RBMK

Encyclopedia

RBMK is an initialism for the Russian reaktor bolshoy moshchnosti kanalniy which means "High Power Channel-type Reactor", and describes a class of graphite-moderated nuclear power reactor

which was built in the Soviet Union

. The RBMK reactor was the type involved in the Chernobyl disaster

. In 2010, there were at least 11 RBMK reactors operating in Russia, but there are no plans to build new RBMK type reactors (the RBMK technology was developed in the 1950s and is now considered obsolete) and there is international pressure to close those that remain.

The RBMK was the culmination of the Soviet nuclear power program to produce a water-cooled power reactor based on their graphite-moderated plutonium

The RBMK was the culmination of the Soviet nuclear power program to produce a water-cooled power reactor based on their graphite-moderated plutonium

production military reactors. The first of these, AM-1

("Атом Мирный", Atom Mirny, Russian for "peaceful atom") produced 5 MW of electricity (30 MW thermal) and delivered power to Obninsk

from 1954 until 1959.

Using light water for cooling and graphite for moderation

, it is possible to use natural uranium

for fuel. Thus, a large power reactor (RBMK reactors at the Ignalina Nuclear Power Plant

in Lithuania were rated at 1500 MWe each, a very large size for the time and even for today) can be built that requires no separated

isotope

s, such as enriched uranium

or heavy water

.

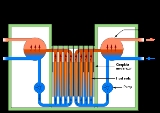

and has dimensions 21.6×21.6×25.5 meters. It houses the vessel of the reactor, made of a cylindrical wall and top and bottom metal plates. The vessel contains the graphite stack and is filled with a helium-nitrogen mixture for providing an inert atmosphere for the graphite and for mediation of heat transfer from the graphite to the coolant channels.

The moderator blocks are made of nuclear graphite

of dimensions 250×250×500 mm. There are holes with 11.4 cm (4.5 in) diameter through the longitudal axis of the blocks for the fuel and control channels. The blocks are stacked inside the reactor vessel into a cylindrical core 14 metre in diameter and 8 metre high. The maximum allowed temperature of the graphite is less or equal to 730 °C (1,346 °F).

The reactor vessel is a steel cylinder with outer diameter of 14.52 metre, wall thickness 16 mm (0.62992125984252 in), height 9.75 metre, and is equipped with a bellows compensator

to absorb axial thermal expansion loads.

The moderator is surrounded by a cylindrical water tank, a welded structure with 3 cm (1.2 in) thick walls, inner diameter of 16.6 metre and outer diameter of 19 metre, internally divided to 16 vertical compartments. The water is supplied to the compartments from the bottom and removed from the top; the water can be used for emergency reactor cooling. The tank contains thermocouples for sensing the water temperature and ion chambers for monitoring the reactor power. The tank, sand layer, and concrete of the reactor pit serve as additional biological shields.

The top of the reactor is covered by the Upper Biological Shield, also called Schema E, Pyatachok, or, after the explosion (of Chernobyl Reactor 4), Elena, a 3 metre thick cylinder 17 metre in diameter. It is penetrated by standpipe

s for fuel and control channel assemblies. The top and bottom are covered with 4 cm (1.57 in) thick steel plates, welded to be helium-tight, and additionally joined by structural supports. The space between the plates and pipes is filled with serpentinite

, a rock containing significant amount of bound water

. The disk is supported on 16 rollers, located on the upper side of the reinforced cylindrical water tank. The structure of the UBS supports the fuel and control channels, the floor above the reactor in the central hall, and the steam-water pipes.

Below the bottom of the reactor core there is the Lower Biological Shield, similar to the UBS, but only 14.5 metre in diameter and 2 metre thick. It is penetrated by the tubes for the lower ends of the pressure channels and carries the weight of the graphite stack and the coolant inlet piping. A steel structure, two heavy plates intersecting in right angle under the center of the LBS and welded to the LBS, supports the LBS and transfers the mechanical load to the building.

Above the UBS there is the upper shield cover; its top surface is the floor of the central hall. It serves as part of the biological shield and for thermal insulation of the reactor space. Its center area above the reactor channel consists of individual removable steel-graphite plugs, located over the tops of the channels.

pressure tubes 8 cm (3.1 in) in inner diameter with 4 mm (0.15748031496063 in) thick walls, led through the channels in the center of the graphite moderator

blocks. The top and bottom parts of the tubes are made of stainless steel

, and joined with the central zircaloy segment with zirconium-steel alloy couplings. The pressure tube is held in the graphite stack channels with two alternating types of 20 mm (0.78740157480315 in) high split graphite rings; one is in direct contact with the tube and has 1.5 mm (0.0590551181102362 in) clearance to the graphite stack, the other one is directly touching the graphite stack and has 1.3 mm (0.0511811023622047 in) clearance to the tube; this assembly reduces transfer of mechanical loads caused by neutron-induced swelling

, thermal expansion of the blocks, and other factors to the pressure tube, while facilitating heat transfer from the graphite blocks. The tubes are welded to the top and bottom metal plates of the reactor vessel.

It is estimated that about 5.5% of the core thermal power is in the form of graphite heat. About 80–85% of this heat is removed by the fuel rod coolant channels, via the graphite rings. The rest of the heat is removed by the control rod channel coolant. The gas circulating in the reactor plays the role of assisting the heat transfer to the coolant channels; itself plays almost no role in heat removal.

There are 1661 fuel channels and 211 control rod channels in the reactor core.

The fuel assembly is suspended in the fuel channel on a bracket, with a seal plug. The seal plug has a simple design, to facilitate its removal and installation by the remotely controlled refueling machine.

The fuel channels may instead of fuel contain fixed neutron absorbers, or be empty and just filled with the cooling water.

The small clearance between the pressure channel and the graphite block makes the graphite core susceptible to damage. If the pressure channel deforms, e.g. by too high internal pressure, the deformation or rupture can cause significant pressure loads to the graphite blocks and lead to their damage, and possibly propagate to neighboring channels.

The fuel pellets are made of uranium dioxide

The fuel pellets are made of uranium dioxide

powder, sintered with a suitable binder into barrels 1.15 cm (0.452755905511811 in) in diameter and 15 mm (0.590551181102362 in) long. The material may contain added europium oxide as a burnable nuclear poison

to lower the reactivity differences between a new and partially spent fuel assembly. To reduce thermal expansion issues and interaction with the cladding, the pellets have hemispherical indentations. A 2 mm (0.078740157480315 in) hole through the axis of the pellet serves to reduce the temperature in the center of the pellet and facilitates removal of gaseous fission products. The enrichment level

is 2% (0.4% for the end pellets of the assemblies). Maximum allowable temperature of the fuel pellet is 2100 °C (3,812 °F).

The fuel rods are zircaloy

(1% Nb) tubes 1.36 cm (0.535433070866142 in) in outer diameter, 0.825 m (32.4803 in) thick. The rods are filled with helium

at 0.5 MPa and hermetically sealed. Retaining rings help to seat the pellets in the center of the tube and facilitate heat transfer from the pellet to the tube. The pellets are axially held in place by a spring

. Each rod contains 3.5 kg (7.7 lb) of fuel pellets. The fuel rods are 3.64 metre long, with 3.4 metre of that being the active length. The maximum allowed temperature of a fuel rod is 600 °C (1,112 °F).

The fuel assemblies consist of two sets of 18 fuel rods. The rods are arranged along the central carrier rod (1.3 cm (0.511811023622047 in) outer diameter) and held in place with 10 stainless steel spacers separated by 360 mm (14.2 in) distance. The two sub-assemblies are joined with a cylinder at the center of the assembly; during the operation of the reactor, this dead space without fuel lowers the neutron flux in the central plane of the reactor. The total mass of uranium in the fuel assembly is 114.7 kg (252.9 lb). The fuel burnup

is 20 MW·d/kg. The total length of the fuel assembly is 10.025 metre, with 6.862 metre of the active region.

In addition to the regular fuel assemblies, there are instrumented ones, containing neutron flux detectors in the central carrier. In this case, the rod is replaced with a tube with wall thickness of 2.5 mm (0.0984251968503937 in); and outer diameter of 1.5 cm (0.590551181102362 in).

Unlike the rectangular PWR/BWR fuel assemblies, the RBMK fuel assembly is cylindrical to fit the round pressure channels.

The refueling machine is mounted on a gantry crane and remotely controlled. The fuel assemblies can be replaced without shutting down the reactor, a factor significant for production of weapon-grade plutonium and, in a civilian context, for better reactor uptime. When a fuel assembly has to be replaced, the machine is positioned above the fuel channel, mates to it, equalizes pressure within, pulls the rod, and inserts a fresh one. The spent rod is then placed in a cooling pond. The capacity of the refueling machine with the reactor at nominal power level is two fuel assemblies per day, with peak capacity of five per day.

s are inserted from above; 24 shortened rods are inserted from below and are used to augment the axial power distribution control of the core. With the exception of 12 automatic rods, the control rods have a 4.5 metre long graphite section at the end, separated by a 1.25 metre long telescope (which creates a water-filled space between the graphite and the absorber), and a boron carbide

neutron absorber section. The role of the graphite section, known as "displacer," is to enhance the difference between the neutron flux attenuation levels of inserted and retracted rods, as the graphite displaces water that would otherwise act as a neutron absorber, although much weaker than boron carbide; a control rod channel filled with graphite absorbs fewer neutrons than when filled with water, so the difference between inserted and retracted control rod is increased. When the control rod is fully retracted, the graphite displacer is located in the middle of the core height, with 1.25 m of water at each of its ends. The displacement of water in the lower 1.25 m of the core as the rod moves down causes a local increase of reactivity in the bottom of the core as the graphite part of the control rod passes that section. This "positive scram" effect was discovered in 1983 at the Ignalina Nuclear Power Plant

; however, the matter was soon forgotten. The control rod channels are cooled by an independent water circuit and kept at 40–70 °C (104–158 °F). The narrow space between the rod and its channel hinders water flow around the rods during their movement and acts as a fluid damper

, which is the primary cause of their slow insertion time (nominally 18–21 seconds for the RCPS rods, or about 0.4 m/s). After the Chernobyl disaster, the control rod servos on other RBMK reactors were exchanged to allow faster rod movements, and even faster movement was achieved by cooling of the control rod tubes by a thin layer of water while letting the rods themselves move in gas.

The division of the control rods between manual and emergency protection groups was arbitrary; the rods could be reassigned from one system to another during reactor operation without technical or organizational problems.

Additional static boron-based absorbers are inserted into the core when it is loaded with fresh fuel. About 240 absorbers are added during initial core loading. These absorbers are gradually removed with increasing burnup. The reactor's void coefficient depends on the core content; it ranges from negative with all the initial absorbers to positive when they are all removed.

The normal reactivity margin is 43–48 control rods.

–nitrogen

atmosphere (70–90% He, 10–30% N2). The gas circuit is composed of a compressor

, aerosol

and iodine filters, adsorber for carbon dioxide

, carbon monoxide

, and ammonia

, a holding tank for allowing the gaseous radioactive products to decay before being discharged, an aerosol filter to remove solid decay products, and a ventilator stack, the iconic chimney above the plant building. The gas is injected to the stack from the bottom in a low flow rate, and exits from the standpipe of each channel via an individual pipe. The moisture and temperature of the outlet gas is monitored; an increase of them is an indicator of a coolant leak.

s, pairs of thick horizontal drums located in side compartments above the reactor top; each has 2.8 metre diameter, 31 metre length, wall thickness of 10 cm (3.9 in), and weighs 240 t (264.6 ST). Steam, with steam quality of about 15%, is taken from the top of the separators by two steam collectors per separator, combined, and led to two turbogenerators in the turbine hall, then to condensers, reheated to 165 °C (329 °F), and pumped by the condensate pump

s to deaerator

s, where remains of gaseous phase and corrosion-inducing gases are removed. The resulting feedwater is led to the steam separators by feedwater pumps

and mixed with water from them at their outlets. From the bottom of the steam separators, the feedwater is led by 12 downpipes (from each separator) to the suction headers of the main circulation pumps, and back into the reactor. There is an ion exchange

system included in the loop to remove impurities from the feedwater.

The turbine consists of one high-pressure rotor and four low-pressure ones. Five low-pressure separators-preheaters are used to heat steam with fresh steam before being fed to the next stage of the turbine. The uncondensed steam is fed into a condenser, mixed with condensate from the separators, fed by the first-stage condensate pump to a chemical purifier, then by a second-stage condensate pump to four deaerators where dissolved and entrained gases are removed; deaerators also serve as storage tanks for feedwater. From the deaerators, the water is pumped through filters and into the bottom parts of the steam separator drums.

The main circulating pumps have the capacity of 5,500–12,000 m³/h and are powered by 6 kV electric motor

s. The normal coolant flow is 8000 m³/h per pump; this is throttled down by control valves to 6000–7000 m³/h when the reactor power is below 500 MWt. Each pump has a flow control valve and a backflow preventing check valve

on the outlet, and shutoff valves on both inlet and outlet. Each of the pressure channels in the core has its own flow control valve

so that the temperature distribution in the reactor core can be optimized. Each channel has a ball type flow meter.

The nominal coolant flow through the reactor is 46,000–48,000 m³/h. The steam flow at full power is 5440–5600 t (5,996.6–6,172.9 ST)/h.

The nominal temperature of the cooling water at the inlet of the reactor is about 265–270 °C (509–518 °F) and the outlet temperature 284 °C (543.2 °F), at pressure of 6.9 MPa (in the drum separator). The pressure and the inlet temperature determine the height at which the boiling begins in the reactor; if the coolant temperature is not sufficiently below its boiling point at the system pressure, the boiling starts at the very bottom part of the reactor instead of its higher parts; the positive void coefficient

of the reactor makes the reactor very sensitive to the feedwater temperature. If the coolant temperature is too close to its boiling point, cavitation

can occur in the pumps and their operation can become erratic or even stop entirely. The feedwater temperature is dependent on the steam production; the steam phase portion is led to the turbines and condensers and returns significantly cooler (155–165 °C (311–329 °F)) than the water returning directly from the steam separator (284 °C). At low reactor power, therefore, the inlet temperature may become dangerously high. The water is kept below the saturation temperature to prevent film boiling and the associated drop in heat transfer rate.

The reactor is tripped in case of too high or low water level in the steam separators (with two selectable low-level thresholds), high steam pressure, low feedwater flow, or loss of two main coolant pumps on either side. These trips can be manually disabled.

The level of water in the steam separators, the percentage of steam in the reactor pressure tubes, the level at which the water begins to boil in the reactor core, the neutron flux and power distribution in the reactor, and the feedwater flow through the core have to be carefully controlled. The level of water in the steam separator is mainly controlled by the feedwater supply, with the deaerator tanks serving as a water reservoir.

The maximum allowed heat-up rate of the reactor and the coolant is 10 °C (50 °F)/h; the maximum cool-down rate is 30 °C (86 °F)/h.

s come online. The Chernobyl disaster

occurred during a botched test of this system. The ECCS has three systems, connected to the coolant system headers. In case of damage, the first ECCS subsystem provides cooling for up to 100 seconds to the damaged half of the coolant circuit (the other half is cooled by the main circulation pumps), and the other two subsystems then handle long-term cooling of the reactor.

The short-term ECCS subsystem consists of two groups of six accumulator tanks, containing water blanketed with nitrogen under pressure of 10 MPa, connected by fast-acting valves to the reactor. Each group can supply 50% of the maximum coolant flow to the damaged half of the reactor. The third group is a set of electrical pumps drawing water from the deaerators. The short-term pumps can be powered by the spindown of the main turbogenerators.

ECCS for long-term cooling of the damaged circuit consists of three pairs of electrical pumps, drawing water from the pressure suppression pools; the water is cooled by the plant service water by means of heat exchangers in the suction lines. Each pair is able to supply half of the maximum coolant flow. ECCS for long-term cooling of the intact circuit consists of three separate pumps drawing water from the condensate storage tanks, each able to supply half of the maximum flow. The ECCS pumps are powered from the essential internal 6 kV lines, backed up by diesel generators. Some valves that require uninterrupted power are also backed up by batteries.

in the reactor is measured by ionization chamber

s located inside and outside the core. The physical power density distribution control system (PPDDCS) has sensors inside the core; the reactor control and protection system (RCPS) uses sensors in the core and in the lateral biological shield tank. The external sensors in the tank are located around the reactor middle plane, therefore do not indicate axial power distribution nor information about the power in the central part of the core. There are over 100 radial and 12 axial power distribution monitors, employing self-powered detectors. Reactivity meters and removable startup chambers are used for monitoring of reactor startup. Total reactor power is recorded as the sum of the currents of the lateral ionization chambers. The moisture and temperature of the gas circulating in the channels is monitored by the pressure tube integrity monitoring system.

The PPDCSS and RCPS are supposed to complement each other. The RCPS system consists of 211 movable control rods. Both systems, however, have deficiencies, most noticeably at low reactor power levels. The PPDDCS is designed to maintain reactor power density distribution between 10 and 120% of nominal levels and to control the total reactor power between 5 and 120% of nominal levels. The LAC-LAP (local automatic control and local automatic protection) RPCS subsystems rely on ionization chambers inside the reactor and are active at power levels above 10%. Below those levels, the automatic systems are disabled and the in-core sensors are not accessible. Without the automatic systems and relying only on the lateral ionization chambers, control of the reactor becomes very difficult; the operators do not have sufficient data to control the reactor reliably and have to rely on their intuition. During startup of a reactor with a poison-free core this lack of information can be manageable because the reactor behaves predictably, but a non-uniformly poisoned core can cause large nonhomogenities of power distribution, with potentially catastrophic results.

The reactor emergency protection system (EPS) was designed to shut down the reactor when its operational parameters are exceeded. The design accounted for steam collapse in the core when the fuel element temperature falls below 265 °C, coolant vaporization in fuel channels in cold reactor state, and sticking of some emergency protection rods. However, the slow insertion speed of the control rods, together with their design causing localized positive reactivity as the displacer moves through the lower part of the core, created a number of possible situations where initiation of the EPS could itself cause or aggravate a reactor runaway.

The computer system for calculation of the reactivity margin was collecting data from about 4,000 sources. Its purpose was to assist the operator with steady-state control of the reactor. Ten to fifteen minutes were required to cycle through all the measurements and calculate the results.

The operators could disable some safety systems, reset or suppress some alarm signals, and bypass automatic scram

, by attaching patch cable

s to accessible terminals. This practice was allowed under some circumstances.

The reactor is equipped with a fuel rod leak detector. A scintillation counter

detector, sensitive to energies of short-lived fission products, is mounted on a special dolly and moved over the outlets of the fuel channels, issuing an alert if increased radioactivity is detected in the steam-water flow.

, RBMK design also includes a partial containment structure (not a full containment building

) for dealing with emergencies. The pipes underneath the reactor are sealed inside leak-tight boxes containing a large amount of water. If these pipes leak or burst, the radioactive material is trapped by the water inside these boxes. However, RBMK reactors were designed to allow fuel rods to be changed without shutting down (as in the pressurized heavy water CANDU reactor), both for refueling and for plutonium

production (for nuclear weapon

s). This required large cranes above the core. As the RBMK reactor is very tall (about 7 metre), the cost and difficulty of building a heavy containment structure prevented building of additional emergency containment structure for pipes on top of the reactor. In the Chernobyl accident, the pressure rose to levels high enough to blow the top off the reactor, breaking open these pipes in the process.

The bottom part of the reactor is enclosed in a leaktight compartment. There is a space between the reactor bottom and the floor. The reactor cavity overpressure protection system consists of steam relief assemblies embedded in the floor and leading to Steam Distributor Headers covered with rupture disc

s and opening into the Steam Distribution Corridor below the reactor, on level +6. The floor of the corridor contains entrances of a large number of vertical pipes, leading to the bottoms of the Pressure Suppression Pools ("bubbler" pools) located on levels +3 and +0. In the event of an accident, which was predicted to be at most a rupture of one or two pressure channels, the steam was to be bubbled through the water and condensed there, reducing the overpressure in the leaktight compartment. The flow capacity of the pipes to the pools limited the protection capacity to simultaneous rupture of two pressure channels; a higher number of failures would cause pressure buildup sufficient to lift the cover plate ("Structure E", after the explosion nicknamed "Elena"), sever the rest of the fuel channels, destroy the control rod insertion system, and potentially also withdraw control rods from the core. The containment was designed to handle failures of the downcomers, pumps, and distribution and inlet of the feedwater. The leaktight compartments around the pumps can withstand overpressure of 0.45 MPa. The distribution headers and inlets enclosures can handle 0.08 MPa and are vented via check valve

s to the leaktight compartment. The reactor cavity can handle overpressure of 0.18 MPa and is vented via check valves to the leaktight compartment. The pressure suppression system can handle a failure of one reactor channel, a pump pressure header, or a distribution header. Leaks in the steam piping and separators are not handled, except for maintaining slightly lower pressure in the riser pipe gallery and the steam drum compartment than in the reactor hall. These spaces are also not designed to withstand overpressure. The steam distribution corridor contains surface condensers. The fire sprinkler systems, operating during both accident and normal operation, are fed from the pressure suppression pools through heat exchangers cooled by the plant service water, and cool the air above the pools. Jet coolers are located in the topmost parts of the compartments; their role is to cool the air and remove the steam and radioactive aerosol particles.

Hydrogen removal from the leaktight compartment is performed by removal of 800 m³/h of air, its filtration, and discharge into the atmosphere. The air removal is stopped automatically in case of a coolant leak and has to be reinstated manually. Hydrogen is present during normal operation due to leaks of coolant (assumed to be up to 2 t (2.2 ST) per hour).

is used as the example.

s connected to the 750 kV grid by a single generator transformer. The generators are connected to their common transformer by two switches in series. Between them, the unit transformers are connected to supply power to the power plant's own systems; each generator can therefore be connected to the unit transformer to power the plant, or to the unit transformer and the generator transformer to also feed power to the grid. The 330 kV line is normally not used, and serves as an external power supply, connected by a station transformer to the power plant's electrical systems. The plant can be powered by its own generators, or get power from the 750 kV grid through the generator transformer, or from the 330 kV grid via the station transformer, or from the other power plant block via two reserve busbar

s. In case of total external power loss, the essential systems can be powered by diesel generator

s. Each unit transformer is connected to two 6 kV main power boards, A and B (e.g. 7A, 7B, 8A, 8B for generators 7 and 8), powering principal non-essential drivers and connected to transformers for the 4 kV main power and the 4 kV reserve busbar. The 7A, 7B, and 8B boards are also connected to the three essential power lines (namely for the coolant pumps), each also having its own diesel generator. In case of a coolant circuit failure with simultaneous loss of external power, the essential power can be supplied by the spinning down turbogenerators for about 45–50 seconds, during which time the diesel generators should start up. The generators are started automatically within 15 seconds at loss of off-site power.

s. These are located in the 600 metre-long machine hall, adjacent to the reactor building. The turbine

s, the venerable five-cylinder K-500-65/3000, are supplied by the Kharkiv

turbine plant; the electrical generator

s are the TVV-500. The turbine and the generator rotors are mounted on the same shaft; the combined weight of the rotor

s is almost 200 t (220.5 ST) and their nominal rotational speed is 3000 rpm. The turbogenerator is 39 metre long and its total weight is 1200 t (1,322.8 ST). The coolant flow for each turbine is 82880 t (91,359.6 ST)/h. The generator produces 20 kV 50 Hz AC power. The generator's stator is cooled by water while its rotor is cooled by hydrogen

. The hydrogen for the generators is manufactured on-site by electrolysis

. The design and reliability of the turbines earned them the State Prize of Ukraine for 1979.

The Kharkiv turbine plant (now Turboatom) later developed a new version of the turbine, K-500-65/3000-2, in an attempt to reduce use of valuable metal. The Chernobyl plant was equipped with both types of turbines; Block 4 had the newer ones. The newer turbines, however, turned out to be more sensitive to their operating parameters, and their bearings

had frequent problems with vibration

s.

and a neutron absorber

. This means that not only can it slow down neutrons to velocities in equilibrium with surrounding molecules ("thermalize"

them and turn them into low-energy neutrons that are far more likely to interact with the Uranium-235 nuclei than the fast neutrons produced by fission initially), but it can also absorb some of them outright. Heavy water

is also a good neutron moderator, but does not absorb neutrons as easily.

In RBMKs, light water was used as a coolant; moderation was instead carried out by graphite

. As graphite already moderated neutrons, light water had a lesser effect in slowing them down, but could still absorb them. This means that the reactor's moderation level (adjustable by appropriate neutron-absorbing rods) had to account for the neutrons absorbed by light water.

In the case of evaporation of water to steam

, the place occupied by water would be occupied by water vapor, which has a density vastly lower than that of liquid water (the exact number depends on pressure and temperature; at standard conditions, steam is about as dense as liquid water). Because of this lower density (of mass, and consequently of atom nuclei able to absorb neutrons), light water's neutron-absorption capability practically disappears when it boils. This allows more neutrons to fission more U-235 nuclei and thereby increase the reactor power, which leads to higher temperatures that boil even more water, creating a thermal feedback loop

.

In RBMKs, generation of steam in the coolant water would then in practice create a void, a bubble that does not absorb neutrons; the reduction in moderation by light water is irrelevant, as graphite is still moderating the neutrons, enabling them to be absorbed more easily to continue the reaction. This event would dramatically alter the balance of neutron production, causing a runaway condition in which more and more neutrons are produced, and their density grows exponentially fast. Such a condition is called a positive void coefficient

, and it is particularly high for RBMK reactors.

A high void coefficient does not automatically make a reactor unsafe

, as some of the fission neutrons are emitted with a delay of seconds or even minutes (post-fission neutron emission from daughter nuclei), so steps can be taken to reduce the fission rate before it gets too high, but it does make it much harder to control the reactor and makes it imperative that the control systems are very reliable. Some RBMK designs did include control rods on electromagnetic grapples, thus controlling the reaction speed and, if necessary, stopping the reaction completely. The RBMK at Chernobyl, however, had manual control rods.

After the Chernobyl disaster

, all RBMKs in operation underwent significant changes, lowering their void coefficient

s to +0.7 β

. This new number decreases the possibility of a low-coolant meltdown

.

, the First Deputy Director of the Kurchatov Institute of Atomic Energy

, revealed that the Institute's scientists had long known that the RBMK reactor had significant design flaws. Legasov's death from suicide, apparently as a result of becoming bitterly disillusioned with the failure of the authorities to confront the flaws, caused shockwaves throughout the Soviet nuclear industry and the problems with the RBMK design were rapidly accepted.

Following Legasov's death all remaining RBMKs were retrofitted with a number of updates for safety

. The largest of these updates fixes the RBMK control rod design. Previously the control rods were designed with graphite tips, which when initially inserted into the reactor first speed up the reaction and after that begin slowing or stopping it. This design flaw contributed to the first explosion of the Chernobyl accident.

The updates are:

(Russian: МКЭР, Многопетлевой Канальный Энергетический Реактор [Mnogopetlevoy Kanalnyi Energeticheskiy Reaktor] which means Multi-loop pressure tube power reactor), with improved safety and containment. The physical prototype of the MKER-1000 is the 5th unit of the Kursk nuclear power plant. The construction of Kursk 5 is still uncertain. A MKER-800, MKER-1000 and MKER-1500 planned for the Leningrad nuclear power plant.

), all three surviving reactors at the Chernobyl plant have now been closed (the fourth having been destroyed in the accident). Chernobyl 5 and 6 were under construction at the time of the mishap at Chernobyl, but further construction was stopped due to the high level of contamination at the site limiting its longer term future. Both reactors at Ignalina

in Lithuania

were also shut down. Russia is the only country to still operate reactors of this design: Saint Petersburg

(4 RBMK-1000), Smolensk

(3 RBMK-1000) and Kursk

(4 RBMK-1000).

Nuclear reactor

A nuclear reactor is a device to initiate and control a sustained nuclear chain reaction. Most commonly they are used for generating electricity and for the propulsion of ships. Usually heat from nuclear fission is passed to a working fluid , which runs through turbines that power either ship's...

which was built in the Soviet Union

Soviet Union

The Soviet Union , officially the Union of Soviet Socialist Republics , was a constitutionally socialist state that existed in Eurasia between 1922 and 1991....

. The RBMK reactor was the type involved in the Chernobyl disaster

Chernobyl disaster

The Chernobyl disaster was a nuclear accident that occurred on 26 April 1986 at the Chernobyl Nuclear Power Plant in Ukraine , which was under the direct jurisdiction of the central authorities in Moscow...

. In 2010, there were at least 11 RBMK reactors operating in Russia, but there are no plans to build new RBMK type reactors (the RBMK technology was developed in the 1950s and is now considered obsolete) and there is international pressure to close those that remain.

Plutonium

Plutonium is a transuranic radioactive chemical element with the chemical symbol Pu and atomic number 94. It is an actinide metal of silvery-gray appearance that tarnishes when exposed to air, forming a dull coating when oxidized. The element normally exhibits six allotropes and four oxidation...

production military reactors. The first of these, AM-1

Obninsk Nuclear Power Plant

Obninsk Nuclear Power Station, , was built in the "Science City" of Obninsk, about 110 km southwest of Moscow. It was the first civilian nuclear power station in the world...

("Атом Мирный", Atom Mirny, Russian for "peaceful atom") produced 5 MW of electricity (30 MW thermal) and delivered power to Obninsk

Obninsk

Obninsk is a city in Kaluga Oblast, Russia, located southwest of Moscow. Population: Obninsk is one of the major Russian science cities. The first nuclear power plant in the world for the large-scale production of electricity opened here on June 27, 1954, and it also doubled as a training...

from 1954 until 1959.

Using light water for cooling and graphite for moderation

Neutron moderator

In nuclear engineering, a neutron moderator is a medium that reduces the speed of fast neutrons, thereby turning them into thermal neutrons capable of sustaining a nuclear chain reaction involving uranium-235....

, it is possible to use natural uranium

Uranium

Uranium is a silvery-white metallic chemical element in the actinide series of the periodic table, with atomic number 92. It is assigned the chemical symbol U. A uranium atom has 92 protons and 92 electrons, of which 6 are valence electrons...

for fuel. Thus, a large power reactor (RBMK reactors at the Ignalina Nuclear Power Plant

Ignalina Nuclear Power Plant

The Ignalina Nuclear Power Plant is a closed two-unit RBMK-1500 nuclear power station in Visaginas, Lithuania. It was named after the nearby city of Ignalina...

in Lithuania were rated at 1500 MWe each, a very large size for the time and even for today) can be built that requires no separated

Isotope separation

Isotope separation is the process of concentrating specific isotopes of a chemical element by removing other isotopes, for example separating natural uranium into enriched uranium and depleted uranium. This is a crucial process in the manufacture of uranium fuel for nuclear power stations, and is...

isotope

Isotope

Isotopes are variants of atoms of a particular chemical element, which have differing numbers of neutrons. Atoms of a particular element by definition must contain the same number of protons but may have a distinct number of neutrons which differs from atom to atom, without changing the designation...

s, such as enriched uranium

Enriched uranium

Enriched uranium is a kind of uranium in which the percent composition of uranium-235 has been increased through the process of isotope separation. Natural uranium is 99.284% 238U isotope, with 235U only constituting about 0.711% of its weight...

or heavy water

Heavy water

Heavy water is water highly enriched in the hydrogen isotope deuterium; e.g., heavy water used in CANDU reactors is 99.75% enriched by hydrogen atom-fraction...

.

Reactor design and behavior

Reactor vessel, moderator and shielding

The reactor pit is made of reinforced concreteReinforced concrete

Reinforced concrete is concrete in which reinforcement bars , reinforcement grids, plates or fibers have been incorporated to strengthen the concrete in tension. It was invented by French gardener Joseph Monier in 1849 and patented in 1867. The term Ferro Concrete refers only to concrete that is...

and has dimensions 21.6×21.6×25.5 meters. It houses the vessel of the reactor, made of a cylindrical wall and top and bottom metal plates. The vessel contains the graphite stack and is filled with a helium-nitrogen mixture for providing an inert atmosphere for the graphite and for mediation of heat transfer from the graphite to the coolant channels.

The moderator blocks are made of nuclear graphite

Nuclear Graphite

Nuclear graphite is any grade of graphite, usually electro-graphite, specifically manufactured for use as a moderator or reflector within nuclear reactors...

of dimensions 250×250×500 mm. There are holes with 11.4 cm (4.5 in) diameter through the longitudal axis of the blocks for the fuel and control channels. The blocks are stacked inside the reactor vessel into a cylindrical core 14 metre in diameter and 8 metre high. The maximum allowed temperature of the graphite is less or equal to 730 °C (1,346 °F).

The reactor vessel is a steel cylinder with outer diameter of 14.52 metre, wall thickness 16 mm (0.62992125984252 in), height 9.75 metre, and is equipped with a bellows compensator

Expansion joint

An expansion joint or movement joint is an assembly designed to safely absorb the heat-induced expansion and contraction of various construction materials, to absorb vibration, to hold certain parts together, or to allow movement due to ground settlement or earthquakes...

to absorb axial thermal expansion loads.

The moderator is surrounded by a cylindrical water tank, a welded structure with 3 cm (1.2 in) thick walls, inner diameter of 16.6 metre and outer diameter of 19 metre, internally divided to 16 vertical compartments. The water is supplied to the compartments from the bottom and removed from the top; the water can be used for emergency reactor cooling. The tank contains thermocouples for sensing the water temperature and ion chambers for monitoring the reactor power. The tank, sand layer, and concrete of the reactor pit serve as additional biological shields.

The top of the reactor is covered by the Upper Biological Shield, also called Schema E, Pyatachok, or, after the explosion (of Chernobyl Reactor 4), Elena, a 3 metre thick cylinder 17 metre in diameter. It is penetrated by standpipe

Standpipe

In North America, a standpipe is a type of rigid water piping which is built into multi-story buildings in a vertical position, to which fire hoses can be connected, allowing manual application of water to the fire...

s for fuel and control channel assemblies. The top and bottom are covered with 4 cm (1.57 in) thick steel plates, welded to be helium-tight, and additionally joined by structural supports. The space between the plates and pipes is filled with serpentinite

Serpentinite

Serpentinite is a rock composed of one or more serpentine group minerals. Minerals in this group are formed by serpentinization, a hydration and metamorphic transformation of ultramafic rock from the Earth's mantle...

, a rock containing significant amount of bound water

Water of crystallization

In crystallography, water of crystallization or water of hydration or crystallization water is water that occurs in crystals. Water of crystallization is necessary for the maintenance of crystalline properties, but capable of being removed by sufficient heat...

. The disk is supported on 16 rollers, located on the upper side of the reinforced cylindrical water tank. The structure of the UBS supports the fuel and control channels, the floor above the reactor in the central hall, and the steam-water pipes.

Below the bottom of the reactor core there is the Lower Biological Shield, similar to the UBS, but only 14.5 metre in diameter and 2 metre thick. It is penetrated by the tubes for the lower ends of the pressure channels and carries the weight of the graphite stack and the coolant inlet piping. A steel structure, two heavy plates intersecting in right angle under the center of the LBS and welded to the LBS, supports the LBS and transfers the mechanical load to the building.

Above the UBS there is the upper shield cover; its top surface is the floor of the central hall. It serves as part of the biological shield and for thermal insulation of the reactor space. Its center area above the reactor channel consists of individual removable steel-graphite plugs, located over the tops of the channels.

Pressure channels

The fuel channels consist of welded zircaloyZircaloy

Zirconium alloys are solid solutions of zirconium or other metals, a common subgroup having the trade mark Zircaloy. Zirconium has very low absorption cross-section of thermal neutrons, high hardness, ductility and corrosion resistance...

pressure tubes 8 cm (3.1 in) in inner diameter with 4 mm (0.15748031496063 in) thick walls, led through the channels in the center of the graphite moderator

Neutron moderator

In nuclear engineering, a neutron moderator is a medium that reduces the speed of fast neutrons, thereby turning them into thermal neutrons capable of sustaining a nuclear chain reaction involving uranium-235....

blocks. The top and bottom parts of the tubes are made of stainless steel

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

, and joined with the central zircaloy segment with zirconium-steel alloy couplings. The pressure tube is held in the graphite stack channels with two alternating types of 20 mm (0.78740157480315 in) high split graphite rings; one is in direct contact with the tube and has 1.5 mm (0.0590551181102362 in) clearance to the graphite stack, the other one is directly touching the graphite stack and has 1.3 mm (0.0511811023622047 in) clearance to the tube; this assembly reduces transfer of mechanical loads caused by neutron-induced swelling

Neutron-induced swelling

Neutron-induced swelling is the increase of volume and decrease of density of materials subjected to intense neutron radiation. Neutrons impacting the material's lattice rearrange its atoms, causing buildup of dislocations, voids, and Wigner energy...

, thermal expansion of the blocks, and other factors to the pressure tube, while facilitating heat transfer from the graphite blocks. The tubes are welded to the top and bottom metal plates of the reactor vessel.

It is estimated that about 5.5% of the core thermal power is in the form of graphite heat. About 80–85% of this heat is removed by the fuel rod coolant channels, via the graphite rings. The rest of the heat is removed by the control rod channel coolant. The gas circulating in the reactor plays the role of assisting the heat transfer to the coolant channels; itself plays almost no role in heat removal.

There are 1661 fuel channels and 211 control rod channels in the reactor core.

The fuel assembly is suspended in the fuel channel on a bracket, with a seal plug. The seal plug has a simple design, to facilitate its removal and installation by the remotely controlled refueling machine.

The fuel channels may instead of fuel contain fixed neutron absorbers, or be empty and just filled with the cooling water.

The small clearance between the pressure channel and the graphite block makes the graphite core susceptible to damage. If the pressure channel deforms, e.g. by too high internal pressure, the deformation or rupture can cause significant pressure loads to the graphite blocks and lead to their damage, and possibly propagate to neighboring channels.

Fuel

Uranium dioxide

Uranium dioxide or uranium oxide , also known as urania or uranous oxide, is an oxide of uranium, and is a black, radioactive, crystalline powder that naturally occurs in the mineral uraninite. It is used in nuclear fuel rods in nuclear reactors. A mixture of uranium and plutonium dioxides is used...

powder, sintered with a suitable binder into barrels 1.15 cm (0.452755905511811 in) in diameter and 15 mm (0.590551181102362 in) long. The material may contain added europium oxide as a burnable nuclear poison

Nuclear poison

A neutron poison is a substance with a large neutron absorption cross-section in applications, such as nuclear reactors. In such applications, absorbing neutrons is normally an undesirable effect...

to lower the reactivity differences between a new and partially spent fuel assembly. To reduce thermal expansion issues and interaction with the cladding, the pellets have hemispherical indentations. A 2 mm (0.078740157480315 in) hole through the axis of the pellet serves to reduce the temperature in the center of the pellet and facilitates removal of gaseous fission products. The enrichment level

Enriched uranium

Enriched uranium is a kind of uranium in which the percent composition of uranium-235 has been increased through the process of isotope separation. Natural uranium is 99.284% 238U isotope, with 235U only constituting about 0.711% of its weight...

is 2% (0.4% for the end pellets of the assemblies). Maximum allowable temperature of the fuel pellet is 2100 °C (3,812 °F).

The fuel rods are zircaloy

Zircaloy

Zirconium alloys are solid solutions of zirconium or other metals, a common subgroup having the trade mark Zircaloy. Zirconium has very low absorption cross-section of thermal neutrons, high hardness, ductility and corrosion resistance...

(1% Nb) tubes 1.36 cm (0.535433070866142 in) in outer diameter, 0.825 m (32.4803 in) thick. The rods are filled with helium

Helium

Helium is the chemical element with atomic number 2 and an atomic weight of 4.002602, which is represented by the symbol He. It is a colorless, odorless, tasteless, non-toxic, inert, monatomic gas that heads the noble gas group in the periodic table...

at 0.5 MPa and hermetically sealed. Retaining rings help to seat the pellets in the center of the tube and facilitate heat transfer from the pellet to the tube. The pellets are axially held in place by a spring

Spring (device)

A spring is an elastic object used to store mechanical energy. Springs are usually made out of spring steel. Small springs can be wound from pre-hardened stock, while larger ones are made from annealed steel and hardened after fabrication...

. Each rod contains 3.5 kg (7.7 lb) of fuel pellets. The fuel rods are 3.64 metre long, with 3.4 metre of that being the active length. The maximum allowed temperature of a fuel rod is 600 °C (1,112 °F).

The fuel assemblies consist of two sets of 18 fuel rods. The rods are arranged along the central carrier rod (1.3 cm (0.511811023622047 in) outer diameter) and held in place with 10 stainless steel spacers separated by 360 mm (14.2 in) distance. The two sub-assemblies are joined with a cylinder at the center of the assembly; during the operation of the reactor, this dead space without fuel lowers the neutron flux in the central plane of the reactor. The total mass of uranium in the fuel assembly is 114.7 kg (252.9 lb). The fuel burnup

Burnup

In nuclear power technology, burnup is a measure of how much energy is extracted from a primary nuclear fuel source...

is 20 MW·d/kg. The total length of the fuel assembly is 10.025 metre, with 6.862 metre of the active region.

In addition to the regular fuel assemblies, there are instrumented ones, containing neutron flux detectors in the central carrier. In this case, the rod is replaced with a tube with wall thickness of 2.5 mm (0.0984251968503937 in); and outer diameter of 1.5 cm (0.590551181102362 in).

Unlike the rectangular PWR/BWR fuel assemblies, the RBMK fuel assembly is cylindrical to fit the round pressure channels.

The refueling machine is mounted on a gantry crane and remotely controlled. The fuel assemblies can be replaced without shutting down the reactor, a factor significant for production of weapon-grade plutonium and, in a civilian context, for better reactor uptime. When a fuel assembly has to be replaced, the machine is positioned above the fuel channel, mates to it, equalizes pressure within, pulls the rod, and inserts a fresh one. The spent rod is then placed in a cooling pond. The capacity of the refueling machine with the reactor at nominal power level is two fuel assemblies per day, with peak capacity of five per day.

Control rods

Most of the reactor control rodControl rod

A control rod is a rod made of chemical elements capable of absorbing many neutrons without fissioning themselves. They are used in nuclear reactors to control the rate of fission of uranium and plutonium...

s are inserted from above; 24 shortened rods are inserted from below and are used to augment the axial power distribution control of the core. With the exception of 12 automatic rods, the control rods have a 4.5 metre long graphite section at the end, separated by a 1.25 metre long telescope (which creates a water-filled space between the graphite and the absorber), and a boron carbide

Boron carbide

Boron carbide is an extremely hard boron–carbon ceramic material used in tank armor, bulletproof vests, and numerous industrial applications...

neutron absorber section. The role of the graphite section, known as "displacer," is to enhance the difference between the neutron flux attenuation levels of inserted and retracted rods, as the graphite displaces water that would otherwise act as a neutron absorber, although much weaker than boron carbide; a control rod channel filled with graphite absorbs fewer neutrons than when filled with water, so the difference between inserted and retracted control rod is increased. When the control rod is fully retracted, the graphite displacer is located in the middle of the core height, with 1.25 m of water at each of its ends. The displacement of water in the lower 1.25 m of the core as the rod moves down causes a local increase of reactivity in the bottom of the core as the graphite part of the control rod passes that section. This "positive scram" effect was discovered in 1983 at the Ignalina Nuclear Power Plant

Ignalina Nuclear Power Plant

The Ignalina Nuclear Power Plant is a closed two-unit RBMK-1500 nuclear power station in Visaginas, Lithuania. It was named after the nearby city of Ignalina...

; however, the matter was soon forgotten. The control rod channels are cooled by an independent water circuit and kept at 40–70 °C (104–158 °F). The narrow space between the rod and its channel hinders water flow around the rods during their movement and acts as a fluid damper

Dashpot

A dashpot is a mechanical device, a damper which resists motion via viscous friction. The resulting force is proportional to the velocity, but acts in the opposite direction, slowing the motion and absorbing energy. It is commonly used in conjunction with a spring...

, which is the primary cause of their slow insertion time (nominally 18–21 seconds for the RCPS rods, or about 0.4 m/s). After the Chernobyl disaster, the control rod servos on other RBMK reactors were exchanged to allow faster rod movements, and even faster movement was achieved by cooling of the control rod tubes by a thin layer of water while letting the rods themselves move in gas.

The division of the control rods between manual and emergency protection groups was arbitrary; the rods could be reassigned from one system to another during reactor operation without technical or organizational problems.

Additional static boron-based absorbers are inserted into the core when it is loaded with fresh fuel. About 240 absorbers are added during initial core loading. These absorbers are gradually removed with increasing burnup. The reactor's void coefficient depends on the core content; it ranges from negative with all the initial absorbers to positive when they are all removed.

The normal reactivity margin is 43–48 control rods.

Gas circuit

The reactor operates in a heliumHelium

Helium is the chemical element with atomic number 2 and an atomic weight of 4.002602, which is represented by the symbol He. It is a colorless, odorless, tasteless, non-toxic, inert, monatomic gas that heads the noble gas group in the periodic table...

–nitrogen

Nitrogen

Nitrogen is a chemical element that has the symbol N, atomic number of 7 and atomic mass 14.00674 u. Elemental nitrogen is a colorless, odorless, tasteless, and mostly inert diatomic gas at standard conditions, constituting 78.08% by volume of Earth's atmosphere...

atmosphere (70–90% He, 10–30% N2). The gas circuit is composed of a compressor

Gas compressor

A gas compressor is a mechanical device that increases the pressure of a gas by reducing its volume.Compressors are similar to pumps: both increase the pressure on a fluid and both can transport the fluid through a pipe. As gases are compressible, the compressor also reduces the volume of a gas...

, aerosol

Aerosol

Technically, an aerosol is a suspension of fine solid particles or liquid droplets in a gas. Examples are clouds, and air pollution such as smog and smoke. In general conversation, aerosol usually refers to an aerosol spray can or the output of such a can...

and iodine filters, adsorber for carbon dioxide

Carbon dioxide

Carbon dioxide is a naturally occurring chemical compound composed of two oxygen atoms covalently bonded to a single carbon atom...

, carbon monoxide

Carbon monoxide

Carbon monoxide , also called carbonous oxide, is a colorless, odorless, and tasteless gas that is slightly lighter than air. It is highly toxic to humans and animals in higher quantities, although it is also produced in normal animal metabolism in low quantities, and is thought to have some normal...

, and ammonia

Ammonia

Ammonia is a compound of nitrogen and hydrogen with the formula . It is a colourless gas with a characteristic pungent odour. Ammonia contributes significantly to the nutritional needs of terrestrial organisms by serving as a precursor to food and fertilizers. Ammonia, either directly or...

, a holding tank for allowing the gaseous radioactive products to decay before being discharged, an aerosol filter to remove solid decay products, and a ventilator stack, the iconic chimney above the plant building. The gas is injected to the stack from the bottom in a low flow rate, and exits from the standpipe of each channel via an individual pipe. The moisture and temperature of the outlet gas is monitored; an increase of them is an indicator of a coolant leak.

Cooling and steam circuits

The reactor has two independent cooling circuits, each having four main circulating pumps (three operating, one standby). The cooling water is fed to the reactor through lower water lines to a common pressure header (one for each cooling circuit), which is split to 22 group distribution headers, each feeding 38–41 pressure channels through the core, where the feedwater boils.The mixture of steam and water is led by the upper steam lines, one for each pressure channel, from the reactor top to the steam separatorSteam separator

A Steam separator, sometimes referred to as a moisture separator, is a device for separating water droplets from steam. The simplest type of steam separator is the steam dome on a steam locomotive...

s, pairs of thick horizontal drums located in side compartments above the reactor top; each has 2.8 metre diameter, 31 metre length, wall thickness of 10 cm (3.9 in), and weighs 240 t (264.6 ST). Steam, with steam quality of about 15%, is taken from the top of the separators by two steam collectors per separator, combined, and led to two turbogenerators in the turbine hall, then to condensers, reheated to 165 °C (329 °F), and pumped by the condensate pump

Condensate pump

A condensate pump is a specific type of pump used to pump the condensate produced in an HVAC , refrigeration, condensing boiler furnace or steam system...

s to deaerator

Deaerator

A deaerator is a device that is widely used for the removal of oxygen and other dissolved gases from the feedwater to steam-generating boilers. In particular, dissolved oxygen in boiler feedwaters will cause serious corrosion damage in steam systems by attaching to the walls of metal piping and...

s, where remains of gaseous phase and corrosion-inducing gases are removed. The resulting feedwater is led to the steam separators by feedwater pumps

Boiler feedwater pump

A boiler feedwater pump is a specific type of pump used to pump feedwater into a steam boiler. The water may be freshly supplied or returning condensate produced as a result of the condensation of the steam produced by the boiler...

and mixed with water from them at their outlets. From the bottom of the steam separators, the feedwater is led by 12 downpipes (from each separator) to the suction headers of the main circulation pumps, and back into the reactor. There is an ion exchange

Ion exchange

Ion exchange is an exchange of ions between two electrolytes or between an electrolyte solution and a complex. In most cases the term is used to denote the processes of purification, separation, and decontamination of aqueous and other ion-containing solutions with solid polymeric or mineralic 'ion...

system included in the loop to remove impurities from the feedwater.

The turbine consists of one high-pressure rotor and four low-pressure ones. Five low-pressure separators-preheaters are used to heat steam with fresh steam before being fed to the next stage of the turbine. The uncondensed steam is fed into a condenser, mixed with condensate from the separators, fed by the first-stage condensate pump to a chemical purifier, then by a second-stage condensate pump to four deaerators where dissolved and entrained gases are removed; deaerators also serve as storage tanks for feedwater. From the deaerators, the water is pumped through filters and into the bottom parts of the steam separator drums.

The main circulating pumps have the capacity of 5,500–12,000 m³/h and are powered by 6 kV electric motor

Electric motor

An electric motor converts electrical energy into mechanical energy.Most electric motors operate through the interaction of magnetic fields and current-carrying conductors to generate force...

s. The normal coolant flow is 8000 m³/h per pump; this is throttled down by control valves to 6000–7000 m³/h when the reactor power is below 500 MWt. Each pump has a flow control valve and a backflow preventing check valve

Check valve

A check valve, clack valve, non-return valve or one-way valve is a mechanical device, a valve, which normally allows fluid to flow through it in only one direction....

on the outlet, and shutoff valves on both inlet and outlet. Each of the pressure channels in the core has its own flow control valve

Flow control valve

A flow control valve regulates the flow or pressure of a fluid. Control valves normally respond to signals generated by independent devices such as flow meters or temperature gauges.Control valves are normally fitted with actuators and positioners...

so that the temperature distribution in the reactor core can be optimized. Each channel has a ball type flow meter.

The nominal coolant flow through the reactor is 46,000–48,000 m³/h. The steam flow at full power is 5440–5600 t (5,996.6–6,172.9 ST)/h.

The nominal temperature of the cooling water at the inlet of the reactor is about 265–270 °C (509–518 °F) and the outlet temperature 284 °C (543.2 °F), at pressure of 6.9 MPa (in the drum separator). The pressure and the inlet temperature determine the height at which the boiling begins in the reactor; if the coolant temperature is not sufficiently below its boiling point at the system pressure, the boiling starts at the very bottom part of the reactor instead of its higher parts; the positive void coefficient

Void coefficient

In nuclear engineering, the void coefficient is a number that can be used to estimate how much the reactivity of a nuclear reactor changes as voids form in the reactor moderator or coolant...

of the reactor makes the reactor very sensitive to the feedwater temperature. If the coolant temperature is too close to its boiling point, cavitation

Cavitation

Cavitation is the formation and then immediate implosion of cavities in a liquidi.e. small liquid-free zones that are the consequence of forces acting upon the liquid...

can occur in the pumps and their operation can become erratic or even stop entirely. The feedwater temperature is dependent on the steam production; the steam phase portion is led to the turbines and condensers and returns significantly cooler (155–165 °C (311–329 °F)) than the water returning directly from the steam separator (284 °C). At low reactor power, therefore, the inlet temperature may become dangerously high. The water is kept below the saturation temperature to prevent film boiling and the associated drop in heat transfer rate.

The reactor is tripped in case of too high or low water level in the steam separators (with two selectable low-level thresholds), high steam pressure, low feedwater flow, or loss of two main coolant pumps on either side. These trips can be manually disabled.

The level of water in the steam separators, the percentage of steam in the reactor pressure tubes, the level at which the water begins to boil in the reactor core, the neutron flux and power distribution in the reactor, and the feedwater flow through the core have to be carefully controlled. The level of water in the steam separator is mainly controlled by the feedwater supply, with the deaerator tanks serving as a water reservoir.

The maximum allowed heat-up rate of the reactor and the coolant is 10 °C (50 °F)/h; the maximum cool-down rate is 30 °C (86 °F)/h.

ECCS

The reactor is equipped with an emergency core cooling system (ECCS), consisting of dedicated water reserve tank, hydraulic accumulators, and pumps. ECCS piping is integrated with the normal reactor cooling system. In case of total loss of power, the ECCS pumps are supposed to be powered by the rotational momentum of the turbogenerator rotor for the time before the diesel generatorDiesel generator

A diesel generator is the combination of a diesel engine with an electrical generator to generate electrical energy....

s come online. The Chernobyl disaster

Chernobyl disaster

The Chernobyl disaster was a nuclear accident that occurred on 26 April 1986 at the Chernobyl Nuclear Power Plant in Ukraine , which was under the direct jurisdiction of the central authorities in Moscow...

occurred during a botched test of this system. The ECCS has three systems, connected to the coolant system headers. In case of damage, the first ECCS subsystem provides cooling for up to 100 seconds to the damaged half of the coolant circuit (the other half is cooled by the main circulation pumps), and the other two subsystems then handle long-term cooling of the reactor.

The short-term ECCS subsystem consists of two groups of six accumulator tanks, containing water blanketed with nitrogen under pressure of 10 MPa, connected by fast-acting valves to the reactor. Each group can supply 50% of the maximum coolant flow to the damaged half of the reactor. The third group is a set of electrical pumps drawing water from the deaerators. The short-term pumps can be powered by the spindown of the main turbogenerators.

ECCS for long-term cooling of the damaged circuit consists of three pairs of electrical pumps, drawing water from the pressure suppression pools; the water is cooled by the plant service water by means of heat exchangers in the suction lines. Each pair is able to supply half of the maximum coolant flow. ECCS for long-term cooling of the intact circuit consists of three separate pumps drawing water from the condensate storage tanks, each able to supply half of the maximum flow. The ECCS pumps are powered from the essential internal 6 kV lines, backed up by diesel generators. Some valves that require uninterrupted power are also backed up by batteries.

Reactor control/supervision systems

The distribution of power densityPower density

Power density is the amount of power per unit volume....

in the reactor is measured by ionization chamber

Ionization chamber

The ionization chamber is the simplest of all gas-filled radiation detectors, and is used for the detection or measurement of ionizing radiation...

s located inside and outside the core. The physical power density distribution control system (PPDDCS) has sensors inside the core; the reactor control and protection system (RCPS) uses sensors in the core and in the lateral biological shield tank. The external sensors in the tank are located around the reactor middle plane, therefore do not indicate axial power distribution nor information about the power in the central part of the core. There are over 100 radial and 12 axial power distribution monitors, employing self-powered detectors. Reactivity meters and removable startup chambers are used for monitoring of reactor startup. Total reactor power is recorded as the sum of the currents of the lateral ionization chambers. The moisture and temperature of the gas circulating in the channels is monitored by the pressure tube integrity monitoring system.

The PPDCSS and RCPS are supposed to complement each other. The RCPS system consists of 211 movable control rods. Both systems, however, have deficiencies, most noticeably at low reactor power levels. The PPDDCS is designed to maintain reactor power density distribution between 10 and 120% of nominal levels and to control the total reactor power between 5 and 120% of nominal levels. The LAC-LAP (local automatic control and local automatic protection) RPCS subsystems rely on ionization chambers inside the reactor and are active at power levels above 10%. Below those levels, the automatic systems are disabled and the in-core sensors are not accessible. Without the automatic systems and relying only on the lateral ionization chambers, control of the reactor becomes very difficult; the operators do not have sufficient data to control the reactor reliably and have to rely on their intuition. During startup of a reactor with a poison-free core this lack of information can be manageable because the reactor behaves predictably, but a non-uniformly poisoned core can cause large nonhomogenities of power distribution, with potentially catastrophic results.

The reactor emergency protection system (EPS) was designed to shut down the reactor when its operational parameters are exceeded. The design accounted for steam collapse in the core when the fuel element temperature falls below 265 °C, coolant vaporization in fuel channels in cold reactor state, and sticking of some emergency protection rods. However, the slow insertion speed of the control rods, together with their design causing localized positive reactivity as the displacer moves through the lower part of the core, created a number of possible situations where initiation of the EPS could itself cause or aggravate a reactor runaway.

The computer system for calculation of the reactivity margin was collecting data from about 4,000 sources. Its purpose was to assist the operator with steady-state control of the reactor. Ten to fifteen minutes were required to cycle through all the measurements and calculate the results.

The operators could disable some safety systems, reset or suppress some alarm signals, and bypass automatic scram

Scram

A scram or SCRAM is an emergency shutdown of a nuclear reactor – though the term has been extended to cover shutdowns of other complex operations, such as server farms and even large model railroads...

, by attaching patch cable

Patch cable

A patch cable or patch cord is an electrical or optical cable used to connect one electronic or optical device to another for signal routing. Devices of different types are connected with patch cords...

s to accessible terminals. This practice was allowed under some circumstances.

The reactor is equipped with a fuel rod leak detector. A scintillation counter

Scintillation counter

A scintillation counter measures ionizing radiation. The sensor, called a scintillator, consists of a transparent crystal, usually phosphor, plastic , or organic liquid that fluoresces when struck by ionizing radiation. A sensitive photomultiplier tube measures the light from the crystal...

detector, sensitive to energies of short-lived fission products, is mounted on a special dolly and moved over the outlets of the fuel channels, issuing an alert if increased radioactivity is detected in the steam-water flow.

Containment

Initially, the RBMK design focused solely on accident prevention and mitigation, not on containment of severe accidents. However, since the Three Mile Island accidentThree Mile Island accident

The Three Mile Island accident was a core meltdown in Unit 2 of the Three Mile Island Nuclear Generating Station in Dauphin County, Pennsylvania near Harrisburg, United States in 1979....

, RBMK design also includes a partial containment structure (not a full containment building

Containment building

A containment building, in its most common usage, is a steel or reinforced concrete structure enclosing a nuclear reactor. It is designed, in any emergency, to contain the escape of radiation to a maximum pressure in the range of 60 to 200 psi...

) for dealing with emergencies. The pipes underneath the reactor are sealed inside leak-tight boxes containing a large amount of water. If these pipes leak or burst, the radioactive material is trapped by the water inside these boxes. However, RBMK reactors were designed to allow fuel rods to be changed without shutting down (as in the pressurized heavy water CANDU reactor), both for refueling and for plutonium

Plutonium

Plutonium is a transuranic radioactive chemical element with the chemical symbol Pu and atomic number 94. It is an actinide metal of silvery-gray appearance that tarnishes when exposed to air, forming a dull coating when oxidized. The element normally exhibits six allotropes and four oxidation...

production (for nuclear weapon

Nuclear weapon

A nuclear weapon is an explosive device that derives its destructive force from nuclear reactions, either fission or a combination of fission and fusion. Both reactions release vast quantities of energy from relatively small amounts of matter. The first fission bomb test released the same amount...

s). This required large cranes above the core. As the RBMK reactor is very tall (about 7 metre), the cost and difficulty of building a heavy containment structure prevented building of additional emergency containment structure for pipes on top of the reactor. In the Chernobyl accident, the pressure rose to levels high enough to blow the top off the reactor, breaking open these pipes in the process.

The bottom part of the reactor is enclosed in a leaktight compartment. There is a space between the reactor bottom and the floor. The reactor cavity overpressure protection system consists of steam relief assemblies embedded in the floor and leading to Steam Distributor Headers covered with rupture disc

Rupture disc

Burst disc redirects here. For the human back ailment see Spinal disc herniation.A rupture disc, also known as a bursting disc or burst diaphragm, is a non-reclosing pressure relief device that, in most uses, protects a pressure vessel, equipment or system from overpressurization or potentially...

s and opening into the Steam Distribution Corridor below the reactor, on level +6. The floor of the corridor contains entrances of a large number of vertical pipes, leading to the bottoms of the Pressure Suppression Pools ("bubbler" pools) located on levels +3 and +0. In the event of an accident, which was predicted to be at most a rupture of one or two pressure channels, the steam was to be bubbled through the water and condensed there, reducing the overpressure in the leaktight compartment. The flow capacity of the pipes to the pools limited the protection capacity to simultaneous rupture of two pressure channels; a higher number of failures would cause pressure buildup sufficient to lift the cover plate ("Structure E", after the explosion nicknamed "Elena"), sever the rest of the fuel channels, destroy the control rod insertion system, and potentially also withdraw control rods from the core. The containment was designed to handle failures of the downcomers, pumps, and distribution and inlet of the feedwater. The leaktight compartments around the pumps can withstand overpressure of 0.45 MPa. The distribution headers and inlets enclosures can handle 0.08 MPa and are vented via check valve

Check valve

A check valve, clack valve, non-return valve or one-way valve is a mechanical device, a valve, which normally allows fluid to flow through it in only one direction....

s to the leaktight compartment. The reactor cavity can handle overpressure of 0.18 MPa and is vented via check valves to the leaktight compartment. The pressure suppression system can handle a failure of one reactor channel, a pump pressure header, or a distribution header. Leaks in the steam piping and separators are not handled, except for maintaining slightly lower pressure in the riser pipe gallery and the steam drum compartment than in the reactor hall. These spaces are also not designed to withstand overpressure. The steam distribution corridor contains surface condensers. The fire sprinkler systems, operating during both accident and normal operation, are fed from the pressure suppression pools through heat exchangers cooled by the plant service water, and cool the air above the pools. Jet coolers are located in the topmost parts of the compartments; their role is to cool the air and remove the steam and radioactive aerosol particles.

Hydrogen removal from the leaktight compartment is performed by removal of 800 m³/h of air, its filtration, and discharge into the atmosphere. The air removal is stopped automatically in case of a coolant leak and has to be reinstated manually. Hydrogen is present during normal operation due to leaks of coolant (assumed to be up to 2 t (2.2 ST) per hour).

Other systems

For the non-nuclear systems described here, the Chernobyl Nuclear Power PlantChernobyl Nuclear Power Plant

The Chernobyl Nuclear Power Plant or Chornobyl Nuclear Power Plant is a decommissioned nuclear power station near the city of Pripyat, Ukraine, northwest of the city of Chernobyl, from the Ukraine–Belarus border, and about north of Kiev. Reactor 4 was the site of the Chernobyl disaster in...

is used as the example.

Electrical systems

The power plant is connected to the 330 kV and 750 kV electrical grid. The block has two electrical generatorElectrical generator

In electricity generation, an electric generator is a device that converts mechanical energy to electrical energy. A generator forces electric charge to flow through an external electrical circuit. It is analogous to a water pump, which causes water to flow...