Shielded metal arc welding

Encyclopedia

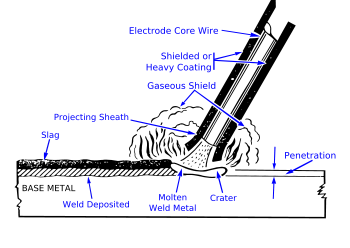

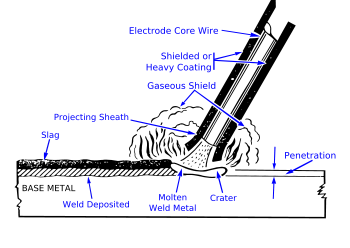

Shielded metal arc welding (SMAW), also known as manual metal arc (MMA) welding, flux shielded arc welding or informally as stick welding, is a manual arc welding

process that uses a consumable electrode

coated in flux

to lay the weld. An electric current, in the form of either alternating current

or direct current

from a welding power supply

, is used to form an electric arc

between the electrode and the metal

s to be joined

. As the weld is laid, the flux coating of the electrode disintegrates, giving off vapors that serve as a shielding gas

and providing a layer of slag, both of which protect the weld area from atmospheric contamination.

Because of the versatility of the process and the simplicity of its equipment and operation, shielded metal arc welding is one of the world's most popular welding processes. It dominates other welding processes in the maintenance and repair industry, and though flux-cored arc welding

is growing in popularity, SMAW continues to be used extensively in the construction of steel structures and in industrial fabrication. The process is used primarily to weld iron

and steel

s (including stainless steel

) but aluminium

, nickel

and copper

alloy

s can also be welded with this method.

there was little development in electrical welding until Auguste de Méritens

developed a carbon arc torch, patented in 1881. Nikolay Benardos

developed carbon arc welding

, obtaining patents from 1887 showing a rudimentary electrode holder. In 1888 consumable metal electrode was invented by Nikolay Slavyanov

. Later in 1890 C. L. Coffin

received for his arc welding method that utilized a metal electrode. The process, like SMAW, deposited melted electrode metal into the weld as filler.Cary and Helzer, 5

Around 1900 A. P. Strohmenger and Oscar Kjellberg

released the first coated electrodes. Strohmenger used Clay

and lime

coating to stabilize the arc, while Kjellberg dipped iron wire into mixtures of carbonate

s and silicate

s to coat the electrode.Cary and Helzer, 6 In 1912 Strohmenger released a heavily coated electrode but high cost and complex production methods prevented these early electrodes from gaining popularity. In 1927 the development of an extrusion

process reduced the cost of coating electrodes while allowing manufacturers to produce more complex coating mixtures designed for specific applications. In the 1950s manufacturers introduced iron powder into the flux coating, making it possible to increase the welding speed.Lincoln Electric, 1.1-4–1.1-6, 1.1-8

In 1938 K. K. Madsen described an automated variation of SMAW, now known as gravity welding. It briefly gained popularity in the 1960s after receiving publicity for its use in Japan

ese shipyards though today its applications are limited. Another little used variation of the process, known as firecracker welding

, was developed around the same time by George Hafergut in Austria

.

To strike the electric arc, the electrode is brought into contact with the workpiece by a very light touch with the electrode to the base metal then is pulled back slightly. This initiates the arc and thus the melting of the workpiece and the consumable electrode, and causes droplets of the electrode to be passed from the electrode to the weld pool

To strike the electric arc, the electrode is brought into contact with the workpiece by a very light touch with the electrode to the base metal then is pulled back slightly. This initiates the arc and thus the melting of the workpiece and the consumable electrode, and causes droplets of the electrode to be passed from the electrode to the weld pool

. As the electrode melts, the flux covering disintegrates, giving off shielding gases that protect the weld area from oxygen

and other atmospheric

gases. In addition, the flux provides molten slag which covers the filler metal as it travels from the electrode to the weld pool. Once part of the weld pool, the slag floats to the surface and protects the weld from contamination as it solidifies. Once hardened, it must be chipped away to reveal the finished weld. As welding progresses and the electrode melts, the welder must periodically stop welding to remove the remaining electrode stub and insert a new electrode into the electrode holder. This activity, combined with chipping away the slag, reduce the amount of time that the welder can spend laying the weld, making SMAW one of the least efficient welding processes. In general, the operator factor, or the percentage of operator's time spent laying weld, is approximately 25%.Cary and Helzer, 102, 115

The actual welding technique utilized depends on the electrode, the composition of the workpiece, and the position of the joint being welded. The choice of electrode and welding position also determine the welding speed. Flat welds require the least operator skill, and can be done with electrodes that melt quickly but solidify slowly. This permits higher welding speeds. Sloped, vertical or upside-down welding requires more operator skill, and often necessitates the use of an electrode that solidifies quickly to prevent the molten metal from flowing out of the weld pool. However, this generally means that the electrode melts less quickly, thus increasing the time required to lay the weld.Lincoln Electric Company, 6.2-1

, a condition associated with direct current characterized by the electric arc being deflected away from the weld pool by magnetic forces. Arc blow can also cause porosity in the weld, as can joint contamination, high welding speed, and a long welding arc, especially when low-hydrogen electrodes are used. Porosity, often not visible without the use of advanced nondestructive testing

methods, is a serious concern because it can potentially weaken the weld. Another defect affecting the strength of the weld is poor fusion, though it is often easily visible. It is caused by low current, contaminated joint surfaces, or the use of an improper electrode. Shallow penetration, another detriment to weld strength, can be addressed by decreasing welding speed, increasing the current or using a smaller electrode. Any of these weld-strength-related defects can make the weld prone to cracking, but other factors are involved as well. High carbon, alloy or sulfur content in the base material can lead to cracking, especially if low-hydrogen electrodes and preheating are not employed. Furthermore, the workpieces should not be excessively restrained, as this introduces residual stresses into the weld and can cause cracking as the weld cools and contracts.Lincoln Electric, 6.2-18–6.2-20, 3.2-1

in the form of heavy leather

glove

s and long sleeve jackets. Additionally, the brightness of the weld area can lead to a condition called arc eye, in which ultraviolet light causes inflammation of the cornea

and can burn the retina

s of the eyes. Welding helmet

s with dark face plates are worn to prevent this exposure, and in recent years, new helmet models have been produced that feature a face plate that self-darkens upon exposure to high amounts of UV light. To protect bystanders, especially in industrial environments, transparent welding curtains often surround the welding area. These curtains, made of a polyvinyl chloride

plastic film, shield nearby workers from exposure to the UV light from the electric arc, but should not be used to replace the filter glass used in helmets.Cary and Helzer, 42, 49–51

In addition, the vaporizing metal and flux materials expose welders to dangerous gases and particulate matter. The smoke

produced contains particles of various types of oxide

s. The size of the particles in question tends to influence the toxicity of the fumes, with smaller particles presenting a greater danger. Additionally, gases like carbon dioxide

and ozone

can form, which can prove dangerous if ventilation is inadequate. Some of the latest welding masks are fitted with an electric powered fan to help disperse harmful fumes.Cary and Helzer, 52–62

has become more popular in industrial environments. However, because of the low equipment cost and wide applicability, the process will likely remain popular, especially among amateurs and small businesses where specialized welding processes are uneconomical and unnecessary.Lincoln Electric Company, 5.1-1–5.1-2

SMAW is often used to weld carbon steel, low and high alloy steel, stainless steel, cast iron

, and ductile iron

. While less popular for nonferrous materials, it can be used on nickel and copper and their alloys and, in rare cases, on aluminium. The thickness of the material being welded is bounded on the low end primarily by the skill of the welder, but rarely does it drop below 0.05 in (1.5 mm). No upper bound exists: with proper joint preparation and use of multiple passes, materials of virtually unlimited thicknesses can be joined. Furthermore, depending on the electrode used and the skill of the welder, SMAW can be used in any position.Cary and Helzer, 103

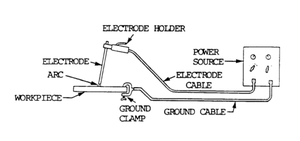

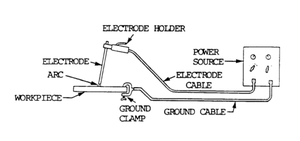

Shielded metal arc welding equipment typically consists of a constant current welding power supply and an electrode, with an electrode holder, a ground clamp, and welding cables (also known as welding leads) connecting the two.

Shielded metal arc welding equipment typically consists of a constant current welding power supply and an electrode, with an electrode holder, a ground clamp, and welding cables (also known as welding leads) connecting the two.

The preferred polarity of the SMAW system depends primarily upon the electrode being used and the desired properties of the weld. Direct current with a negatively charged electrode (DCEN) causes heat to build up on the electrode, increasing the electrode melting rate and decreasing the depth of the weld. Reversing the polarity so that the electrode is positively charged (DCEP) and the workpiece is negatively charged increases the weld penetration. With alternating current the polarity changes over 100 times per second, creating an even heat distribution and providing a balance between electrode melting rate and penetration.Jeffus, 46–47

Typically, the equipment used for SMAW consists of a step-down transformer

and for direct current models a rectifier

, which converts alternating current into direct current. Because the power normally supplied to the welding machine is high-voltage alternating current, the welding transformer is used to reduce the voltage and increase the current. As a result, instead of 220 V

at 50 A

, for example, the power supplied by the transformer is around 17–45 V at currents up to 600 A. A number of different types of transformers can be used to produce this effect, including multiple coil and inverter

machines, with each using a different method to manipulate the welding current. The multiple coil type adjusts the current by either varying the number of turns in the coil (in tap-type transformers) or by varying the distance between the primary and secondary coils (in movable coil or movable core transformers). Inverters, which are smaller and thus more portable, use electronic components to change the current characteristics.Jeffus, 49–53

Electrical generator

s and alternator

s are frequently used as portable welding power supplies, but because of lower efficiency and greater costs, they are less frequently used in industry. Maintenance also tends to be more difficult, because of the complexities of using a combustion engine as a power source. However, in one sense they are simpler: the use of a separate rectifier is unnecessary because they can provide either AC or DC.Jeffus, 49, 52–53 However, the engine driven units are most practical in field work where the welding often must be done out of doors and in locations where transformer type welders are not usable because there is no power source available to be transformed.

In some units the alternator is essentially the same as that used in portable generating sets used to supply mains power, modified to produce a higher current at a lower voltage but still at the 50 or 60 Hz grid frequency. In higher-quality units an alternator with more poles is used and supplies current at a higher frequency, such as 400 Hz. The smaller amount of time the high-frequency waveform spends near zero makes it much easier to strike and maintain a stable arc than with the cheaper grid-frequency sets or grid-frequency mains-powered units.

The composition of the electrode core is generally similar and sometimes identical to that of the base material. But even though a number of feasible options exist, a slight difference in alloy composition can strongly impact the properties of the resulting weld. This is especially true of alloy steels such as HSLA steel

s. Likewise, electrodes of compositions similar to those of the base materials are often used for welding nonferrous materials like aluminium and copper.Lincoln Electric, 6.2-13, 9.2-1, 10.1-3 However, sometimes it is desirable to use electrodes with core materials significantly different from the base material. For example, stainless steel electrodes are sometimes used to weld two pieces of carbon steel, and are often utilized to weld stainless steel workpieces with carbon steel workpieces.Lincoln Electric, 7.2-5, 7.2-8

Electrode coatings can consist of a number of different compounds, including rutile

, calcium fluoride

, cellulose

, and iron powder. Rutile electrodes, coated with 25%–45% TiO2, are characterized by ease of use and good appearance of the resulting weld. However, they create welds with high hydrogen content, encouraging embrittlement

and cracking. Electrodes containing calcium fluoride (CaF2), sometimes known as basic or low-hydrogen electrodes, are hygroscopic and must be stored in dry conditions. They produce strong welds, but with a coarse and convex-shaped joint surface. Electrodes coated with cellulose, especially when combined with rutile, provide deep weld penetration, but because of their high moisture content, special procedures must be used to prevent excessive risk of cracking. Finally, iron powder is a common coating additive, as it improves the productivity of the electrode, sometimes as much as doubling the yield.Weman, 65–66

To identify different electrodes, the American Welding Society established a system that assigns electrodes with a four- or five-digit number. Covered electrodes made of mild or low alloy steel carry the prefix E, followed by their number. The first two or three digits of the number specify the tensile strength of the weld metal, in thousand pounds per square inch (ksi). The penultimate digit generally identifies the welding positions permissible with the electrode, typically using the values 1 (normally fast-freeze electrodes, implying all position welding) and 2 (normally fast-fill electrodes, implying horizontal welding only). The welding current and type of electrode covering are specified by the last two digits together. When applicable, a suffix is used to denote the alloying element being contributed by the electrode.Cary and Helzer, 105

Common electrodes include the E6010, a fast-freeze, all-position electrode with a minimum tensile strength of 60 ksi (410 MPa

) which is operated using DCEP. Its cousin E6011 is similar except that it is used with alternating current. E7024 is a fast-fill electrode, used primarily to make flat or horizontal welds using AC, DCEN, or DCEP. Examples of fill-freeze electrodes are the E6012, E6013, and E7014, all of which provide a compromise between fast welding speeds and all-position welding.Lincoln Electric, 6.2-7–6.2-10

Arc welding

Arc welding is a type of welding that uses a welding power supply to create an electric arc between an electrode and the base material to melt the metals at the welding point. They can use either direct or alternating current, and consumable or non-consumable electrodes...

process that uses a consumable electrode

Electrode

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit...

coated in flux

Flux (metallurgy)

In metallurgy, a flux , is a chemical cleaning agent, flowing agent, or purifying agent. Fluxes may have more than one function at a time...

to lay the weld. An electric current, in the form of either alternating current

Alternating current

In alternating current the movement of electric charge periodically reverses direction. In direct current , the flow of electric charge is only in one direction....

or direct current

Direct current

Direct current is the unidirectional flow of electric charge. Direct current is produced by such sources as batteries, thermocouples, solar cells, and commutator-type electric machines of the dynamo type. Direct current may flow in a conductor such as a wire, but can also flow through...

from a welding power supply

Welding power supply

A welding power supply is a device that provides an electric current to perform welding. Welding usually requires high current and it can need above 12,000 amperes in spot welding. Low current can also be used; welding two razor blades together at 5 amps with gas tungsten arc welding is a good...

, is used to form an electric arc

Electric arc

An electric arc is an electrical breakdown of a gas which produces an ongoing plasma discharge, resulting from a current flowing through normally nonconductive media such as air. A synonym is arc discharge. An arc discharge is characterized by a lower voltage than a glow discharge, and relies on...

between the electrode and the metal

Metal

A metal , is an element, compound, or alloy that is a good conductor of both electricity and heat. Metals are usually malleable and shiny, that is they reflect most of incident light...

s to be joined

Welding joints

Welding joints are formed by welding two or more workpieces, made of metals or plastics, according to a particular geometry. The most common types are butt and lap joints; there are various lesser used welding joints including flange and corner joints....

. As the weld is laid, the flux coating of the electrode disintegrates, giving off vapors that serve as a shielding gas

Shielding gas

Shielding gases are inert or semi-inert gases that are commonly used in several welding processes, most notably gas metal arc welding and gas tungsten arc welding . Their purpose is to protect the weld area from atmospheric gases, such as oxygen, nitrogen, carbon dioxide, and water vapour...

and providing a layer of slag, both of which protect the weld area from atmospheric contamination.

Because of the versatility of the process and the simplicity of its equipment and operation, shielded metal arc welding is one of the world's most popular welding processes. It dominates other welding processes in the maintenance and repair industry, and though flux-cored arc welding

Flux-cored arc welding

Flux-cored arc welding is a semi-automatic or automatic arc welding process. FCAW requires a continuously-fed consumable tubular electrode containing a flux and a constant-voltage or, less commonly, a constant-current welding power supply...

is growing in popularity, SMAW continues to be used extensively in the construction of steel structures and in industrial fabrication. The process is used primarily to weld iron

Iron

Iron is a chemical element with the symbol Fe and atomic number 26. It is a metal in the first transition series. It is the most common element forming the planet Earth as a whole, forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust...

and steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

s (including stainless steel

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

) but aluminium

Aluminium

Aluminium or aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances....

, nickel

Nickel

Nickel is a chemical element with the chemical symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel belongs to the transition metals and is hard and ductile...

and copper

Copper

Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish...

alloy

Alloy

An alloy is a mixture or metallic solid solution composed of two or more elements. Complete solid solution alloys give single solid phase microstructure, while partial solutions give two or more phases that may or may not be homogeneous in distribution, depending on thermal history...

s can also be welded with this method.

Development

After the discovery of the electric arc in 1800 by Humphry DavyHumphry Davy

Sir Humphry Davy, 1st Baronet FRS MRIA was a British chemist and inventor. He is probably best remembered today for his discoveries of several alkali and alkaline earth metals, as well as contributions to the discoveries of the elemental nature of chlorine and iodine...

there was little development in electrical welding until Auguste de Méritens

Auguste de Méritens

Baron Auguste de Méritens was a French electrical engineer of the 19th century.He was born in 1834.He is best known his work on magneto generators, particularly those used for arc lighting and lighthouses...

developed a carbon arc torch, patented in 1881. Nikolay Benardos

Nikolay Benardos

Nikolay Nikolayevich Benardos was a Ukrainian inventor who in 1881 introduced carbon arc welding, which was the first practical arc welding method.- References :* * at weldworld.ru...

developed carbon arc welding

Carbon arc welding

Carbon arc welding is a process which produces coalescence of metals by heating them with an arc between a nonconsumable carbon electrode and the work-piece. It was the first arc-welding process ever developed but is not used for many applications today, having been replaced by twin-carbon-arc...

, obtaining patents from 1887 showing a rudimentary electrode holder. In 1888 consumable metal electrode was invented by Nikolay Slavyanov

Nikolay Slavyanov

Nikolay Gavrilovich Slavyanov was a Russian inventor who in 1888 introduced arc welding with consumable metal electrodes, or shielded metal arc welding, the second historical arc welding method after carbon arc welding invented earlier by Nikolay Benardos.- References :* * at weldworld.ru...

. Later in 1890 C. L. Coffin

C. L. Coffin

Charles L. Coffin of Detroit was awarded for an arc welding process using a metal electrode. This was the first time that metal melted from the electrode carried across the arc to deposit filler metal in the joint to make a weld. About the same time, N.G. Slavianoff, a Russian, presented the same...

received for his arc welding method that utilized a metal electrode. The process, like SMAW, deposited melted electrode metal into the weld as filler.Cary and Helzer, 5

Around 1900 A. P. Strohmenger and Oscar Kjellberg

Oscar Kjellberg

Oscar Kjellberg was a Swedish inventor and industrialist. Founder of ESAB, in 1904, and Kjellberg Finsterwalde, in 1922. He invented the coated electrode used in manual metal arc welding , by dipping a bare iron wire in a thick mixture of carbonates and silicates...

released the first coated electrodes. Strohmenger used Clay

Clay

Clay is a general term including many combinations of one or more clay minerals with traces of metal oxides and organic matter. Geologic clay deposits are mostly composed of phyllosilicate minerals containing variable amounts of water trapped in the mineral structure.- Formation :Clay minerals...

and lime

Lime (mineral)

Lime is a general term for calcium-containing inorganic materials, in which carbonates, oxides and hydroxides predominate. Strictly speaking, lime is calcium oxide or calcium hydroxide. It is also the name for a single mineral of the CaO composition, occurring very rarely...

coating to stabilize the arc, while Kjellberg dipped iron wire into mixtures of carbonate

Carbonate

In chemistry, a carbonate is a salt of carbonic acid, characterized by the presence of the carbonate ion, . The name may also mean an ester of carbonic acid, an organic compound containing the carbonate group C2....

s and silicate

Silicate

A silicate is a compound containing a silicon bearing anion. The great majority of silicates are oxides, but hexafluorosilicate and other anions are also included. This article focuses mainly on the Si-O anions. Silicates comprise the majority of the earth's crust, as well as the other...

s to coat the electrode.Cary and Helzer, 6 In 1912 Strohmenger released a heavily coated electrode but high cost and complex production methods prevented these early electrodes from gaining popularity. In 1927 the development of an extrusion

Extrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile. A material is pushed or drawn through a die of the desired cross-section...

process reduced the cost of coating electrodes while allowing manufacturers to produce more complex coating mixtures designed for specific applications. In the 1950s manufacturers introduced iron powder into the flux coating, making it possible to increase the welding speed.Lincoln Electric, 1.1-4–1.1-6, 1.1-8

In 1938 K. K. Madsen described an automated variation of SMAW, now known as gravity welding. It briefly gained popularity in the 1960s after receiving publicity for its use in Japan

Japan

Japan is an island nation in East Asia. Located in the Pacific Ocean, it lies to the east of the Sea of Japan, China, North Korea, South Korea and Russia, stretching from the Sea of Okhotsk in the north to the East China Sea and Taiwan in the south...

ese shipyards though today its applications are limited. Another little used variation of the process, known as firecracker welding

Firecracker welding

Firecracker welding is a rarely used form of shielded metal arc welding .A flux-coated electrode, as used for SMAW , is laid horizontally above a close-fitting butt weld. An arc is struck at one end of the electrode, which then burns along the length of the electrode...

, was developed around the same time by George Hafergut in Austria

Austria

Austria , officially the Republic of Austria , is a landlocked country of roughly 8.4 million people in Central Europe. It is bordered by the Czech Republic and Germany to the north, Slovakia and Hungary to the east, Slovenia and Italy to the south, and Switzerland and Liechtenstein to the...

.

Operation

Weld pool

thumb|Weld pool diagramWeld pool commonly refers to the dime-sized workable portion of a weld where the base metal has reached its melting point and is ready to be infused with filler material. The weld pool is central to the success of the welding process...

. As the electrode melts, the flux covering disintegrates, giving off shielding gases that protect the weld area from oxygen

Oxygen

Oxygen is the element with atomic number 8 and represented by the symbol O. Its name derives from the Greek roots ὀξύς and -γενής , because at the time of naming, it was mistakenly thought that all acids required oxygen in their composition...

and other atmospheric

Earth's atmosphere

The atmosphere of Earth is a layer of gases surrounding the planet Earth that is retained by Earth's gravity. The atmosphere protects life on Earth by absorbing ultraviolet solar radiation, warming the surface through heat retention , and reducing temperature extremes between day and night...

gases. In addition, the flux provides molten slag which covers the filler metal as it travels from the electrode to the weld pool. Once part of the weld pool, the slag floats to the surface and protects the weld from contamination as it solidifies. Once hardened, it must be chipped away to reveal the finished weld. As welding progresses and the electrode melts, the welder must periodically stop welding to remove the remaining electrode stub and insert a new electrode into the electrode holder. This activity, combined with chipping away the slag, reduce the amount of time that the welder can spend laying the weld, making SMAW one of the least efficient welding processes. In general, the operator factor, or the percentage of operator's time spent laying weld, is approximately 25%.Cary and Helzer, 102, 115

The actual welding technique utilized depends on the electrode, the composition of the workpiece, and the position of the joint being welded. The choice of electrode and welding position also determine the welding speed. Flat welds require the least operator skill, and can be done with electrodes that melt quickly but solidify slowly. This permits higher welding speeds. Sloped, vertical or upside-down welding requires more operator skill, and often necessitates the use of an electrode that solidifies quickly to prevent the molten metal from flowing out of the weld pool. However, this generally means that the electrode melts less quickly, thus increasing the time required to lay the weld.Lincoln Electric Company, 6.2-1

Quality

The most common quality problems associated with SMAW include weld spatter, porosity, poor fusion, shallow penetration, and cracking. Weld spatter, while not affecting the integrity of the weld, damages its appearance and increases cleaning costs. It can be caused by excessively high current, a long arc, or arc blowArc blow

Arc blow is the, usually unwanted, deflection of the arc during arc welding.There are two types of arc blow commonly known in the electric welding industry: magnetic and thermal.- Magnetic arc blow :...

, a condition associated with direct current characterized by the electric arc being deflected away from the weld pool by magnetic forces. Arc blow can also cause porosity in the weld, as can joint contamination, high welding speed, and a long welding arc, especially when low-hydrogen electrodes are used. Porosity, often not visible without the use of advanced nondestructive testing

Nondestructive testing

Nondestructive testing or Non-destructive testing is a wide group of analysis techniques used in science and industry to evaluate the properties of a material, component or system without causing damage....

methods, is a serious concern because it can potentially weaken the weld. Another defect affecting the strength of the weld is poor fusion, though it is often easily visible. It is caused by low current, contaminated joint surfaces, or the use of an improper electrode. Shallow penetration, another detriment to weld strength, can be addressed by decreasing welding speed, increasing the current or using a smaller electrode. Any of these weld-strength-related defects can make the weld prone to cracking, but other factors are involved as well. High carbon, alloy or sulfur content in the base material can lead to cracking, especially if low-hydrogen electrodes and preheating are not employed. Furthermore, the workpieces should not be excessively restrained, as this introduces residual stresses into the weld and can cause cracking as the weld cools and contracts.Lincoln Electric, 6.2-18–6.2-20, 3.2-1

Safety

SMAW welding, like other welding methods, can be a dangerous and unhealthy practice if proper precautions are not taken. The process uses an open electric arc, which presents a risk of burns which are prevented by personal protective equipmentPersonal protective equipment

Personal protective equipment refers to protective clothing, helmets, goggles, or other garment or equipment designed to protect the wearer's body from injury by blunt impacts, electrical hazards, heat, chemicals, and infection, for job-related occupational safety and health purposes, and in...

in the form of heavy leather

Leather

Leather is a durable and flexible material created via the tanning of putrescible animal rawhide and skin, primarily cattlehide. It can be produced through different manufacturing processes, ranging from cottage industry to heavy industry.-Forms:...

glove

Glove

A glove is a garment covering the hand. Gloves have separate sheaths or openings for each finger and the thumb; if there is an opening but no covering sheath for each finger they are called "fingerless gloves". Fingerless gloves with one large opening rather than individual openings for each...

s and long sleeve jackets. Additionally, the brightness of the weld area can lead to a condition called arc eye, in which ultraviolet light causes inflammation of the cornea

Cornea

The cornea is the transparent front part of the eye that covers the iris, pupil, and anterior chamber. Together with the lens, the cornea refracts light, with the cornea accounting for approximately two-thirds of the eye's total optical power. In humans, the refractive power of the cornea is...

and can burn the retina

Retina

The vertebrate retina is a light-sensitive tissue lining the inner surface of the eye. The optics of the eye create an image of the visual world on the retina, which serves much the same function as the film in a camera. Light striking the retina initiates a cascade of chemical and electrical...

s of the eyes. Welding helmet

Helmet

A helmet is a form of protective gear worn on the head to protect it from injuries.Ceremonial or symbolic helmets without protective function are sometimes used. The oldest known use of helmets was by Assyrian soldiers in 900BC, who wore thick leather or bronze helmets to protect the head from...

s with dark face plates are worn to prevent this exposure, and in recent years, new helmet models have been produced that feature a face plate that self-darkens upon exposure to high amounts of UV light. To protect bystanders, especially in industrial environments, transparent welding curtains often surround the welding area. These curtains, made of a polyvinyl chloride

Polyvinyl chloride

Polyvinyl chloride, commonly abbreviated PVC, is a thermoplastic polymer. It is a vinyl polymer constructed of repeating vinyl groups having one hydrogen replaced by chloride. Polyvinyl chloride is the third most widely produced plastic, after polyethylene and polypropylene. PVC is widely used in...

plastic film, shield nearby workers from exposure to the UV light from the electric arc, but should not be used to replace the filter glass used in helmets.Cary and Helzer, 42, 49–51

In addition, the vaporizing metal and flux materials expose welders to dangerous gases and particulate matter. The smoke

Smoke

Smoke is a collection of airborne solid and liquid particulates and gases emitted when a material undergoes combustion or pyrolysis, together with the quantity of air that is entrained or otherwise mixed into the mass. It is commonly an unwanted by-product of fires , but may also be used for pest...

produced contains particles of various types of oxide

Oxide

An oxide is a chemical compound that contains at least one oxygen atom in its chemical formula. Metal oxides typically contain an anion of oxygen in the oxidation state of −2....

s. The size of the particles in question tends to influence the toxicity of the fumes, with smaller particles presenting a greater danger. Additionally, gases like carbon dioxide

Carbon dioxide

Carbon dioxide is a naturally occurring chemical compound composed of two oxygen atoms covalently bonded to a single carbon atom...

and ozone

Ozone

Ozone , or trioxygen, is a triatomic molecule, consisting of three oxygen atoms. It is an allotrope of oxygen that is much less stable than the diatomic allotrope...

can form, which can prove dangerous if ventilation is inadequate. Some of the latest welding masks are fitted with an electric powered fan to help disperse harmful fumes.Cary and Helzer, 52–62

Application and materials

Shielded metal arc welding is one of the world's most popular welding processes, accounting for over half of all welding in some countries. Because of its versatility and simplicity, it is particularly dominant in the maintenance and repair industry, and is heavily used in the construction of steel structures and in industrial fabrication. In recent years its use has declined as flux-cored arc welding has expanded in the construction industry and gas metal arc weldingGas metal arc welding

Gas metal arc welding , sometimes referred to by its subtypes metal inert gas welding or metal active gas welding, is a semi-automatic or automatic arc welding process in which a continuous and consumable wire electrode and a shielding gas are fed through a welding gun...

has become more popular in industrial environments. However, because of the low equipment cost and wide applicability, the process will likely remain popular, especially among amateurs and small businesses where specialized welding processes are uneconomical and unnecessary.Lincoln Electric Company, 5.1-1–5.1-2

SMAW is often used to weld carbon steel, low and high alloy steel, stainless steel, cast iron

Cast iron

Cast iron is derived from pig iron, and while it usually refers to gray iron, it also identifies a large group of ferrous alloys which solidify with a eutectic. The color of a fractured surface can be used to identify an alloy. White cast iron is named after its white surface when fractured, due...

, and ductile iron

Ductile iron

Ductile iron, also known as ductile cast iron, nodular cast iron, spheroidal graphite iron, spherulitic graphite cast iron and SG iron, is a type of cast iron invented in 1943 by Keith Millis...

. While less popular for nonferrous materials, it can be used on nickel and copper and their alloys and, in rare cases, on aluminium. The thickness of the material being welded is bounded on the low end primarily by the skill of the welder, but rarely does it drop below 0.05 in (1.5 mm). No upper bound exists: with proper joint preparation and use of multiple passes, materials of virtually unlimited thicknesses can be joined. Furthermore, depending on the electrode used and the skill of the welder, SMAW can be used in any position.Cary and Helzer, 103

Equipment

Power supply

The power supply used in SMAW has constant current output, ensuring that the current (and thus the heat) remains relatively constant, even if the arc distance and voltage change. This is important because most applications of SMAW are manual, requiring that an operator hold the torch. Maintaining a suitably steady arc distance is difficult if a constant voltage power source is used instead, since it can cause dramatic heat variations and make welding more difficult. However, because the current is not maintained absolutely constant, skilled welders performing complicated welds can vary the arc length to cause minor fluctuations in the current.Jeffus, 47The preferred polarity of the SMAW system depends primarily upon the electrode being used and the desired properties of the weld. Direct current with a negatively charged electrode (DCEN) causes heat to build up on the electrode, increasing the electrode melting rate and decreasing the depth of the weld. Reversing the polarity so that the electrode is positively charged (DCEP) and the workpiece is negatively charged increases the weld penetration. With alternating current the polarity changes over 100 times per second, creating an even heat distribution and providing a balance between electrode melting rate and penetration.Jeffus, 46–47

Typically, the equipment used for SMAW consists of a step-down transformer

Transformer

A transformer is a device that transfers electrical energy from one circuit to another through inductively coupled conductors—the transformer's coils. A varying current in the first or primary winding creates a varying magnetic flux in the transformer's core and thus a varying magnetic field...

and for direct current models a rectifier

Rectifier

A rectifier is an electrical device that converts alternating current , which periodically reverses direction, to direct current , which flows in only one direction. The process is known as rectification...

, which converts alternating current into direct current. Because the power normally supplied to the welding machine is high-voltage alternating current, the welding transformer is used to reduce the voltage and increase the current. As a result, instead of 220 V

Volt

The volt is the SI derived unit for electric potential, electric potential difference, and electromotive force. The volt is named in honor of the Italian physicist Alessandro Volta , who invented the voltaic pile, possibly the first chemical battery.- Definition :A single volt is defined as the...

at 50 A

Ampere

The ampere , often shortened to amp, is the SI unit of electric current and is one of the seven SI base units. It is named after André-Marie Ampère , French mathematician and physicist, considered the father of electrodynamics...

, for example, the power supplied by the transformer is around 17–45 V at currents up to 600 A. A number of different types of transformers can be used to produce this effect, including multiple coil and inverter

Inverter (electrical)

An inverter is an electrical device that converts direct current to alternating current ; the converted AC can be at any required voltage and frequency with the use of appropriate transformers, switching, and control circuits....

machines, with each using a different method to manipulate the welding current. The multiple coil type adjusts the current by either varying the number of turns in the coil (in tap-type transformers) or by varying the distance between the primary and secondary coils (in movable coil or movable core transformers). Inverters, which are smaller and thus more portable, use electronic components to change the current characteristics.Jeffus, 49–53

Electrical generator

Electrical generator

In electricity generation, an electric generator is a device that converts mechanical energy to electrical energy. A generator forces electric charge to flow through an external electrical circuit. It is analogous to a water pump, which causes water to flow...

s and alternator

Alternator

An alternator is an electromechanical device that converts mechanical energy to electrical energy in the form of alternating current.Most alternators use a rotating magnetic field but linear alternators are occasionally used...

s are frequently used as portable welding power supplies, but because of lower efficiency and greater costs, they are less frequently used in industry. Maintenance also tends to be more difficult, because of the complexities of using a combustion engine as a power source. However, in one sense they are simpler: the use of a separate rectifier is unnecessary because they can provide either AC or DC.Jeffus, 49, 52–53 However, the engine driven units are most practical in field work where the welding often must be done out of doors and in locations where transformer type welders are not usable because there is no power source available to be transformed.

In some units the alternator is essentially the same as that used in portable generating sets used to supply mains power, modified to produce a higher current at a lower voltage but still at the 50 or 60 Hz grid frequency. In higher-quality units an alternator with more poles is used and supplies current at a higher frequency, such as 400 Hz. The smaller amount of time the high-frequency waveform spends near zero makes it much easier to strike and maintain a stable arc than with the cheaper grid-frequency sets or grid-frequency mains-powered units.

Electrode

The choice of electrode for SMAW depends on a number of factors, including the weld material, welding position and the desired weld properties. The electrode is coated in a metal mixture called flux, which gives off gases as it decomposes to prevent weld contamination, introduces deoxidizers to purify the weld, causes weld-protecting slag to form, improves the arc stability, and provides alloying elements to improve the weld quality. Electrodes can be divided into three groups—those designed to melt quickly are called "fast-fill" electrodes, those designed to solidify quickly are called "fast-freeze" electrodes, and intermediate electrodes go by the name "fill-freeze" or "fast-follow" electrodes. Fast-fill electrodes are designed to melt quickly so that the welding speed can be maximized, while fast-freeze electrodes supply filler metal that solidifies quickly, making welding in a variety of positions possible by preventing the weld pool from shifting significantly before solidifying.Lincoln Electric, 6.2-1The composition of the electrode core is generally similar and sometimes identical to that of the base material. But even though a number of feasible options exist, a slight difference in alloy composition can strongly impact the properties of the resulting weld. This is especially true of alloy steels such as HSLA steel

HSLA steel

High-strength low-alloy steel is a type of alloy steel that provides better mechanical properties or greater resistance to corrosion than carbon steel. HSLA steels vary from other steels in that they are not made to meet a specific chemical composition but rather to specific mechanical properties...

s. Likewise, electrodes of compositions similar to those of the base materials are often used for welding nonferrous materials like aluminium and copper.Lincoln Electric, 6.2-13, 9.2-1, 10.1-3 However, sometimes it is desirable to use electrodes with core materials significantly different from the base material. For example, stainless steel electrodes are sometimes used to weld two pieces of carbon steel, and are often utilized to weld stainless steel workpieces with carbon steel workpieces.Lincoln Electric, 7.2-5, 7.2-8

Electrode coatings can consist of a number of different compounds, including rutile

Rutile

Rutile is a mineral composed primarily of titanium dioxide, TiO2.Rutile is the most common natural form of TiO2. Two rarer polymorphs of TiO2 are known:...

, calcium fluoride

Calcium fluoride

Calcium fluoride is the inorganic compound with the formula CaF2. This ionic compound of calcium and fluorine occurs naturally as the mineral fluorite . It is the source of most of the world's fluorine. This insoluble solid adopts a cubic structure wherein calcium is coordinated to eight fluoride...

, cellulose

Cellulose

Cellulose is an organic compound with the formula , a polysaccharide consisting of a linear chain of several hundred to over ten thousand β linked D-glucose units....

, and iron powder. Rutile electrodes, coated with 25%–45% TiO2, are characterized by ease of use and good appearance of the resulting weld. However, they create welds with high hydrogen content, encouraging embrittlement

Hydrogen embrittlement

Hydrogen embrittlement is the process by which various metals, most importantly high-strength steel, become brittle and fracture following exposure to hydrogen...

and cracking. Electrodes containing calcium fluoride (CaF2), sometimes known as basic or low-hydrogen electrodes, are hygroscopic and must be stored in dry conditions. They produce strong welds, but with a coarse and convex-shaped joint surface. Electrodes coated with cellulose, especially when combined with rutile, provide deep weld penetration, but because of their high moisture content, special procedures must be used to prevent excessive risk of cracking. Finally, iron powder is a common coating additive, as it improves the productivity of the electrode, sometimes as much as doubling the yield.Weman, 65–66

To identify different electrodes, the American Welding Society established a system that assigns electrodes with a four- or five-digit number. Covered electrodes made of mild or low alloy steel carry the prefix E, followed by their number. The first two or three digits of the number specify the tensile strength of the weld metal, in thousand pounds per square inch (ksi). The penultimate digit generally identifies the welding positions permissible with the electrode, typically using the values 1 (normally fast-freeze electrodes, implying all position welding) and 2 (normally fast-fill electrodes, implying horizontal welding only). The welding current and type of electrode covering are specified by the last two digits together. When applicable, a suffix is used to denote the alloying element being contributed by the electrode.Cary and Helzer, 105

Common electrodes include the E6010, a fast-freeze, all-position electrode with a minimum tensile strength of 60 ksi (410 MPa

Pascal (unit)

The pascal is the SI derived unit of pressure, internal pressure, stress, Young's modulus and tensile strength, named after the French mathematician, physicist, inventor, writer, and philosopher Blaise Pascal. It is a measure of force per unit area, defined as one newton per square metre...

) which is operated using DCEP. Its cousin E6011 is similar except that it is used with alternating current. E7024 is a fast-fill electrode, used primarily to make flat or horizontal welds using AC, DCEN, or DCEP. Examples of fill-freeze electrodes are the E6012, E6013, and E7014, all of which provide a compromise between fast welding speeds and all-position welding.Lincoln Electric, 6.2-7–6.2-10