-stationary part of a rotary electric motor, electric generator or alternator, which rotates because the wires and magnetic field of the motor are arranged so that a torque is developed about the rotor's axis. In some designs, the rotor can act to serve as the motor's armature,...

, each containing miles of heavy copper

Copper

Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish...

conductor—no permanent magnet

Magnet

A magnet is a material or object that produces a magnetic field. This magnetic field is invisible but is responsible for the most notable property of a magnet: a force that pulls on other ferromagnetic materials, such as iron, and attracts or repels other magnets.A permanent magnet is an object...

s here. In operation it generates up to 21,000 ampere

Ampere

The ampere , often shortened to amp, is the SI unit of electric current and is one of the seven SI base units. It is named after André-Marie Ampère , French mathematician and physicist, considered the father of electrodynamics...

s at 24,000 volt

Volt

The volt is the SI derived unit for electric potential, electric potential difference, and electromotive force. The volt is named in honor of the Italian physicist Alessandro Volta , who invented the voltaic pile, possibly the first chemical battery.- Definition :A single volt is defined as the...

s AC

Alternating current

In alternating current the movement of electric charge periodically reverses direction. In direct current , the flow of electric charge is only in one direction....

(504 MWe) as it spins at either 3,000 or 3,600 rpm

Revolutions per minute

Revolutions per minute is a measure of the frequency of a rotation. It annotates the number of full rotations completed in one minute around a fixed axis...

, synchronized to the power grid. The rotor spins in a sealed chamber cooled with hydrogen

Hydrogen

Hydrogen is the chemical element with atomic number 1. It is represented by the symbol H. With an average atomic weight of , hydrogen is the lightest and most abundant chemical element, constituting roughly 75% of the Universe's chemical elemental mass. Stars in the main sequence are mainly...

gas, selected because it has the highest known heat transfer coefficient of any gas and for its low viscosity

Viscosity

Viscosity is a measure of the resistance of a fluid which is being deformed by either shear or tensile stress. In everyday terms , viscosity is "thickness" or "internal friction". Thus, water is "thin", having a lower viscosity, while honey is "thick", having a higher viscosity...

which reduces windage

Windage

Windage is a force created on an object by friction when there is relative movement between air and the object.There are two causes of windage:# the object is moving and being slowed by resistance from the air...

losses. This system requires special handling during startup, with air in the chamber first displaced by carbon dioxide

Carbon dioxide

Carbon dioxide is a naturally occurring chemical compound composed of two oxygen atoms covalently bonded to a single carbon atom...

before filling with hydrogen. This ensures that the highly explosive hydrogen–oxygen

Oxygen

Oxygen is the element with atomic number 8 and represented by the symbol O. Its name derives from the Greek roots ὀξύς and -γενής , because at the time of naming, it was mistakenly thought that all acids required oxygen in their composition...

environment is not created.

The power grid frequency

Utility frequency

The utility frequency, line frequency or mains frequency is the frequency at which alternating current is transmitted from a power plant to the end-user. In most parts of the world this is 50 Hz, although in the Americas it is typically 60 Hz...

is 60 Hz

Hertz

The hertz is the SI unit of frequency defined as the number of cycles per second of a periodic phenomenon. One of its most common uses is the description of the sine wave, particularly those used in radio and audio applications....

across North America

North America

North America is a continent wholly within the Northern Hemisphere and almost wholly within the Western Hemisphere. It is also considered a northern subcontinent of the Americas...

and 50 Hz in Europe

Europe

Europe is, by convention, one of the world's seven continents. Comprising the westernmost peninsula of Eurasia, Europe is generally 'divided' from Asia to its east by the watershed divides of the Ural and Caucasus Mountains, the Ural River, the Caspian and Black Seas, and the waterways connecting...

, Oceania

Oceania

Oceania is a region centered on the islands of the tropical Pacific Ocean. Conceptions of what constitutes Oceania range from the coral atolls and volcanic islands of the South Pacific to the entire insular region between Asia and the Americas, including Australasia and the Malay Archipelago...

, Asia

Asia

Asia is the world's largest and most populous continent, located primarily in the eastern and northern hemispheres. It covers 8.7% of the Earth's total surface area and with approximately 3.879 billion people, it hosts 60% of the world's current human population...

(Korea

Korea

Korea ) is an East Asian geographic region that is currently divided into two separate sovereign states — North Korea and South Korea. Located on the Korean Peninsula, Korea is bordered by the People's Republic of China to the northwest, Russia to the northeast, and is separated from Japan to the...

and parts of Japan

Japan

Japan is an island nation in East Asia. Located in the Pacific Ocean, it lies to the east of the Sea of Japan, China, North Korea, South Korea and Russia, stretching from the Sea of Okhotsk in the north to the East China Sea and Taiwan in the south...

are notable exceptions) and parts of Africa

Africa

Africa is the world's second largest and second most populous continent, after Asia. At about 30.2 million km² including adjacent islands, it covers 6% of the Earth's total surface area and 20.4% of the total land area...

.

The electricity flows to a distribution yard where transformer

Transformer

A transformer is a device that transfers electrical energy from one circuit to another through inductively coupled conductors—the transformer's coils. A varying current in the first or primary winding creates a varying magnetic flux in the transformer's core and thus a varying magnetic field...

s increase the voltage for transmission to its destination.

The steam turbine-driven generators

Turbo generator

A turbo generator is a turbine directly connected to an electric generator for the generation of electric power. Large steam powered turbo generators provide the majority of the world's electricity and are also used by steam powered turbo-electric ships.Smaller turbo-generators with gas turbines...

have auxiliary systems enabling them to work satisfactorily and safely. The steam turbine generator being rotating equipment generally has a heavy, large diameter shaft. The shaft therefore requires not only supports but also has to be kept in position while running. To minimize the frictional resistance to the rotation, the shaft has a number of bearings

Bearing (mechanical)

A bearing is a device to allow constrained relative motion between two or more parts, typically rotation or linear movement. Bearings may be classified broadly according to the motions they allow and according to their principle of operation as well as by the directions of applied loads they can...

. The bearing shells, in which the shaft rotates, are lined with a low friction material like Babbitt metal

Babbitt metal

Babbitt, also called Babbitt metal or bearing metal, is any of several alloys used for the bearing surface in a plain bearing.The original Babbitt metal was invented in 1839 by Isaac Babbitt in Taunton, Massachusetts, USA. Other formulations were later developed...

. Oil lubrication is provided to further reduce the friction between shaft and bearing surface and to limit the heat generated.

Stack gas path and cleanup

- see Flue gas emissions from fossil fuel combustionFlue gas emissions from fossil fuel combustionFlue-gas emissions from fossil-fuel combustion refers to the combustion product gas resulting from the much as 10 to 25 volume percent or more of the flue gas. This is closely followed in volume by water vapor created by the combustion of the hydrogen in the fuel with atmospheric oxygen...

and Flue gas desulfurizationFlue gas desulfurizationSulfur dioxide is one of the elements forming acid rain. Tall flue-gas stacks disperse emissions by diluting the pollutants in ambient air and transporting them to other regions....

for more details

As the combustion flue gas

Flue gas

Flue gas is the gas exiting to the atmosphere via a flue, which is a pipe or channel for conveying exhaust gases from a fireplace, oven, furnace, boiler or steam generator. Quite often, the flue gas refers to the combustion exhaust gas produced at power plants...

exits the boiler it is routed through a rotating flat basket of metal mesh which picks up heat and returns it to incoming fresh air as the basket rotates, This is called the air preheater

Air preheater

An air preheater is a general term to describe any device designed to heat air before another process with the primary objective of increasing the thermal efficiency of the process...

. The gas exiting the boiler is laden with fly ash

Fly ash

Fly ash is one of the residues generated in combustion, and comprises the fine particles that rise with the flue gases. Ash which does not rise is termed bottom ash. In an industrial context, fly ash usually refers to ash produced during combustion of coal...

, which are tiny spherical ash particles. The flue gas contains nitrogen

Nitrogen

Nitrogen is a chemical element that has the symbol N, atomic number of 7 and atomic mass 14.00674 u. Elemental nitrogen is a colorless, odorless, tasteless, and mostly inert diatomic gas at standard conditions, constituting 78.08% by volume of Earth's atmosphere...

along with combustion products carbon dioxide

Carbon dioxide

Carbon dioxide is a naturally occurring chemical compound composed of two oxygen atoms covalently bonded to a single carbon atom...

, sulfur dioxide

Sulfur dioxide

Sulfur dioxide is the chemical compound with the formula . It is released by volcanoes and in various industrial processes. Since coal and petroleum often contain sulfur compounds, their combustion generates sulfur dioxide unless the sulfur compounds are removed before burning the fuel...

, and nitrogen oxide

Nitrogen oxide

Nitrogen oxide can refer to a binary compound of oxygen and nitrogen, or a mixture of such compounds:* Nitric oxide, also known as nitrogen monoxide, , nitrogen oxide* Nitrogen dioxide , nitrogen oxide...

s. The fly ash is removed by fabric bag filters or electrostatic precipitator

Electrostatic precipitator

An electrostatic precipitator , or electrostatic air cleaner is a particulate collection device that removes particles from a flowing gas using the force of an induced electrostatic charge...

s. Once removed, the fly ash byproduct can sometimes be used in the manufacturing of concrete

Concrete

Concrete is a composite construction material, composed of cement and other cementitious materials such as fly ash and slag cement, aggregate , water and chemical admixtures.The word concrete comes from the Latin word...

. This cleaning up of flue gases, however, only occurs in plants that are fitted with the appropriate technology. Still, the majority of coal fired power plants in the world do not have these facilities. Legislation in Europe has been efficient to reduce flue gas pollution. Japan has been using flue gas cleaning technology for over 30 years and the US has been doing the same for over 25 years. China is now beginning to grapple with the pollution caused by coal fired power plants.

Where required by law, the sulfur and nitrogen oxide pollutant

Pollutant

A pollutant is a waste material that pollutes air, water or soil, and is the cause of pollution.Three factors determine the severity of a pollutant: its chemical nature, its concentration and its persistence. Some pollutants are biodegradable and therefore will not persist in the environment in the...

s are removed by stack gas scrubber

Flue gas desulfurization

Sulfur dioxide is one of the elements forming acid rain. Tall flue-gas stacks disperse emissions by diluting the pollutants in ambient air and transporting them to other regions....

s which use a pulverized limestone

Limestone

Limestone is a sedimentary rock composed largely of the minerals calcite and aragonite, which are different crystal forms of calcium carbonate . Many limestones are composed from skeletal fragments of marine organisms such as coral or foraminifera....

or other alkaline wet slurry to remove those pollutants from the exit stack gas. Other devices use catalysts to remove Nitrous Oxide compounds from the flue gas stream. The gas travelling up the flue gas stack

Flue gas stack

A flue-gas stack is a type of chimney, a vertical pipe, channel or similar structure through which combustion product gases called flue gases are exhausted to the outside air. Flue gases are produced when coal, oil, natural gas, wood or any other fuel is combusted in an industrial furnace, a power...

may by this time have dropped to about 50 °C (122 °F). A typical flue gas stack may be 150–180 m (492.1–590.6 ft) tall to disperse the remaining flue gas components in the atmosphere. The tallest flue gas stack in the world is 419.7 metres (1,377 ft) tall at the GRES-2

GRES-2 Power Station

The GRES-2 Power Station is a coal-fueled power generating station in Ekibastuz, Kazakhstan. GRES-2, built in 1987, has installed capacity of 1,000 MWe and has the world's tallest flue gas stack at high. The chimney is about taller than the Inco Superstack in Sudbury, Canada. Locals refer to it...

power plant in Ekibastuz

Ekibastuz

Ekibastuz is a town in Pavlodar Province, northeastern Kazakhstan. it had a population of 141,000. It is served by Ekibastuz Airport.-History:...

, Kazakhstan

Kazakhstan

Kazakhstan , officially the Republic of Kazakhstan, is a transcontinental country in Central Asia and Eastern Europe. Ranked as the ninth largest country in the world, it is also the world's largest landlocked country; its territory of is greater than Western Europe...

.

In the United States and a number of other countries, atmospheric dispersion modeling

Atmospheric dispersion modeling

Atmospheric dispersion modeling is the mathematical simulation of how air pollutants disperse in the ambient atmosphere. It is performed with computer programs that solve the mathematical equations and algorithms which simulate the pollutant dispersion...

studies are required to determine the flue gas stack height needed to comply with the local air pollution

Air pollution

Air pollution is the introduction of chemicals, particulate matter, or biological materials that cause harm or discomfort to humans or other living organisms, or cause damage to the natural environment or built environment, into the atmosphere....

regulations. The United States also requires the height of a flue gas stack to comply with what is known as the "Good Engineering Practice

Good Engineering Practice

"Good engineering practice" or "GEP" is a term applied to engineering and technical activities to ensure that a company manufactures products of the required quality as expected by the relevant regulatory authorities...

(GEP)" stack height. In the case of existing flue gas stacks that exceed the GEP stack height, any air pollution dispersion modeling studies for such stacks must use the GEP stack height rather than the actual stack height.

Fly ash collection

Fly ashFly ash

Fly ash is one of the residues generated in combustion, and comprises the fine particles that rise with the flue gases. Ash which does not rise is termed bottom ash. In an industrial context, fly ash usually refers to ash produced during combustion of coal...

is captured and removed from the flue gas by electrostatic precipitators or fabric bag filters (or sometimes both) located at the outlet of the furnace and before the induced draft fan. The fly ash is periodically removed from the collection hoppers below the precipitators or bag filters. Generally, the fly ash is pneumatically transported to storage silos for subsequent transport by trucks or railroad cars .

Bottom ash collection and disposal

At the bottom of the furnace, there is a hopper for collection of bottom ashBottom ash

Bottom ash refers to part of the non-combustible residues of combustion. In an industrial context, it usually refers to coal combustion and comprises traces of combustibles embedded in forming clinkers and sticking to hot side walls of a coal-burning furnace during its operation. The portion of...

. This hopper is always filled with water to quench the ash and clinkers falling down from the furnace. Some arrangement is included to crush the clinkers and for conveying the crushed clinkers and bottom ash to a storage site .

Boiler make-up water treatment plant and storage

Since there is continuous withdrawal of steam and continuous return of condensateCondensation

Condensation is the change of the physical state of matter from gaseous phase into liquid phase, and is the reverse of vaporization. When the transition happens from the gaseous phase into the solid phase directly, the change is called deposition....

to the boiler, losses due to blowdown and leakages have to be made up to maintain a desired water level in the boiler steam drum. For this, continuous make-up water is added to the boiler water system. Impurities in the raw water input to the plant generally consist of calcium

Calcium

Calcium is the chemical element with the symbol Ca and atomic number 20. It has an atomic mass of 40.078 amu. Calcium is a soft gray alkaline earth metal, and is the fifth-most-abundant element by mass in the Earth's crust...

and magnesium

Magnesium

Magnesium is a chemical element with the symbol Mg, atomic number 12, and common oxidation number +2. It is an alkaline earth metal and the eighth most abundant element in the Earth's crust and ninth in the known universe as a whole...

salts which impart hardness to the water. Hardness in the make-up water to the boiler will form deposits on the tube water surfaces which will lead to overheating and failure of the tubes. Thus, the salts have to be removed from the water, and that is done by a water demineralising treatment plant (DM). A DM plant generally consists of cation, anion, and mixed bed exchangers. Any ions in the final water from this process consist essentially of hydrogen ions and hydroxide ions, which recombine to form pure water. Very pure DM water becomes highly corrosive once it absorbs oxygen from the atmosphere because of its very high affinity for oxygen.

The capacity of the DM plant is dictated by the type and quantity of salts in the raw water input. However, some storage is essential as the DM plant may be down for maintenance. For this purpose, a storage tank is installed from which DM water is continuously withdrawn for boiler make-up. The storage tank for DM water is made from materials not affected by corrosive water, such as PVC

Polyvinyl chloride

Polyvinyl chloride, commonly abbreviated PVC, is a thermoplastic polymer. It is a vinyl polymer constructed of repeating vinyl groups having one hydrogen replaced by chloride. Polyvinyl chloride is the third most widely produced plastic, after polyethylene and polypropylene. PVC is widely used in...

. The piping and valves are generally of stainless steel. Sometimes, a steam blanketing arrangement or stainless steel doughnut float is provided on top of the water in the tank to avoid contact with air. DM water make-up is generally added at the steam space of the surface condenser (i.e., the vacuum side). This arrangement not only sprays the water but also DM water gets deaerated, with the dissolved gases being removed by an air ejector attached to the condenser.

Fuel preparation system

In coal-fired power stations, the raw feed coal from the coal storage area is first crushed into small pieces and then conveyed to the coal feed hoppers at the boilers. The coal is next pulverized into a very fine powder. The pulverizers may be ball millBall mill

A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, and ceramics.-Description:...

s, rotating drum grinders, or other types of grinders.

Some power stations burn fuel oil

Fuel oil

Fuel oil is a fraction obtained from petroleum distillation, either as a distillate or a residue. Broadly speaking, fuel oil is any liquid petroleum product that is burned in a furnace or boiler for the generation of heat or used in an engine for the generation of power, except oils having a flash...

rather than coal. The oil must kept warm (above its pour point

Pour point

The pour point of a liquid is the lowest temperature at which it will pour or flow under prescribed conditions. It is a rough indication of the lowest temperature at which oil is readily pumpable. In crude oil a high pour point is generally assosiated with a high paraffin content. And typically...

) in the fuel oil storage tanks to prevent the oil from congealing and becoming unpumpable. The oil is usually heated to about 100 °C before being pumped through the furnace fuel oil spray nozzles.

Boilers in some power stations use processed natural gas

Natural gas processing

Natural-gas processing is a complex industrial process designed to clean raw natural gas by separating impurities and various non-methane hydrocarbons and fluids to produce what is known as pipeline quality dry natural gas.-Background:...

as their main fuel. Other power stations may use processed natural gas as auxiliary fuel in the event that their main fuel supply (coal or oil) is interrupted. In such cases, separate gas burners are provided on the boiler furnaces.

Barring gear

Barring gear (or "turning gear") is the mechanism provided to rotate the turbine generator shaft at a very low speed after unit stoppages. Once the unit is "tripped" (i.e., the steam inlet valve is closed), the turbine coasts down towards standstill. When it stops completely, there is a tendency for the turbine shaft to deflect or bend if allowed to remain in one position too long. This is because the heat inside the turbine casing tends to concentrate in the top half of the casing, making the top half portion of the shaft hotter than the bottom half. The shaft therefore could warp or bend by millionths of inches.This small shaft deflection, only detectable by eccentricity meters, would be enough to cause damaging vibrations to the entire steam turbine generator unit when it is restarted. The shaft is therefore automatically turned at low speed (about one percent rated speed) by the barring gear until it has cooled sufficiently to permit a complete stop.

Oil system

An auxiliary oil system pump is used to supply oil at the start-up of the steam turbine generator. It supplies the hydraulic oil system required for steam turbine's main inlet steam stop valve, the governing control valves, the bearing and seal oil systems, the relevant hydraulic relays and other mechanisms.At a preset speed of the turbine during start-ups, a pump driven by the turbine main shaft takes over the functions of the auxiliary system.

Generator cooling

While small generators may be cooled by air drawn through filters at the inlet, larger units generally require special cooling arrangements. HydrogenHydrogen

Hydrogen is the chemical element with atomic number 1. It is represented by the symbol H. With an average atomic weight of , hydrogen is the lightest and most abundant chemical element, constituting roughly 75% of the Universe's chemical elemental mass. Stars in the main sequence are mainly...

gas cooling, in an oil-sealed casing, is used because it has the highest known heat transfer coefficient of any gas and for its low viscosity

Viscosity

Viscosity is a measure of the resistance of a fluid which is being deformed by either shear or tensile stress. In everyday terms , viscosity is "thickness" or "internal friction". Thus, water is "thin", having a lower viscosity, while honey is "thick", having a higher viscosity...

which reduces windage

Windage

Windage is a force created on an object by friction when there is relative movement between air and the object.There are two causes of windage:# the object is moving and being slowed by resistance from the air...

losses. This system requires special handling during start-up, with air in the generator enclosure first displaced by carbon dioxide

Carbon dioxide

Carbon dioxide is a naturally occurring chemical compound composed of two oxygen atoms covalently bonded to a single carbon atom...

before filling with hydrogen. This ensures that the highly flammable hydrogen does not mix with oxygen

Oxygen